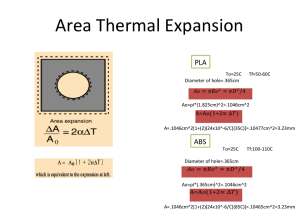

Area Thermal Expansion

By Jessica Salazar – 3D Manufacturing

Aluminum expands when heat is applied; this was not considered and remained a problem with the previous design of the heat bed. The heat bed was screwed down with no room for expansion this made imprecise prints and was not a smooth surface. The aluminum would concave up in the middle of the heat bed making it uneven and impossible to work with. In order to fix this problem we took all the measurements needed to calculate the area of thermal expansion. The misconception of a hole on the plate is that when the plate is heated it will expand in all directions or just on the whole but that is not the case. If we have a plate that does not have a hole it will expand outward. It does not matter if the hole is there or not it will still expand outward through the whole plate. Therefore, the hole will get bigger as well as the plate.

We found out that the thermal coefficient expansion for aluminum is equal to 24×10^-6. We plugged in the numbers needed for the expression and came out to .10465cm^2 for PLA or 3.23mm as well as ABS. Our holes would have to be modified to these numbers.