Tolerance of 3-D BioPrinter

By Omair Tariq, Systems and Test Engineer

Purpose

The purpose of this blog post is to determine the tolerance of our 3-D Bioprinter. Our level 1 requirement was that the printed object’s measurement should be within 0.7 mm of the value specified in the 3-D model of the object.

Equipment Needed

|

Equipment |

Quantity |

|

3-D BioPrinter |

1 |

|

Vernier Caliper |

1 |

|

2% agarose, 4% starch solution |

50 ml |

|

Laptop with Slic3r and Pronterface Installed |

1 |

|

USB Cables |

2 |

Table 1. Equipment needed for accuracy testing

|

Perimeter |

Value |

|

Nozzle diameter (20 gauge needle inner diameter)[1] |

0.6mm |

|

Filament Diameter |

29mm |

|

Travel Speed |

20 mm/s |

|

First Layer Speed |

10 mm/s |

|

Fill Density |

1 |

|

Fill Pattern |

Rectilinear |

|

Top/Bottom fill pattern |

Rectilinear |

|

Perimeter Speed |

20 mm/s |

|

Small perimeters |

20 mm/s |

|

External Perimeters |

20 mm/s |

|

Infill |

20 mm/s |

|

Solid Infill |

20 mm/s |

|

Top solid infill |

20 mm/s |

|

Support Material |

20 mm/s |

|

Bridges |

20 mm/s |

|

Gap Fill |

20 mm/s |

|

All Acceleration Controls |

0 mm/s2 |

Table 2. Slic3r Settings used for test print

Procedure

1.) A 20mm x 20mm x 5mm block was printed using the BioPrinter.

Figure 1. A 20mm x 20mm x 5 mm cube

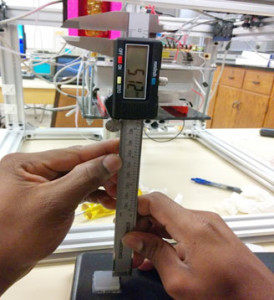

2.) It’s dimensions were then measured using a Vernier Caliper.

l = 19.85 mm (0.15mm within value specified in 3-D Model)

w = 19.97 mm (0.03 mm within value specified in 3-D Model)

h = 5.12 mm (0.12 mm within value specified in 3-D Model)

Figure 2. Length of 3-D Printed Cube

Figure 3. Width of 3-D Printed Cube

Figure 4. Height of 3-D Printed Cube

Conclusion

The printed part’s length, width, and height were well within the expected range. Based on a single measurements from a single part printed in this procedure, the x-axis has a tolerance of 0.15 mm , the y-axis has a tolerance of 0.03 mm and z-axis has a tolerance of 0.12 mm. This leads us to the conclusion that the printer has clearly met the level requirement of the values being within 0.7 mm of the specified values. In an ideal world, the tolerance would be specified after taking measurements from hundreds of printed parts and the tolerance values averaged.

Watch a video of the BioPrinter:

https://www.youtube.com/watch?