By Kevin Huynh, Project Manager / Computer Systems and Software

Objective:

For Spring 2014, one of the requirements for the biped is to add in some form of servo overcurrent protection. The goal of this is to prevent the servos from drawing too much current, overheating, and destroying the control circuit boards inside of the case. A situation where this can happen is when the servos are stalled from reaching their desired position, but they continue to draw the maximum current possible–2.3 A at 4.8 V for the Power HD1501 MG servos from the following datasheet:

http://www.pololu.com/file/0J729/HD-1501MG.pdf

The LiPo battery pack used for ROFIA is the Turnigy 1300 mAh 2S 20C LiPo pack, found below:

http://www.hobbyking.com/hobbyking/store/__9165__turnigy_1300mah_2s_20c_lipo_pack.html

This battery pack can easily supply 2.3 A for all twelve of the servos if they were all to stall at the same time.

The above calculation shows the LiPo battery pack can safely and continuously deliver up to 52 A to the servos for about 3 minutes, which is more than enough to supply the stall current to all of the servos simultaneously (27.6 A).

Possible Solutions:

The two methods that were considered for servo overcurrent protection were foldback current limiters and resettable fuses.

Solution Chosen for the Biped:

The resettable fuses were chosen for their low cost, simplicity of implementation, and because the specifications needed were easier to find on a polyfuse than a foldback current limiter IC. The drawbacks of the polyfuses can be mitigated by replacing the polyfuses as they trip by inserting the polyfuses into female headers soldered onto a protoshield, rather than soldering the polyfuses themselves. Since the stall current of the Power HD 1501MG servos is 2.3 A at 4.8 V, the 06R120BU Littelfuse was chosen.

http://www.mouser.com/ProductDetail/Littelfuse/06R120BU/?qs=sGAEpiMZZMsxR%252bBXi4wRUCTGuoKQj3D%2fwUhoRMyepPw%3d

http://www.mouser.com/ds/2/240/Littelfuse_USBR-36712.pdf

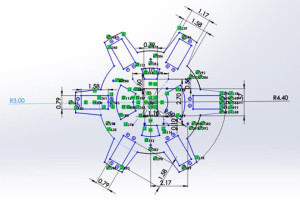

The main specification that was taken into consideration when choosing a polyfuse was the trip current. Since the stall current of the Power HD 1501MG servo is 2.3 A at 4.8 V, the polyfuse trip current was chosen to be 2.0 A. This ensures that the polyfuse will trip before the servo can reach the stalling current and damage itself. Other specifications, such as the hold current and maximum voltage, were satisfactory for the biped. The hold current rating of 1.2 A is well below the stalling current, so it is a safe operating current for the Power HD 1501MG servos. Since the output voltage of the UBEC is approximately 5.3 V and the operating voltage of the servos range from 4.8 V to 6.0 V, the polyfuse maximum voltage rating of 6 V is acceptable. The connections between the LiPo battery, UBEC buck converter, polyfuses, and servos are shown below. The servo pulse pins connect to digital pins on an Arduino Mega ADK.