Goliath Fall 2017

Design versus Printing Errors

Vanessa Enriquez (Manufacturing Engineer)

Approved by: Mark Huffman (Project Manager)

Table of Contents

Introduction

Vanessa Enriquez (Manufacturing Engineer)

Approved by: Mark Huffman (Project Manager)

The printing process was complicated because the difference between a design error and a printing error was noted fairly late in the process. The errors were identified on the more intricate panels, left and rights sides. The problems arose after the second print, at which point it was too late to make any substantial design changes prior to the final demonstration.

Design Errors

Vanessa Enriquez (Manufacturing Engineer)

Approved by: Mark Huffman (Project Manager)

The design errors from the previous model F16 Goliath were not notable in the PLA printed F17 model [1]. For example, the section pictured below was only noticed in the ABS printed F17 final model.

Figure 1 – Weak support

The features were too thin, which caused the piece to break off during the cleaning process. The side panel was simply reprinted because it was assumed a printing error that could be fixed by adjusting the quality. This ultimately led to a waste of time and resources that could have been avoided by considering the thickness of each feature when designing.

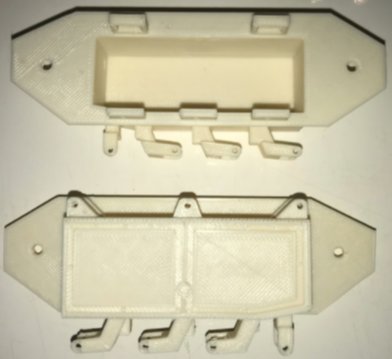

The orientation of the printed part also factored into the quality. This printing problem was dealt with by trial and error. The side panel was reprinted in the positions pictured below.

Figure 2 – Printing orientation

The first side panel in figure 4 resulted in the broken wheel support seen in figure 3. The second side panel fixed the weak support issue and had a well-defined tank design. Although, the latter resulted in warped hinges on the opposite side. The layout also affected the amount of support material used which resulted in the finishes shown below.

Figure 3 – Support material and finishes

The first and second panels correspond to the panels in figure 4. Notice the rough finish on the first panel due to the support material. In this example, both types of errors were present but the solution was in design. The hinges on the inside of the panel have to be removed and redesigned to avoid printing on a small surface area. This way the side can maintain the tank design.

Printing Errors

Vanessa Enriquez (Manufacturing Engineer)

Approved by: Mark Huffman (Project Manager)

The change in printing material also added to the process. Compared to PLA, ABS proves to be stronger and has a cleaner finish when treated with acetone [2]. It also comes with a shrinking factor. Once the print cools off a popping sound indicates that the print has shrunk to its final dimension. For the first attempt of the ABS printed side panel, the print was scaled up to 101% to compensate. The cut outs did not line up well with the top and bottom panel that were also printed at 101%. After a couple measurements, the average percent error was calculated and the final print was scaled at 100.7%. This trial and error process showed the inconsistency of 3d printing that can be attributed to calibration or the settings chosen as well.

Suggestions

Vanessa Enriquez (Manufacturing Engineer)

Approved by: Mark Huffman (Project Manager)

Ideally in an efficient 3d print design the use of support material is minimal. Parts should be drawn with large surface area to avoid printing in air. The material used should be based on the customer requests as opposed to what is necessary to make the poor design function. Due to the lack of time, some of the errors mentioned were included in the final model. I suggest starting with the successful F16 model to resolve the minor design errors. In an effort to make the deadline, quick and poor design solutions were implemented in the final F17 chassis which will only complicate any further changes. The print time requirement was emphasized by the customer but by considering these aspects of 3d printing first, the time requirement will be fulfilled as a direct result. Every factor of printing (design, orientation, material, etc.) plays an important role in a quality print and understanding the difference between the two type of errors will simplify the process.