Resource Report

By Tuan Vo, Project Manager

The weight of the aircraft must be of proportion to the amount of thrust the propulsion components can support. This resource reports defines resource as all components, power, and mass requirements related to the aircraft.

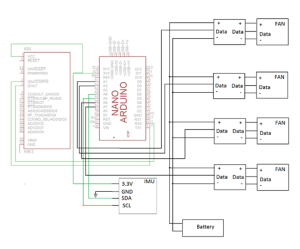

Study by Juan Montano on components and mass provides us with total mass when powered by 4 fans. Note the structure mass is estimated based on a previous model hexacopter using all the same components except the Tinyduino controller and number of fans. Also at the time of writing this document, the two batteries are being shipped.

| Part/#fans | Measured weight (total) |

| Fan (4) | 460g |

| ECS(4) | 120g |

| Battery* | 380g |

| Structure** | 298g |

| XBee | 7g |

| Arduino Nano | 8g |

| IMU | 2g |

| Components (excluding the body) | 977g |

| Total: | 1275g |

Power resource:

| Part | Voltage(V) | Current |

| Electric Fan | 14.8 | 16.5A @ 100% thrust |

| Arduino Nano | 5V | NA |

| XBee | 2.8-3.4V | NA |

| IMU | 3.3V | 10mA |

| LiPo 4s 14.8 | 14.8V | 1300mAh (2600mAh total) |

| 9V battery | 9V | 500mAh |

* The Arduino Nano, XBee, and IMU operates under 50mAh which is negligible considering the current draw of the fans is many thousand times larger.

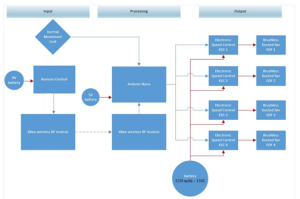

Task Description

- Receive parts from customer.

- Evaluate parts for functionality. Make lists of parts needed.

- Determine system requirements from mission objectives obtained from the customer.

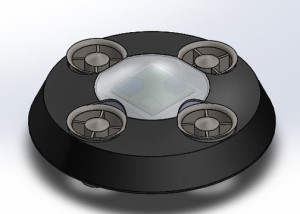

- Establish model of the aircraft using 3D modelling. Create major components needed such as fans, microcontroller, and power source.

- Write a Preliminary Design Document to give to customer to obtain funding.

- Purchase parts. Work with programming the microcontroller and wireless communication device, XBee, while waiting for parts to arrive.

- Build a remote control device to receive user input and transmit via XBee to the microcontroller.

- Build the body of the aircraft. Cut the foam for the middle section and mold carbon fiber for the top and bottom piece. Cut out as necessary.

- Do systems tests that can be done without mounting the fans onto the body.

- Mount fans onto the body and carry out the rest of the system tests.

- Final adjustments to programming and structure based on tests.

- Final presentation to the customer.