Fall 2016 Solar Panels: Project Summary

/in Pathfinder Solar Panel/by Inna EchualBy Inna Echual (Project Manager)

Table of Contents

Project Overview

Executive Summary

Project Objective

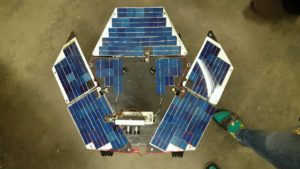

The design of the Fall 2016 Pathfinder project was taken directly from NASA’s Mars Exploration Rovers, Opportunity and Spirit. The Pathfinder will be designed to be self-sufficient using solar panels, as well as implement the solar deployment mechanism employed by the two aforementioned rovers. The solar panels should able recharge the Pathfinder’s battery allowing it to traverse rough terrain. The solar panels must also articulate to track the sun, maximizing the amount of solar power received.

Mission Profile

The project will be demonstrated by parking the Pathfinder in the Central Quad on California State University, Long Beach located at 33°46’40.7″N 118°06’48.9″W. In addition to the location near the defined travel course, the parking spot was chosen as it had low traffic and free of shading. The parking spot is indicated in Figure 1.

Figure 1: Pathfinder Charging Spot

Figure 2: Pathfinder Charging Spot (Magnified)

Project Features

-

Customized Solar Panels

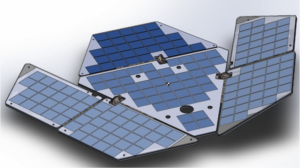

This will be done using 5 strings in parallel of 30 solar cells stringed together in series to fit the customized solar shape of the aforementioned rovers (see compare our layout in Figure 3 with Spirit’s layout in Figure 4).

Figure 3: Fall 2016 Solar Panels

Figure 4: Spirit Rover Panels

-

Panel Proportionality

The solar panels will be configured to be identical to the form factor of the solar panels on the Opportunity and Spirit rovers (see Figure 5).

Figure 5: Form Factor Consideration

Experiments Checklist

- Experiments on Solar Cell Cutting and Efficiency to determine stringing

- Back of the Envelope calculations to determine stringing and layout

- Experiment using MPU 6050 to determine rover balance

- Experiment using DC motor as a stepper motor with an encoder

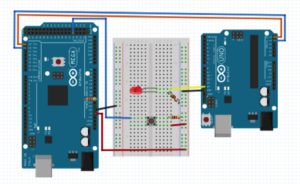

- I2C – test communication between Arduino Uno and Arduino Mega

- Sun tracking with photo resistors

System Design

System Block Diagram

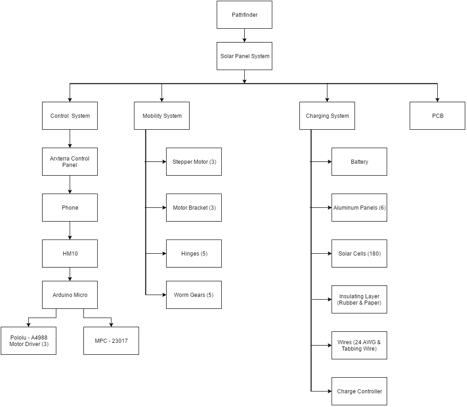

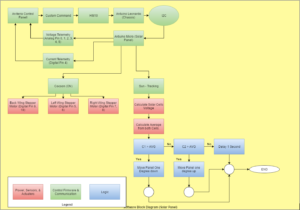

Figure 6: Updated System Block Diagram from CDR

Updated System Block Diagram from CDR brief.

Subsystem Design

Interface Definition

Interface Matrix

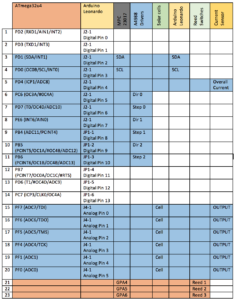

Figure 7: Interface Matrix

Interface Control Document

As defined in the mission profile, the Pathfinder will be allowed to travel a course on the upper campus of CSULB. This system is designed to replicate the Spirit & Opportunity Mars Rovers. The program objective is to be self-sufficient. In order for this system to be successful with it’s mission, the two systems; Chassis & Solar Panel, must work together with one another. The Solar Panel will be in charge of supplying power to the battery, and the Chassis will then be able to use this battery and travel the course.

The Interface Control Document will be used to provide an outline for the responsibilities aligned with each system. It also sets out the interfacing requirements to help move the design forward for each of our systems in the following disciplines: Mechanical Interfacing, Power Transactions, and Control Mechanism & Data Transfer. It also includes some constraints, assumptions, and possible risks involved in these factors.

Interface Control Document

Mission Command and Control

Software Block Diagram

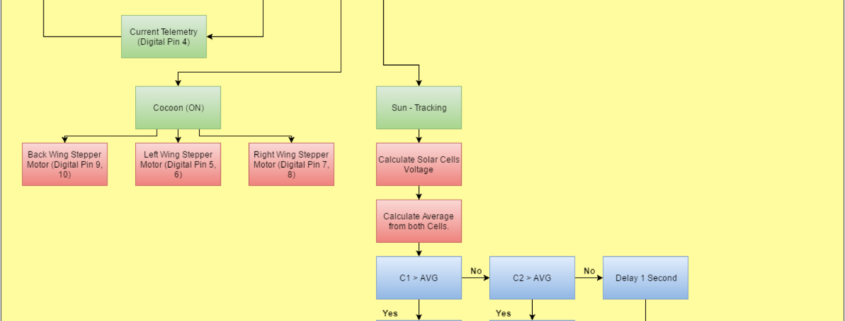

Figure 7: Software Block Diagram

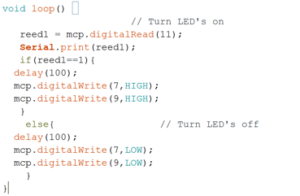

The software block diagram in Figure 7 explains an overall understanding of what the Solar Panel system’s software entails. It also includes a portion of the Chassis system and how we are interfacing with one another electronically, along with a legend on the bottom left to help detect what the different colors mean.

Electronics Design

DC Motor With Encoder Experiment

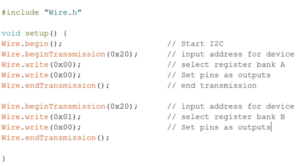

Creating a Port Expander Using IC MCP23017

Firmware

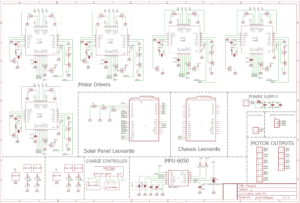

PCB Schematic

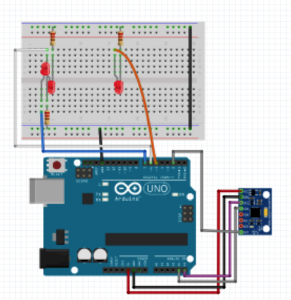

Figure 8: Fritzing Diagram for Motor Driver

Figure 9: Fritzing Diagram for I2C Communication

Figure 10: Breadboard for Motor Driver

Figure 11: Schematic

PCB Layout

Hardware Design

Folding Mechanism Trade-Off Study

Choosing Panel Thickness / Stress Tests

Verification and Validation Test Plan

Project Status

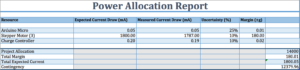

Power Allocation

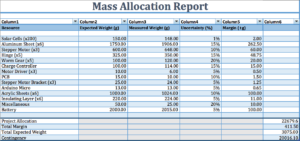

Mass Allocation

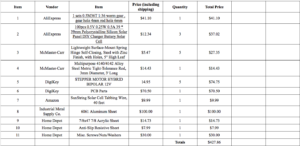

Cost Report

Concluding Thoughts

Lessons Learned

- Being the project manager helped me learn a lot about group and project management. Because this project is an integrated project with the Thursday class, it was very difficult to coordinate meeting times together or even contact the other group, therefore our project would fall back at times.

- It is hard to manage the conflicts among cost, schedule and performance. Our pathfinder team was having trouble on getting all the parts we wanted on time. Because we were short on time, there were sacrifices we had to make in terms of which parts of the project we wanted to get working depending on how many requirements it could fulfill.

- I learned too late that I should be stricter on tasks I wanted to get done to keep the project on schedule.

Resources

[1] Project Video [2] Critical Design Review (CDR) [3] Preliminary Design Review (PDR) [4] Project Schedule [5] Verification and Validation Documents [6] SolidWorks Files (zipped) [7] Fritzing Files (zipped) [8] EagleCAD Files (zipped) [9] Ardino / C++ Code [10] Bill of Materials [11] Final Interface Control Document (dated 12/13/16)References

[1] Spirit Rover Cleaned: https://commons.wikimedia.org/wiki/File:Spirit_Rover_Cleaned.jpgFall 2016 Solar Panels: Mechanical Design *

/in Pathfinder Solar Panel/by Inna EchualBy Ridwan Maassarani (Design and Manufacturing)

Approved by Inna Echual (Project Manager)

As a requirement, solar panels had to be manufactured that is of the same form factor as the spirit and opportunity mars rovers that were designed by NASA. To accomplish this, my team and I visited JPL and was able to find model at their museum. In addition, a small scale model was purchased from the gift shop for taking measurements later on if needed.

Figure 1: Small-Scale Model from JPL

Figure 2: High-Quality Rendering Photo (top view)

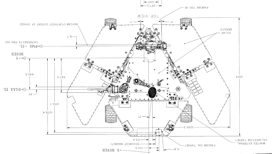

Figure 3: Spirit Rover Dimensionas

I was also able to obtain a schematic picture by contacting the same individual who made the high quality rendering pictures. Here’s is the website for more information: http://v5.nicksotiriadis.gr/mars-rover-project/

From all this information, I took measurements and a ratio of 10 was used based on the requirement that the panels needed to fit a 19-inch-wide cabinet and to the panels were scaled accordingly in SolidWorks using the scale feature.

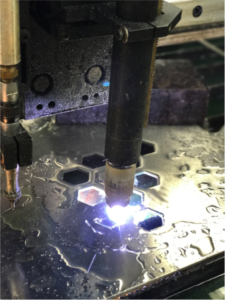

After the dimensions of the panels was established, a folding mechanism had to be devised to fulfill the cocooning state requirement. From my earlier blog post, I go over the various type of gears and types of mechanism that could perform a folding motion but utilizing worm gears for their high torque and self-locking feature was the best choice. First, torque needed to be transferred to the panels from the gears. The best option was to schedule an appointment with the mechanical design center and weld the rod to one leaf of the hinge. I tried to do this many times but failed since Electrical Engineering students do not normally get help from the mechanical center so there was no fluid was to get help. This forced the use of an epoxy called JB weld, used as a welding alternative for metals which by the end of the semester failed. In future 400D project, I hope the mechanical center will become a place where students can get their designs manufactured with ease. I have stablished some kind of relationship with Joe, the person who runs all the equipment such as welding, drilling, and plasma cutting. Here’s are my panels cut using their plasma cutter:

After making a connection from rod to panel, the gear needed to be attached firmly to the rod so that when the worm rod spins, torque is delivered to the gear, rod, and finally the panel. Ideally, metal gears need to have a press fit such as stepper motors in a printer. Press fitting gears is a science and there was no time nor the budget to get custom sized gears. So, a hollow rod was purchased from home depot and fitted in the gears bore to get a better fit from gear to rod as well as from worm rod to stepper shaft. The gears came with a set screw; this was used to secure the gears further. Since this is not the best method of connecting these gears, epoxy was used again for safe measure. For the next semester, I would recommend researching how to securely connect the gear to the shaft, rod to hinge, and worm rod to stepper shaft. Another improvement would be to make a gear box for these gears, this will serve as an encasement as well as a place to fill grease so that they are always lubed. Having lubed gears will prevent any friction between the teeth, it is crucial for metal gears.

In conclusion, another improvement would be to limit the amount of freedom the hinge has when unfolded. This can be done by welding some metal between the main panel and the right panel, this will help when the rover is being operated at the same time the panels are installed. It will remove the additional torque generated when the rover is being operated.

Fall 2016 Solar Panels: PCB Layout *

/in Pathfinder Solar Panel/by Inna EchualBy Ridwan Maassarani (Design and Manufacturing)

Approved by Inna Echual (Project Manager)

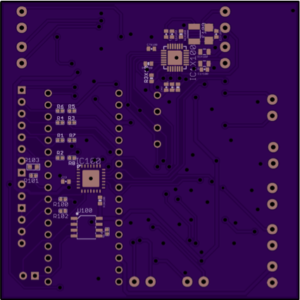

A custom PCB that can drive five stepper motors was needed to reduce the footprint on the rover. The custom PCB would also cut down on cost since stepper motor drivers that can run 3 or more motors can gen expensive. It was also difficult to find a motor driver than can run five motors. So, a custom PCB was made based on the A4988 stepper motor drivers capable of driving two coils.

Fall 2016 Solar Panels: Requirements Update

/in Pathfinder Solar Panel/by Inna EchualBy Stephan Khamis (Missions, Systems, and Test)

Approved by Inna Echual (Project Manager)

Introduction

This blog post contains our most up-to-date requirements for the Solar Panel system of the Pathfinder project. Within this blog post you will learn about the changes we have made since the CDR to update this document.

Updated Requirements

Solar Panel Requirements

- The Pathfinder shall be self-sufficient using solar panels.

- According to accuweather the sun rises at 6:50 AM and sets at 4:46 PM on December 15, 2016. The Pathfinder will start to explore at 2:45 PM.

- Starting at 80% battery life, the Solar Panels shall be able to charge the battery system to 95% in under 8 hours.

- The solar panel shall be wired to produce at least 12 Volts and 300 mA to charge our battery system.

- The battery will have a charge controller to prevent the battery from exceeding 12 Volts of charge, which is the maximum capacity of the battery system.

- The solar panels shall be able to enter and exit a cocoon state.

- The motorized folding mechanism shall be done using a stepper motor, a motor bracket, a worm gear, and a piano hinge for each of the 3 folds.

- The Solar Panels will have a fixed north/south orientation for the panels to track the east to west movement of the sun.

- Two main side panels consisting of two smaller panels shall articulate with the sun using stepper motors specified to handle 1188 oz/inch.

- The solar cells should be used to measure and compare the voltage at an angle using a voltage divider.

- The Solar Panels will be able to withstand 50 lbs, under the force of gravity.

- Two main side panels consisting of two smaller panels shall articulate with the sun using stepper motors specified to handle 1188 oz/inch.

- The form factor of the Solar Panels shall be identical to that of the Spirit and Opportunity

- Six panels shall be cut proportional to the six panels on the Spirit and Opportunity

- The solar panels shall use 39 mm x 39 mm polycrystalline solar cells to accommodate the customized shape of the Spirit and Opportunity

- The Pathfinder will be able to fit into the east most cabinet in ECS – 317.

- The Pathfinder shall have dimensions no greater than 19” x 34” x 26” in its closed cocoon state.

- The Solar Panel component of the Pathfinder shall be able to be added and removed from the Chassis within 20 minutes (wiring and mechanical), without the use of power tools for future separate usage of the Chassis and Solar Panel system.

- The Pathfinder shall have requirements agreed between both the Solar Panel and Chassis group within the Interface Control Document (ICD).

- The Solar Panel group will provide 5.76 inches from the front top plate towards the center to accommodate the placement of the Chassis’ Pan & Tilt Mechanism.

- The Solar Panel group will provide an availability of 10 inches between side panel motors required by the Chassis group.

- The base of the Solar Panel will have four equally spaced 0.5” holes to establish a concentric interfacing point with the Chassis

- The Solar Panel group will be allowed a power allocation of 2 Amps at 12 Volts, while the Chassis group will be allowed a power allocation of 11.4 Amps at 12 Volts.

- The Solar Panels will not exceed 50 lbs as required by the Chassis group.

- The Pathfinder should be able to ride itself back up using the side Solar Panels and Custom Command; Cocoon.

- The expenses of the Solar Panel system should be limited to $200.

- The Solar Panel System shall be completed by December 14, 2016.

- The Solar Panel system shall use a custom PCB.

- The Solar Panel system shall use custom commands.

- The Solar Panel system should use custom telemetry.

Above are the Solar Panel system’s most up-to-date requirements. These requirements are more than just sentences asking what needs to be done, they’re directing the path we are taking in order to complete this project. These are requirements that we must meet and must be able to verify and validate. Requirements must satisfy two of three questions:

- Is it verifiable?

- Meaning is this a requirement that we are capable of verifying?

- Is it quantifiable?

- Meaning is this a requirement that we can quantify in numbers and test.

- Is it realizable?

- Given the fact that we have only 16 weeks in this course to design and build, some things just aren’t realizable to do within that timeframe.

Throughout the semester, we have been refining our requirements and finalized them by CDR. But, after speaking with the customer, president, and systems divison manager, we added a few requirements that would help us in creating a test plan. The added requirements are the last few; 7-12. These are requirements to help show that we will have the project completed by a certain date, under a budget, interfacing requirements, and some custom commands/telemetry the customer would like.

Past Requirements

As stated before, we have added quite a few requirements since CDR. These requirements stemmed from speaking with the customer, president, and systems division manager while creating a test plan matrix for the final on December 14 & 15, 2016.

Future Updates

As of now, we have no plans to updating or changing anything. But, to speak for what I think should be done in the following semester, there could be work done. I believe these are decent requirements but, they are not perfect.

Fall 2016 Solar Panels: System Block Diagram Update

/in Pathfinder Solar Panel/by Inna EchualBy Stephan Khamis (Mission, Systems, and Test)

Approved By Inna Echual (Project Manager)

Table of Contents

Introduction

As a result the feedback we received during the critical design review (CDR), we decided the system block diagram for our system. This blog post contains our most up-to-date system block diagram for the Solar Panel system of the Pathfinder project. Within this blog post you will learn about the changes we have made since the CDR to update this document.

Previous System Block Diagram

Figure 1: System Block Diagram Presented During CDR

Figure 1 shows our the System Block Diagram that we presented during our CDR. The first major difference we had to make was the switch from an Arduino Leonardo to an Arduino Micro. Per the customer, the use of the MPU – 6050 was told to be removed because the panels never had an explicit requirement for autonomous recovery if the rover fell over. We also added around 32 solar cells to help us make our 12V 1A mark of charge to charge our battery system. We also decreased the number of motorized folds to 3 rather than 5 because the stepper motors on the sub sided panels would be completely destroyed if they tried to recover the rover to an upright position.

Updated System Block Diagram

Figure 2: Updated System Block Diagram

Figure 2 shows our solar panel system’s updated system block diagram. The system block diagram explains an overall understanding of what the Solar Panel system entails. Because the pathfinder is an integrated project, also includes a portion of the Chassis system and how we are interfacing with one another electronically and a legend on the top right to help detect what the different colors and arrows mean.

On the left-hand side, you will notice the Solar Panel System, and on the right-hand side, you will notice the Chassis system. Since the Solar Panel is our priority and project, it is much more detailed than the basic interfacing that is shown on the Chassis system. Both the Solar Panel and Chassis system are using an Arduino But, the Solar Panel is using an Arduino Micro rather than a Leonardo. The two Arduinos will be interfacing with one another via an I2C. We also decided to add an MPC-23017 in order to make room for our reed switches, which will be used to prevent the cocooning mechanism from hitting the adjacent panels, which can possibly damage the cells.

Looking on the left-hand side of the overall System Block Diagram, it shows the power connections between the solar cells, battery, Pololu – A4988 motor drivers. Connecting to the motor drivers are the 3 stepper motors that will be used to help cocoon the Solar Panels. Connected to the solar cells is a charge controller that will help prevent the solar cells from providing more than 12V of charge, which is the maximum capacity of the battery.

Now looking at the right-hand side you will see the interfacing and communication going on between the Chassis and Solar Panel systems. Through the I2C connection of the Arduino Leonardo and Micro, the Leonardo will be able to help send commands to our Arduino Micro using the Arxterra Application/Control Panel. The Arxterra application will be controlled through an Android phone (Provided by the Chassis group) and will connect to the Arduino Leonardo via HM-10 BLE Bluetooth.

Future Updates

As of now, there are no future updates that I plan to change within the now updated System Block Diagram.

Fall 2016 Solar Panels: Product Breakdown Structure Update

/in Pathfinder Solar Panel/by Inna EchualBy Stephan Khamis (Mission, Systems, and Test)

Approved by Inna Echual (Project Manager)

Table of Contents

Introduction

This blog post contains our most up-to-date product breakdown structure for the Solar Panel system of the Pathfinder project. Within this blog post you will learn about the changes we have made since the critical design review (CDR) to update this document.

Updated Product Breakdown Structure

Figure 1: Updated Product Breakdown Structure

Due to feedback we got during the CDR presentation, our Product Breakdown Structure was updated to reflect our project. This Product Breakdown structure states all the item’s that we have used to create our Solar Panels. This flow down structure is helpful as it explains where the items are used for. I will also state why we decided to use some of these items.

As stated before, this is a flow down diagram. The Pathfinder is the main overall system and a part of that, is the Solar Panel (in which we care about). Within the Solar Panel system, you’ll find four main systems that were used to help complete this project: Control System, Mobility System, Charging System, and PCB.

Control System

The main idea for the Control System is to be able to control our Solar Panels—in other words, we should be able send commands and receive telemetry data. The first main product in which we are utilizing is Professor Hill’s Arxterra Control Panel. The corresponding app will be used so the joint Pathfinder group will be using an android phone. Most of the other projects used a 3Dot board which has Bluetooth LTE built into it. The Android Phone uses an HM-10 Bluetooth connection.

Three Pololu-A4988 Motor Drivers will be attached to our Arduino Micro, which will be used to control our stepper motors, and an MPC-23017 chip to make room on the Micro for our reed sensors. These reed sensors will stop the stepper motors and prevent the panels from overfolding and hit/damage the adjacent panel.

Mobility System

Within our mobility system, we will be using stepper motors (3), motor brackets (3), hinges (5), worm gears (5). These products are key to satisfying our cocooning mechanism. The stepper motors will be used to control the three folds that we have going on in our cocooning mechanism. The motor brackets will be used to connect our motors to the aluminum panels. The hinges will be used to fold the panels together. And the worm gears are also used in conjunction of our motors and hinges. We chose the hinges because it provided a low input, high output torque.

Charging System

The charging sufficient is the key to satisfying our mission profile, which is to have the Pathfinder be self-sufficient. The products within this system are as follows: 12-V 7000-mAh Lead Acid Battery, aluminum panels (6), solar cells (181), rubber insolation layer, sticker paper cavities, 24 AWG wires, tabbing wire, and charge controller. We decided to salvage and use the battery from the previous semester because it was still in great shape. One of the main requirements was to have our solar panels represent the form factor of the Spirit & Opportunity rovers. The two aforementioned rovers consists of six differently shaped panels. This leads to why we chose 39 mm x 39 mm polycrystalline solar cells. Not only are polycrystalline cells efficient but these were small enough to help us complete the form factor of the Spirit & Opportunity rovers. We also added an insulating layer and acrylic plating to protect the environment from the elements when it undergoes its mission. The cells were connected together using tabbing wire. A concern of charging a battery is allowing more voltage which can destroy the battery, so we decided to counter this with a charge controller that will not allow the voltage going into the battery to exceed 12-V.

PCB

We used a custom PCB board because essentially, it’s clean and small. This will help save us space within the electrical box that we shared with the Chassis group

Future Updates

As of now, we are not planning on updating our PBS. But, I may suggest for the next semester to be wise about the sizing and solar cells they choose to use. Some are very fragile and will break more often than not when soldering. They also don’t output the stated output on the website. It’s very unlikely it will ever hit those perfect conditions. I suggest using bigger solar cells, because at the end of the day, it’s best to complete the mission of charging a battery no matter what it looks like.

Fall 2016 Solar Panels: Software Block Diagram Update

/in Pathfinder Solar Panel/by Inna EchualBy Stephan Khamis (Mission, Systems, and Test)

Approved by Inna Echual (Project Manager)

Table of Contents

Introduction

This blog post contains our most up-to-date software block diagram (SBD) for the Solar Panel system of the Pathfinder project. Within this blog post you will learn about the changes we have made since the CDR to update this diagram to reflect our design.

Previous Software Block Diagram

Figure 1: Software Block Diagram Presented During CDR

The software block diagram the group presented during our CDR presentation is shown in Figure 1. The group received feedback from the Missions, System, and Test division manager, president, and the customer that the SBD lacked details of our system and was missing key parts of our software design. As a result, the necessary changes were made to define our current Software Block Diagram.

Updated Software Block Diagram

Figure 2: Updated Software Block Diagram

Figure 2: Updated Software Block Diagram

The software block diagram in Figure 2 is the aforementioned update and it explains an overall understanding of what the Solar Panel systems software entails. It also includes a portion of the Chassis system and how we are interfacing with one another electronically, along with a legend on the bottom left to help detect what the different colors mean.

The Arduino Leonardo from the Chassis will be set as the master and connected to the Arxterra Control Panel. The Arduino Micro from our system will be set as the slave. The roles of each Arduino is as follows: the Chassis system will be sending the Solar Panel system custom commands (cocooning) and an autonomous command (sun-tracking). This will be done through an HM-10 BLE Bluetooth to an Android phone provided by the Chassis group. While the Chassis group is supplying us with Commands, we will then be supplying the Chassis with custom telemetry, such as current and voltage readings. The current readings will be provided from a current sensor that is pinned to digital pin 4 on the Arduino Micro. The solar cells will provide the voltage telemetry. This is done by connecting the solar cells outputs to Analog Pins 0, 1, 2, 3, 4, and 5.

Furthermore, the commands for the Solar Panels will be heavily communicating with the stepper motors. As you can see above, when the Cocoon command is switched on, it will then activate all three stepper motors. These stepper motors are connected to Digital Pins 5 and 6 for the left wing, Digital Pins 7 and 8 for the right wing, and Digital Pins 9 and 10 for the back wing.

The Sun – Tracking command, is autonomous and will always be running through a loop that is explained within the diagram. In simple terms, the program will compare the voltage readings through the solar cells on the left and right wings. For the wing with the greater voltage, the wings will then adjust itself to that direction of the sun.

Future Updates

As of now, there are no future updates that I plan to change within the now updated Software Block Diagram.

References

[1] Arduino MICRO and Genuino MICRO Reference: https://www.arduino.cc/en/Main/ArduinoBoardMicro [2] Arduino Leonardo: https://www.arduino.cc/en/Main/ArduinoBoardLeonardo [3] Fall 2016 Solar Panels: 12C Communication Experiement: http://arxterra.com/fall-2016-solar-panels-i2c-communication-experiment/Fall 2016 Solar Panels: Creating a Port Expander Using IC MCP23017

/in Pathfinder Solar Panel/by Inna EchualBy Jose Rodriguez (Electronics & Control)

Approved By Inna Echual (Project Manager)

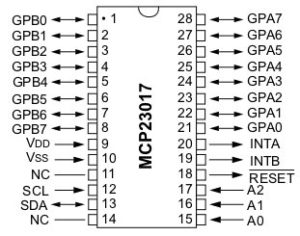

Objective: Because of our current design, a port expander is needed because there are no more available pins on our Arduino to read data from the reed switches. The reed switches will be used to halt the panels from cocooning more than it needs to; if it goes past a certain angle, it could hit the adjacent panel and damage its cells.

How to Set Up the IC

The Microchip MCP23017 is a 16-bit serial expander with I2C serial interface. This 28-pin IC offers sixteen inputs or outputs. Figure 1 shows the pinout data sheet for the IC:

Figure 1: MCP23017 Pinout [1]

Firstly, the expander was checked to see if it worked using two LEDs, which will be set high and low using the IC. Note that there are two banks, A and B, and each bank has a total of 8 pins. Both banks will be used in this blog to understand either or both of their activations.

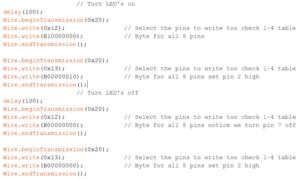

The code in Figure 2 is used to set up ports as outputs. The address for the device can be found on the data sheet [2], but to save time it is x20. To set pins as input, a one need to be set on the fourth column of the code depending on the required pin. Hex values are used, so for example, FF will set all pins as inputs. F0 sets the first 4 pins as inputs and the last 4 pins as outputs.

Figure 2: Code to Set Up Input and Output Ports

Once setup is complete, it becomes simple to set ports as high or low. The code in Figure 3 shows how to set up the pins using binary values. Four lines of code are needed to write on pins. The code takes a lot of space but there is a library that has been made for the MCP23017 by Adafruit that adds 1,000 bytes of memory.

Figure 3: Code to Set up Pins

The Adafruit library needs to be downloaded and saved in the Arduino library because it can be used with the IC. The code for using the library is shown in Figure 4. First the Adafruit library has to be included by writing #include. The code from Adafruit is similar to that of the Arduino when it comes to setting up pins, but mcp. needs to be added before pinMode. The setup is straight forward however note that Bank b refers to pins 8 to 15.

Figure 4: Code to Use Adafruit Library

Alternatively, the following code in Figure 5 turns two led on and off, but is more efficient as it requires less code. Either method can be used but the latter is cleaner than the other. If memory code is an issue, then the longer method (firts code) will be optimal to save memory.

Figure 5: Alternative Code to Light LEDs

Conclusion

Adding a port expander is not as hard as one will think as using the Adafruit library makes the process even easier. To read a pin the command that will be needed is mcp.digitalRead only. The second method makes the code cleaner, but the first method gives an individual an idea of what is going on behind the second method.

References

[1] Maximising your Arduino’s I/O ports with MCP23017: http://tronixstuff.com/2011/08/26/tutorial-maximising-your-arduinos-io-ports/ [2] MCP23017 Data Sheet: http://ww1.microchip.com/downloads/en/DeviceDoc/21952b.pdf

Fall 2016 Solar Panels: Choosing Panel Thickness (Stress Tests)

/in Pathfinder Solar Panel/by Inna EchualBy Ridwan Maassarani (Design & Manufacturing)

Edited and Approved By Inna Echual (Project Manager)

Objective: The thickness of our panels must be carefully chosen as “too large” of a thickness could result in additional weight, possibly causing unnecessary strain and bending. Though the chassis could withstand our panels weight a maximum 50 lbs (as stated by the chassis group), we would like to chose a weight that would minimize bending as bending could cause our solar cells to break due to their delicate state.

Choosing Optimal Thickness

The thickness of the panels should be chosen so that it can carry its own weight under the force of gravity, as well as be well below the maximum 50 lbs. load requirement set by the chassis group. Cutting various panel configuration numerous times using varying aluminum thicknesses would take a long time and waste expensive material, the stress analysis tool feature in SolidWorks was used.

Figure 1: Panel Reference

The panel being evaluated is the butt panel (see Figure 1). The stress analysis tool was used on the butt panel to verify that it wouldn’t bend under the force of gravity.

The first step is to define a location where the object being tested will not move. In my case, it is three mounting holes for the hinge. Gravity acting on the top of the back panel was defined as the load. Using the mass properties tool under evaluate in SolidWorks, the approximate mass of the back panel was obtained to be 383.93 grams.

Note that the additional of the cells, rubber sheets, and glass will increase the weight; to remedy this, the weight of a single cell was measured and multiplied with the amount of cells that can fit onto the back panel.

Figure 2: Solar Cell Arrangement on Butt Panel

Currently, 33 cells can fit on the butt panel comfortably with 2mm spacing between them (also taking into account panel cutouts for the gears, see Figure 2 above). The weight of one cell was measured to be 0.75 grams so an approximate addition of 24.75 grams is added due to cells. Masses pertaining to the solder and copper tape is negligible but the cell system was rounded to 30 grams.

The total mass was converted to Newtons, which was entered into one of the SimulationXpress analysis wizard. Since aluminum was determined to be the material of our panels, it was selected in the design.

Figure 3: Butt Panel Displacement using 3.175mm Aluminum

Figure 3 shows the displacement acting on the panel. An eDrawing file can be saved once the results have been calculated. Furthermore, the tool can be used to optimize the design. For example, it allows the user to change dimension right and set goals to meet the customer’s needs. SolidWorks will calculate multiple scenarios to meet specific goals.

Table 1: Base to Butt Panel Deflection Data

Graph 1: Thickness (mm) vs. Deflection (mm) of Butt Panel

Data concerning deflection was generated and inputted on Excel in order to determine panel thickness unacceptable deflection is seen. Table 1 shows the deflection from the base panel to the butt panel. The relationship between the varying thicknesses and resulting deflection is shown in Graph 1. The x-axis shows different thicknesses of 6061-T6 aluminum in millimeters and the y-axis represents the deflection distance in millimeters.

The four side panels (left front, left back, right front, right back) are similar in size and weight so the same stress analysis was done on the deflection between the base panel and the right front panel. Figure 4 shows the displacement acting on the aforementioned panel.

Figure 4: Right Front Panel Displacement using 3.175mm Aluminum

Figure 4 shows the deflection between the base and right front panel. Table 2 and Graph 2 contain the data on the relationship between thickness and deflection distance, as done with the butt panel.

Conclusion

Based on the data, we were able to determine that 1.25 in (3.175 mm) is the optimal thickness our aluminum should be to minimize bending. Our motors will be able to handle this weight and the total weight (including the addition of cells, wires, glass, motors, etc.) is still under the weight restriction of 50 lbs as set by the chassis group.