Auto Bed Leveling

By Gregorio Rios – 3D Modeling

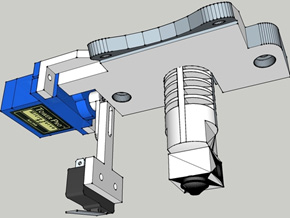

Auto leveling is the process of having a servo attached to the side of an extruder along with a switch to test several points on the printer’s bed.

3D Printers require their print bed to be perfectly level to the print head. If it’s not properly leveled it will not stick to the bed and may fall off, or warp. Auto bed leveling does not level the bed itself, it helps compensate for the bed not being leveled. Physically leveling is a tedious but a necessary process for 3D printing. Having to level the bed every time you print without auto bed leveling involves making multiple adjustments: getting a corner in the right position, adjusting and verifying that other corners did not get out of alignment before rechecking.

The way that auto bed-leveling works is by analyzing several points on the bed and taking that data to calculate the plane that the print bed actually sits on. The calculations are done by modifying the software responsible for printing. The printer is then adjusted so that the printed objects are perpendicular to the bed, which is not leveled.

The only items you need are a servo and a switch. Both the servo and the switch will attach to 3D printed mounted parts. A servo allows the 3D printed arm to swing down, so that the switch can test several points on the bed. With this simple process it will make printing more proficient without too much prep work.