Spring 2017 Velociraptor Preliminary Project Plan

Project Team:

Jesus Enriquez (Project Manager)

Oscar Ramirez (Mission, Systems, & Test)

Mohammar Mairena (Electronics & Control)

Andrea Lamore (Manufacturing)

Table of Contents

Work Breakdown Structure

By Jesus Enriquez (Project Manager)

The figure below shows the Work Breakdown Structure for the Velociraptor project splitting the responsibilities and tasks of each member within their respective division. The structure was developed through research and development of Level 1 Requirements that were agreed upon between the Customer and Project Management team. Specific tasks were assigned as solutions to complete the mission profile of the project as explained in the Preliminary Design Document.

Project Schedule

By Jesus Enriquez (Project Manager)

The following figure below show the project timeline from a Top Level Project and System/Subsystem Level perspective. The tasks within the Top Level Perspective derive from the Level 1 requirements as agreed upon between the Customer and the Project Management team. The top level consists of 4 main components: Planning, Design, Assembly, Project Launch. These different components have specific tasks that are critical paths to one another throughout the semester in order to reach project completion.

The system/subsystem level project schedule is structured to compliment the Product Breakdown Structure and the tasks assigned to each respective division. These tasks are split amongst the systems and subsystems engineers as shown in the figure which include MST, E&C, and Manufacturing.

Top Level Schedule

System/Subsystem Level Tasks

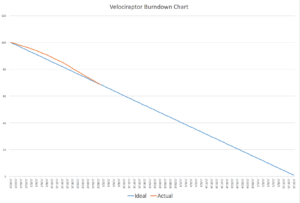

Burn Down & Project Percent Completion

The figure below shows the burn down report graphically representing metrics of the project and how well our project team is meeting project deadlines. Our project was graphed in percentage terms over the course of 15 weeks (full semester). As detailed in the figure, the “Orange” data shows us the actual work or state of the project completed, whereas the “blue” data shows us the ideal task completion our project should follow. This Burn Down report follows the task as given in the Gant Chart shown in the Project Schedule.

System Resource Reports

By Oscar Ramirez (Mission, Systems, & Test)

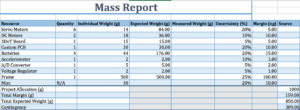

Mass Report

The goal for the mass of the velociraptor was to be able to carry a sufficient load (secret weapon) while continuing to operate normally. The mass of the robot should not affect basic functions such as walking or turning. The mass ideally should be less than one kilogram since power consumption from our motors will begin to become an issue. The total expected weight of the robot is 850 grams and falls below one kilogram, which should be sufficient enough for our motors to handle. The aluminum frame while sturdy is a lightweight metal with a low density and weighs less than polylactic acid (3d printed plastic).

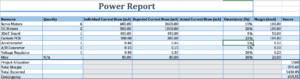

Power Report

The amount of power that will be consumed by the velociraptor will ideally less than 5500mA. For this we will need four batteries that can provide this much or greater combined current. The majority of the power being consumed is from the Servo and DC motors but the 3DoT board and the custom PCB will also have an expected current draw of 750mA. The rest of the current drawn from the robot is almost negligible compared to the motors and boards but is still accounted for. Finding the type of batteries that can supply this much combined current should not be too much of an issue since most batteries that can power our robot typically output more than 1500mAh.

Project Cost Estimates

By Oscar Ramirez (Mission, Systems, & Test)

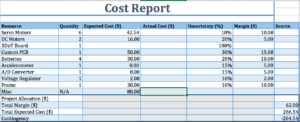

Cost Report

The overall cost of the project should be $266.54 therefore a budget of $300 should cover all expenses and uncertainties. The highest factors contributing to this cost are the motors and custom PCB, which should take a considerable amount from the budget since they are the main components. There is some uncertainty with the custom PCB cost since we have gotten some rough quotes from different suppliers. The material should be relatively cheap since we are using aluminum but the cost to stencil the aluminum to our design is a cost that has been accounted for in the miscellaneous section of the cost report. More miscellaneous costs include wire, small components, and additional parts. Overall this project could be completed with a budget of $300 but this is not accounting for the 3DoT board.

Resources:

- https://hobbyking.com/en_us/towerpro-mg92b- 360-mini- digital-robotic- servo-3- 5kg-0-048sec- 13-8g.html

- http://arxterra.com/fall-2016- velociraptor-w- preliminary-project- plan/

- https://www.adafruit.com/products/2019gclid=CjwKEAiA3NTFBRDKheuO6IG43VQSJAA74F77G0GPI6v5JDgxwulfMspg8EP1gATbZGylBD57y4JpBoCU9Pw_wcB

- https://www.metalsdepot.com/products/alum2.phtml?page=sheet

- http://cds.linear.com/docs/en/datasheet/1107fa.pdf

- https://www.arxterra.com/spring-2016- velociraptor-preliminary- project-plan/