Servo Examination

By Kevin Huynh, Project Manager / Computer Systems and Software

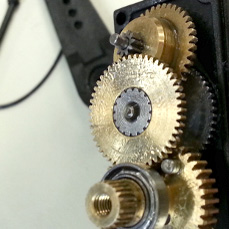

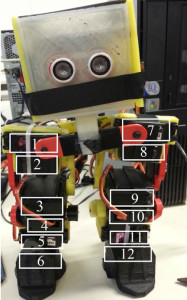

The purpose of this servo examination was to discern the reason for the servos malfunctioning. During the servo testing, it was discovered that three Power HD 1501MG servos were broken and the broken servos were closer to the feet of the robot, suggesting that the load was wearing out the servo by shear stress. We took apart the servos to figure out why the servos were actually breaking. Four servos were taken apart to examine the servo gears and shaft, three of the servos were the nonresponsive Power HD 1501MG servos mentioned in the servo functionality testing and one was a functional Power HD 1501MG servo as a base to compare the broken servos to. There seemed to be nothing physically wrong with the servos.

Next, we examined the circuit board on the other side of the servo. Two of the three broken servos had burned circuit boards, the third servo appeared to have no damage at all.

Servo Examination Conclusion:

Since there seemed to be nothing wrong with the gears or shafts of the servo, it is unlikely that the servos were directly damaged by carrying the weight of ROFI. Since the circuit boards were burned, it is likely that the servos drew too much current and overheated. This is likely the result of the servos stalling, but continuing to draw a large amount of current in an attempt to reach the position specified by the programming. The constant draw of current eventually overheated the servo and burned the circuit board. We will be looking into ways to prevent the servos from drawing too much current from the LiPo batteries even if the servos stall, starting with a foldback current limiter.