2016 Spring 2016: 3DoT David CDR ppt and CDR Debrief

BY: Omar Mouline (Project Manager),

On 04/20/2016 the the professor Gary Hill and with the assistance of the President gave us a debrief on our CDR. in the link blow is the CDR power point that was presented on the 04/06/2016 :

Table of Contents

First slide:

Remark:

Points were deducted For the picture used in the title page. The picture had to be a picture of our design.

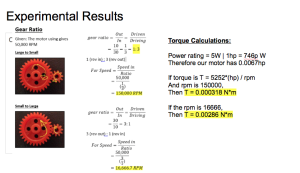

Experimental Result

Problem:

The RPM calculation did not look right. The values were too large for the gear ratio we are using.

Solution:

The RPM calculation was recalculated and documented in this Blog Post:

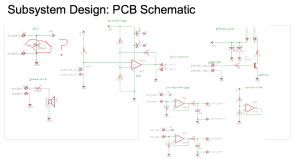

Subsystem Design: PCB Schematic

Problem:

Capacitor value is too big for the PCB. what was the justification for the 2200 uF capacitor?

Solution:

The Electronics engineer worked with the division manager and they are planing to change the capacitor

President Remarks:

Create a training document on bypass capacitor.

Look at similar boards and copy them.

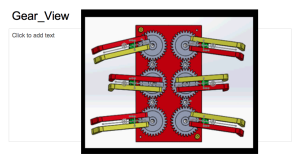

Hardware Design

Problem:

Worried about the gearing and motor torque.

Solution

We were very precise on the correction of our studies on the subject and we have it all explain on these blog posts:

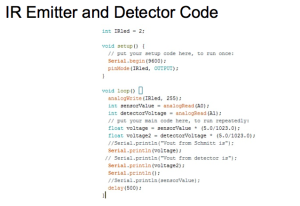

Software design:

Remark:

Detector code looked weak. This code was used just to test if the IR components functioned. The actual detector code will be developed and tested once the prototype is assembled.

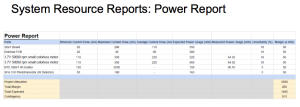

Power report

Problem:

All values on the power report are under no load conditions. These values will change when the robot is operating.

Solution:

We will get the actual measurement of voltage and current for each component when it is operating.

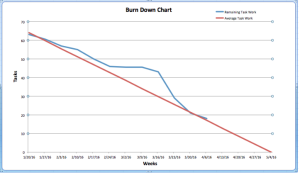

Project Update

Problem:

Lot of work were done over spring break, still more problems to solve.

Solution:

For the burndown the 50% for starting a task and 50% to complete the task does not give us an exact ready. The change of project design made us rush the tasks to come back on time. We finished a lot hard task in a very short time, we did our best and we were not on a little bit behind time, but since we were starting all the tasks and accomplished some it showed that we were in a good schedule.

General Remarks

- Nice project schedule, does not look like on schedule.

- it is normal since we changed the design.

- have 3 caps for incoming power

- Double check if the motors will work with system restrictions.