Subsystem Requirements: Power Budget

by Robert Licari and Anthony Vo

Power supply of the Rover:

Rover must provide sufficient power to clear the course of 50m.

To ensure that the rover is able to complete its mission in a timely fashion, the rover’s load cannot exceed 6.72 Wh. For this to be true, we must consider how much power and current draw will go into each of our major components powered by this battery pack. In accordance with this math, we should be able to run approximately 13 W of power during the duration of 30 mins. Keeping this in mind, we will continue with the analysis of our motors.

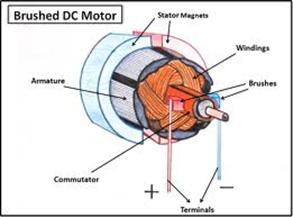

DC Motor:

120:1 Plastic Gearmotor 90-Degree Output

| Typical operating voltage: | 6 V |

| Gear ratio: | 120:1 |

| Free-run speed @ 6V: | 85 rpm |

| Free-run current @ 6V: | 70 mA |

| Stall current @ 6V: | 800 mA |

| Stall torque @ 6V: | 75 oz·in |

The single most important consideration that we have is with our DC Motors. We will be running two motors which will alter the above specifications as follows:

Stall current @ 6V => 1.6 A

Stall Torque @ 6V => 1.05924 N-m (converted from 150 oz*in)

Given this information, we will be able to determine that ~1 N-m of torque is where our DC motor will stall a will effectively put us dead in the water. So long as our torque remains underneath this value we can safely say that our current draw will be under 1.6 A and that our motors will not stall.

For this purpose, we will be working backwards. Our considerations will work from an outlandish power involving our Stall values, and we will be able to take steps backward in order to figure out where we want to be in terms of power usage and current draw.

Therefore, we will, once again, use our power equation utilizing our stall values and our rated voltage:

P_stall = V * I_stall

P_ stall = 6V * 1.6 A

= 9.6 W

This value is our stall power for both of our motors at Stall. Now, we do not wish for our motors to stall because that would be detrimental to our fundamental mission objective of forward motion. Therefore, we will simply scale backwards from our stall power and find a current draw that will fit with the specifications of our battery pack.

Here are some basic equations demonstrating this:

Let I = P / V

If P = 9 W then

9 W / 6 V = 1.5 A

If P = 5 W then

5 W / 6 V = 0.83 A

If P = 3 W then

3 W / 6 V = 0.5 A

These current values will be considered when we bring our Rover from rest to forward motion, and are integral to the mission objective. From a purely theoretical standing, the motor will never draw this much power at free-run, but we must also consider that the amount of time that our rover is at free-run speed will be minimal given the nature of the course we must navigate. Taking these into consideration, it is best to err on the side of the worst case scenario in order to avoid the necessity for a new battery pack or motor.

To meet our loose requirement for under 13 W of power consumption, if we consider our motors to draw about 5 W collectively, we are well under the power consumption thus far.

Also, do keep in mind that we are using the specification of 6 V, which can be subject to change as a work-around for our power budget.

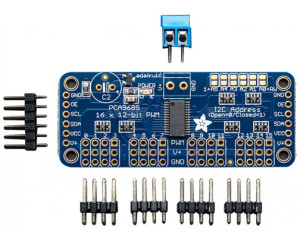

Servo Motor:

Towerpro MG996R 10kg servo

Weight 55g

Dimension 40.7*19.7*42.9mm

Stall torque 10kg/cm = 0.01 kg/m

Operating speed 0.20sec/60degree(4.8v)

Operating voltage 4.8-7.2V

Temperature range 0_ 55

Servo Plug: JR (Fits JR and Futaba)

Just like for the DC Motor, we will consider a purely electrical requirement. We will use the same approach that we have used previously but utilize different formulae in order to account for our different specifications.

Our first goal was to find an equation that could accurately and easily find a reasonable power consumption. Therefore, we will be using this equation:

P = ( N * T ) / C_1

For the use of this equation, we will use the fact that N is the number of revolutions per minute (RPM) and that C_1 is a Torque conversion constant related to the desired units of power that follows the below table

We must also consider that our operating speed is in improper units as well. So we will use the conversion provided by our conversion calculator (see Sources), which will give us the following:

0.2s / 60 degrees = 1/300 s/degree

=> ~50 RPM @ 4.8 V

Now that we have our operating speed in RPM, we can begin using our new power equation in order to discover what our stall power is and work backwards just as we did with the DC motor.

If P = ( N * T ) / C_1

Our stall power will be the following:

P_stall = ( N * T_stall ) / C_1

= ( 50 RPM * 10 kg/cm ) / 97.3

= 5.1387 W

This tells us that our maximum power before stall is ~ 5 W at our operation voltage of 4.8V. Now if we work backwards just as we’ve done before:

If P = 5 W then

5 W / 4.8 V = 1.0417 A

If P = 3 W then

3 W / 4.8 V = 0.6250 A

For our application here, we have a tremendous amount of flexibility with the servos. Unlike the DC Motor, the servos will not be running constantly in order to fuel our objective, but we must also consider that there is a finite amount of power that we have at our disposal. Therefore, if we propose that our servos run at approximately 3 W collectively then we can use that in our calculation of our battery life.