Current Draw

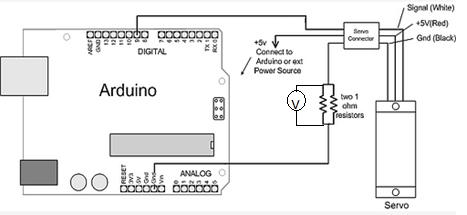

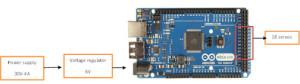

Figure 1: Circuit (Voltage showed on voltage meter will be equivalent to current draw from the servo)

By Tien Dang

Objective:

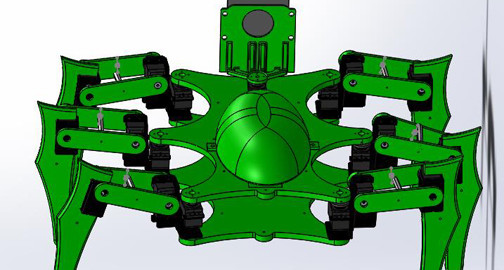

For the Hexapod project, one of requirement is to determine the maximum current and to make sure the battery provide enough power for 18 servos to be run simultaneously and safely.

Servo Current:

In order to determine the maximum current, a trade off study has been done on the Power HD 1501 MG servo. We found out that the current drawn may reach up to 2.3 A.

http://www.pololu.com/file/0J729/HD-1501MG.pdf

To make sure the test is accurate; we performed a current test for our project to determine that the current will not exceed 2.3A. The maximum weight of the Hexapod (2066.74 grams which equal to 4.55 pounds), we used objects that has equivalent weight tie to the servo as following pictures.

Figure 2: Two parallel resistors were used to measure the current output following (figure 1 schematic).

Demonstration video for current testing:

https://www.youtube.com/watch?v=NhzRON_y3eg&feature=youtu.be

Figure 3: Servo Strength Test

Figure 4 : Object weight (2066 grams = 4.55 lbs)

After the test, we established that the maximum current with the 4.55 pound load is 450mAh at 6V.

Battery Choice:

Since there will be 18 servos that going to be used for the Hexapod, the Turnigy 5000 mAh 2S 30C LiPo pack battery will be the sufficient choice in term of value and weight. Although the Venom battery might be a better choice because it can provide a much longer lifespan for the hexapod to operate (around 1 hour of operation) but due to its pricing ($50 plus shipping) and weight (288 grams which is 0.645 pounds) compare to the Turnigy battery ($20 plus shipping) and weight (275 grams which is 0.606 pounds).

The Turnigy battery can deliver a high discharge rate, which equals to 300A. At the worst case scenario, the maximum current that needed for 18 servos is 81A. So this battery is a perfect choice to supply power for the Hexapod with a minimum duration of 7.5 minutes.

Formula to calculate discharge rate and duration:

Discharge rate = Battery Capacitor * Battery Capacitor Rating

Discharge Duration = (Battery Capacitor / Total Current Drain)

Conclusion:

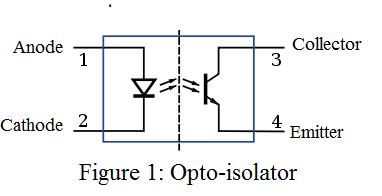

After doing calculations, the Turnigy 5000mAH 2S 30C LiPo pack is a good choice to supply power for 18 servos with duration more than 7.5 minutes. The only problem that we encountered is the safety requirement. Due to the battery high delivering rate of current and power, we need to use opto-isolators and voltage regulator to protect the servos as well as the ADK board.