Our project is AdBot (originally RoSco).

Spring 2016 AdBot Stair Climber

Dang Le (Project Manager), Don Tran (Mission, System and Test), Muhammad Siddiqui (Electronics and Control), Muhammad Maqbool (Manufacturing and Design)

By Dang Le (Project Manager)

This is a summary of the Fall 2015 RoSco team design:

Summary

Source

RoSco2015 Final project Documentation

https://www.arxterra.com/rosco-final-project-documentation/

- RoSco shall be controlled with Arxterra.

- It shall not exceed 16 inches in height when travel underneath barbed wire, as required by the U.S. Army Physical Readiness belly crawl training program.

Source: http://www.armyprt.com/obstacle_negotiation/confidence-obstacle-course-construction-and-safety.shtml

- The rover shall travel over the sprinkler head.

- The rover shall travel at a speed of .5-.75 ft/s

- The internal hardware of rover shall be protected from light rainfall and dripping water.

- The servo chosen was a HD 1501 mg servo with high torque and the motor was fast as 85 RPMs.

- The battery was NiCD 7.2V 700mAh battery and 2.5 times heavier than previous RoSco.

- The PCB will contain headers, the surface mount resistors, capacitors and the HC-06 Bluetooth module.

- Software code was using Bluetooth communication between phone and rover. The Arxterra control panel also communicates to the rover through the phone.

The design problem faced by the previous team was the body of the chassis was not completely waterproof. The legs were constructed weak and were shaky when trying to stand up. The track circumference was over-size compared with the wheels and the team had to deal with a 3D printing machine problem.

Research and Plans

Sources

RoSco Preliminary Design Document

https://www.arxterra.com/rosco-preliminary-design-document/

https://www.arxterra.com/rosco-final-project-documentation/

This begins the first research blog post for the Spring 2016 RoSco team.

Objective

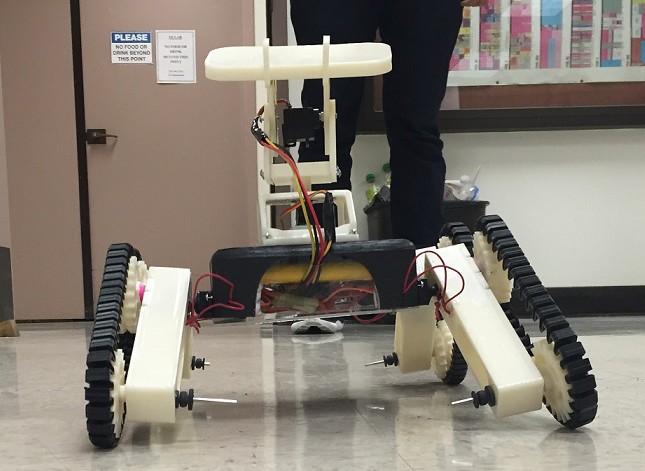

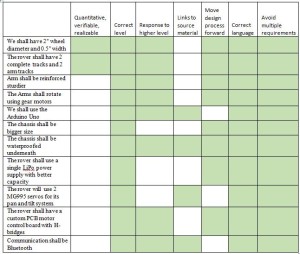

Engineers shall build on top of last semester’s RoSco shown below to get it to climb up stairs, instead of travel underneath a barbed wire course.

Test Course: The test course will be the central steps adjacent to the Student Union building.

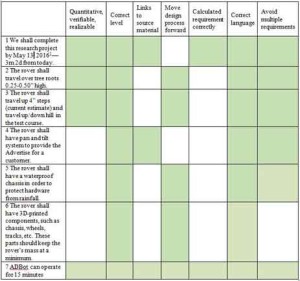

Level 1 Requirements

1http://web.csulb.edu/depts/enrollment/registration/final_exam/spring_chart.html

We will take ADBot to the campus steps and take measurements to make calculations for #3. #4 was waived last semester. ADBot’s had to have 82.5 degrees of vision horizontally, 48 degrees up, and 66 degrees down. The last rover had a problem with power. A group before them1 burned out servos because the smartphone was heavy. They panned and tilted a mirror, although there is no success report. A pan and tilt system is a limited design and does not improve ADBot much. A protocol webcam is lighter and harder to damage. A wide-angle lens could collect more peripheral vision. #5 is a qualitative requirement, so the weight of waterproofing has to be figured out based on budget and obstacles. At this time #6 material specifications is still not definite and in the brainstorming phase.

1http://arxterra.com/project-mini-rosco-project-documentation/

Spring 2016 Cost

Sources

Spring 2015 Power Budget, https://www.arxterra.com/13269/

Spring 2015 RoSco Budget, https://www.arxterra.com/rosco-budget/

Spring 2015 Mass Budget, https://www.arxterra.com/mass-budget-2/

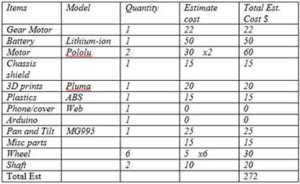

The budget requirement has to be under $200; however, the previous team spent $271. Our estimate is $272 should we add more motors, more wheels, and a better battery. However, the estimate can reduce to $212 by reusing motors and the old battery.

Project Schedule

Source:

https://www.arxterra.com/fall-2015-rosco-schedule-and-wbs/

At this point, the project schedule from previous semester is good. It will help a lot with figuring out our new schedule.

Work Breakdown Structure

Source

https://www.arxterra.com/rosco-final-project-documentation/

The Robot Company (this course) has forced us into a team for the semester. We are only preparing to start training to have technical proficiency in our individual division. Right now, we are sticking to the Company Work Breakdown Structure in the Job Descriptions file. After our training, we will be certain of our actual responsibilities within the team. Last semester, the RoSco divisions swapped around many of their decomposed tasks.

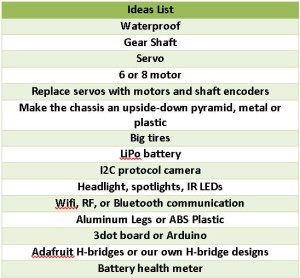

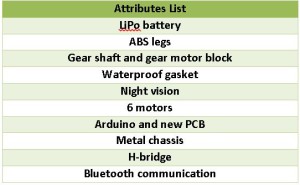

Level 2 Requirements

One of our most important task is to make the both tracks and arms attachments stronger. In the final mass budget4, RoSco weighed 3.3 pounds. The group received their 3D printed parts too late to realize their structural support issue soon. Because new parts will be 3D-printed, the system engineer has a task of figuring out the margins so that parts do not conflict, tracks are not too long, motors will not stall often, and more. We have been deciding on different ways of upgrading the chassis, tracks, and arms, but do not have the required measurements, yet. These requirements are still in the planning phase. Moving legs was a great subsystem engineering solution last semester. Now, we will redesign and replace servos with gear motors and rotary encoders. Bluetooth connection is adequate, but there are better options.

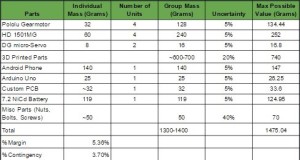

Fall 2015 mass budget

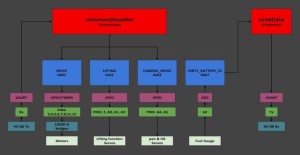

Software block diagram

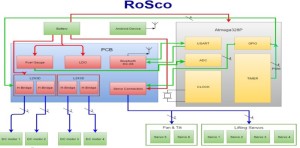

System block diagram (final) from http://arxterra.com/rosco-2015-system-block-diagram/

The system block diagram and software block diagram are so far working. They will have modifications to incorporate a new PCB, new motors, longer distance communication, and any other upgrades.

ADBot needs at least 15 minutes of power to run its previous test courses. One power report1 showed 97,000 W total power and no calculation procedures. Another reports2 used total amp to decide what battery to get–the correlation and calculation is unclear. A third power report calculations3 is unverified, but provides an idea of watt-hour rating and uses a basic division calculation, which may help in case of deciding on a lithium-polymer battery. Overall, the power budget must be studied again. We will find out how much power will be consumed and where the power will be contributed on each mechanical part of the rover.

1http://arxterra.com/13269/

2http://arxterra.com/micro-rover-power-budget/

3https://www.arxterra.com/mini-rosco-power-consumption-tests-and-power-budget/

4http://arxterra.com/rosco-final-project-documentation/

Old Flaws

Verified by: Muhammad Siddiqui (Electronics and Control)

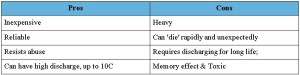

Fall-2015 RoSco used NiCd batteries

Pros and Cons of NiCd Batteries

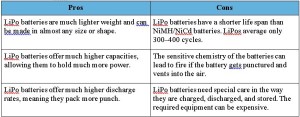

Pros and Con of Lipo batteries

- We are going to use LiPo batteries.

- 2015 RoSco used 4-dc motors and 6-servo motors.

Con of using 10 motors:

- The number motors is directly proportional to the amount of power.

- More servo motors mean more complicated programming.

- We are using 4-dc motors, 2-geared dc motors with shaft/quadrature encoders, and 2-servo motors. Thus, by reducing the number of motors we are reducing the amount of power consumed and number of h-bridges being used in our custom designed h-bridge board.

- Fall-2015 RoSco used the Arduino Uno.

- We are thinking about 3dot board (which is not decided yet—need more time to study cons of both).

- Based on the changes made, we will have to modify the code to make it work for our ADBot.

Design Plans

Verified by: Muhammad Maqbool (Manufacturing and Design)

The RoSco consist of four legs where each leg consist of two wheels. These legs are designed and constructed through SolidWorks. Overall, the ADBot consists of six wheels, four tracks, two arms, pan and tilt, and one chassis that have to be designed this semester. We have to make sure that the arm of the ADBot at the gear-motor connection allows the rover to climb steps. We will be using two shaft pivot for arm that will allow the rover to move upward perfectly. We are going to use 3D printing to print all our required parts. The plastic is going to be ABS, because it is cheaper and reliable. To make sure our ADBot waterproof, we will be using rubber casing to keep all the electronic parts safe from liquid.

We will be publishing and printing a PCB board for our ADBot. Manufacturing team will be responsible for soldering IC components. The designing of the PCB board will be done in Eagle CAD and print through a manufacturing company.

The problems faced by the previous groups was related to 3D printing. Their main concern was to obtain clear prints, which somehow was difficult. Also, I think that we should print extra pieces for wheels and legs just in case if something brakes and it will definitely save time. The first PCB driver was flawed and exceeded the budget by 40 dollars. With smaller components and drill-hole techniques, the board can be greatly simplified to the current revision allowing a tighter configuration of components to reduce the cost of manufacturing significantly to expected costs.

Creativity Challenge

Verified by: Dang Le (Project Manager), Don Tran (Mission, System and Test), Muhammad Siddiqui (Electronics and Control), and Muhammad Maqbool (Manufacturing and Design)