Project Overview

By Sabina Subedi, Project Manager

Project Objective

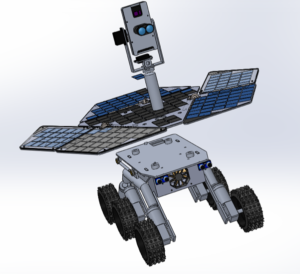

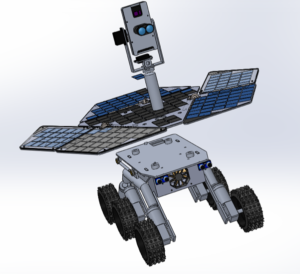

The Pathfinder is an autonomous rover that is self-sufficient using solar panels. The design of the Pathfinder is inspired by the twin Mars rovers “Spirit and Opportunity.” The Pathfinder will utilize navigation waypoints on Arxterra control panel to traverse through the defined course, articulating ultrasonic range finders and LiDar sensor for obstacle avoidance. Digital slip differential will be implemented for unmanned turning of the rover during it’s course. In order to save battery, the Pathfinder will integrate sensors that will send signals to the motors to stop the wheels from spinning under no load conditions.

Mission Profile

The Pathfinder must successfully navigate a 0.18 mile (roundtrip) course to and from the solar panel charging station defined by the solar panel subproject group. The mapped out course contains 2 staircases with 3 steps each, then concrete path leading to solar panels charging station. The Pathfinder shall travel up and down the steps. The Pathfinder shall avoid any obstacles along the way, using ultrasonic and LiDAR sensors. Pathfinder shall complete its mission in one evening. The pathfinder shall conduct its mission at night for better operation of the LiDar sensor.

The Design

Project Features:

- Rocker Bogie suspension system

- High clearance chassis

- Superior stability on uneven surfaces

- Obstacle climbing capability

- Pan and tilt system

- 2 servos for the rotation of the system, one for pan & one for tilt

- Provides live video feed utilizing a cellular phone camera

- Enclosed to protect the phone from external environment

- GPS Navigation Mode with obstacle avoidance

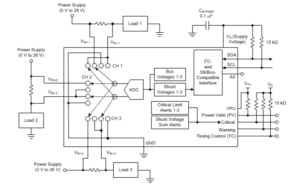

System Design:

By Jose Alcantar, Electronics and Controls Engineer

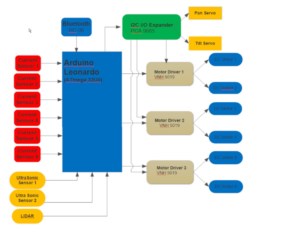

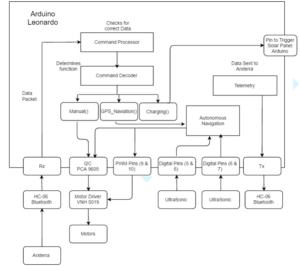

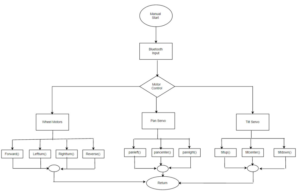

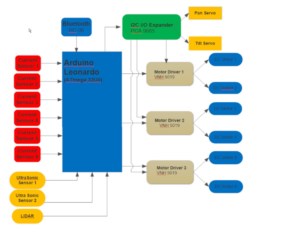

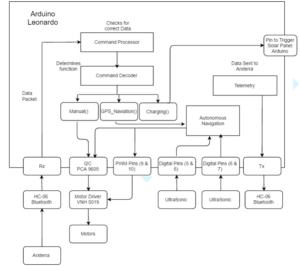

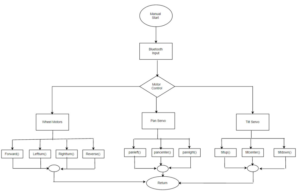

The system block diagram above generalizes how the sensors and actuators will interface through the Arduino Leonardo. First, the Bluetooth receives and transmits any data and the Arduino decodes the data and takes action. The Arduino will either receive sensor data or drive the motors, depending on the commands sent. The diagram also shows the I/O expander is used to control the motor drivers and servos.

Experimental Results:

By Jose Alcantar, Electronics and Controls Engineer

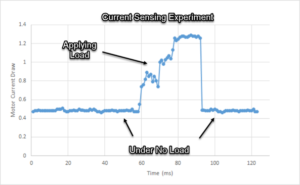

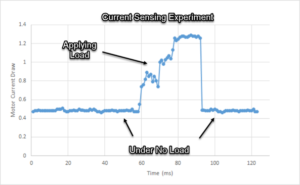

No load conditions threshold:

The plot above shows the current draw data from one motor driven by the VNH5019. The purpose of this experiment was to find a threshold for finding the current drawn at no load conditions. From the graph, the no load current draw is about 500 mA and when a load is applied the motor draws about 1.3A. The threshold is necessary to set the threshold and shut off the motors when the current draw falls below this threshold.

Field of View test for Ultrasonic Sensor:

Purpose:

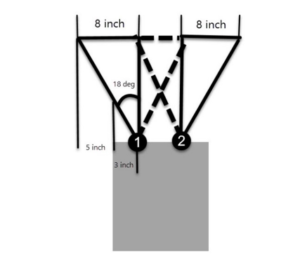

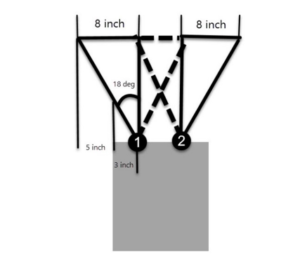

Testing the field of view on the HC-SR04 to find a suitable mounting position for the two ultrasonic sensors along the front of the rover.

Procedure:

An object was placed in front of the ultrasonic sensor about 25 inches away; the position of the object was marked and moved in increments of 5 inches until the object was out of view. When the object was no longer detected the position was marked. The angle of the field of view was then calculated.

Results:

Based on the experiment, the angle of the field of view was found to be 18 degrees when measuring an object 25 inches away. The position of the sensors was determined by considering the clearance needed on each side of the rover. When considering the solar panels, the two ultrasonic sensors need to detect obstacles at least 5 inches to each side of the chassis. This will allow the pathfinder to avoid obstacles that may bump into the solar panels.

Subsystem Design:

By Jose Alcantar, Electronics and Controls Engineer

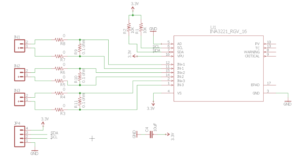

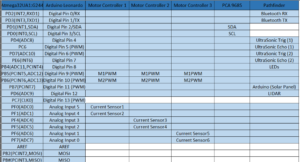

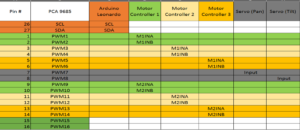

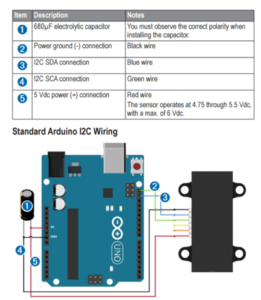

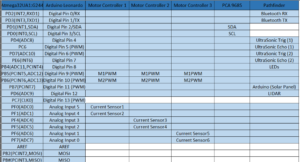

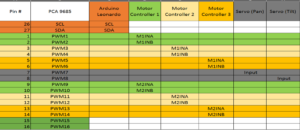

Interface Definition:

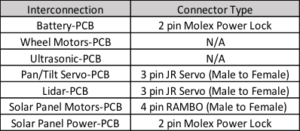

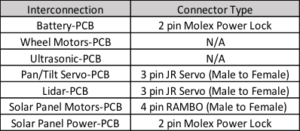

The above table shows the main pinout from the Arduino Leonardo. The main interfacing boards are the three VNH5019 motor drivers the PCA9685 I/O expander, the Bluetooth module, the LEDS, Ultrasonic sensors and the LIDAR.

The above table shows the interconnections of the PCA96805 I/O expander. The majority of the pins control the direction pins of the 6 H-Bridges and the pan and tilt servos.

Software Design:

By Jose Alcantar, Electronics and Controls Engineer

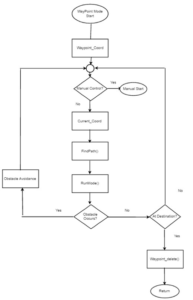

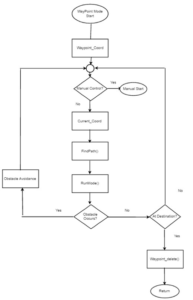

The above flowchart demonstrates how the Arduino receives the incoming data from the Arxterra App and acts based on the commands sent. When a command is sent the command, decoder determines which function to begin. Depending on the mode the Pathfinder will go into either Manual mode, GPS navigation mode or charging state. The called function will drive the motors and read sensor values to complete the requested action.

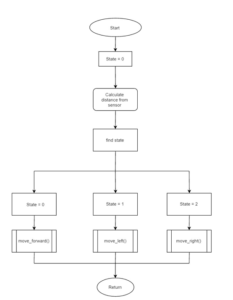

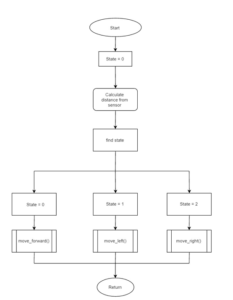

The flow chart demonstrates how the pathfinder will act when avoiding obstacles. The pathfinder will read sensor values and go into either state 1, 2 or 3 depending on the reading of the sensor values. The rover will then either avoid left, avoid right or move forward.

Waypoint Navigation Mode:

For waypoint navigation mode, the Arduino reads the waypoint coordinates and current coordinates of the pathfinder. Then the distance and heading to the next waypoint is calculated the rover then begins moving to its destination while actively avoiding obstacles and continously updating coordinate data. Once the waypoint is reached the waypoint data is deleted and manual mode is activated.

For more detail on the Waypoint navigatioin algotithm see:

http://arxterra.com/waypoint-navigation/

Manual Mode Flowchart:

The flowchart shows the basic algorithm to drive the motors when the direction pad is used to control the pathfinder and pan and tilt servos.

For a more detailed explanation of the MOVE functions see:

http://arxterra.com/implementing-move-command-firmware/

Cable Tree

By Nick Lukin, Design and Manufacturing

The cable tree shows approximately where the wires outside of the main PCB will be laid out on the Pathfinder. It includes connectors for items that can be taken on and off the chassis.

Hardware Design

By Nicholas Lukin, Design and Manufacturing Engineer

Introduction

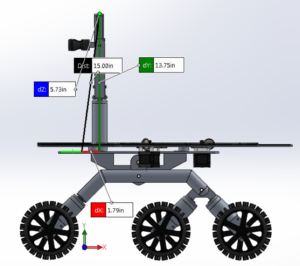

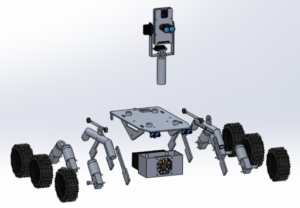

The overall mechanical design consisted of various key features that ensured the customers design requirements were met. The first feature is the pan and tilt phone system. The customer required that the Pathfinder come equipped with an electronically controlled pan and tilt phone holding mechanism. The next feature is the rocker bogie suspension system. This suspension system helped fulfill the requirement of going over rough desert terrain and makes it possible to climb up and down obstacles such as stairs and rocks. The next feature is that the Pathfinder is made out of material that can withstand desert conditions as per the requirement stated by the customer. The final feature is the seamless interfacing areas on the chassis that makes it possible to properly interface with the solar panels that will be attached to the top of the chassis.

Form Factor

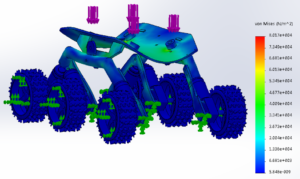

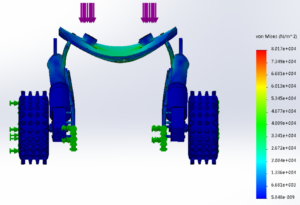

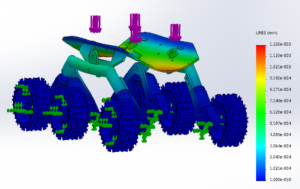

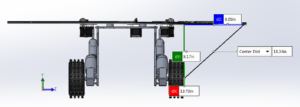

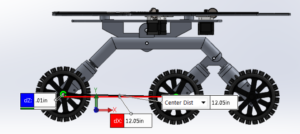

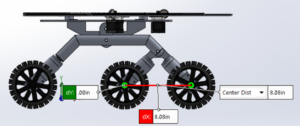

Rocker Bogie Suspension System

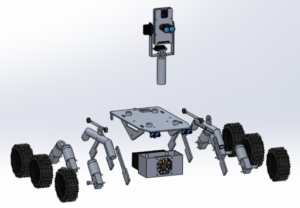

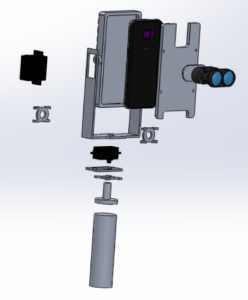

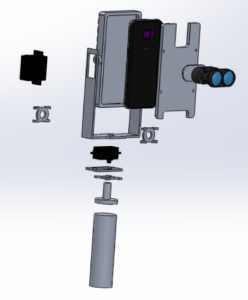

Figure 1: Exploded View

Figure 1 shows the exploded view of the entire chassis including the rocker bogie suspension system. The system itself allows the pathfinder to go over uneven surfaces while maintaining stability and traction. There are two pivot points located in the suspension system. The middle pivot point is attached directly to the top plate of the chassis and allows the plate to stay level while traversing up and down obstacles such as stairs. The back pivot point allows for a further range of motion when going over various obstacles. Having two independent suspension sides allows the Pathfinder to go over a variety of terrain. Each side reacts independently to obstacles which allows the center of mass to stay relativity stable and low.

Tube Leg Design and Material

Figure 2: Tube Leg Design

In order to make the Pathfinder look as close as possible to the Spirit/Opportunity rovers it was decided to make the legs of the rocker bogie suspension system out of tubing instead of plate like the previous Pathfinder designs. Not only did this make the Pathfinder look more realistic but it also added more strength to the overall design. It was decided that the material used for the design would be 6061-T6 aluminum because of its high corrosion resistance and overall strength. Figure 2 shows the overall mass properties of the Pathfinder.

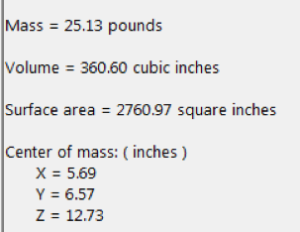

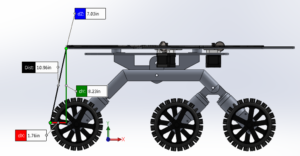

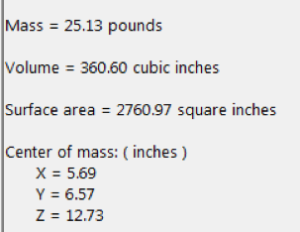

Figure 3: Mass Properties

The overall weight of the Pathfinder is about 25 pounds as shown in figure 2. This weight it light enough to ensure that the motors do not get overworked. If non aerospace grade aluminum was used such as plain 6061 the weight would be around 32 pounds which is a 20% increase.

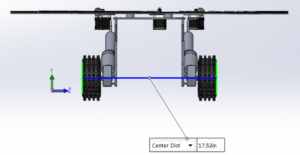

Fabrication of Overall Chassis

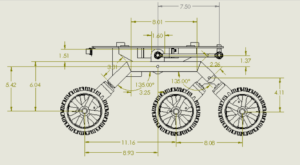

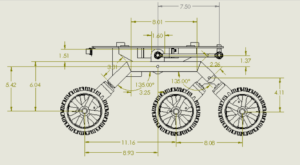

Figure 3: 2-D Drawing for Fabrication

The first step in the fabrication process was to obtain the proper 2-D drawing in order to figure out what material needed to be machined and what needed to be welded. It was decided that the back legs, the top plate and the top side plate would all need to be cut and machined. Figure 4 below shows the machining process.

Figure 4: Machining Legs and Top Plate

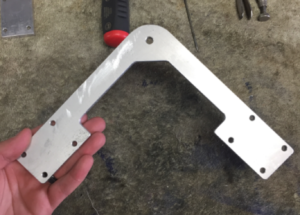

Figure 5: Fabricating Legs

Proper measuring tools had to be used in order to make sure the legs were the correct size and that the overall chassis would be straight when it was planted on all six wheels. Tubing needed to be cut at the proper angles (135 degrees) and welded. Special attention needed to be given while welding to ensure the metal did not warp and create an unwanted dimension.

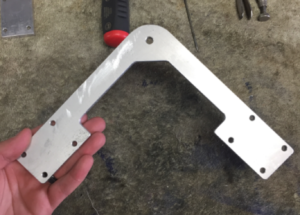

Figure 6: Final Leg Fabrication

Figure 6 shows the final leg fabrication. Each leg was nearly identical to one another. This helped achieve the goal of keeping symmetry throughout the entire design and made sure the Pathfinder would achieve the proper form factor as required by the customer.

Figure 7: Light/Sensor Bar

It was a requirement that the Pathfinder was equipped with some type of lighting and ultrasonic sensors. In order to properly attach the lights and sensors to the chassis it was necessary to custom fabricate some type of holding mechanism. A light/sensor bar was machined in order to properly attach the critical lights and sensors. Figure 7 shows the final product.

Figure 8: Final Chassis Design

Figure 8 shows the final chassis completed with the pan and tilt phone system, wheels and electrical all attached. The final design looks nearly identical to the solid works model. Careful preparation and precise fabrication achieved a design that is accurate and that meets the customers’ expectations.

Pan and Tilt Phone System

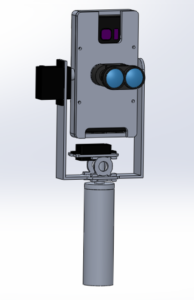

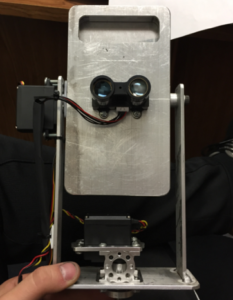

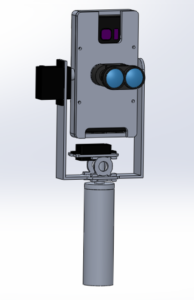

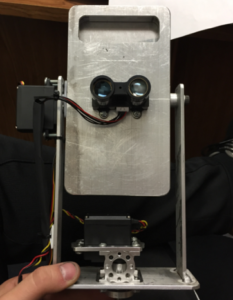

Figure 9: Pan and Tilt Phone Holder

In order for the Pathfinder to see where it is going and to properly connect to the Arxterra control panel the customer required that a Pan and Tilt phone system be built. The system would need to house a Samsung Galaxy S7 edge and be able to withstand a desert environment. The design of the system can be seen in figure 9. The system is controlled through the Arxterra control panel via two servos. We decided to make the phone holder out of 6061-T6 material just like the chassis. This would ensure that the phone would be properly protected and that it was light enough so the servos could move it.

Figure 10: Pan and Tilt Exploded

It was also necessary to attach a lidar sensor to the front of the phone case. Lidar was needed in order to properly implement an autonomous driving mode system. The front plate of the phone holder was designed to leave room for the cameras of the phone, to house the lidar sensor and to properly expose the communication antennas of the phone. All these features can be seen in figure 10.

Figure 11: Fabricating Phone Holder

Figure 11 shows the fabrication of the camera view holes of the front case of the phone holder. It was necessary to properly measure the distance between the top of the phone to the end of the camera to make sure that there was no interference between the metal and the camera.

Figure 12: Final Product

Figure 12 shows the final build of the pan and tilt phone holder mechanism. It was necessary to utilize an off the shelf gimbal system to mechanically drive the pan motion of the holder. This part was connected to the pan servo and ensured smooth lateral operation of the entire system.

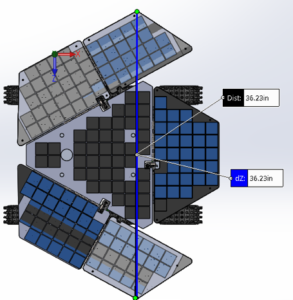

Interfacing the Solar Panels

Figure 13: Solar Panels Interfacing

It was necessary that the chassis and solar panels seamlessly interface as per the requirement of the customer. Proper interfacing was achieved by creating mounting stand offs on the top plate of the chassis of the Pathfinder. The solar panels would then have holes that would properly align with the mounting pads and a small thumb screw would be used in order to properly secure the connection. These stand offs can be seen on the top plate of the chassis in Figure 13. The pan and tilt phone holder would also need to come off by hand in order to properly interface. This was achieved by machining a threaded stud to the top of the phone holder stand. The customer could then easily screw the phone holder on and off by hand.

Figure 14: Actual Interfacing

Figure 14 shows the actual interfacing of the solar panels and the chassis assembly. The 4 thumb screws that were utilized can be seen in figure 14. It was also noticeable that the proper form factor was achieved between the solar panels and the chassis.

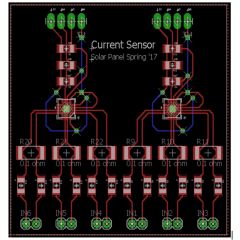

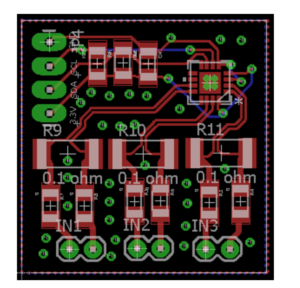

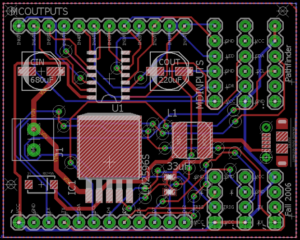

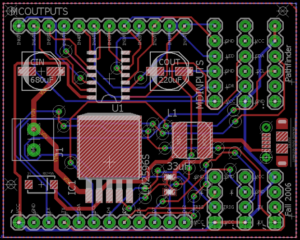

PCB Layout

Figure 15: Final PCB Design

A custom PCB design was required in order to interface all of the boards that were utilized to control the Pathfinder. The overall function of the board was to take various pins from the Arduino and rout those pins to other boards that could directly connect to the custom PCB. Two ultrasonic sensors, a Bluetooth module, a servo driver board, a LED interface, a LIDAR connection and 3 motor driver boards would all be able to directly connect to the board. The board would also implement a buck converter in order to step down the main battery supply voltage from 12V down to 6V to properly charge the phone in the phone holder system.

Interface Design

In order to properly route all the wires from the Arduino pins to the proper locations it was necessary to lay the board out in an efficient manner. All the pins that required headers were laid out as close to the edge of the board as possible. They were also spaced apart so that room was left for whatever connectors would be used. 45 degree bends were utilized on all traces in order to maintain a clean and professional looking PCB. A ground plane was utilized for all ground connections and a power bus was used in order to properly connect VCC across all pin connections. A power plane could not be used since the buck converter would also be on the same board and would be utilizing a different voltage level at its input.

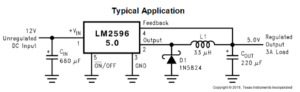

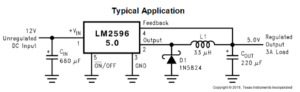

Buck Converter

Figure 16: Typical Buck Design

The LM2596 chip was selected for the buck converter. This chip allows a maximum of 3 amps to be passed through it and has an input voltage range of up to 40 volts and can step down voltages as low as 3.3 volts. For the phone charger we designed the buck converter to output 6 volts to properly charge the Samsung Galaxy S7 edge. All surface mount components were utilized for the design and attention to detail was key during the lay out process. Per the data sheet it was necessary to place the inductor and capacitors as close to the chip as possible. It was also necessary to use the correct size power traces to prevent overheating and possible damage to the board. The buck converter was designed to output a max of 1 amps and therefore a maximum power trace of .032 inches was used. This thick trace can be seen on figure 15 at the input of the buck converter. A micro usb was used on the output of the buck so the phone could easily plug into the charger.

Soldering Process

Figure 17: Soldering the Board

The custom PCB was soldered by hand and then was tested for proper functionality. It was noticed that there was a direct short between ground and Vcc. Initially it was thought that the soldering process caused the short but upon further inspection it was determined that the board came shorted from the factory. Two other boards that were not yet soldered were tested and they both had direct shorts between Vcc and ground.

Verification and Validation Test

https://drive.google.com/open?id=0Bzq09K9mZabrd0E4a01mUElLdlE

Work Breakdown Structure (WBS)

Resource Reports

Please refer to the Project Resources section to find the resource reports, including Mass, Cost and Power Report.

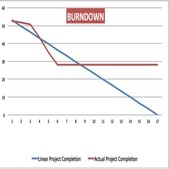

Top Level Schedule

The general top level schedule was created using the generic rubric provided on the class website. The top level schedule specific to the Pathfinder (Chassis subproject) was created using the Work Breakdown Structure above and the general top level schedule. This schedule consists of all tasks that are to be completed before the end of the semester, December 15th, 2016. The project milestones are broken down into four phases: Planning, Design, Assembly and Project Launch. The tasks within the different phases are then divided up by the divisions. All division members are assigned specific tasks that they are responsible for, per “Job Descriptions” document available on the class website. Main tasks then were broken down into sub-tasks, if applicable. All tasks include start and finish dates, as well as percent complete.

Conclusion and Future Plans

Overall the project was a success as we were able to build a functioning rover that achieved the majority of the requirements that were established by the customer. The mechanical design worked as expected with only some small issues. One improvement that is necessary is adding stops to the back pivot point of the rocker bogie suspension system. The range of motion needs to be limited at some point in order to properly go up obstacles such as stairs. Another improvement would be to possibly get bigger wheels. The larger the wheels the better it can go up and over obstacles. I believe that the current design is sufficient for future students to build off of and improve upon.

Project Resources