Fall 2015 MicroBiPed Prototypes

PROTOTPYE MILESTONES

By Railly Mateo (Systems Engineer)

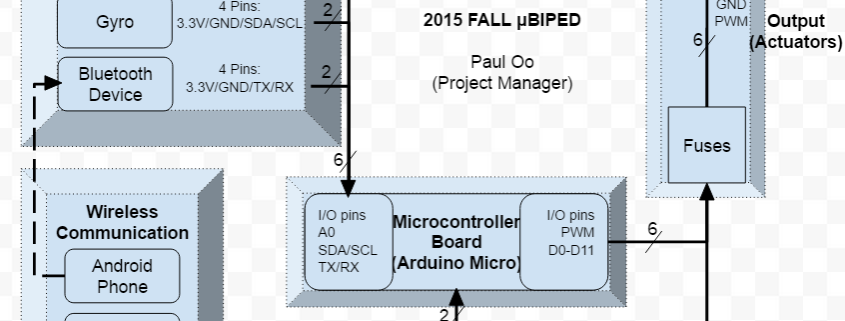

Approved by Paul Oo (Project Manager)

Approved by Railly Mateo (Systems Engineer)

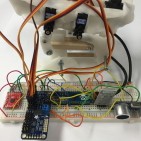

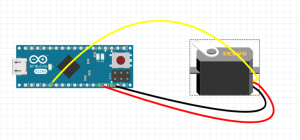

The video above shows the first step taken to understand the mechanics for how our Bipedal robot would walk. This model is considered our 1st Generation (1.0) of BiRex. It is a simply demonstration of a 5-axis leg using MG90S servos to rotate 2 axis, which then cause the rest of the leg to be displaced based on the angles of rotation. The commands used for this demonstration can be found in the Arxterra Application blog post.

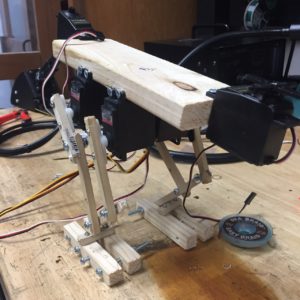

This second video shows how we attempted to understand the coding for making our Bipedal robot walk. This model is considered our 2nd Generation (2.0) of BiRex. Although it has integrated 2 5-axis legs onto a body (wooden plank), this model lacked the feet needed to test stability.

This third video shows how we attempted to understand the motion for making our Bipedal robot walk. This model is considered our further developed 2nd Generation (2.5) of BiRex. As you can see, it has difficulty walking. This lack of balance comes from the fact that our legs cannot support overall stability alone, thus verifying the need to add the head and tail.

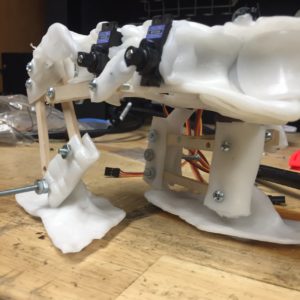

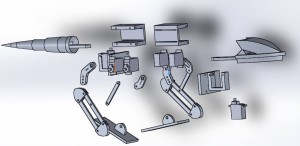

The image above shows the inclusion of servos for head and tail. However, after showing the progress of our prototype to Professor Hill, he recognized the need to change the design of the leg. This model was unable to lift its leg up, but rather slid to go forward. Because of this detail, we were able to implement a more realistic prototype and find valuable feasibility information.

The image above shows the finalized design before moving into producing our last model. Although the plastic molding made the structure too heavy to stay standing, the legs’ rotations resembled human-like walking motion.

Conclusion:

After changing the Mission Profile & Project Objective, we were able to focus our time into learning from trials and errors. This, along with a progressive design innovation, gave us enough data to create proper verification and validation tests.