Level 1 Requirements – Final Iteration

By Kristine Abatay – Project Manager

and Matthew Clegg – Computer & Control Systems

The final statement of our mission objective created a new level 1 requirement regarding wireless control of Spiderbot through the Arxterra control panel and Arxterra Android app. The following is the final list of the level 1 requirements for Spiderbot, along with their corresponding verification tests:

1. Completion of the project will be achieved by May 12, 2014.

This is the date of the final assigned specifically for EE400D.

Test: If project Spiderbot is completed by this date, then this requirement will have been achieved.

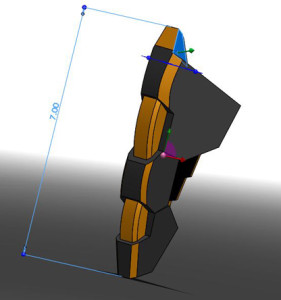

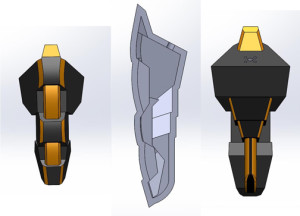

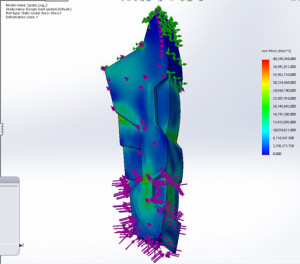

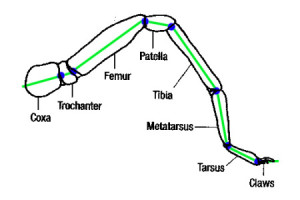

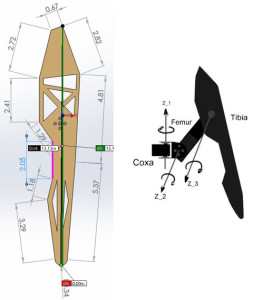

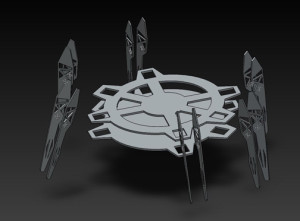

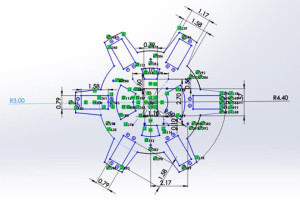

2. The legs and complete chassis components of Spiderbot will be designed to extend into three spatial dimensions.

Test: This requirement will be verified within the SolidWorks program, which enables our manufacturer to define the three axes of a design. If, at any rotated view of a component design, three separate pieces of the design can be chosen to define a respective x-, y-, and z- plane, then this requirement will have been fulfilled.

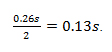

3. Match the speed of the track rover project on a flat surface. This value was determined to be 0.2003 m/s.

Test: In order to verify this requirement, a flat surface, straight-lined course will be measured out and Spiderbot will complete the course while being timed. The resulting quotient of the length of the course, with the amount of time it will take Spiderbot to complete the course, will be calculated. If this value is equal to or less than the calculated rover speed, then requirement will have been achieved.

4. Operate in accordance with the CSULB College of Engineering Health and Safety Policy

(found here: http://www.csulb.edu/colleges/coe/views/safety_and_environment/safety_policy.shtml)

Test: The CSULB College of Engineering Health and Safety Policy states that

“Faculty…shall: Implement the university’s Health and Safety Policy and all other university safety programs in work areas under their supervision/control.”

If Professor Hill, a faculty member of the CSULB College of Engineering, approves the operation of Spiderbot in the classroom, then this requirement will have been met.

5. Have a height clearance of 4 in. and width clearance of 2.5 in.

These values were obtained through measurements of the largest obstacles found in the assigned course. The following image is an aerial view of the course that Spiderbot will have to maneuver. The total length of this route was measured to be 41.80m. It is located in the eastern wing of the CSULB campus.

Test: Verification of this requirement will be done by measuring the height clearance, as well as the length of one leg sweep of the fully constructed Spiderbot.

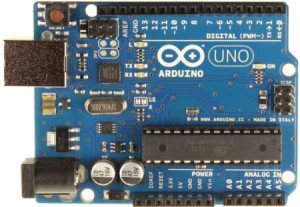

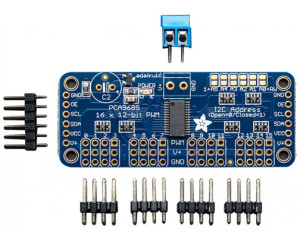

6. Spiderbot will be capable of being wirelessly controlled using the Arxterra Control panel, in conjunction with the Arxterra Android phone application.

Test: If a command sent to Spiderbot through the Arxterra Control panel matches the command that Spiderbot executes during operation from the Arxterra Android phone application, then this requirement will be satisfied.