Form Factor

From Factor

By: Nick Lukin (Design and Manufacturing Engineer)

Introduction

In order to meet the requirement of the Pathfinder being dimensionally proportional to the actual Spirit and Opportunity rovers it was necessary to develop a measurement method in order to properly scale the overall design.

Figure 1: Small Scale Model

Analysis

A small scale model of the actual spirit/opportunity rover was used in order to get base dimensions to work with and to develop an appropriate scale factor. Figure 1 shows the small model that was used to take measurements from. 10 different measurements were taken from the small model. The measurements are summarized in Figure 2.

Figure 2: Summary of Measurements/Dimensions

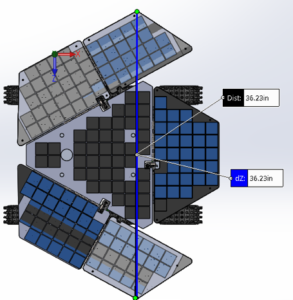

The solar panels group was limited to how wide they could make their overall panels because they needed to be able to fit inside the cabinet in ECS 316. The cabinet is 19 inches wide which meant the max width of the center solar panel was to be 19 inches. Therefore the scale factor of the overall design relied on how wide the solar group decided to make their panels. The final overall width and length of the solar panels was 25.39” and 36.26” respectively. The center panel width was 18.45” which was within the cabinet measurement of 19”. Once the solar panel group finalized their measurements the proper scale factor could be calculated. Dividing the overall solar panel width and length by the small model width and length gave a scale factor of 10.097.

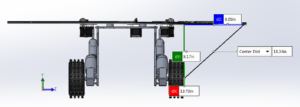

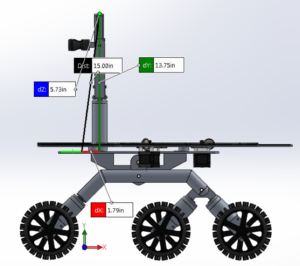

Figure 3: Overall Height

In order to find the overall height of the solidworks model the overall height of the small model (29.6mm) needed to be multiplied by 10.097. The result is about 298.88mm or 11.77 inches as shown in figure 3.

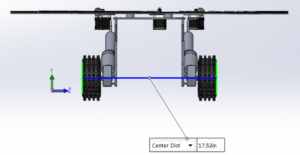

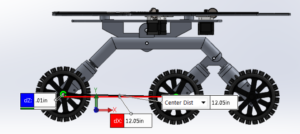

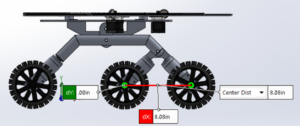

Figure 4: Overall Width (wheel to wheel)

The overall width wheel to wheel on the small model was 44mm. Multiplying this number by the scale factor yielded a measurement of about 444.29mm or 17.49 inches as shown in figure 4.

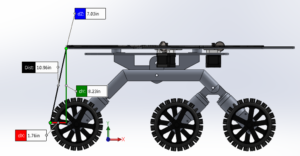

Figure 5: Length (wheel middle to front)

The length between the center of the front wheel and the middle wheel on the small model was 30.2mm. Multiplying this number by the scale factor yielded a measurement of about 304.9mm or 12.01 inches as shown in figure 5.

Figure 6: Length (wheel middle to back)

The length between the center of the middle wheel to the center of the rear wheel on the small model was 20.4mm. Multiplying this number by the scale factor yielded a value of 205.99mm or 8.11 inches as shown in figure 6.

Figure 7: Side Solar

The measurement between the end of the side solar panel and the edge of the wheel on the small model was 22.8mm. This number was multiplied by the scale factor to get a number of about 230.22mm or 9.05 inches as shown in figure 7.

Figure 8: Front Solar Measurement

The measurement between the front of the solar panel edge and the front edge of the wheel was 4.4mm on the small model. After multiplying by the scale factor the measurement came out to 44.43mm or 1.75 inches as shown in figure 8.

Figure 9: Back Solar Measurement

The measurement between the back solar panel edge and the edge of the back wheel on the small model was 3.5mm. Mulitplying by the scale factor yielded a measurement of 35.34mm or 1.39 inches as shown in figure 9.

Figure 10: Length/Width Solar Panels

The overall length and width of the small model solar panels was 92.5 and 63 mm respectively. Multiplying by the scale factor yielded measurements of 36.26 and 25.39 inches respectively as shown in figure 10.

Figure 11: Phone Holder Height

The measurement of the phone holder from the top plate of the chassis to the very top of the phone on the small scale model was 34.4mm. Multiplying by the scale factor yielded a value of 347.35mm or 13.68 inches as shown in figure 11.

Conclusion

Overall we were successful in creating a model in solidworks that matched the proper form factor of the spirit/opportunity rovers. In order to properly achieve the correct proportions it was necessary to assume that the small scale model that was used was accurately proportional to the actual spirit/opportunity rovers. If this is the case our model meets the requirement of achieving the proper form factor. A plus or minus 0.25 tolerance was put on the actual building of the model to account for any errors during the fabrication process.