Fall 2016 Pathfinder (Solar Panels): Preliminary Project Plan

By:

Inna Echual (Project Manager)

Stephan Khamis (Mission, Systems, and Test)

Jose Rodriguez (Electronics and Control)

Ridwan Maassarani (Design and Manufacturing)

Table of Contents

Work Breakdown Structure (WBS)

By Inna Echual (Project Manager)

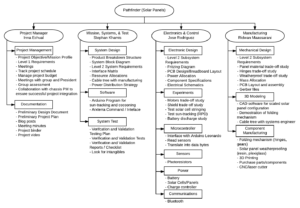

Figure 1: Work Breakdown Structure

The Work Breakdown Structure shown in Figure 1 demonstrates the work needed to complete the solar panel component of the Pathfinder project. The work branches into the four divisions (including project management) and the work/unique tasks underneath associated with each division.

Project Schedule

By Inna Echual (Project Manager)

Top Level Schedule

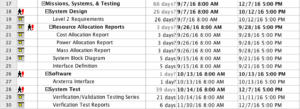

Figure 2: Top-Level Schedule

The top-level schedule shown in Figure 2 follows the blocks shown in the work breakdown structure. The major project deadlines are shown under the tasks of the project manager while each division’s individual tasks are nested under their respective division.

Currently, the tasks related to completing the folding mechanism (research, trade-off studies, 3D-Modeling, component specification and ordering, etc.) has the longest completion date and is our current critical path. We don’t have a solid choice for the folding mechanism yet so we still have to do further research and more studies to establish a design in order for our design to move forward.

System/Subsystem Level Tasks

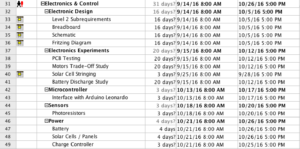

Figure 3: System Tasks

Figure 4: Subsystem (Electronics & Controls) Tasks

Figure 5: Subsystem (Manufacturing) Tasks

Burn Down and Project Percent Completion

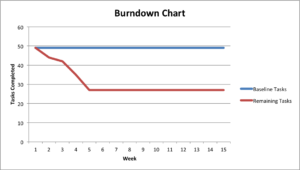

Figure 6: Burndown Chart

The project Burn Down Chart in Figure 6 demonstrates the work completed so far compared to the total amount of tasks expected to complete the project. The group has completed approximately 30 of the total tasks scheduled for the project. Currently, we are still trying to solidify a design for the folding mechanism so we may fall behind in the upcoming weeks due to research and trade-off studies.

System Resource Allocation Reports

By Stephan Khamis (Mission, Systems, and Testing)

Cost Allocation

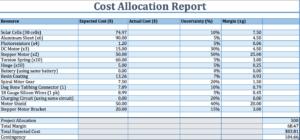

Figure 7: Cost Allocation

Our budget that we have set for ourselves is to keep the project under 500 dollars. All of the expected prices listed in Figure 7 are rough approximations or the average price for that type of component as, for instance, we have yet to define the specifications of the stepper motor will be using so its cost is yet to be defined but we have an approximation of its price. We are reusing some of the parts that were on the previous pathfinder, such as the battery and the charging circuit for the battery. Our total expected cost is $383.81 and we have a contingency of $184.66 dollars. We have allowed ourselves a margin of about $70.

Power Allocation

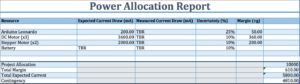

Figure 8: Power Allocation

The expected power allocations are based on the components we expect to be using. We have not specified our motors yet but we have a range of the current draw based on the models we are leaning towards. Battery specifications were to be provided by the chassis group but they have yet to provide us with their experimental data.

Mass Allocation

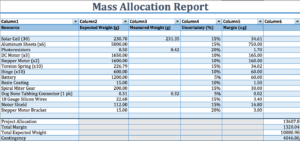

Figure 9: Mass Allocation

The mass report in Figure 9 are rough approximations of the mass of each component we expect to be using. We have yet to define specifically the DC motors and stepper motors we will be using so their mass is yet to be determined but we have a general idea. The aluminum sheets will have a honeycomb cutout structure to reduce its mass.

Project Cost Estimate

By Inna Echual (Project Manager)

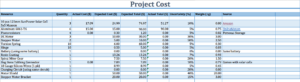

Figure 10: Project Cost Estimate

From the Cost Allocation Report in Figure 7, the overall projected costs are currently estimated to be $383.81. This price will be subjected to change as the project continues and is by no means a representation of a final product. However, we have already selected the type of solar cells we will be using—which are monocrystalline solar cells that already come with the tabbing connectors, ultimately reducing the cost of the overall project. However, the motors and springs have yet to be defined, which I expect will affect our total cost significantly.