Spring 2016 3DOT Goliath,Assembling and Testing the 3Dot Board

By: Ayman Aljohani (Project Manager)

For our Goliath project we will be using a custom made PCB that contains a microcontroller (known as the 3Dot Board) that will perform various tasks (ex. movement, laser shot, detector). The physical PCB will be provided for us; however, it is required to solder all the components onto the PCB.

The steps we will be taking to solder the parts onto the PCB:

- Apply flux to the area you will be soldering and apply the soldering iron.

- Place the component on top of the soldering iron and heat the area to create contact between the soldered iron and the component.Soldering 3DOT Board components manually with Soldering Iron

- Check with multi-meter to make sure the components are connected to the PCB

- If alignment needs to fixed, we will use the heat gun to simultaneously heat the area to remove the component.

- Hold heat gun 3~4 inches away from the PCB for 30 seconds to heat up the board (prevent heat sync).

- Now aim the heat gun around 2 inches at the area you’re interested in for 15 seconds.Soldering with heat gun

- Apply little pressure to fix the alignment of the component.

Applying solder base to the area, this could be done in two ways:

a-All at once using stencil

Applying solder base using stencil

then clean the extra solder base manually

b-Manually apply solder base to all parts. This option takes loner time, but it will give a clear idea about 3DOT components and connections which makes the troubleshooting easier.

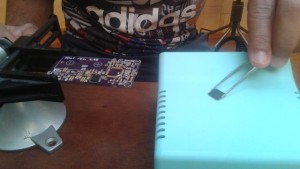

2- Use tweezers to place the components on the 3DOT Board:

3- After placing the component correctly, apply heat by placing the PCB in an oven

Assembled 3DOT Board:

The steps we will be taking to remove parts on the PCB:

- Apply flux to the area interested in to remove the soldering iron from a component.

- Put de-soldering on the area you want to absorb the soldering iron and apply the heated solder tip on top of it.

- Apply until you see the solder iron gets absorbed by the de-soldering material.

- Remove the component after most of the soldering iron has been removed.