By Mevan Fernando and Robert Licari

Introduction by Mevan Fernando

Tethering is when a smartphone is turned into a mobile Wi-Fi hotspot and its 3G/4G data connection is shared. Once tethering is turned on in the smartphone, any device with a wireless connection can connect to the internet via the smartphone’s connection.

Procedure by Mevan Fernando

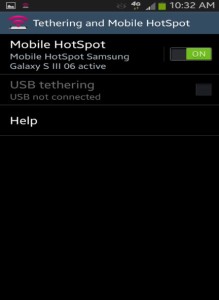

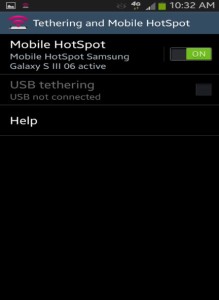

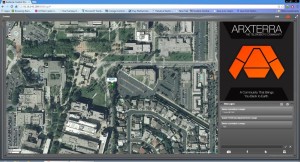

The steps taken to connect to the Wi-Fi hotspot and connection to the Arxterra Control Panel on the mobile data connection is shown below. The mobile phone used was a Samsung Galaxy S3 and the test was run at the site of the route where the robot will navigate. The following set up tutorial is performed with an android phone (Samsung Galaxy S3).

Step 1 – Click on the Mobile Hotspot app on the phone

Step 2 – Turn on Mobile Hotspot

Step 3 – Connect to the mobile data connection using any device with wireless connectivity (password required)

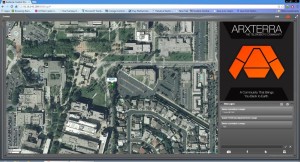

Step 4 – Log in to the Arxterra Control Panel

Step 5 – Start control your robot

Discussion by Robert Licari

Wireless provider

The wireless provider is a simple matter considering that most, if not all, of our employees carry a cellular phone and an almost equivalent number of employees carry smartphones. Taking this into consideration, we can simply utilize the sources provided by different service providers to view their coverage maps; however, they lay claim to all areas around long beach as a part of their “Nationwide Coverage” slogans dictate. To get a more accurate map, utilizing www.sensorly.com (a free coverage map source) we can see that Long Beach is not completely covered by any of the major providers. Sensorly, however, is a user-dependent tool and is thus, not 100% accurate either, but it does provide us with an idea of actual users, in the field, using data at varying speeds from 4G down to 2G (which are relevant for our purposes). Overall, this will not be an issue considering that the field is nearby one of the many sensorly tested areas, which we can safely assume and test for signal strength and viability.

Bandwidth and Range

Our major concern is Bandwidth and Range when we consider our service provider. This factor is almost completely dictated by the amount of customers utilizing bandwidth as well as the distance the client (in this case a laptop) is from the smartphone. This is reliant also upon the service coverage area that we are working in. To be clear the International Telecommunication Union has NOT set a defined standard for the rates of mobile data services. Upon further research, one can find multitudes of numbers with even more multitudes of tests done in controlled or uncontrolled environments. The reason for this is that it is highly dependent upon the above factors and is greatly influenced by movement of the hotspot. Generally speaking, it is widely accepted that we shall be receiving approximately 300 kb/sec. To be blunt, this number is not random, but in a world where some receive 25 Mb/sec and others that receive 25 kb/sec, it is difficult to accurately pinpoint an exact number for any particular time of day. On average, 300 kb/sec will be our acceptable bandwidth, which will begin to deteriorate as we begin to venture farther and farther from our client to a maximum distance of around 50 feet.

Cost

The final concern that we have will be cost, which is, quite possibly, the most varied of our concerns because this is strictly on a case-by-case basis. One person could have an unlimited data plan, while others could have a fixed data download plan that will limit them for the experiment. For this reason, should this be the final factor in deciding whether or not this is our solution, it is simply a matter of finding a volunteer with unlimited data to have their cellular phone be a mobile hotspot.