Bowden Extruder

By Jessica Salazar – 3D Manufacturing

A Bowden extruder is part of a printer where there’s a flexible tube guiding a filament from the extruder motor also known as the cold end is located and the nozzle also called the hot end. The separation of these two parts while running a tube between then would make it from a traditional extruder to a Bowden extruder.

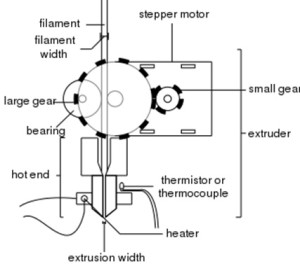

The Direct Extruder

The diagram above shows a typical extruder. A geared motor pulls filament, driving it into the hot-end for melting. The extruder motor is right above the hot-end making the whole part heavier and having to use more force to move and print parts. A direct extruder will often look something like this:

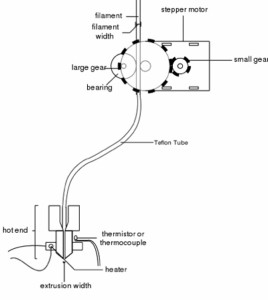

The Bowden Extruder

The diagram above shows the look of a Bowden extruder. Having the stepper motor moved from the top makes the hot end work at faster speed. The running a tube between above is generally made of Teflon.

Pros:

– Reduces the weight of the moving components

– Hot end can be moved with less force

– Faster speeds of printing