Table of Contents

Basics:

- Only 45° angles

- ICs on the 50 mil grid

- At least 10 mil for signals

- At least 16 mil for power

- Add power planes (GND/GND or VDD/GND)

Steps in laying out a PCB:

Written by: Fabian Suske

Approved by: Carolina Barrera

0. Checking the Schematics for Errors

You should get a working Schematic but mistakes happen. As an EE you should be able to understand Schematics and know what’s going on. There you should check for silly mistakes like missing Power (GND/VDD) decoupling capacitors or any project related errors (missing /to many parts). If you want to be extra sure pull up the datasheet and check if the typical application is followed. (Capacitors on a voltage regulator) Make sure the ERC has no errors.

1. Sort the components

Take your schematics and identify groups of components. Take every IC and spread them out. Now take all the small components (Resistors, Capacitors, etc.) and place them as close to the IC pins as possible. Make sure they’re on the correct pins. (I.E. decoupling pins close to VDD pin not GND pin).

Make sure all the connectors and small stuff (power LEDs with resistors) are out of the way. You don’t need them yet.

2. Connect the components.

The first thing you do is locate one ground wire and in the properties hide air wires. We will add at least one GND plane later.

On your separate groups try to connect all air wires with the least amount of space needed. (Make sure you used ratsnest before you start routing). At this point the amount of vias should be very low. Don’t spend too much time finding the ideal route – route the traces fast (you most likely rip them up again anyway). If you have a rather compact setup for each group.

SMD Pads should be connected from directly in front or behind.

Also keep the trace with in width in mind. Like you wouldn’t run 10A through 35 gauge wire. A drawn wire can only handle a certain amount of current. http://www.4pcb.com/trace-width-calculator.html

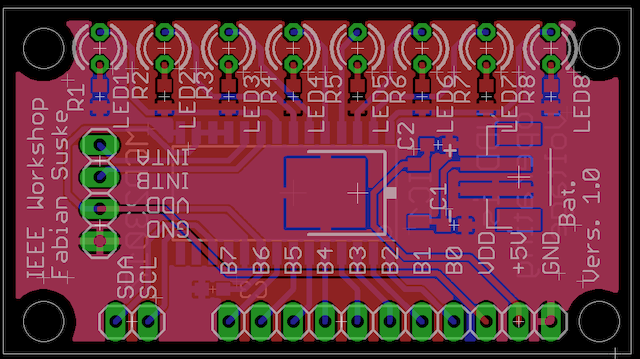

Note the wrong connection on LED 8 (top one) and the overlap on C3. Fix them now!!

3. Moving the groups into position

After you briefly routed the groups it’s important to move the groups into their “final” position. Therefore take the main IC or MCU and place it in the middle. Now move the groups somewhere close to the MCU. You should bear in mind that connectors might needs to be connected (so plane your space). You might want to mirror the group to utilize the space efficiently. Most likely you have some overlapping components or vias in the way. Rip them up and reroute them. Connect the air wires between the ICs at this time to (as well as to the MCU).

4. Placing the rest of the components

Now you should place the connectors into a logical space. This is different for each project. Typically it makes no sense to place a connector on the other end of the chassis /PCB. You should have cable management in mind. You also should place them as close as possible to the IC’s

Fill in the gaps with less important stuff like power LEDs or optional headers.

If your done move everything to the origin and adjust the board dimensions

Note non 45° degrees on JP1. 90° in the middle are okay since more than one trace.

5. Power Planes

Normally on a dual layer PCB you have two GND planes (referred to GND-GND). On small PCBs you might want to have a VDD plane as well (VDD-GND). Apply were applicable.

To add a Power plane you take the polygon tool and completely enclose your PCB. Click then on the name tool and give it the name of your power signal (GND, VDD +3V3 or +5V or whatever). Then open the properties for them and change the rank to 6 and isolate to 12. Also uncheck the “hide air wires” now.

You might see some un-routed air wires now. Connect them to the respective power plane. In order to achieve this you might want to move some components or wires in order to make space for the power plane to reach this plank spots. Adding a via might help as well.

If you have two GND planes you should add some vias in big blanc spots.

To resolve this air wire we add a GND Via

6. DRC

If all air wires are connected (An easy way to check is to deselect all layers except of dimension and Unrouted). Click the Design Rule Check (DRC). Before running the DRC go to clearance and change every value to 6mil. Also change Limit under Mask to 50. (This will give you tented vias (looks nicer))

Then hid apply and run. Fix all issues like overlap, clearance etc. (If you added a via on an IC ground pad you may approve it.).

7. Tweaks, Labels and Holes

The last step after fixing the errors involves making tweaks to the PCB. You might want to reduce the size or fix funny routing (non necessary bends). Also make sure all component names are visible. In order to move them you need to smash the component this will add an origin “+” to the name and you can move them now. Make sure that no name is over a component or pad. If you have tented vias you can place them above vias.

Last but not least you need to add individual text (on the tPlace or bPlace layer) and label all connectors with their respective signals like SDA and SCL for I2C.

If you might have space you can add a project name or maybe even the members name on the PCB.

If you moved wires or vias or even components in order to place Text nice, you need to rerun the DRC each time you messed with the layout.

You might also want to add mounting holes to the PCB here make sure you have enough room for the screw caps.

Note that I changed the design completely to make it way smaller