Spring 2016 RoFi: Verification Test Plan

Christopher Andelin (Project Manager)

Mario Ramirez (Systems Engineer)

Qui Du (Manufacturing Engineer)

Andrew Laqui (Electronics and Controls Engineer)

Henry Ruff (Electronics and Controls Engineer)

Table of Contents

Verification Test Plan

Mario Ramirez (Systems Engineer)

Purpose

To verify requirements based on the verification matrix.

Requirements

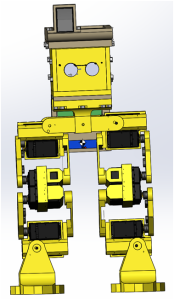

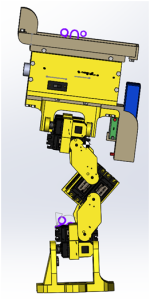

- RoFi shall remain balanced over an inclined surface of up to 8 degrees and a threshold of up to 45 degrees.

- The ultrasonics sensor shall detect an object within 3-400cm and begin an avoid obstacle subroutine.

- Nonslip material, on the bottom of RoFi’s feet, shall have a friction coefficient greater than 0.9.

- The Bluetooth module shall be a power class 2 Bluetooth module which gives a range of 10 feet between the module and the cell phone.

- Servos shall supply a minimum torque of 288kg*cm to move a mass of 862g.

- The periscope attached to the cell phone shall have a lens size of 1.8 * 1.8 * 2.2cm and give a 90 degree view from the cell phone camera.

Matrix

Figure 1A and Figure 1B is the verification matrix.

Tests

Incline

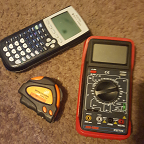

Figure 2 is a table of the tools needed for determining the angle of an inclined surface.

To conduct this test, I can either locate surfaces at varying angles or I can construct a ramp and put things underneath to adjust the angle from 0 to 30 degrees.

Steps:

- Measure angle of desired surface.

- Command RoFi to walk up the surface.

- Gather information from the Arduino IDE serial Monitor and compare to measured results.

Detection

Figure 3 is a table of the tools needed for testing the ultrasonic sensor.

The measuring tape will be used to verify that the results the serial monitor is displaying is accurate and that the sensor can detect objects within its given range.

Steps:

- Setup ultrasonic sensor circuit and code.

- Place the measuring tape alongside the ultrasonic sensor.

- Starting at about 400 cm away from the ultrasonic sensor, move an object at 5 cm increments.

- As object is moved, compare the serial monitor and the measured values.

Feet Material

Figure 4 is a table of the tools needed for calculating the friction coefficient of RoFi’s shoes.

Equation:

- Ff = force of friction

- μ = friction coefficient

- F f = μ *m *g *c o s( α)

Steps:

- Place material that is to be measured on an adjustable ramp.

- Place mass on the material to be measured and angle the ramp until it begins to slide down the ramp.

- Calculate the force needed to move this material down the slope.

- Verify that the force of RoFi’s step is less than the force needed to make the material slip.

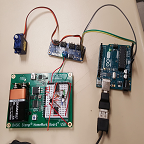

Bluetooth Module

Figure 5 is a table of the tools needed for testing the Bluetooth module.

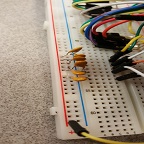

Setup the Bluetooth module with the Arduino and a simple LED for testing. Insure your code is uploaded to the Arduino and begin.

Steps:

- Lay out the measuring tape to read between 1 to 10 feet.

- Starting from 1 foot, turn the LED on and off to insure you are connected.

- Move away 0.5 feet and again turn the LED on and off to insure you are connected.

- Repeat step 3 until you reach 10 feet.

Servos

Figure 6 is a table of the tools needed for testing the servo torque.

https://www.arxterra.com/spring-2016-rofi-torque-report/

Weigh out a mass of 900g, we are using 900 grams because it is easier to obtain this value and if the servo can move 900g it can move 862g. Connect a resistor of 1 ohm or less in series to the ground of the servo. Connect the oscilloscope to measure the voltage over the resistor. Use V/R=I to obtain the current the servo is drawing.

Steps:

- Mount the servo on the edge of a table.

- Connect the mass to the servo with twine or rope.

- As the mass is moving, calculate your current drawn to insure that it is below your stalling current.

Periscope

To verify that the periscope provides a 90 degree view relative to the camera.

Steps:

- Attach periscope to the cellphone camera.

- Take photos and/or video.

- Connect to Arxterra control panel and verify vision.