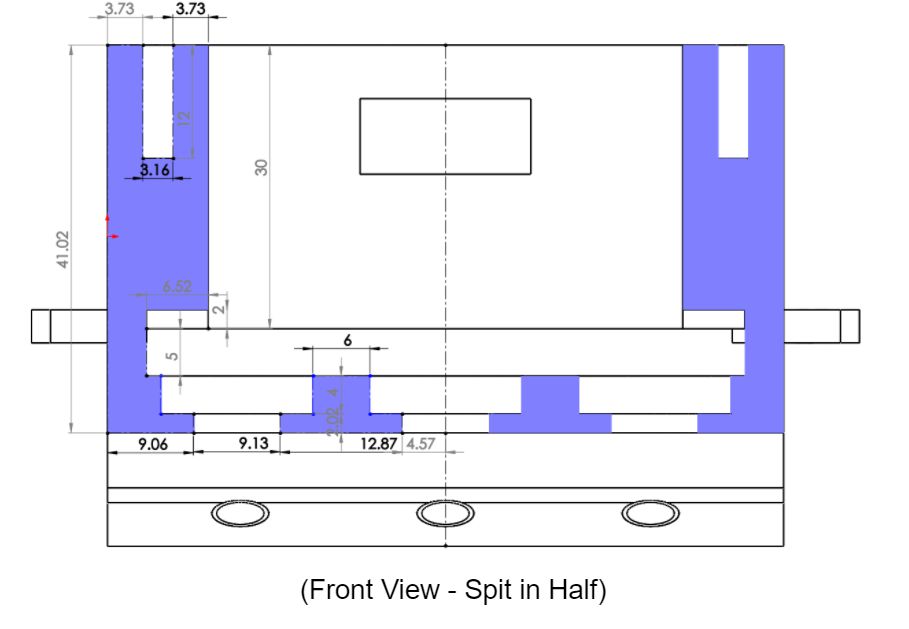

By: Eduardo De La Cruz (Project Manager and Manufacturing Engineer)

Approved by: Miguel Garcia (Quality Assurance)

The purpose of this post is to compile the project schedule from start to finish for all task that need to be finished by each division. The schedule will practically mirror the time frames and due dates priorly established in the task matrix. The goal is to provide a visual reference of how far or close one is from reaching their deadlines for a given task. We will begin by first taking into account the time spent hiring, planning, and learning about the engineering method, then we will be breaking down the time frame it will take each division to complete their task, and lastly we will compile all this information into a project schedule using excel’s Gantt project planner.

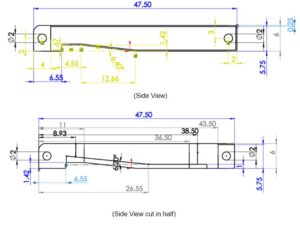

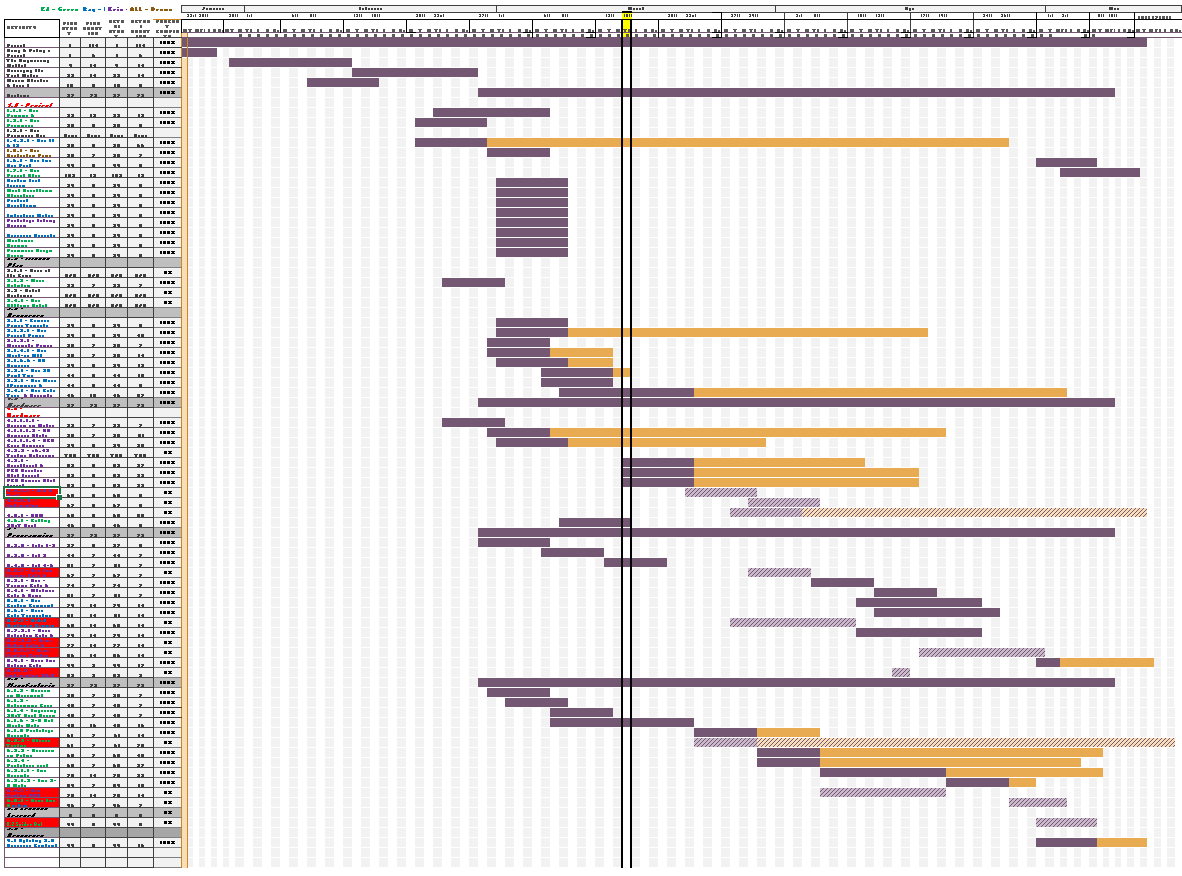

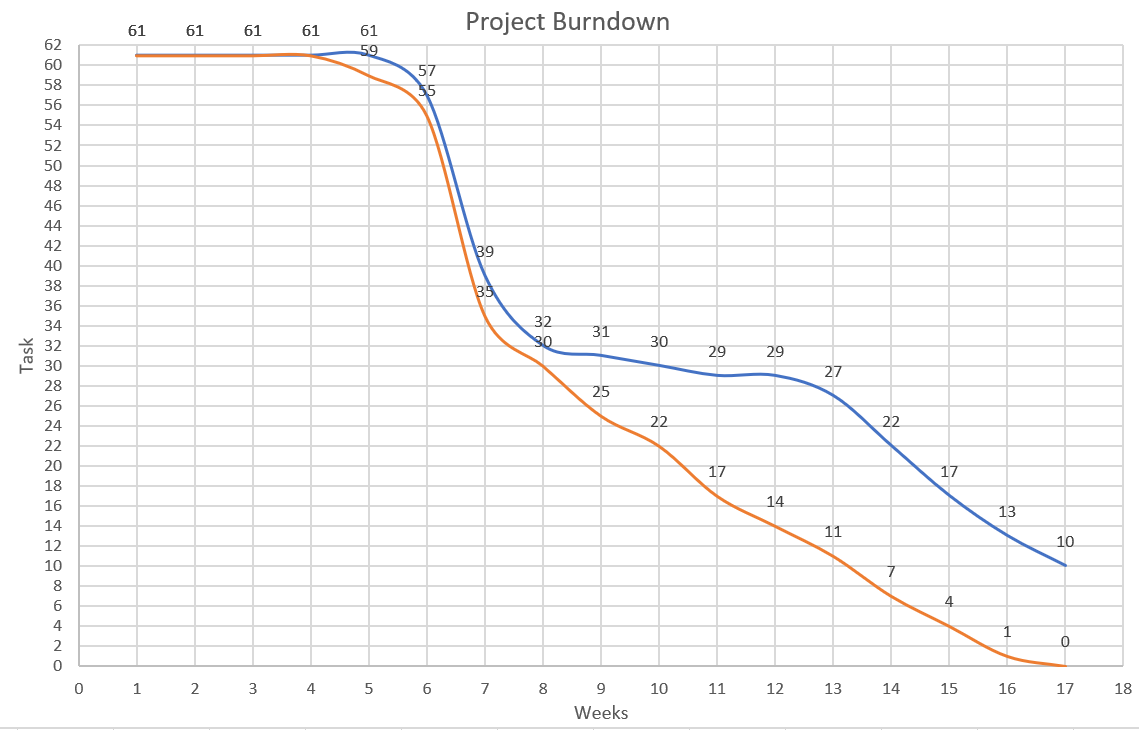

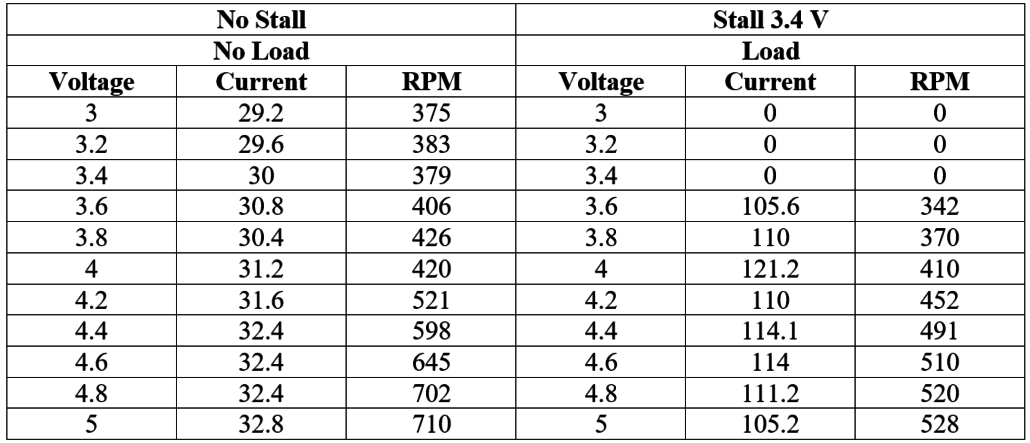

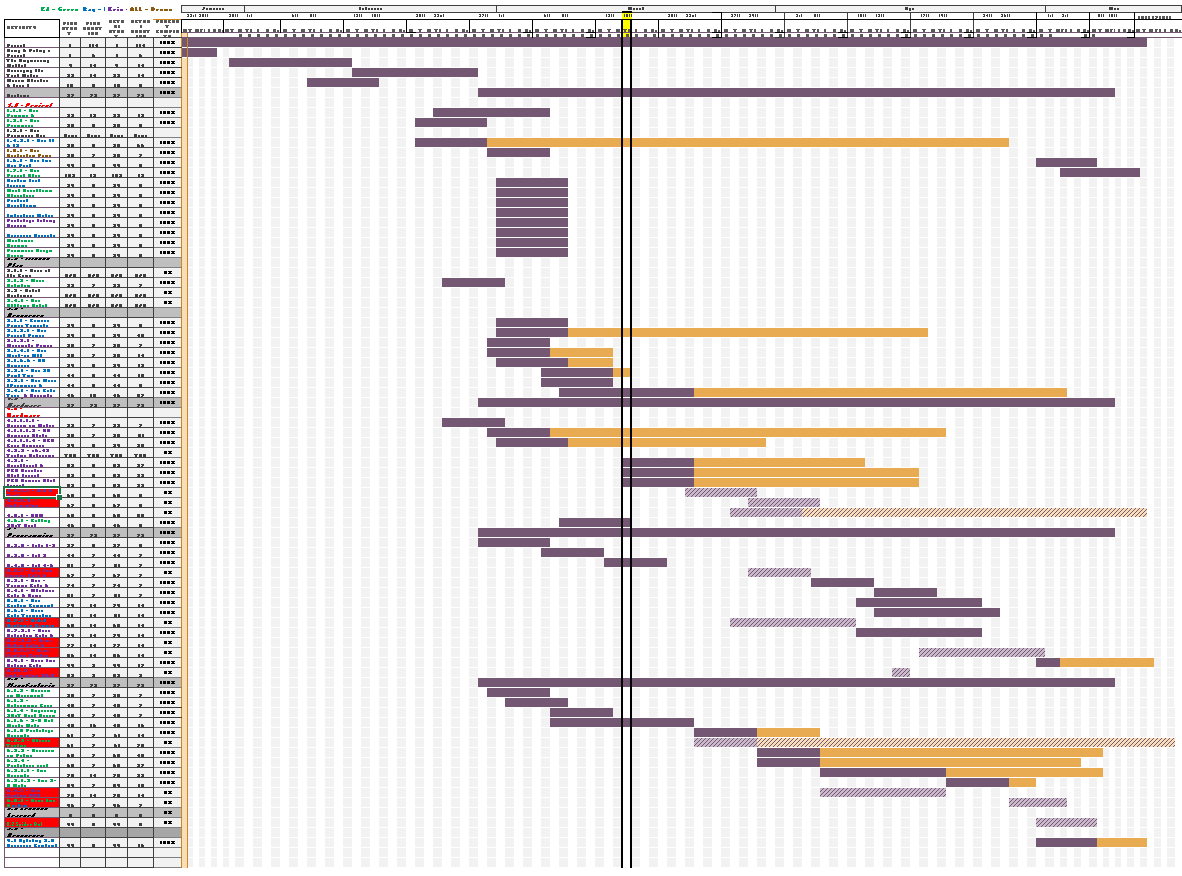

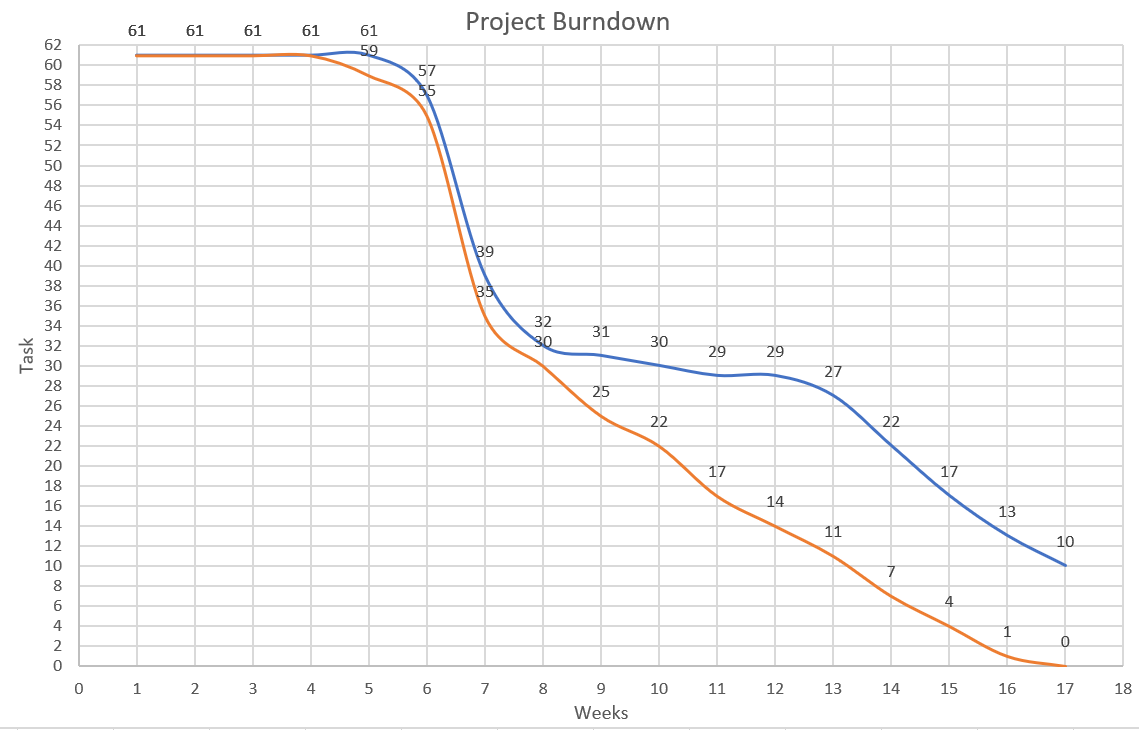

Final Project Schedule (May 15, 2018)

Figure 1: Final Schedule

Note: Task Labeled in red are task we never got too. Purple are task completed in time. Dark yellow are task completed past the due date. Light purple and light yellow are task that where never completed.

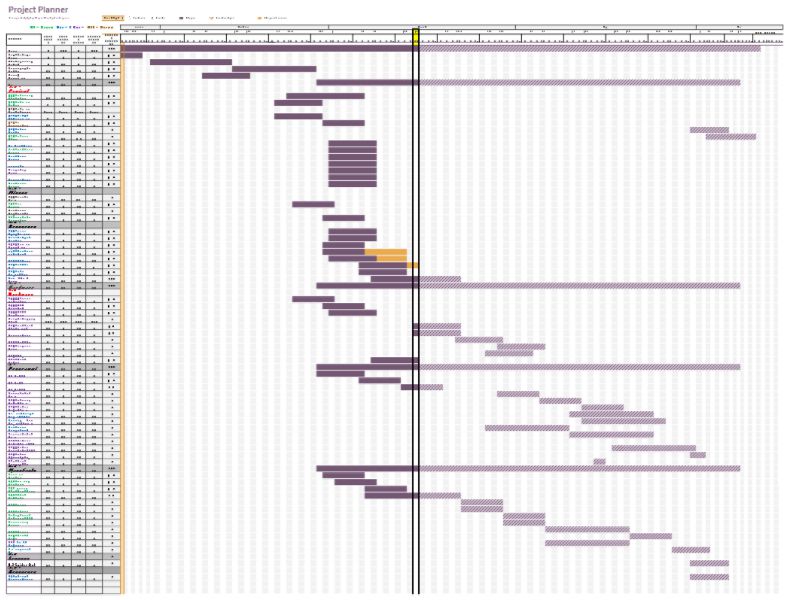

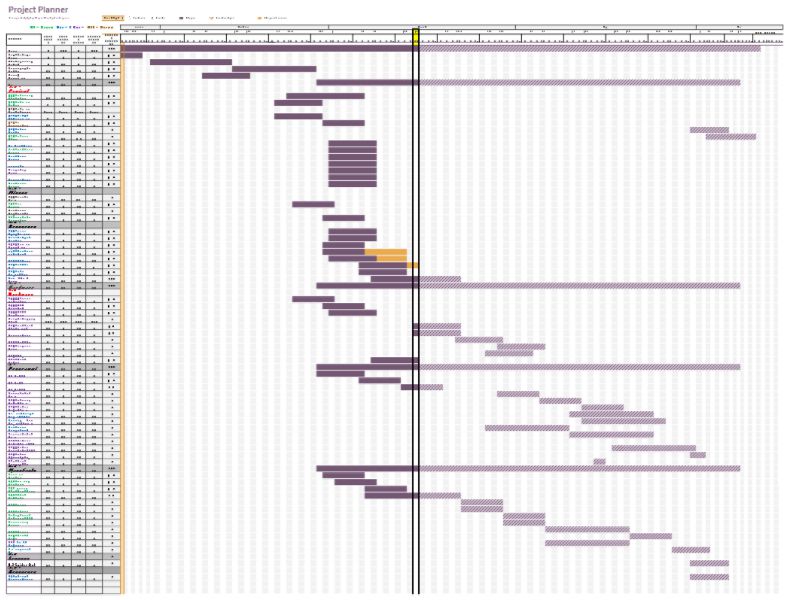

Figure 2: Final Burndown

Blue = Current Progress, Orange = Desired Progress

From the burndown above, we can see that we ended up being 10 task behind. Most of these task were related to hardware testing and software.

Links to:

Final Schedule:

Planner Final2.0

Final Burndown:

burndown

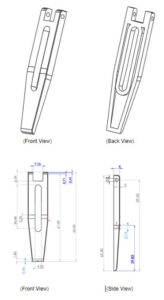

Preliminary Design Project Schedule (March 15, 2018)

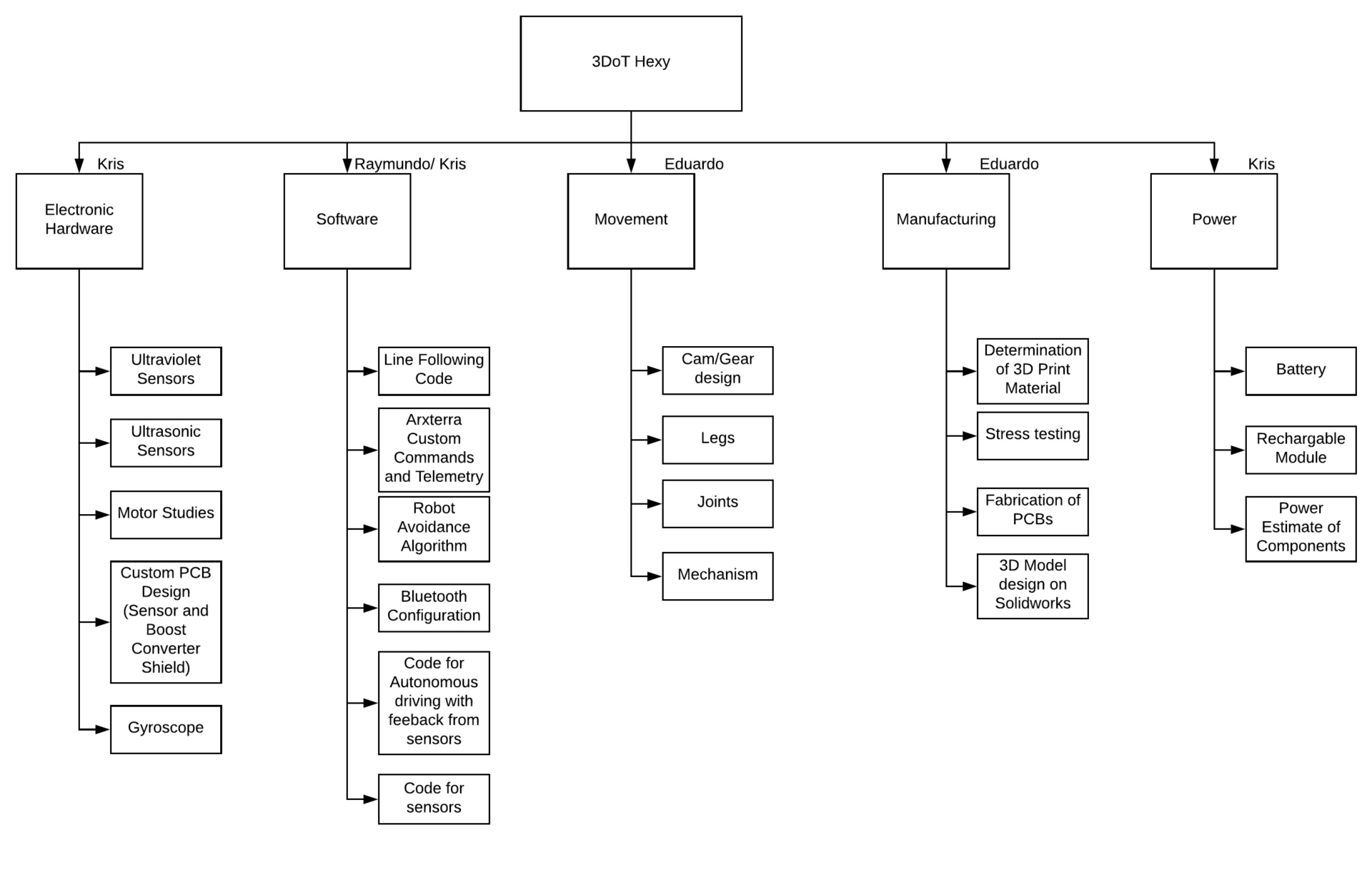

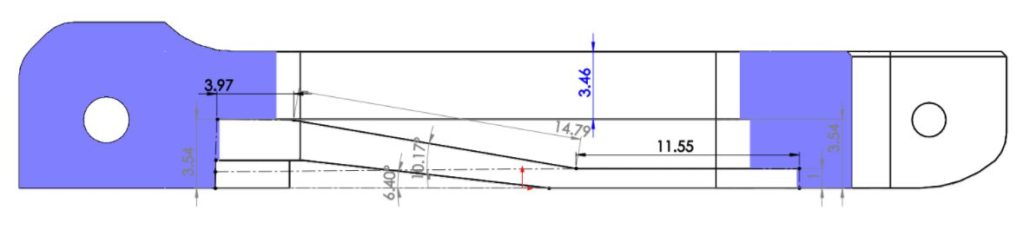

Figure 1 : Project planner generated using excel’s Gantt project planner)

Dark purple represents our progress, light purple represents what needs to be done. If we exceed the due date the bar will turn orange. Orange lets us know how many days it was late.

Task for each division are color coded and their is a legend at the top explaining each color.

Note: Division members may take on task from other divisions if they see that they have the time available in their existing schedules to aid other divisions in getting their task done.

To get a closer look at the specific task in the above project planner, look at the excel spread sheet located in Resources.

Stage 1: Hiring & Picking a Project, Learning the Engineering Method, and Developing a Task Matrix

Week 1: Hiring & Picking a Project

During this week students are introduced to the EE400D robot company, to all job positions available, and to the 6 projects that can be created. Students submit resumes and cover letters applying for a specific roles, form teams, and pick a project to tackle.

Week 2 – 3: Learning the Engineering Method

During this week students are introduced to a series of presentations that cover the engineering method. This method is a systematic approach used to reach a desired solution to a problem. Students will learn the six steps: developing ideas, concepts, planning, designing, development, and launching. Students will present a presentation on creativity development at anytime during these weeks. During this time we also develop project mission and level 1 requirements.

Week 4 – 5: Developing a Task Matrix

Students will read existing blog post from previous semesters, scavenge for what can be reused and develop their own task matrix. The task matrix will require extensive research on what needs to be done by each division to make the project happen. The task matrix requires that students provide for each task: existing references, define what is its predecessor and what it is linked to, who will the task be assigned to, estimated time to complete, and the due date.

Stage 2: Division Specific Task

From week 6 and onwards, each division will focus on completing task that are specific to their job description and that should already be defined in the task matrix.

Week 6

Preliminary Budget, Maze Definition

Week 7

Additional Robot Specific Mission Objectives, Planning & Scheduling, Work Breakdown structure.

Week 8

Preliminary Design Review Blog Post.

Week 9 – 15

Work on keeping everyone on schedule, work on Project Video, regularly update professor about progress, inform team members about changes, upload blog post.

Week 16

Final Blog Post, lessons learned.

Week 17

Project Video.

Mission, System, & Testing

Week 6

Project Specific Lvl. 1 & Lvl. 2 requirements.

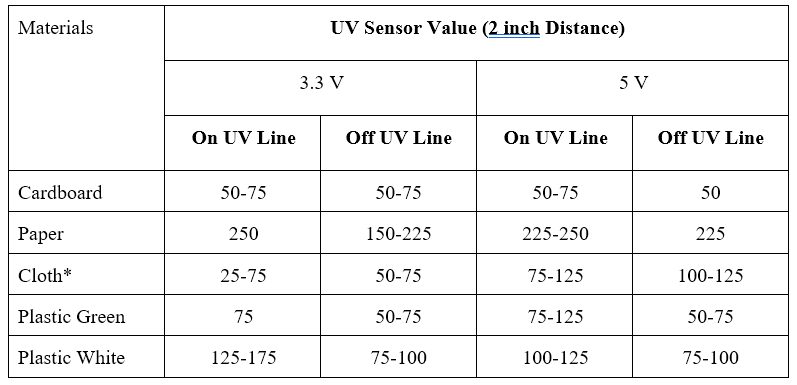

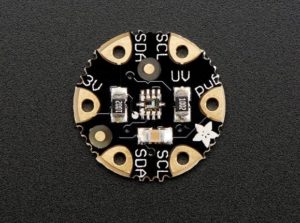

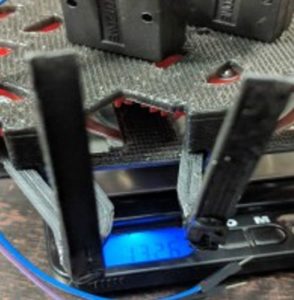

Week 7

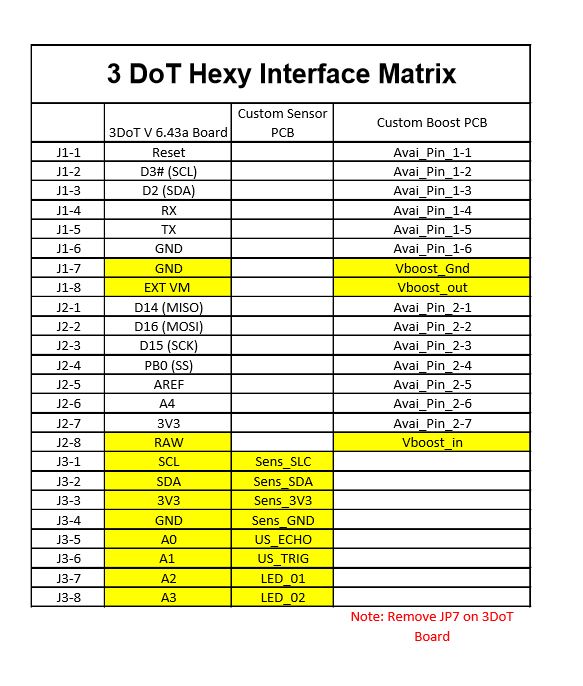

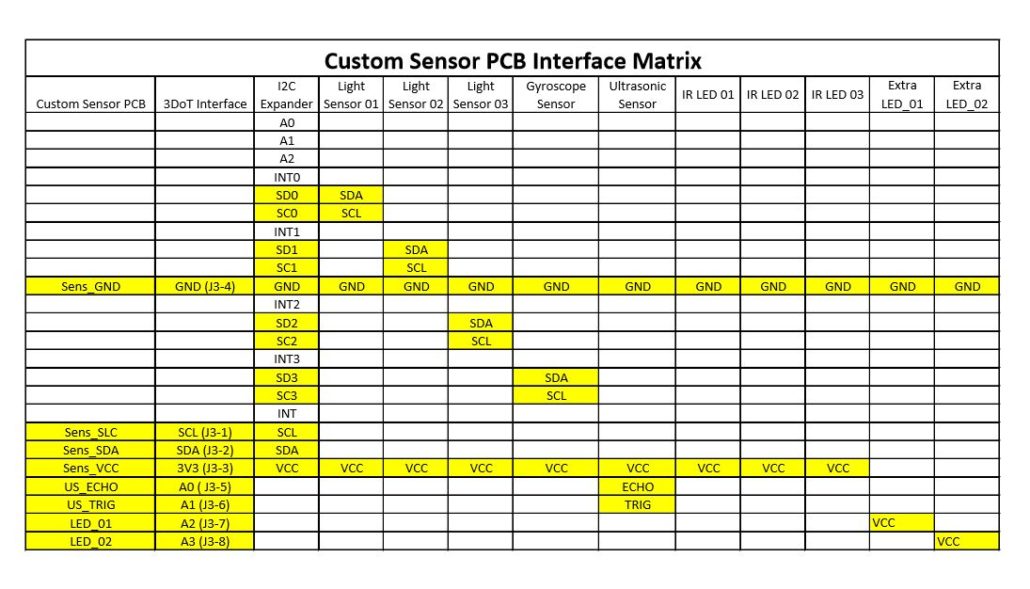

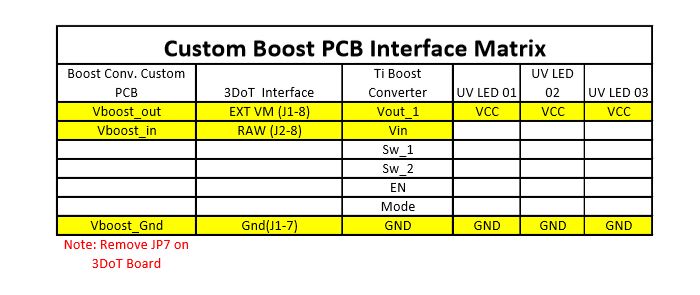

Verification Test Plan and Report, System Block Diagram, Product Breakdown Structure, Interface Matrix, Resource Report (Mass, Power, & Cost) , Robot Avoidance rules (Update), UV sensors.

Week 8

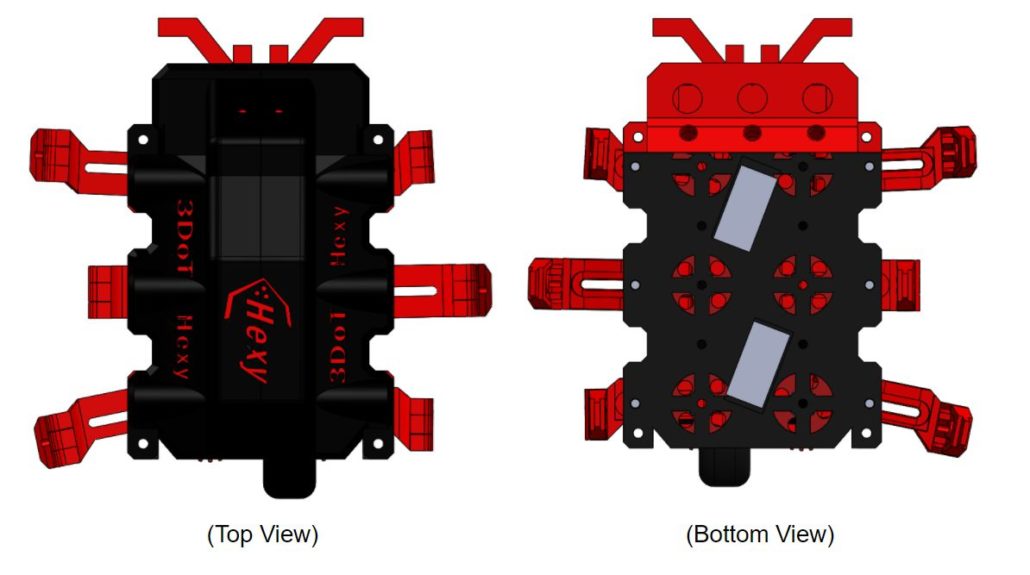

3D print times (preliminary), Mass (Preliminary), Preliminary Design Review Blog Post.

Week 9

cable tree and assembly diagram

Week 10 – 14

Work with E&C in implementing cable tree, system wiring, PCB layout, updating mass, power, and cost report, and creating the arxterra custom commands and telemetry on the App and Arduino.

Week 15

Final System Integration and Test.

Week 16

Final Verification.

Week 17

Execute mission

Week 6

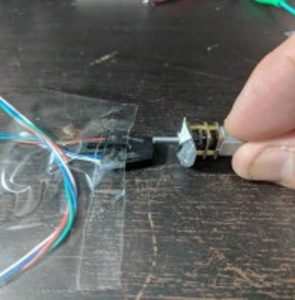

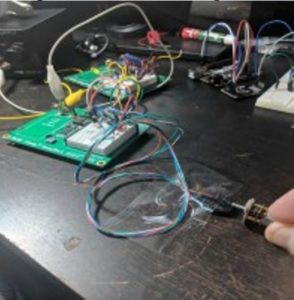

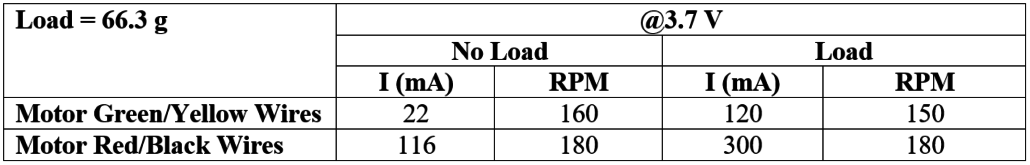

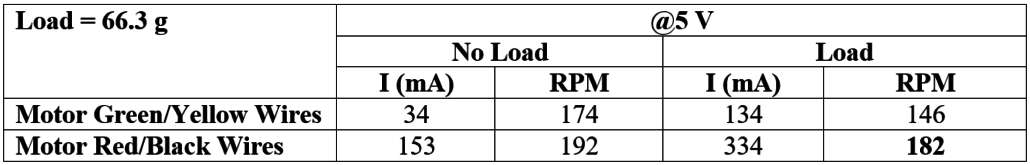

Decision on Motor type selection.

Week 7

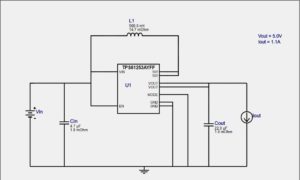

Prototype Fritzing Diagram, Power Estimate of Components, UV sensors study, RGB color sensors.

Week 8

Preliminary Design Review Blog Post, getting 3DoT David working.

Week 9

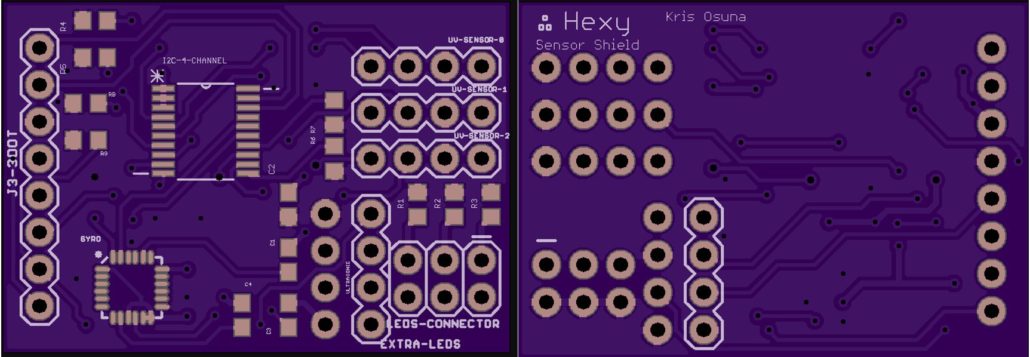

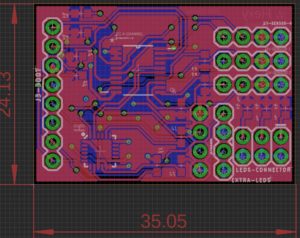

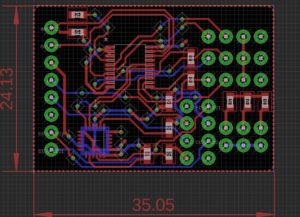

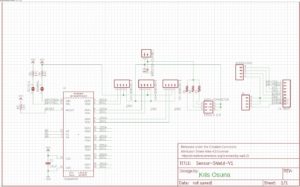

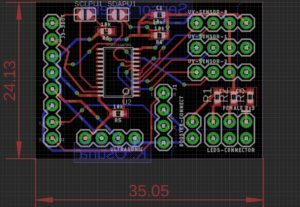

System Schematics (Eagle CAD), Sensor shield layout.

Week 10

Breadboard build and test.

Week 11

Integration Testing on final design, Electronic Component BOM and Order, Spiderbot line following code and demonstration.

Week 12

Robot avoidance general detailed algorithm, Spiderbot turning code and demonstration.

Week 13

whichway code and demonstration, custom PCB Assembly and Fabrication

Week 14

Implementing robot avoidance code, Interfacing with 3DoT David or our model.

Week 15

Final Arduino Code, Final system Integration and testing.

Week 16

Last minute touch ups.

Week 17

Execute mission

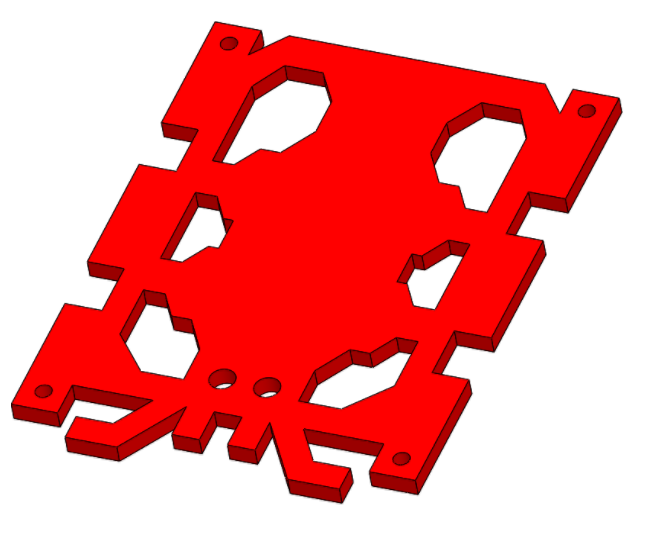

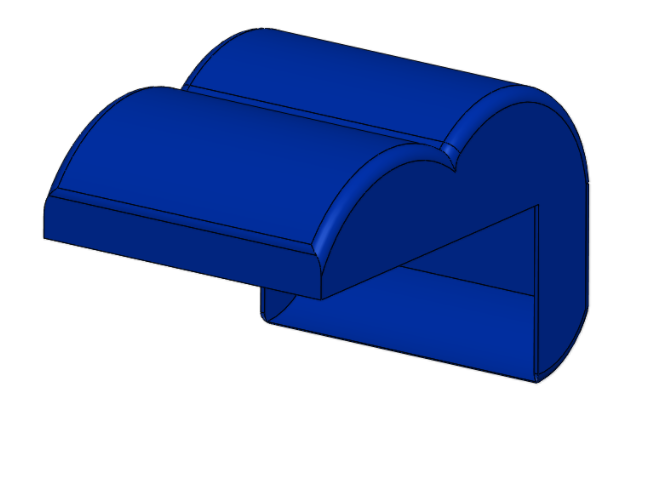

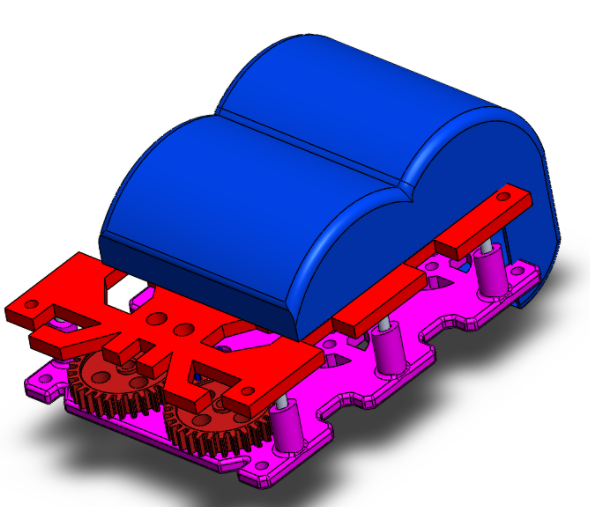

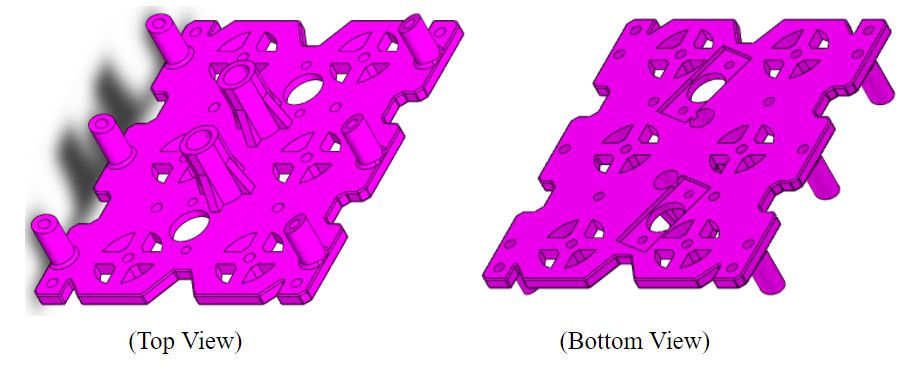

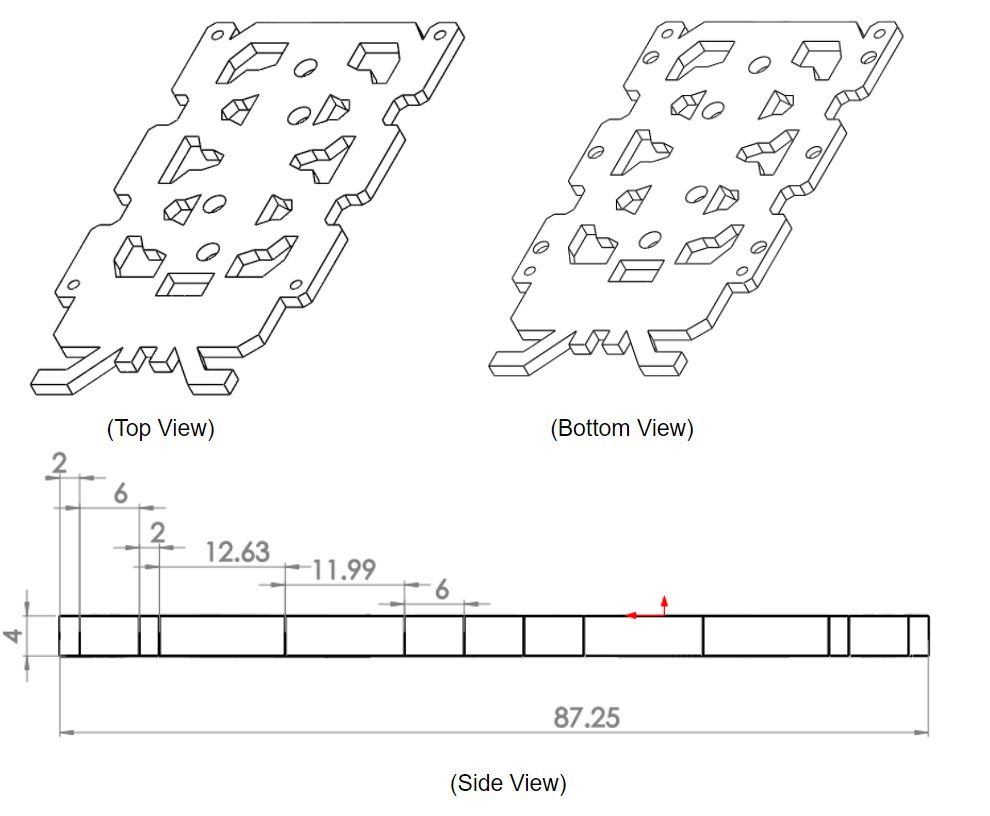

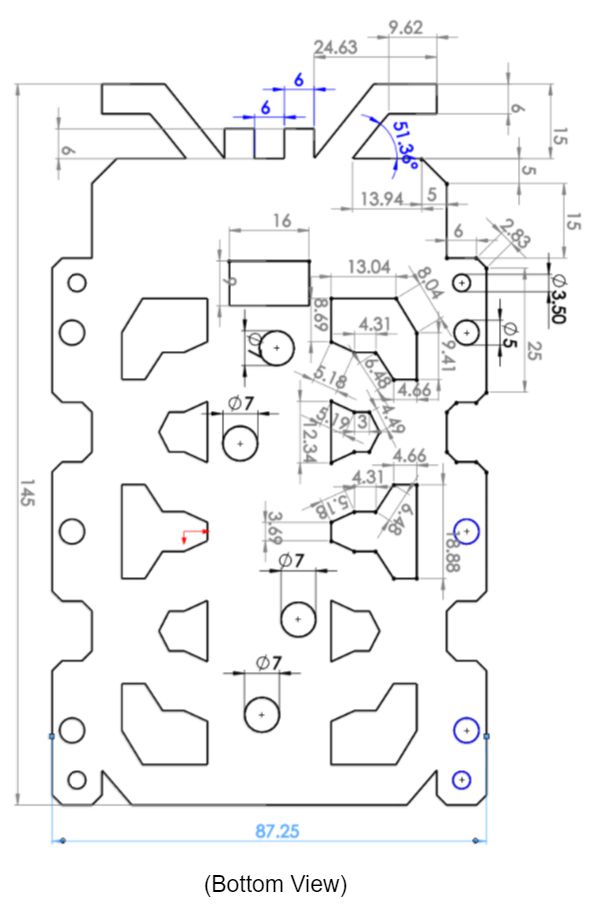

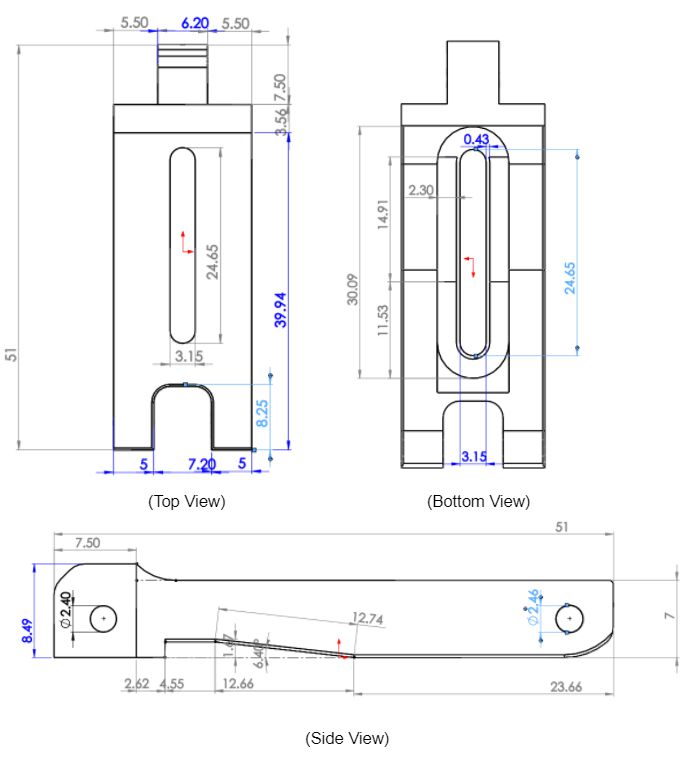

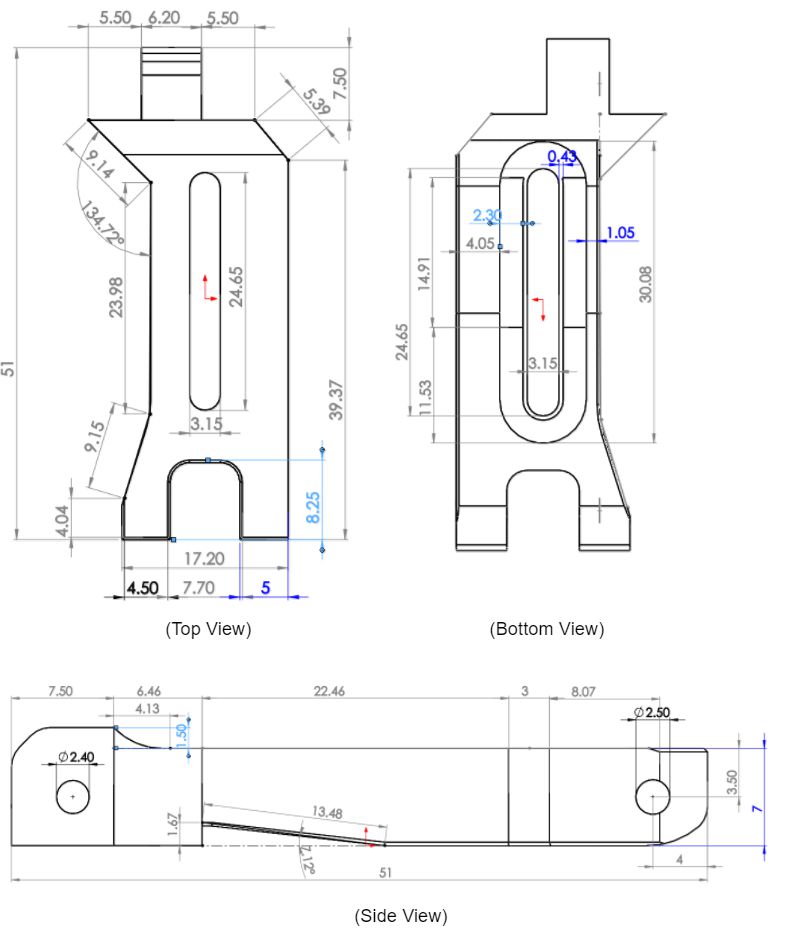

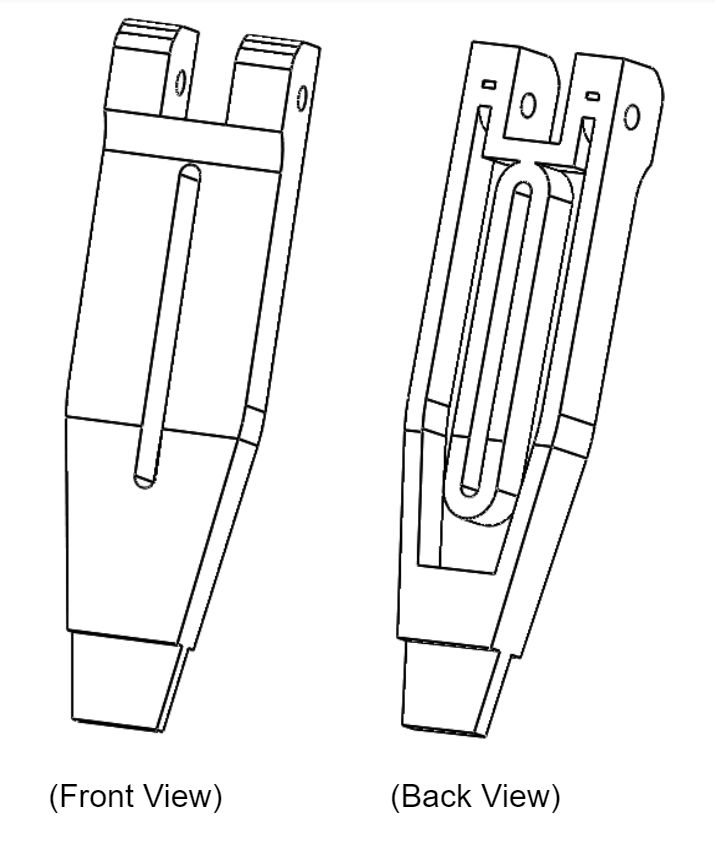

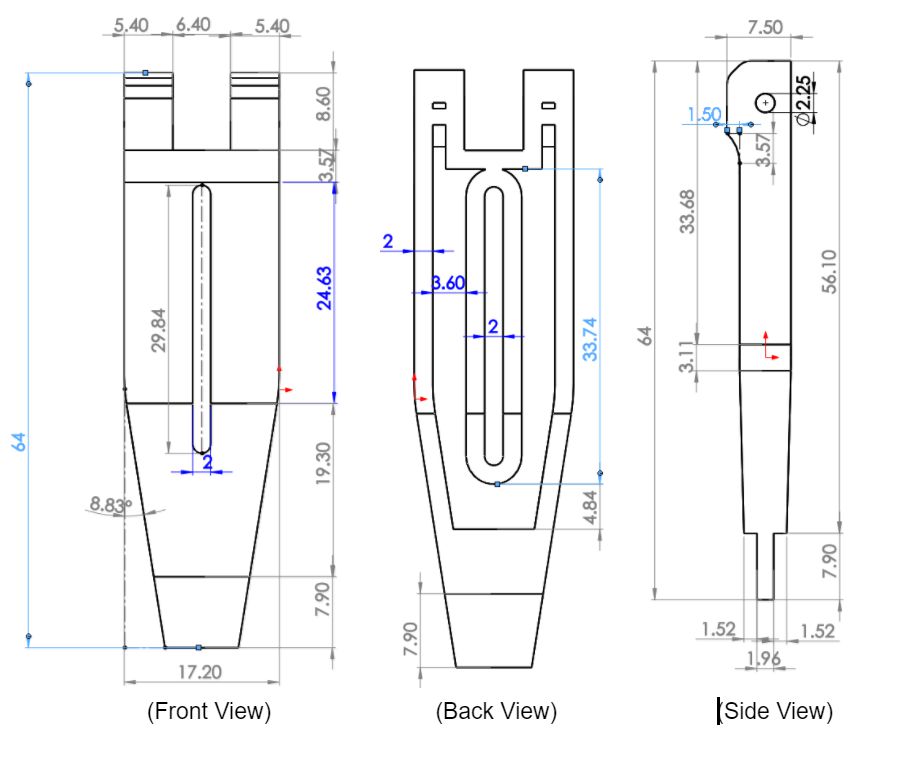

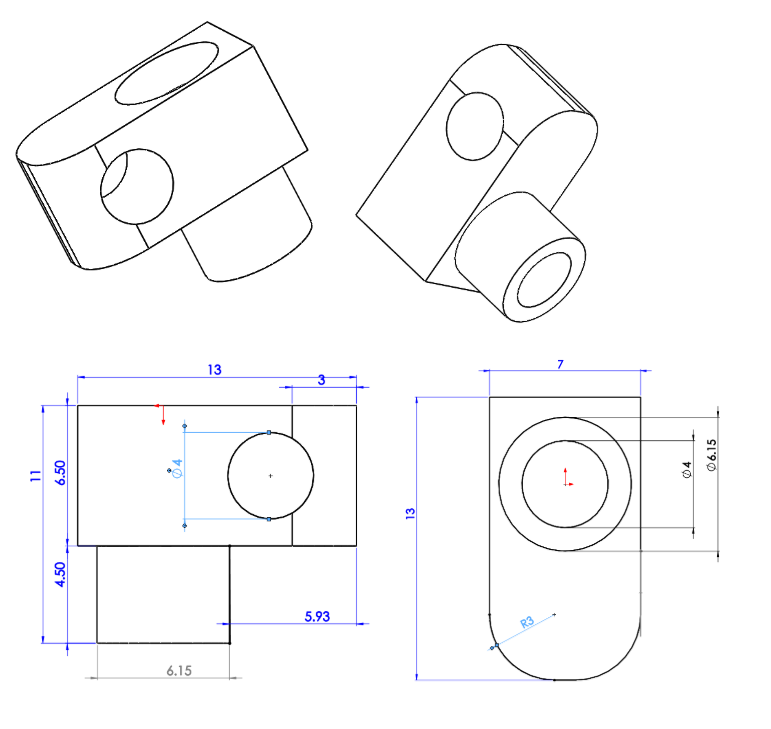

Week 6

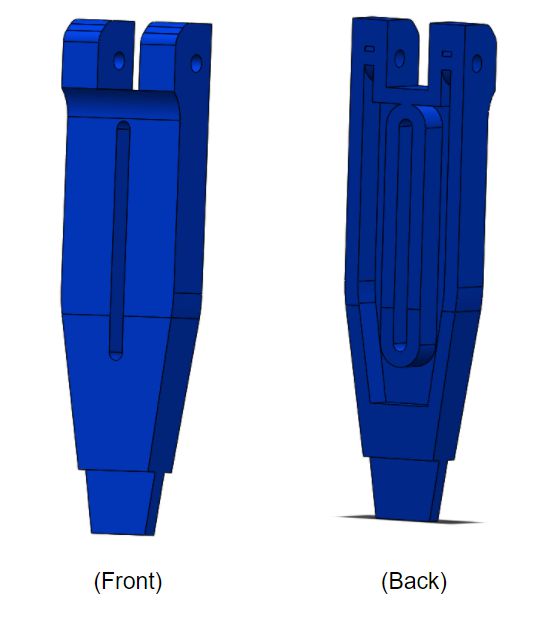

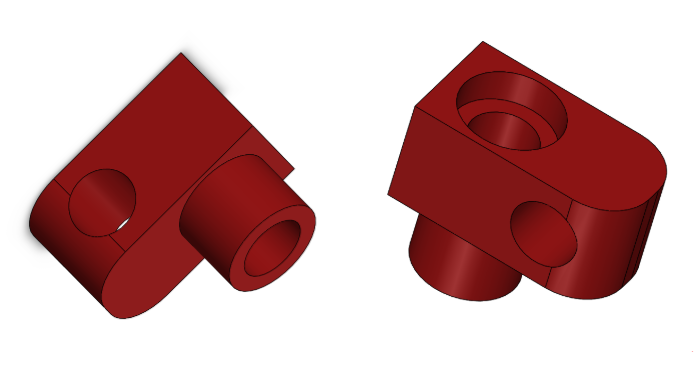

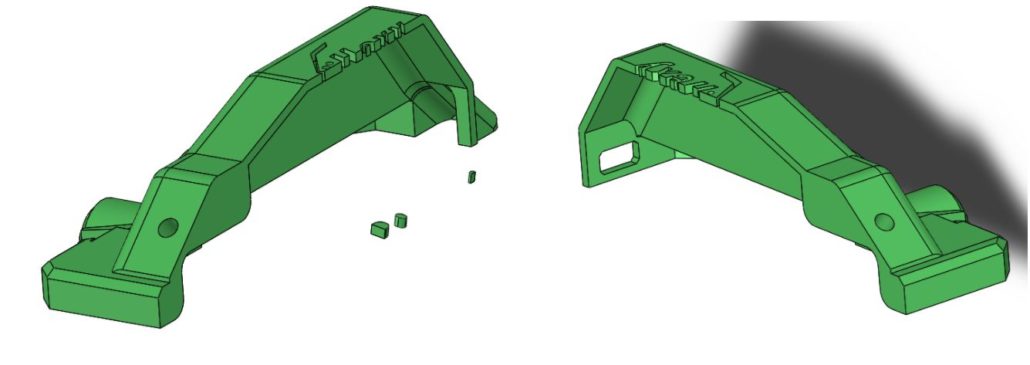

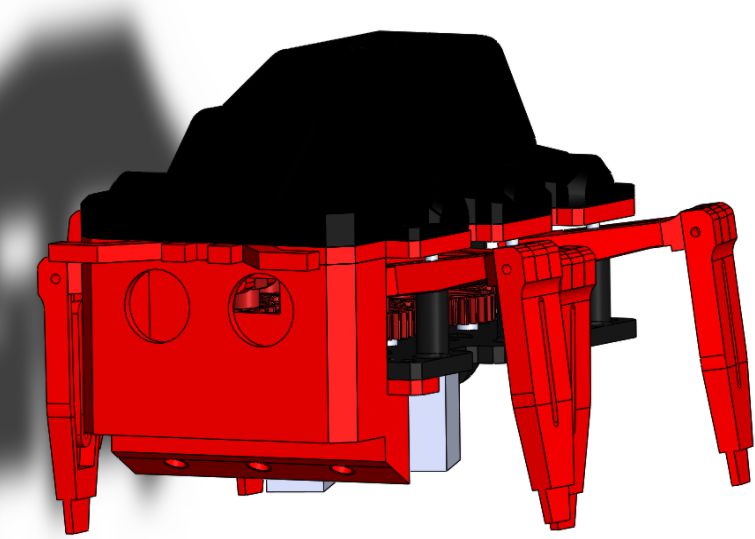

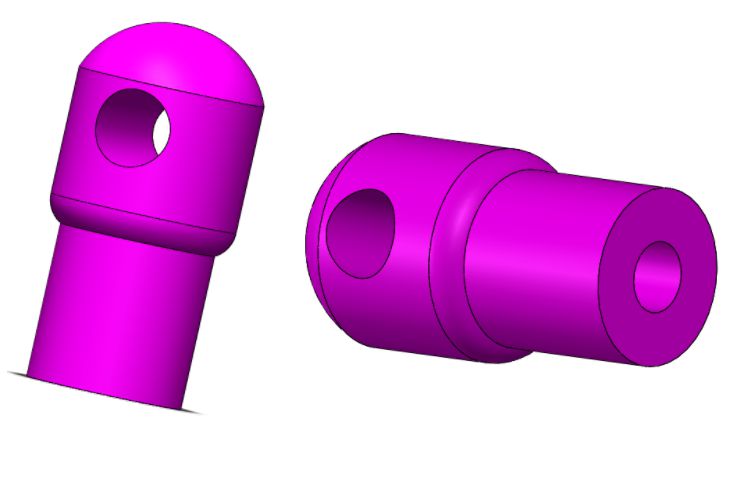

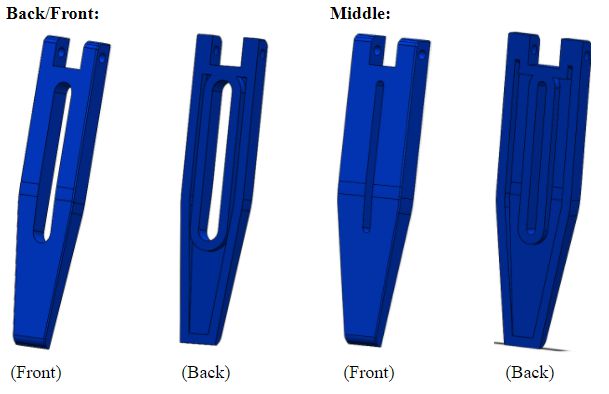

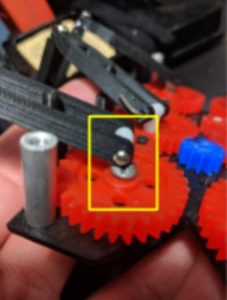

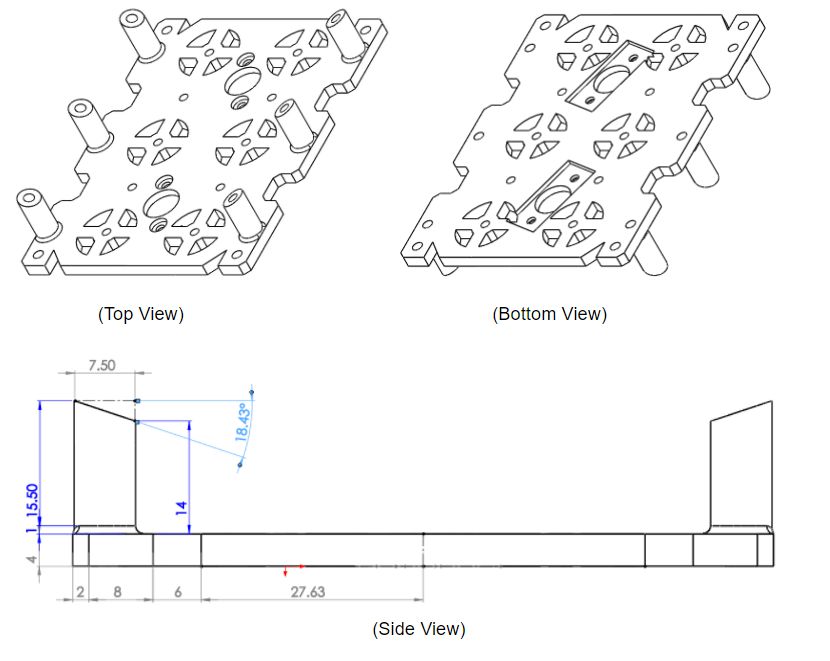

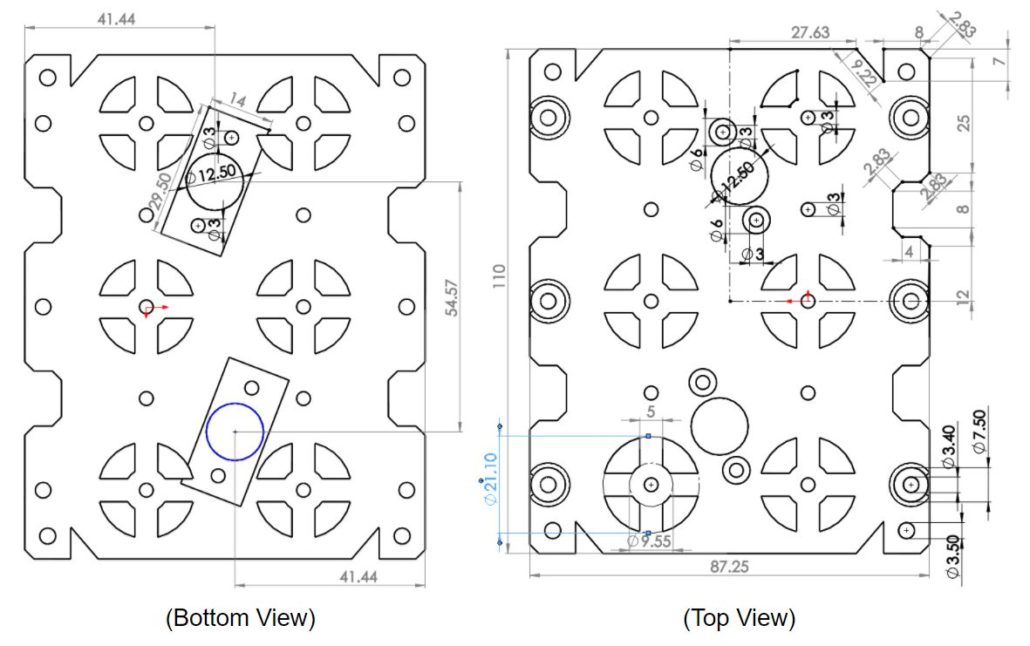

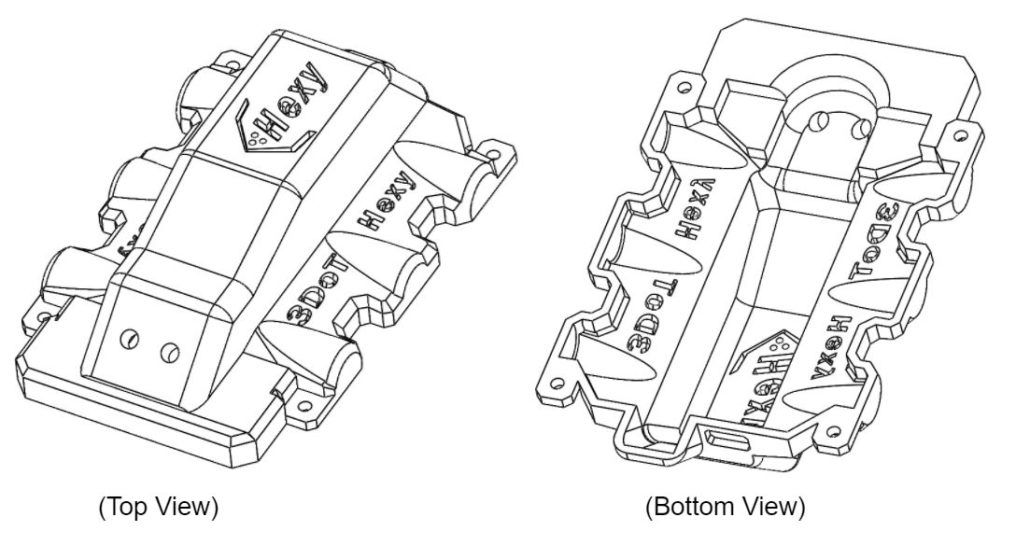

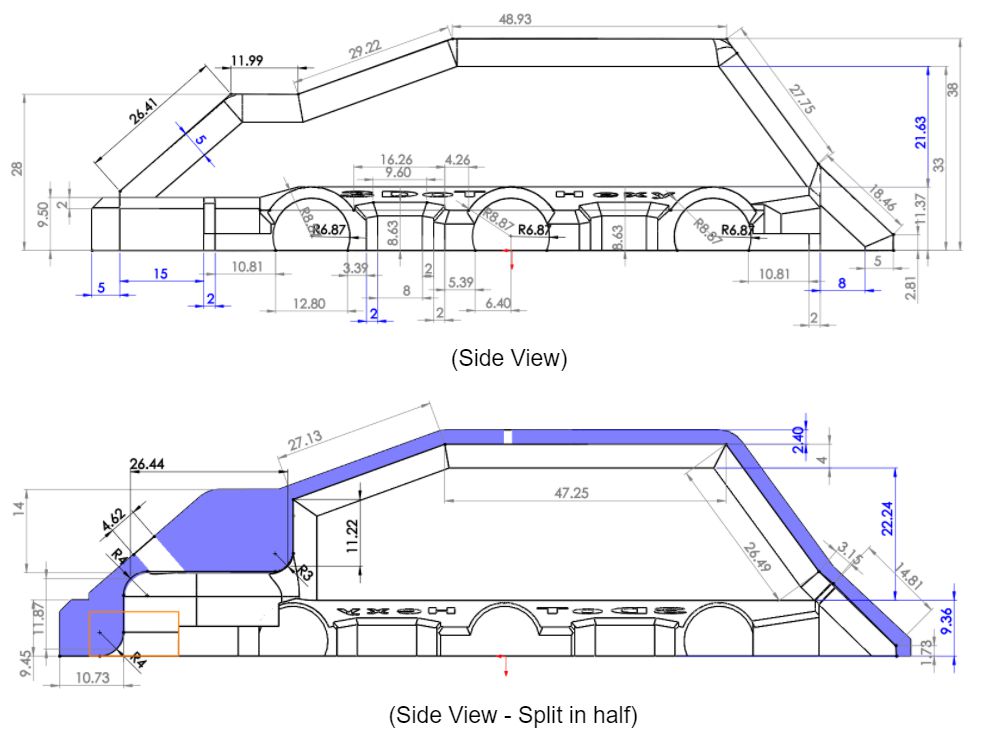

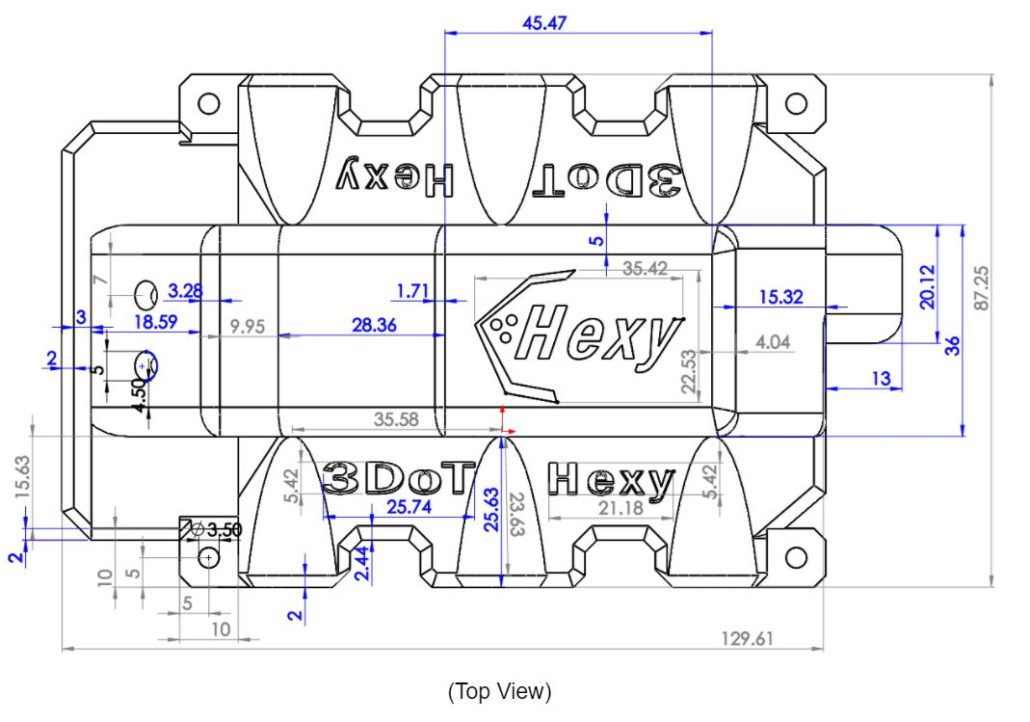

Research and obtain a reference model (Spring 2016:3DoT david design) from which to model your movement mechanism (not a task)

Week 7

Mechanical Drawing, Decision on movement mechanism to implement, Determining gear design

Week 8

Improving 3DoT David Design, Preliminary sketch, Preliminary Design Review Blog Post

Week 9

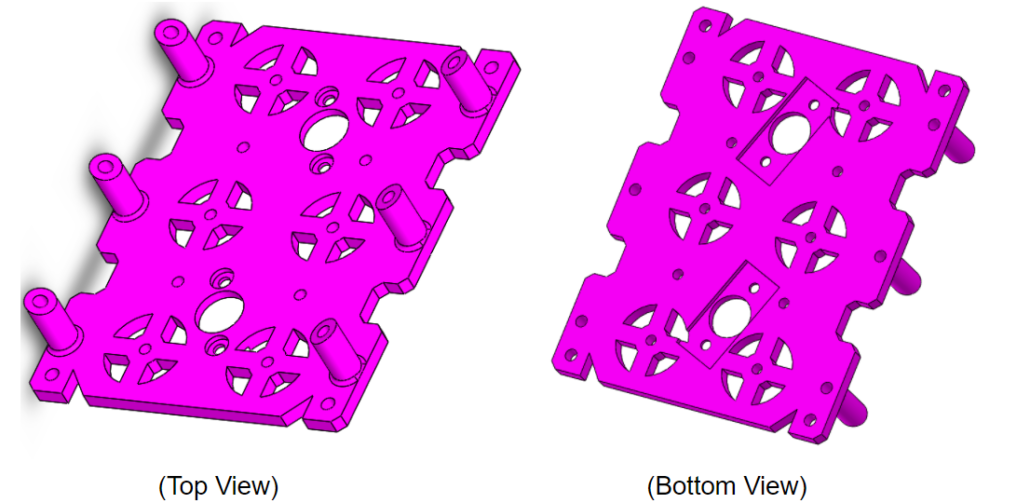

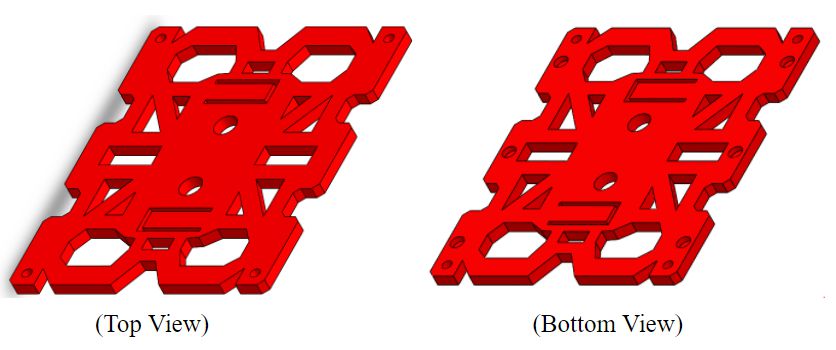

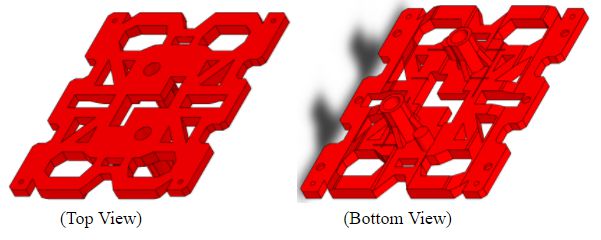

3D solidworks model

Week 10

stress testing

Week 11

Decision on materials and fabrication methods, Manufacturing Prototype.

Week 12 – 13

Revisions, fabrication and assembly of PCB.

Week 14

Final 3D Model.

Week 15 – 17

Aid in other task, last minute revisions on design (if any).

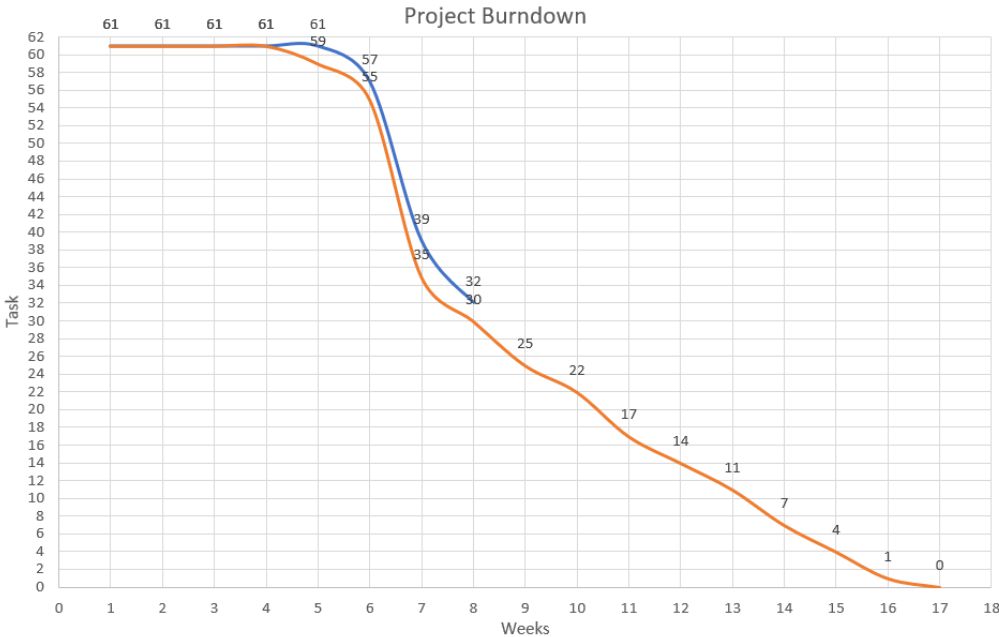

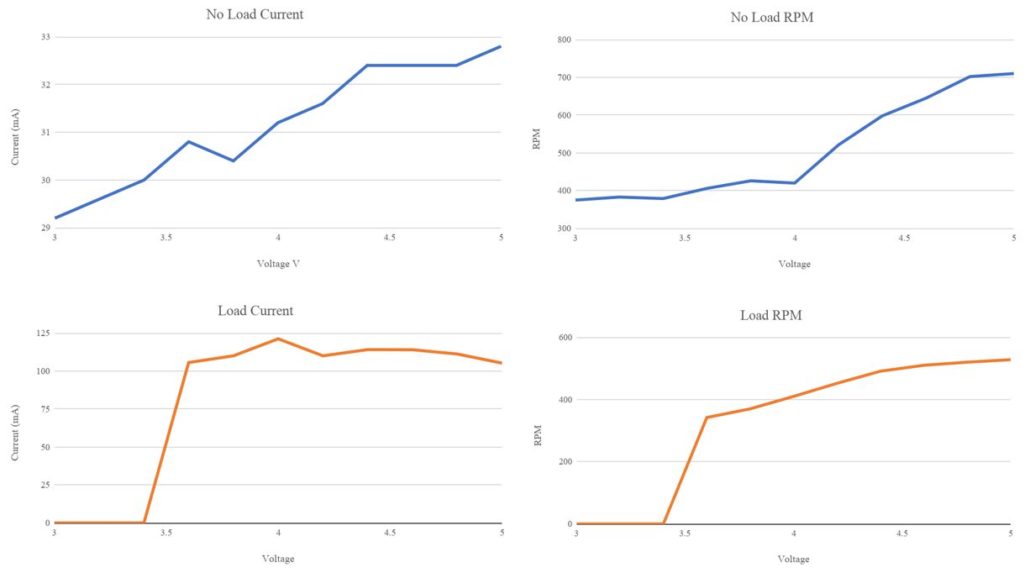

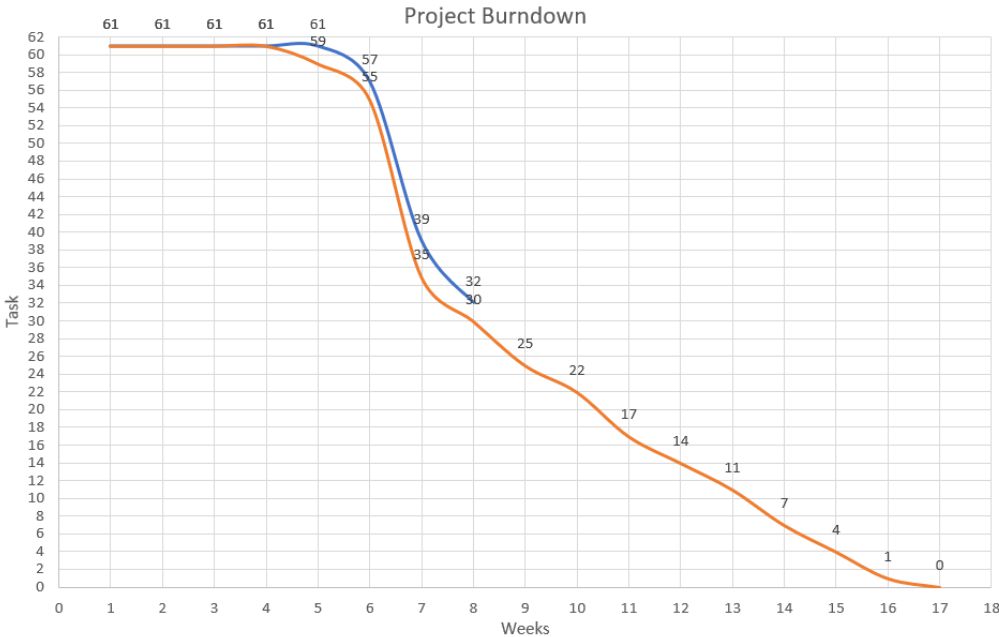

Preliminary Burndown (March 15, 2018)

The graph shows how task will be distributed over the course of the semester. The goal is to finish all task before execution of the mission.

Figure 2: Preliminary Burndown

Blue = Current Progress, Orange = Desired Progress

As off week 8, we have completed about half of the task defined in the task matrix. So far, we have submitted most if not all preliminary task documentations, and a few trade studies done by each division engineer showing their progress. For more details on what is due each week based on the above burndown read, “Spring 2018 3DoT Hexy: Project Planning and Scheduling”.

- https//drive.google.com/drive/folders/1XX5b3j3zwPvR-v6-B63a0Ad5g8Auu3_Y

- https://www.arxterra.com/wp-content/uploads/2018/04/Planner-Final2.0.xlsx