Changes to the Chassis

December 18th, 2018/Pathfinder Chassis #6

By Cristian Figueroa and Larry Vinh

Table of Contents

Introduction

by:Larry Vinh

Earlier in the semester, we had a meeting with Jeff Gomes to discuss the mechanical design of the Pathfinder Chassis. Mr. Gomes had multiple recommendations that should be done to improve the Chassis. Some of the recommendations are needed to improve the performance of the Chassis to complete its mission. In this blog post, we discuss the recommendations that were given and the ones that still need to be completed.

Changes Done

by: Cristian Figueroa

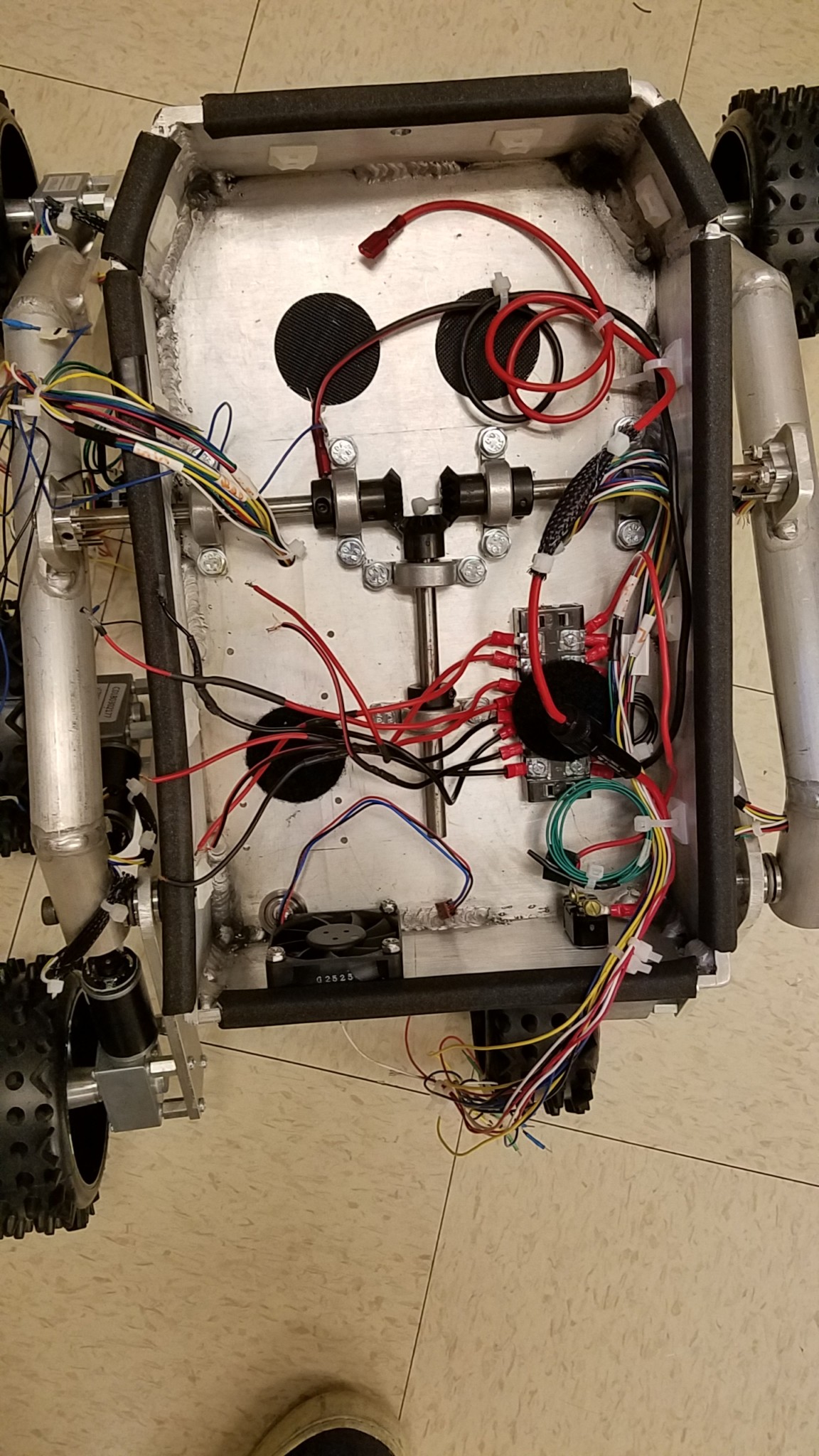

Figure 1 shows the state of the inside the chassis when we first started working on it. The rocker bogie suspension system was not functioning as it should have. The chassis was angled upwards when it should have been parallel to the floor. The wiring was exposed and cluttered.

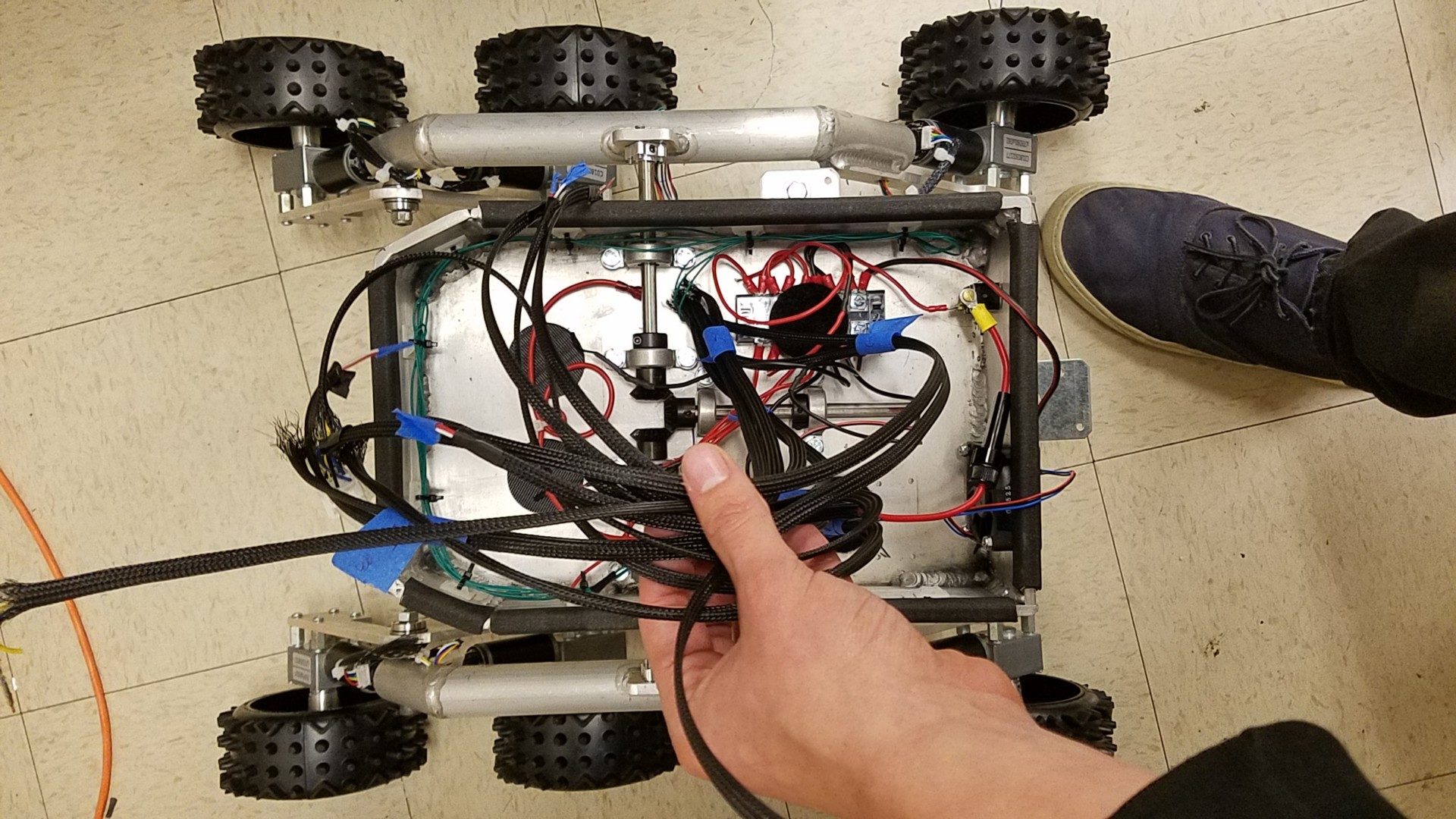

Figure 2 shows the work that we did in order to fix the wiring and the rocker-bogie suspension system. The chassis is now parallel to the ground, as it should be. We covered the wires in cable braid to protect them from any exposure. We also separated the wires into the way they should be plugged into the electronics. The three wires for each motor are crimped and are in the header for the shaft encoder on the PCB. The other two wires of each motor go into the screw terminal on the motor shield drivers.

We also changed the thrust bearings that used to be on the foot to leg part of the chassis with flange bearings. We redid the wire crimping on the wire connecting the on switch to the battery as seen by the yellow ring crimp in figure 2. The wires in the Chassis were crimped compared to having the strands of the wire exposed.

Changes Needed

by: Cristian Figueroa

Changes Chassis still needs:

- Grommets between the rocker bogie system and the legs of the Chassis

- Drain Plug for hole on the bottom of the Chassis

- Mechanical stop for rear legs of the Chassis

- Dust cover for the Motor Drivers

- Waterproof top gasket

- Rubber washers for the bolts on the Chassis’s leg

Another possible solution in place of the mechanical stop for the Chassis is to determine when the wheel is experiencing no load. One could measure the current going to a motor under no load. Then, code the Arduino to have Pathfinder rotate the wheel back until the current measured is above the no load condition.

Conclusion

By: Larry Vinh

The cable guide organized the wires in the Chassis and made it easier to identify the set of wires coming from a certain motor. The flange bearing helps stabilizes the Pathfinder in case of rocky terrain or any terrains that will cause the Pathfinder to vibrate heavily. The wire crimping should help with a stable connection and decrease the likelihood of a wire disconnecting. These changes should help the Pathfinder on its mission through upper campus CSULB.