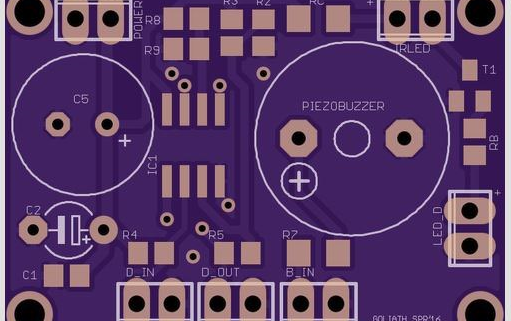

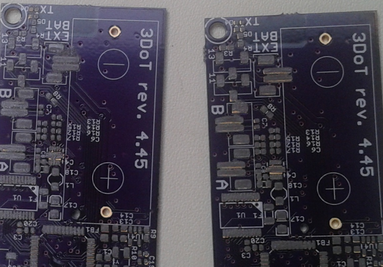

Spring 2016 3DOT Goliath, PCB testing

By: Kevin Moran (Electronics and Control Engineer)

Once the PCB was assembled by the manufacturing engineer (Jerry Lui), it was to test it. If all the testing and assembling had been done correctly then the PCB should have worked with a problem. As testing began we quickly realized that the PCB was not sending any voltage to the IR emitter. With the help of Jeff Cool, Tae Le, and Jerry Lui, we realized that the problem was with the NPN transistor we had ordered.

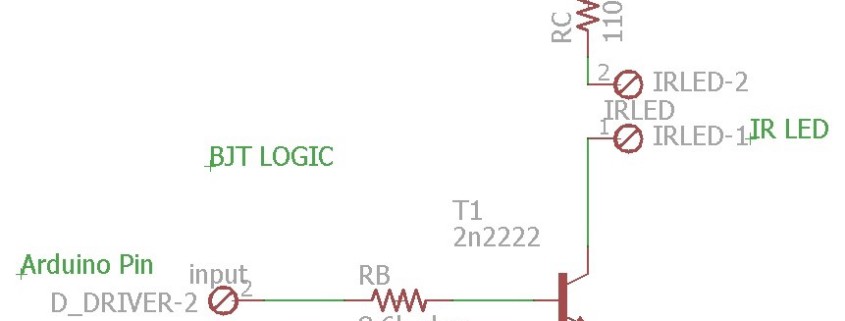

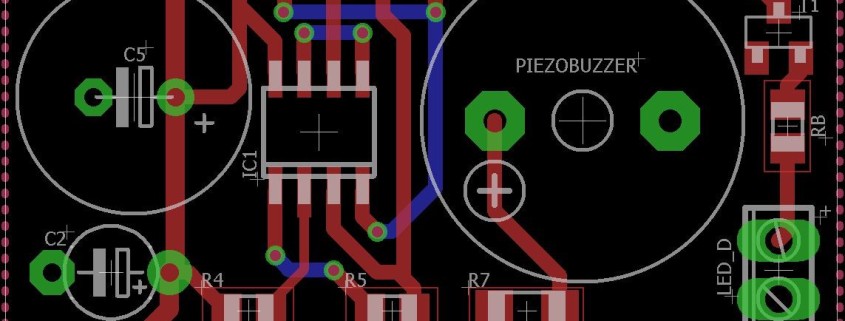

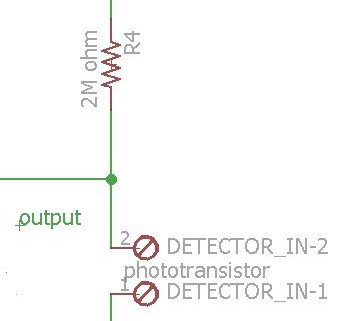

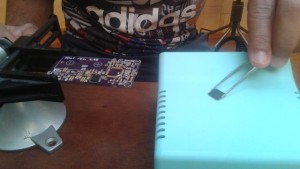

The problem was with this 2n2222 transistor above. The RB was not being used as a base, but rather the collector (which should be connected to ground). After many attempts, we came to the conclusion that the SMD transistor had been placed wrong.

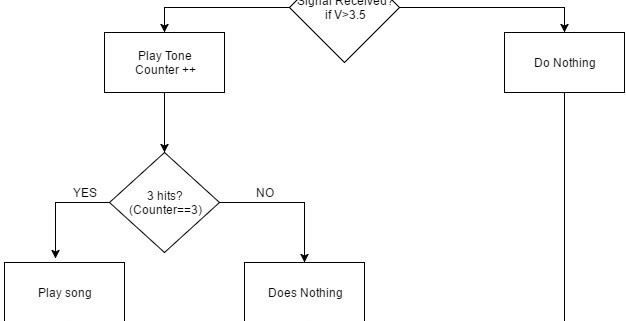

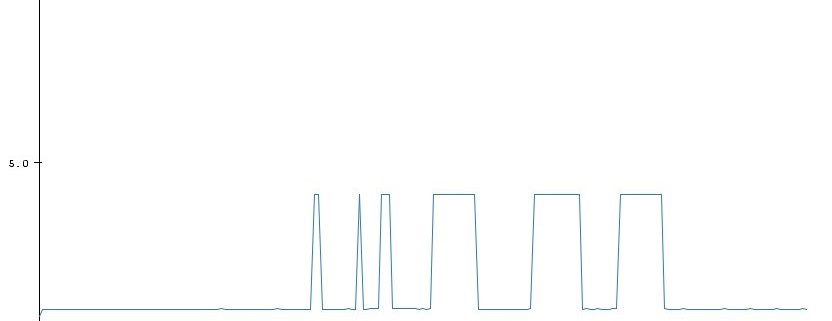

As can be seen by the arrow, once we compared the diagram of the transistor, with this picture, we realized that the resistor RB was going to the right connection of the transistor, when it should have been pointed to the left connector, and the right connector straight to ground. Thanks to the ingenuity and quick thinking of Jerry Lui, he was able to quickly fix this problem, by flipping the SMA transistor over. After that was fixed, we tested the IR emitter and we saw voltage going through it, and the receiver worked perfectly as well. Below is the final output of the PCB, converting an analog signal into a single bit digital signal! YAY!

As can be seen, a perfect digital signal with either a 0 or 1 bit. On/off applications. Now we are ready to defeat the 3DoT Spider bot.

Sources:

http://www.mouser.com/ProductDetail/TTElectronics/2N2222ACSM/?qs=%2fha2pyFaduhY4tRQXhKL%2feLyX%252bM6m2ylmJNPJCp%2fVeaSnptWjDmpSA%3d%3d