Acetone Vapor Bath

By Mustafa Alkhulaitit – Project Manager

After researching some of the techniques for smoothing the surface of a printed object, we made a conclusion that acetone vapor bath is one of the simplest ways for achieving the desired goal. Up to this point, we do not have the 3D printer to perform this experiment, so some simple equipment and materials will be used for now.

The Process:

The way the acetone vapor bath works is very simple. First of all, the reason of this process is to get rid of the horizontal lines of a printed object.

A smoother surface is a lot better looking than those horizontal lines, and smoother surface means stronger shine and therefore, higher resolution. The acetone bath works only on ABS plastic.

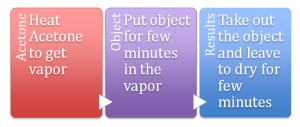

The process is as follows:

The time to leave any object in the bath varies because bigger objects may need extended times.

The Tools:

- Acetone – when heated to a boiling state, it melts out the plastic

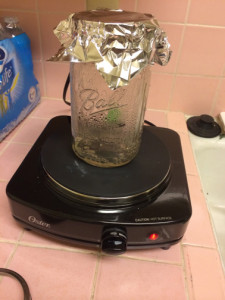

- Electric Hot plate – easier to maintain heat

- Aluminum foil – so object doesn’t stick to the base

- Glass jar or glass teapot – to put the object inside

- Food can – make base out of any aluminum food can so object doesn’t have direct contact with acetone; a hook can also be made out of an aluminum hanger