Spring 2018 AT-ST 3D Print Time

By: Joseph Cho (Mission, Systems, and Testing) And Danny Pham (Manufacturing)

Verified By: Initiser Kabir (Project Manager)

Approved By: Miguel Garcia (Quality Assurance)

Table of Contents

Introduction

This blog post will estimate the time taken for the 3D printing of AT-ST. Our current design is not finalized and will see changes in the near future. With this estimate, our project cost will be more accurately calculated and plans may change to align with the schedule.

Design diagrams

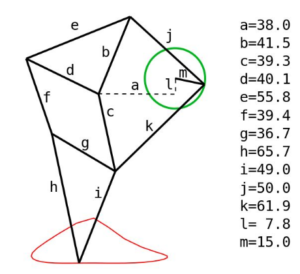

Theo Jansen Leg

Description:

The Theo Jansen legs will be 3D printed and made with ABS(Acrylonitrile Butadiene Styrene). Most of these measurements are scaled numbers from the design of the actual Theo Jansen legs. The width/thickness was taken from measuring the previous semester Velociraptor project. There is a slight difference between the width and thickness. Also a thickness of 3.1mm for carbon fiber is thick and efficient enough to support the structure of the legs while saving money. Velociraptor of Spring 2017 had thickness of 3.175 mm, but their design had bigger and heavier parts loaded on to the legs. The main parts to print for the body will be the 4x3x2.5” box, side panels, and some gears.

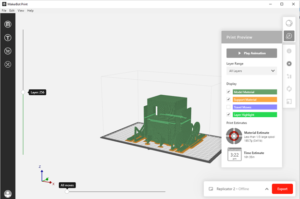

We will be using the Makerbot Print program with the settings below to calculate the print time.

Calculations

(0.5mm nozzle, 50mm/s, 0.2mm layer height, 20% fill)

Description:

According to the Replicator 2 3D printer, it will take 16h and 35 minutes to print our robot. This fails the level one requirement of maximum print time for a single part to be two hours and the total print time for the robot to be less than six hours. The box body is the biggest part of the robot so it will take the longest time to print. In order to fulfill our level one requirement, we should adjust the size and dimensions of the body. The components for each leg piece are already thin and quick to print.

Actual Print Time

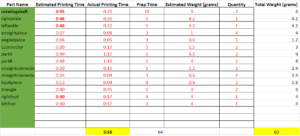

Figure 4: Print times

Description:

The Actual print time without the laser printable parts was 5 hours and 56 minutes. This is within the 6 hour project allocation for the 3D printing time.