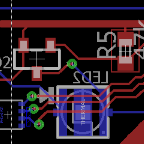

Generic Color Sensor Hedge follower PCB Layout

Written by Charles Banuelos The PCB design below is for a generic hedge following shield. The PCB is a work in progress with the finalizing of the dimension dependent upon the testing of the color sensors. The LEDs chosen are significantly larger than the previous design and this is due to availability. […]

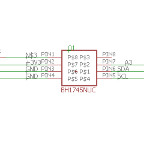

Generic Color Sensor Schematic

Written by Charles Banuelos MFG DM-updated 11/29/2017 The schematic below is for a hedge following shield that will connect directly to the 3DoT board. The hedge following shield will connect to the 3DoT board using the same 6 pin header that is used for the 3DoT IR shield. The design follows Thomas Forman’s designs from EE444. The […]

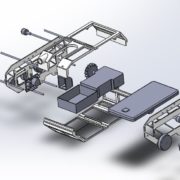

Spring 2017 Final Blog Post – Pick and Place

Belinda Vivas (Project Manager) Tyler Jones (Manufacturing) Kevin Ruelas (Electronics) By: Chastin Realubit (MST) Table of Contents Executive Summary Program Objective By: Belinda Vivas (Project Manager) The objective of the Second Generation of the Pick and Place is to: ❖Build up from the First Generation of the Pick and Place machine and create an user […]

Fall 2016 Solar Panels: The Solar Panel Sandwich (the “Encapsulation”)

By Ridwan Maassarani (Design and Manufacturing) Approved by Inna Echual (Project Manager) Table of Contents Introduction In order to secure the cells onto the panel, one must consider the way of “sandwiching” the cells onto place. A rubber substrate was used for insulating the solar cells from the aluminum sheet. Here, I will review the […]

Fall 2016 Solar Panels: Mission Profile Update

By Inna Echual (Project Manager) Mission Profile Update The team received the PDR debrief from meeting with the customer and the president. A concern of theirs was that our mission profile presented during the PDR (1) was not updated as the Chassis group in the Thursday class had changed their course to an area with […]

Spring 2016 Pathfinder: Mission Profile and Project Objective Update

By: Peiyuan Xu (Project Manager) Table of Contents Mission Profile Update The team received the PDR debrief from meeting with the customer, student assistant and the president. One of the comments they had was that the mission profile was unclear. The team then develop a new mission profile which will clarify the confusion of the […]

Spring 2016 A-TeChToP Detailed Mission Profile

By: Cody Dunn (Project Manager) Overview This blog post discusses the Mission Profile in more detail and explains the California FITNESSGRAM, a standard test implemented at California public schools in elementary, middle, and high school.

Spring 2016 3DoT Goliath Final Project Document

By: Ayman Aljohani ( Project Manager) Team members: Ayman Aljohani (Project Manager) Tae Lee ( Mission and Systems Engineer) Kevin Moran (Electronics and control Engineer) Jerry Lui (Manufacturing Engineer) Table of Contents Executive Summary Objective The objective of the 3DOT Goliath is to design a small-scaled version of the Goliath Tank, as a toy, […]

Spring 2016: 3DoT David Software Design

BY: Christopher Hirunthanakorn (Missions, Systems and Test Engineer) Introduction: The purpose of this blog post is to summarize all of the work that has been done for the software design of the 3DoT David and inform the reader of the final state of the software. It will cover the software flow chart to introduce the tasks […]