Spring 2017 Velociraptor: Custom Commands (Servo Motor)

Authors

By: Oscar Ramirez (Mission, Systems, & Test)

-Body

Edited and Approved By: Jesus Enriquez (Project Manager)

-Introduction & Conclusion

Table of Contents

Introduction

One of the bug requirements that we needed to satisfy for our Velociraptor was giving it the ability to perform a turn in order to navigate the maze. To solve this issue we decided to integrate servos into the robot to turn the hip through the universal joint. This post covers a brief background on the testing we performed through the arxterra app to control the servo for the turn.

Requirement L2-8: The Velociraptor shall be able to turn.

Servo Control

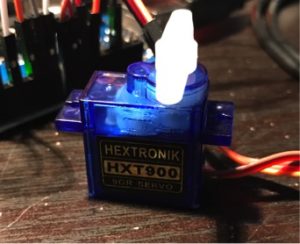

For our velociraptor to turn we needed a servo to control the hip motion to an appropriate angle so that the robot could take a step with the hips turned and take another step with the hips back to their regular state to complete the turn. To control this hip motion a servo motor was the ideal solution.

To begin I included the servo library in my code and declared servo11 as my servo. Next I created a handler and subroutine for this servo. A servo motor will typically only rotate from 0 to 180 degrees and for our purpose we would only need it to go from 0 to about 15 degrees to complete the hip motion. Using a Boolean command from the Arxterra app I set two angles, 0 and 15 defining 15 as “ON” and 0 as “OFF”. Finally using the pwn pin 11 on the Arduino I set up the servo and tested the range of motion with the Arxterra app going from 0 to 15 (toggling the on and off switch).

Reference code:

void servoHandler (uint8_t cmd, uint8_t param[], uint8_t n)

{

Serial.write(cmd); // servo command = 0x41

Serial.write(n); // number of param = 1

for (int i=0;i<n;i++) // param = 90 degrees

{

Serial.write (param[i]);

}

int x = param[0]*180/127;

if (x==1){

servo11.write(21);

}

else if (x==0){

servo11.write(0);

}

}

Conclusion

After performing this test, we were able to successfully send commands to the servo to turn a specific amount of degrees as required. The only thing that was the set back in this test was that there was a lot of iterative designing going on throughout the mechanical assembly of the robot so it did not leave us with enough time for full-proof testing. This provided proof of concept for our robot. This is why it is consistently recommended to focus on the mechanics of the robot more than anything before diving into the servo testing for turning.