AT-ST/Fall/2018-Back of the Envelope Calculations and Motor Specs

/in 3Dot AT-ST Generation #2/by Wendy GuerraSpring 2018 AT-ST Rapid Prototyping

/in 3Dot AT-ST/by Intiser KabirBy: Danny Pham (Manufacturing and Design Engineer)

Verified By: Intiser Kabir (Project Manager)

Approved By: Miguel Garcia (Quality Assurance)

Table of Contents

Introduction

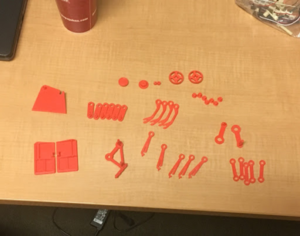

3D printing using a plastic can cause inaccuracies in the dimensions and measurements of the piece that you are printing. Even if the pieces are designed to be simple shapes, dimensions can be skewed because plastic can become deformed while the 3D printer melts the plastic. To counter this, we printed many copies of different pieces. Despite our efforts, pieces continued to be skewed and we had to sand down the pieces in order for the pieces to fit in our prototype.

All of the components we printed are not simple shapes. The connectors have small edges and holes that 3D printing can not avoid making inaccuracies for. In order to remedy this, we printed many copies of a few complex pieces with different 3D printer settings to see if a change in accuracy, layers, and density would fix some of these errors. As you can see in the image above, many of the pieces came out very well. Some of the holes and edges in the pieces had to be sanded out in order to fit other pieces, but the main design and function of the pieces was printed correctly.

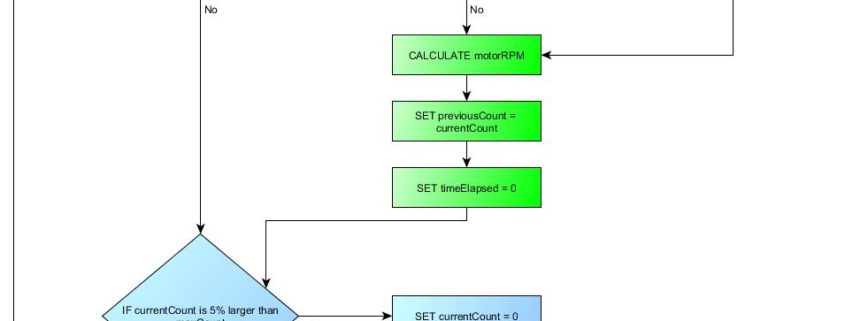

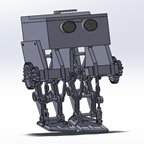

Printing components

Figure 1: These are the components we printed that will be put together to build the legs of the robot.

We printed the pieces with PLA so the printed components are brittle and easy to break. We had to replace these with new reprints and increased the number of layers and density so that the components weren’t as easy to break when putting the bot together.

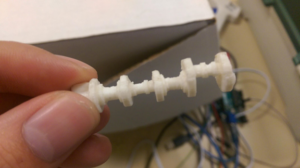

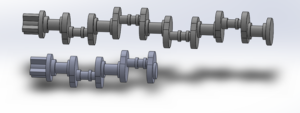

The main piece that gave us the most trouble to print was the rotating shaft. Because it’s design is complex, the shapes are easy to deform. The component was also not flat, so we had to use a more supporting material as a platform for the material to sit on while it was 3D printing. When we printed the rotating shaft vertically, it was very easy to snap. After we changed the 3D printing setting to print it sideways instead of vertical, it was very sturdy yet it looked messy. Changing some accuracy settings allowed us to create a good rotating shaft that looked clean and was sturdy enough to rotate on the robot without breaking.

The first print of the rotating shaft. It is a complex piece to print because of alternating circles and different sizes throughout the shaft. It was also very easy to snap because we printed it vertically.

Figure 4: Future print of the rotating shaft using higher precision settings and sideways printing instead of vertical.

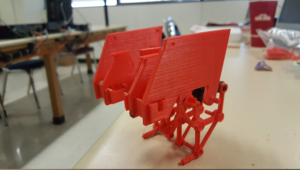

The printed motor case fit the motor pretty well. The only thing I did not account for was having space for the wires to stick out without constraining the motor in the case. A simple solution to fix this was to cut out a bit of the edge on the side so that the wires can stick out while allowing the motor to fit in the case.

Figure 5: Printed case for the motor to sit in. It contains a hole on the side so the shaft can rotate freely without issue.

The pieces we printed required a lot of sanding just to fit each other. Almost all of the pieces had some inaccuracies in dimensions and shapes because of 3D printing. Some pieces were too big to fit in the holes for other components. We tried modifying the size of the holes and edges on Solidworks for reprinting, to account for 3D printing inaccuracies, and many other issues came up. These issues included having holes too big, dimensions still deformed, and more cost for paying for reprints. We decided that sanding down the components to fit each other would work best in saving money and also fixing the issue of deformities in the components.

One leg put together after sanding down the pieces. Each component of the leg fit pretty well and the leg moved pretty well. The connections were not too tight or too loose.

We will be designing a new box to fit the ultrasonic sensor, servo, and other electronics.

Conclusion

After putting the components together, the robot came out similar to the Solidworks model. There were some minor errors in the prototype. Some of the pieces were a loose fit instead of snug, but overall, the pieces connected to each other well and the motion of the leg was not disrupted. The shaft rotated cleanly and the leg moved in a Theo Jansen motion as intended.

References

- https://grabcad.com/library/theo-jansen-type-biped-walking-robot-strandbeest-1

- https://drive.google.com/open?id=10GJDTiolPUA9C2i3yNMLMN5Ndx_wRcU-

- Final 3D Model: Linked when blog is published

Spring 2018 AT-ST Final Model

/in 3Dot AT-ST/by Intiser KabirBy: Danny Pham (Manufacturing and Design Engineer)

Verified By: Intiser Kabir (Project Manager)

Approved By: Miguel Garcia (Quality Assurance)

Introduction

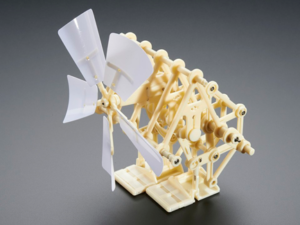

After the preliminary design review presentation, we decided to steer away from the split leg option that the previous semester used because it was difficult to balance. There were many complications with the previous design that caused the robot to fail, such as the unstable design of the legs and feet. To give us some ideas, Hill let us borrow a Theo Jansen Biped kit that moved with the Theo Jansen leg design using a fan. We decided that since the kit was well balanced, we could try to incorporate the use of motors instead of a fan into the leg design of this kit in order to make a walking robot that could walk and turn.

This is the fully built Theo Jansen Biped Kit that moves by using the fan to rotate the shaft. It includes an automatic weight shifting mechanism and three gears that connect the fan and the shaft.

After building the kit, we saw that the main action that moved the kit was a fan that moved three gears in a gear system. A shaft that runs through the kit is rotated by a gear connected to the shaft. The rotating shaft moves the entire Theo Jansen kit. We modified the design of the kit so that instead of using a fan to move the kit, a motor on each leg would move each leg. First, we removed the fan and the gear attached to the fan.

We found the entire kit on a Solidworks file on grabcad. The link is sourced below. This is an image of the kit on Solidworks after I removed the fan.

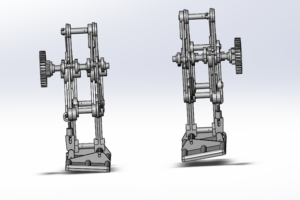

The kit above includes a rotating shaft that moves both legs simultaneously at different motions to create the walking motion. Since we are implementing a motor to do that for each leg, we split the shaft in half and implemented that on each side so that one shaft will move one leg, and the other shaft will rotate the other leg.

Image of the original rotating shaft and the edited shaft that is cut in half. We will be using the half shaft on each leg instead of just one shaft for both legs. Each shaft will be connected to their own motor through the gears.

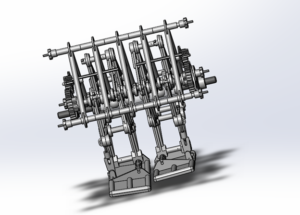

The edited rotating shafts and a gear are connected to each leg. The frame of the kit and the automatic weight shifting mechanism are removed from the model. This will be the framework of the legs.

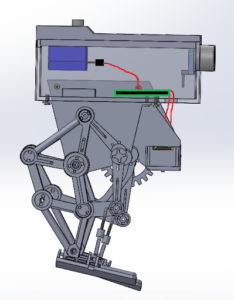

After removing the chassis of the kit, we designed our own frame with the same concept as the kit model. The chassis will hold the rotating shaft in place while it rotates. It is also connected to the rest of the frame and will be the main anchor that holds the robot together. We added a general box on top of the frame to hold the electronics.

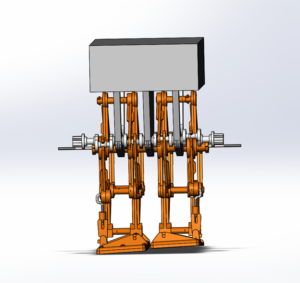

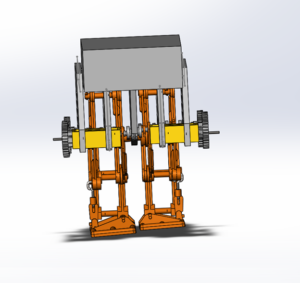

The legs are connected together with the shafts to three frame pieces that hold the legs and the body together. It also holds a box on top to fit electronics and other miscellaneous parts.

We initially planned to just stick the motor directly onto the rotating shaft on each end so that the motor rotated the shaft directly. However, Hill recommended that to balance the center of mass well, the weight of the legs should be closer together. If we went with having the motor on each side of the shafts, the weight would be shifted farther apart and make it more difficult to balance the robot. We decided to move the motor right in front of the legs so that the weight of the motor would be directly on the same plane as each leg. Since the weight would be closer to each other, the kit would have an easier time to walk while balancing itself. We created a case for our motors and modified our existing frame pieces to hold these motor cases. Since we are not putting the motors directly to the shaft, we created a two gear system. The motor spins one gear and the one gear will spin the other gear that is directly attached to the shaft so that the motor will rotate the shaft. We went with a gear system that moved from small gear to big gear and that will create more torque for the robot to move.

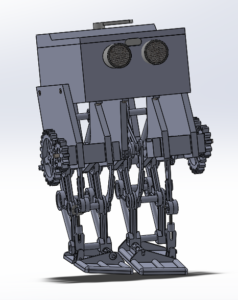

This is the robot after attaching gears and motor cases to the robot. We added two more frame pieces on the side to hold the motor cases and to hold the top box in place. This will add more stability to the robot and allow us to keep the motors closer to the center of the robot.

After finishing the leg and chassis design, we redesigned the box to hold the ultrasonic sensors, servo, and other electronic parts. First, we made the box longer to hold the 3DoT board and have space for the ultrasonic sensor and cables.

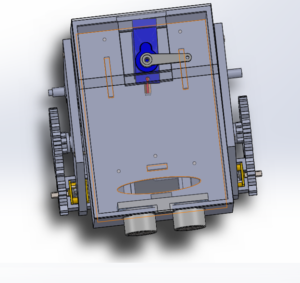

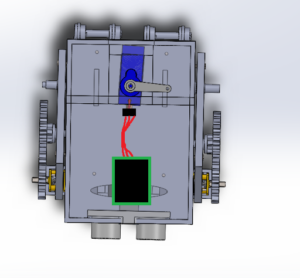

A transparent image of the redesigned box. I cut out holes in the front of the box to fit the ultrasonic sensor. A hole in the front bottom side of the box was also cut out for wires to come into the box from the two motors in front. I created small panels sticking out from the bottom side of the box so the 3DoT board will fit perfectly between the panels. Finally, I created a roof with a servo mounted to it so that the servo will act as the weight shifting mechanism.

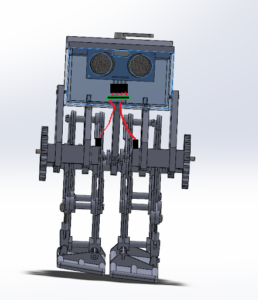

Final 3D model of the robot. It contains the servo, ultrasonic sensor and the other electronic components in the box. There is a two gear system on each side of the robot.

Conclusion

There are a few things I would fix for this model. Because there are gaps between components in the model, it would be nice to hide some of the wires with panels that covered these gaps. I would also fix some of the screw holes for the model. In Solidworks, it is easy to reach these holes to put screws in, but for the actual model, it can be impossible to reach. Finally, I would adjust some holes in the box. When you 3D print the part, the 3D printing can deform the part so that your dimensions for size and holes are off. We had to sand down the parts to fix that. The issue for this type of design is that these components were not meant to be 3D printed. The design worked as intended but could be improved on. A solution to this is to redesign each component so that it is held together by screws instead of the connections and edges already on the kit components. Redesigning the components to basic connector shapes and using more screws to hold each part together will allow for easier 3D printing but maintaining the function of this design.

References

Spring 2018 AT-ST Cable Tree

/in 3Dot AT-ST/by Intiser KabirBy: Samuel Yoo (Electronics and Controls Software Engineer)

Danny Pham (Manufacturing and Design Engineer)

Verified By: Intiser Kabir (Project Manager)

Approved By: Miguel Garcia (Quality Assurance)

Table of Contents

Introduction

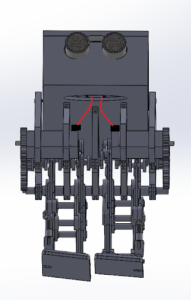

This blog post shows the wiring design for the AT-ST robot. It will show how the wires connect from the board inside the box to the servo, ultrasonic sensor, and the motors outside of the box on the final model images.

The wiring for the AT-ST robot contains only ribbon wires. There were two different types of cables, one with the female-to-female connector and the female to male connectors. The female to male connectors were store bought and used for the ultrasonic sensor and the servo. The female-to-female connectors were made from components and used for the dc motor only. There are two methods of making these type of wires; the first one is soldering a wire with a male connector and a female connector with male pins. After soldering the part together place, shrink wire on the connections and heat up the wire to get a good conductivity. The other method is getting a ribbon cable, housing, and female pins. With the listed components, first, remove some of the plastic off the wire to get the metal. Then taking the female pins, crimp them on the ribbon cable. After that step is done for each wire piece, insert them into the housing.

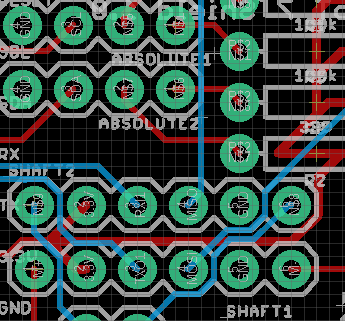

Wiring

- Wires – Red

- Board – Black box Green outline

- Connectors – Black box

Description: Front image of the wiring design. It shows wires connecting from the motors through the hole in the box to the board. The wires connect from the ultrasonic sensor inside the box directly to the board.

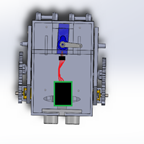

Description: Top image of the wiring. The wires connect directly from the servo to the board.

Description: Side view of the wiring design. It shows the wires connecting to the board from the servo and the motors.

Description: Front angled image of the board. It shows a better view of the hole on the bottom side of the box and the wires connecting from the motors into the box.

Conclusion

The connectors for the wiring made it much easier to connect and disconnect the electronic parts. Some other issues with this design are that since the final model is not closed, there are a lot of gaps that wires come through that aren’t hidden. A simple solution to hide the wires is to design new panels that would go on the front that will hide the motor wires.

References

- Final 3D Model Blog post: Linked when Published

- Interface matrix: https://www.arxterra.com/at-st_interface_matrix/

Spring 2018 AT-ST Theo Jansen Leg

/in 3Dot AT-ST/by Intiser KabirBy: Danny Pham (Manufacturing and Design Engineer)

Verified By: Intiser Kabir (Project Manager)

Approved By: Miguel Garcia (Quality Assurance)

Introduction

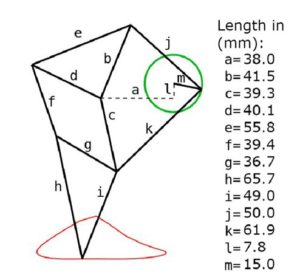

The Theo Jansen Leg design is a design by Theo Jansen consisting of rods connecting to each other. One of the rods in the design is a static point that holds the whole leg in place and another rod which rotates in a circular motion. By rotating this specific connector in a circular motion, the whole leg moves in a circle and creates a walking motion.

Description: The gif of the Theo Jansen leg shows the simulation of a walking motion by rotating a connector in a circular motion.

The reason the Theo Jansen Leg works well with motors is because the connector spins in a circle similar to a motor. One way to look at this is spinning a crank wheel. If you attach a motor to the connector, the motor will spin that connector in a circular motion and create the walking motion for the leg. The motor is essentially turning a crank wheel that allows the rest of the leg to simulate the walking motion. A servo would not work with this design because servos only turn 180 degrees. A motor can spin this continuously and allow the leg design to walk forward without any interruptions.

Description: These measurements are used by Theo Jansen for his leg design. The green circle represents the connector spinning in the circular motion or the crank wheel. The red line represents the circular motion that the leg moves in to create the walking motion.

One main issue to look out for using this design is controlling how the foot pivots on the ground while walking. Keeping the foot parallel to the ground is essential in order to have stability in the leg while walking. If the foot is not parallel to the ground when it is in contact with the ground, the motion is disrupted by the angle of the connector next to the foot. This will disrupt the stability of the leg and cause the leg to fall over or not walk at all.

Conclusion

The Theo Jansen leg design works well with motors. This leg design will work with our requirement of moving the legs of our robot with motors. The main priority for this design to function with our robot is having stability while the motor is running the leg. The parallel foot to the ground is essential for keeping the leg motion smooth and stable.