Spring 2016 Velociraptor: Preliminary Project Plan

Khoi Vu (Project Manager)

Camilla Jensen ( Systems and Test Engineer)

Table of Contents

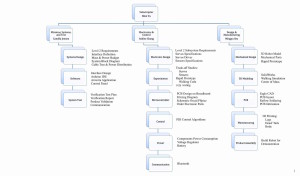

Work Breakdown Structure

Figure 1 describes the work distribution for project Velociraptor. There are three branches which consist of Mission, Systems, and Test, Electronics and Control, and Design & Manufacturing. Each branch has its unique work breakdown headed by individual engineers. All three branches will be overseen by the Velociraptor’s Project Manager

Figure 1

Project Schedule

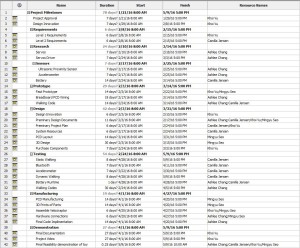

Top Level Schedule

The charts shown below are the preliminary work schedule that Velociraptor’s team members are assigned. Each task has a start and a deadline that must be completed. Tasks are divided based on the Work Breakdown Structure (WBS) in figure 1.

Figure 2

Figure 3

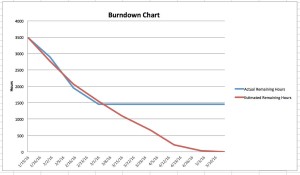

Burn Down and Project Percent Completion

The burndown chart provides an insight on the hours of work that had been contributed and the remaining hours that are needed to complete the project. This chart shows how productive the team has been for the past two months.

Figure 4

System/Subsystem Level Tasks

Camilla Jensen (Systems Engineer)

1. Learning C++ programming language to write algorithms using the Arduino IDE to

decode instructions to the Velociraptor from the Arxterra Application on an Android

device.

2. Learning how to use the HC-06 Bluetooth wireless device and configure with the

Arxterra Application.

3. Generated system resource reports (Mass, Power and Budget) that will define the size of

battery for Velociraptor.

4. Will work with E&C to optimize walking codes for Velociraptor.

5. Will create verification and validation test plan and perform tests to ensure each device

meets all defined requirements.

Ashlee Chang (Electronics & Control Engineer)

1. Research servo options and conduct a trade-off study to select the most fitting servo to handle the total mass of the velociraptor.

2. Research sensor options and conduct a trade-off study to select the most fitting ultrasonic sensor and accelerometer to meet the object detection and adaption to incline requirements.

3. Generate a fritzing diagram with all electrical components to map out all wire connections and testing on a breadboard

4. Prepare a circuit schematic in Eagle CAD that will be passed on to M&D for manufacturing

5. Research power subsystem requirements, selecting an appropriate battery, and meeting the specific voltage and amperage requirements of each component

6. Test the PCB to ensure all electrical components are fully operational.

7. Write the Arduino C++ walking code to control the servos; this includes static walking, dynamic walking, adapting to an incline using the accelerometer sensor, being able to turn in response to an object hindrance

8. Work with S&T on the interfacing between the velociraptor Bluetooth and Arxterra app

Mingyu Seo (Manufacturing & Design)

1. Create a complete 3D model of the Velociraptor by using Solidworks for the prototype.

2. Perform stress analysis, Center of Mass, and breaking points to determine the acceptability of

the robot.

3. Build a prototype for Electronics and Systems Engineer to validate MCU subsystem & Control

Firmware as well as for final robot validation.

4. Fabricate the PCB design provided by Electronics Engineer and order an SMT solder paste stencil.

5. Manufacture mechanical parts for velociraptor using the laser cutter.

6. Specify and order off-the-shelf parts for final assembly of the robot.

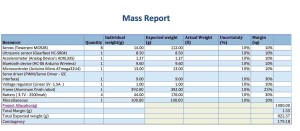

System Resource Reports

Since the goal for this semesters Velociraptor was to reduce the mass from last semesters MicroBiped, the project allocation has been set to 1.00kg and thus reduce the bulkiness and increase stability for the robot.

Figure 5: Mass Report

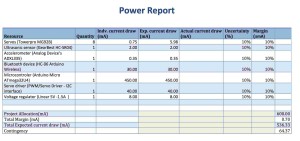

In the figure below (figure 6) presents the estimated power consumption of the Velociraptor biped robot. The majority of the power will be consumed by the eight servos that is used to provide torque for movement of legs, tail, and head.

Figure 6: Power Report

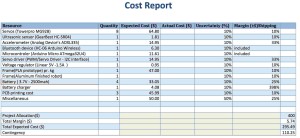

Project Cost Estimate

Figure 7: Estimated Project Cost

Figure 7 is the estimated cost that will be required to manufacture the Velociraptor biped robot. The margins of the Cost Report displays an estimated price for shipping. Many of the parts had free shipping or it was included in the price of the product. The Battery charger’s shipping costs were 4 times the cost of the charger since it’s shipped from China.