Goliath Fall 2017

Goliath Breadboarding

Mark Huffman (Project Manager)

Goliath Breadboarding

By Mark Huffman (Project Manager)

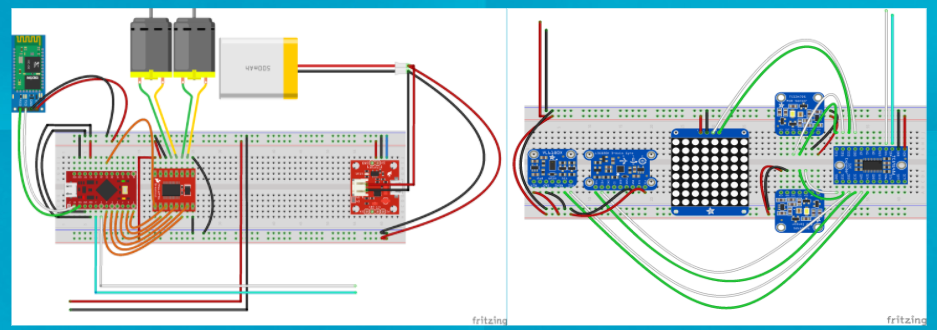

All major components have been laid out on a breadboard for testing the majority of the program work. Most importantly being the color sensors and gyro. As both provide vital functions for navigating the maze. This breadboarding has provided very useful as the previous Goliath has been used as a test platform with room for new components on top. All major programming work can be completed or at the very least defined while the final body work is completed.

The items connected up include:

LED Grid Display – Connected to I2C

Color Sensors – Connected to the I2C multiplexer (0 and 1)

Gyro Sensor – Connected to I2C

The only sensor missing at this time is the IR proximity sensor. But, it could be easily extended off the breadboard.

Fritzing Diagram

By John Ocampo (Electronics and Controls Engineer)

Links to Data Sheets and Libraries

By Mark Huffman (Project Manager)

Led Grid Display

LED Usage Guide: https://learn.adafruit.com/adafruit-led-backpack/1-2-8×8-matrix

LED Backpack Library: https://github.com/adafruit/Adafruit_LED_Backpack

LED GFX Library: https://github.com/adafruit/Adafruit-GFX-Library

LED Driver Datasheet: https://cdn-shop.adafruit.com/datasheets/ht16K33v110.pdf

Color Sensor

Color Sensor Usage Guide: https://learn.adafruit.com/adafruit-color-sensors/overview

Color Sensor Library: https://github.com/adafruit/Adafruit_TCS34725

Color Sensor Datasheet: https://cdn-shop.adafruit.com/datasheets/TCS34725.pdf

I2C Mutiplexer

Multiplexer Usage Guide: https://learn.adafruit.com/adafruit-tca9548a-1-to-8-i2c-multiplexer-breakout/overview

Multiplexer Datasheet: https://cdn-shop.adafruit.com/datasheets/tca9548a.pdf

Gyro Sensor

Gyro Sensor Usage Guide: https://learn.adafruit.com/adafruit-triple-axis-gyro-breakout/overview

Gyro Sensor Library: https://github.com/adafruit/Adafruit_L3GD20_U

Gyro Sensor Datasheet: http://www.st.com/content/ccc/resource/technical/document/datasheet/43/37/e3/06/b0/bf/48/bd/DM00036465.pdf/files/DM00036465.pdf/jcr:content/translations/en.DM00036465.pdf

IR Proximity Sensor

IR Sensor Usage Guide: Hook-up Guide VL6180

IR Sensor Library: https://github.com/sparkfun/SparkFun_ToF_Range_Finder-VL6180_Arduino_Library/tree/V_1.1.0

IR Sensor Datasheet: https://cdn.sparkfun.com/datasheets/Sensors/Proximity/DM00112632.pdf