Advanced Arduino Assembly – 3Dot Paperbot

Assembly Robot PreLab 1 – An Amazing Programming Problem

Table of Contents

The Original Problem

The problem we will be trying to solve for the semester was originally taken from a puzzle book. Here is the problem as defined by the puzzle book.

“In the forest, you will find beehives and more importantly honeycombs. Along the path are bees. The number of bees at any given location is indicated by a number. There are a few ways your bear can travel to the forest. Your aim is to teach your bear how to make his way to the forest while encountering as few bees as possible”

Take a few minutes and see if you can solve the puzzle.

For this semester, we will be using an updated maze that allows for a little more customization based on your tastes. If you took a look at the playing cards within your maze kit, you will find several different playing cards that you can print out and will be placing throughout the maze. There is a core set of rules and conditions that we will follow to keep the labs manageable but you will be able to have some fun with the theme of your personal mazes.

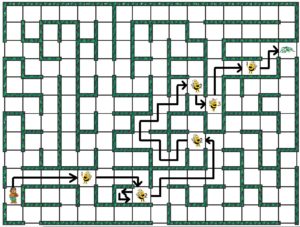

To provide a basic example to work with, we will be using a bear to represent the robot and it will be passing by / collecting a certain number of objects (bees) as shown in figure 3. The focus of this prelab is to guide you through the steps for solving the problem of navigating through the maze with the selected path. While it may seem unrelated to writing the actual code, these are core concepts that you will need to understand in order to succeed in the class.

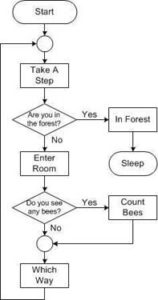

Draw A Flowchart

The first step to take when approaching any programming problem is to create a high level representation of what the code needs to do in the form of a flowchart. While most of this work will not be directly translated into code, it is an essential step to identify potential ways to structure the program and possibly catch any mistakes before spending time to implement it. Some of you may not know where to start for such an open ended problem like writing a program to help the bear navigate the path shown and the best way to develop your own method is through experience. Now let’s see if you can translate your path through the maze into a flowchart. Everything provided below is to be used as a reference on how to break down the problem into manageable parts. Keep in mind, you are not limited to only what is listed.

- Assume the Bear is initially facing north at the entrance into the maze. The Bear has a way to keep track of the number of objects it has passed which is a notepad. The length of each step is exactly one square.

- There are certain things that the bear can do or check in the attempt to exit the maze. The bear could take a step into the next room, check to see what type of room is encountered, or decide on which way to go next. The entire list of instructions that the bear can take are listed below. Compare it with your own list of instructions that you thought of to see how close you were.

Actuators and corresponding unconditional instructions

- Take a step.

- Turn left

- Turn right

- Turn around

- Count and record the number of bees in the current room.

Sensors and corresponding conditional instructions

- Did you hit a wall?

- Can your left paw touch a wall?

- Can your right paw touch a wall?

- Are you out of the maze?

- Do you see any bees?

- Are you thinking of a number {not equal, less than, greater than or equal} to 0?

- Is the number the Bear is considering {not equal, less than, greater than or equal} to some constant?

Memory operations

The bear can remember 8-bit unsigned and 1-bit (binary) numbers. The bear records a number in his notepad. He can only save one number per page. You may assign a descriptive name to a page (ex. bees), simply use the page number (page1), or think of it as a variable (X). In the following example X = 0.

C++ Equivalent Instructions

- Erase page X. page0 = 0;

- Increment the number on a page. page0++;

Nodes

- Start

- Stop

Tips and Tricks

- You may not need all the instructions provided.

- Although not required, you can use subroutines.

Take a few minutes to see if you can sketch-out your flowchart. If you don’t know where to start; don’t worry, in the next few sections, I will step you through how to write your own flowchart.

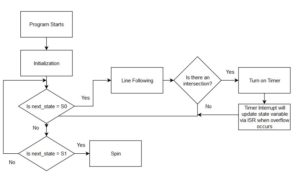

- The path through the maze can be modeled as follows. Figure 4 provides an overview of everything the bear will be doing to get out of the maze. Each block will be expanded on in future labs to describe exactly what our assembly program will be doing. The order that certain actions are done could be swapped around in your solution but this is how we will be implementing it. For example, this prelab will focus on defining the “Which Way” block, which determines the direction the bear should face while going through the maze.

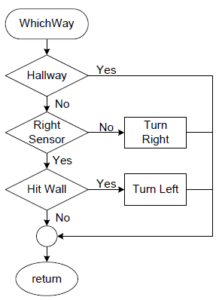

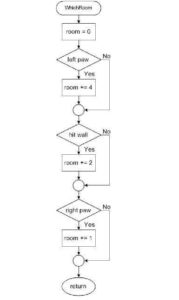

Creating the WhichWay Flowchart

First, we need to clarify what the Which Way block will be doing. From Figure 4, we know that the bear has just entered a room in the maze and now needs to determine which direction to go. The bear will be taking another step after the Which Way block, so we only need to make sure that the bear is in the correct orientation. There are two ways the bear can decide which way to turn when entering a room. You can count how many rooms the bear has passed or identify what type of room the bear is in. We will be doing the latter for our lab. Based on this information, these are the only instructions needed for this flowchart.

- Turn left

- Turn right

- Turn around

- Did you hit a wall?

- Can your left paw touch a wall?

- Can your right paw touch a wall?

- Increment the number on a page

- Is the number on page N of the notepad {not equal, less than, greater than or equal} to some constant?

With that in mind, we need to define a way to identify the rooms the bear enters.

Square Naming Convention

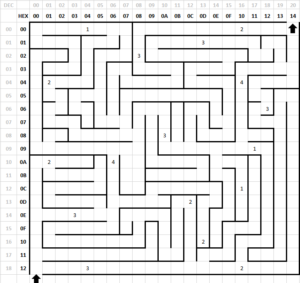

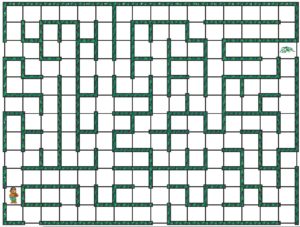

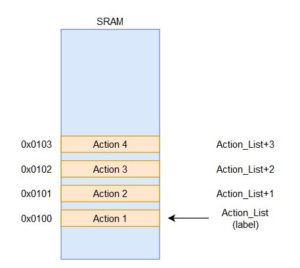

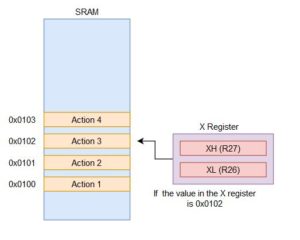

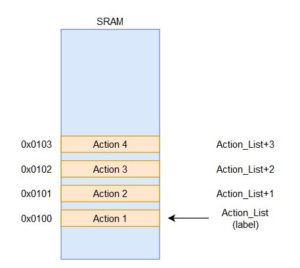

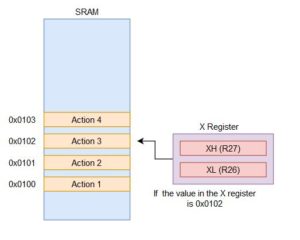

Here is a standardized naming convention to help you define the decision points in any maze. In order to provide a design example, the following maze identifies the squares (i.e., intersections) where the bear needs to make a decision for the shortest path solution.

Squares are numbered by concatenating the binary values (yes = 1, no = 0) for the answers to the following three questions (sensor inputs).

Can your left paw touch a wall? – Did you hit a wall? – Can your right paw touch a wall?

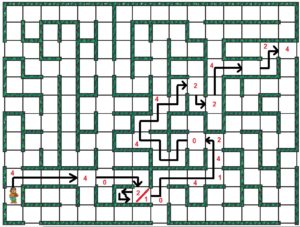

The answers to these three questions provide all the information that our bear can know about any given square. Let’s look at a few examples to see how this works. After taking the first step, the bear can touch a wall with his left paw (1), has not hit a wall (0), and cannot touch a wall with its right paw (0). For our convention, this would correspond to input condition 4 = 1002. As seen in the illustration I have therefore numbered this square 4. Assuming the bear turns right; after taking another step the bear finds himself in a hallway where his left and right paws touch a wall and he does not hit a wall. This corresponds to square 5 (1012). Although you could write a 5 in this square, for the sake of brevity, I left it blank (your bear walks down a lot of hallways). Notice that the numbers are based on the direction the bear is facing and not a universal reference point, like facing north. This corresponds to the fact that within the maze our bear has no idea where north, or any direction for that matter, is (our bear forgot his compass). So, let’s continue to the next intersection. Here the bear’s left paw is touching a wall (1), he does not hit a wall (0), and his right paw cannot touch a wall (0). We therefore would write another 4 (1002) in this square. Continuing in this fashion, all intersections are identified for our minimum solution. When you have squares that you pass through twice, please indicate the order by using a / to separate the numbers. For example, there is one square in the example path that has 2/1. This means that the square is considered type 2 when the bear enters it for the first time when it comes down and it is considered a type 1 when returning from the dead end.

Using this notation, the only squares that need to be labeled are the intersections (0, 1, 2, and 4). All other squares can be left blank as indicated in figure 5.

Example Path Solution

Using the square naming convention and the example path through the maze presented in the last section, let’s design a solution for the actions the bear needs to take.

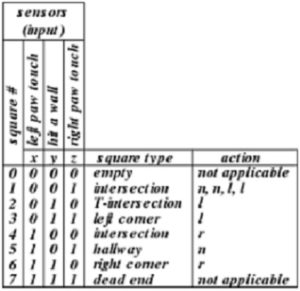

Build a Truth Table

Draw your Flowchart – Solution for a Fully “Deterministic” Maze

A fully deterministic maze is one where for any given intersection the bear will always (it is predetermined) take the same action. For example, whenever the bear encounters intersection 4 he will always turn right. For a non-deterministic maze, he may turn right one time and turn left another. The complexity of the sequence of actions will depend on what your path looks like. If we to consider one of the simpler deterministic algorithms possible for the WhichWay block, it could look like what is shown in Figure 6. There is no ambiguity about what should happen if this is the 5th hallway the bear has encountered as everything is clearly laid out. However, it is very unlikely that the path that you create later in the lab can be handled with a deterministic solution.

Once you have your flowchart, implementation in the C programming language or Assembly is fairly straightforward.

Prelab 1 Assignment

At this point, we are ready to discuss how you will be defining your unique path through the maze. Starting with the blank maze, one of the many entrances has to be chosen for your start point and the exit has to be chosen in the opposite quadrant. For example, if an entrance is chosen in the bottom left like in figure 7, then the exit used has to be within the top right. They are indicated using the bear playing card and green waves playing card.

Because the maze is a 16×12 grid, you can divide it into four quadrants and figure out which one is opposite to the entrance that you choose. Once you have defined those two spots, we can move onto the target square.

Find Your Target Square

There will be one location that the bear has to pass through on its path. This target square is determined from your student ID number. Write down the last four digits of your student ID as two 2-digit decimal numbers. These digits will provide the coordinates (row and column) of your target square. For example, if the last four digits of your student ID were 7386, your two 2-digit numbers would be 73 and 86. Divide using long division on each number and write the remainder down. Specifically, the row will be divided by 12 and the column will be divided by 16. Those remainders are now your row and column numbers. In our example, 12 divides into 73 six times with a remainder of 1 and 16 divides into 86 five times with a remainder of 6. Next convert the remainders into a hexadecimal (base 16) number. For our example, 1 = 0x01 (where the prefix 0x signifies a number in hexadecimal) and 6 = 0x06. Your target square would therefore be in row 0x01 and column 0x06.

How to Find Your Path

In addition to the target square, there are several conditions that need to be met for your path to be considered valid. Design a path through the maze such that:

- The bear goes through the target square.

- The bear must get lost at least once. Specifically, he must at some point turn-around. This is typically, but does not need to be, at a dead end.

- The bear encounters at least 10 bees but does not exceed 15 (inclusive). Placement of the bees is left up to you with the bee playing cards. Try to spread them randomly throughout the maze. You are allowed to only use the 1, 2, and 3 bee cards. If you would like to use the higher number cards, please discuss it with your lab instructor.

- Finally, the maze must be non-deterministic. This means that at some intersection along the path the bear will need to take a different action. For example, the first time he encounters a T-intersection he turns left and the second time he turns right. The good news is that, if your path meets the first three criteria, the odds are extremely high that it will be nondeterministic.

Let’s look at how you can develop a flowchart for your unique path.

Design Methodology for a “Non-deterministic” Maze

As previously mentioned, most maze solutions are non-deterministic. The phrase “not fully deterministic” means, while one set of input conditions in one part of the maze will determine one action (go straight), in another part of the maze the exact same conditions will require a different action (turn right). By looking at your truth-table you can recognize a “non-deterministic” path as having two or more 1’s in the same row. A quick inspection of the truth table generated from the deterministic path solution(Figure 6) reveals that the bear follows a fully deterministic path. Specifically, for any given intersection the bear will always take the same action. For example, if the bear’s left paw is touching a wall (1), he does not hit a wall (0), and his right paw is not touching a wall (0), then the bear will always turn right.

| Sensors | |||||

| Square # | Left Paw | Hit Wall | Right Paw | Square Type | Action |

| 0 | 0 | 0 | 0 | Empty / 4 way Intersection | Turn Right |

| 1 | 0 | 0 | 1 | Intersection | Forward |

| 2 | 0 | 1 | 0 | T-intersection | Turn Right |

| 3 | 0 | 1 | 1 | Left Corner | Turn Left |

| 4 | 1 | 0 | 0 | Intersection | Turn Right |

| 5 | 1 | 0 | 1 | Hallway | Forward |

| 6 | 1 | 1 | 0 | Right Corner | Turn Right |

| 7 | 1 | 1 | 1 | Dead End | N/A |

Table 2: Truth table of Deterministic Path

Take some time to see if you come to the same list of actions as shown in table 2. Keep in mind that the action for square type 7 is N/A or not applicable because there is no possible action for it based on the deterministic path algorithm. You are only able to use N/A in your truth table if the bear will not encounter it on the path and therefore does not need to consider an action for it. For those of you that spent the time to test what the algorithm will do for the example path we have, I know that the bear will be stuck in a dead end but that is the purpose of these examples (to get you to start thinking about it). While this seems pretty simple, your unique path is non-deterministic and will be a bit harder. Let’s begin by looking at this example and use it to build the truth table for your path.

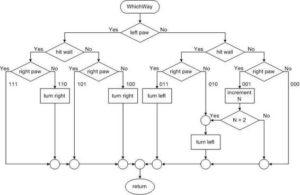

The good news is that with the exception of square number 1 all other actions are deterministic. The bad news is that only when we encounter room 1 after the second time do we start turning left. Please note that each action for square type 1 is listed because we need to see when the actions in the sequence change. You can infer from the table that the path will have four encounters with square type 1 and there is a specific action for each time you pass that square type. If those actions are not followed, the bear will go down a different path and not your unique path. This does not mean that the other square types are only encountered once. They have been condensed into one action because it turned out to be deterministic for that square type. You should still keep track of the sequence of actions for each square type as you are analyzing it and reduce it down to one if it satisfies the condition for being deterministic. To solve this more difficult problem of handling square type 1, we will create a binary tree that allows us to resolve all 8 squares, allowing us to then take any action needed. This binary tree can now be easily translated into C++ or Assembly.

This allows us to break up what the WhichWay subroutine will need to do for this specific path into implementable blocks of code.

EXTRA – A Modular Solution

For those of you with some previous programming experience, we can approach this problem with a more elegant solution. FOR THE PRELAB, you do not need to do it this way. A more modular solution separates the identification of the square (referred to as a room) from the action to be taken. Identification of the room is placed into a C++ or Assembly subroutine which returns the room number. The calling program must then determine the action to be taken based on the room number returned. The flowchart for the room subroutine is provided here and once again easily implemented in C++ using if or switch conditional instructions as discussed in the next lab.

Disclaimer – The discussion about the modular solution is to introduce you to other possible methods for approaching this problem. It is representative of how programming can be done in a variety of ways. You do not need to make a flowchart similar to this one.

Step-by-Step Instructions

After all of that background information, here are the step-by-step instructions for the prelab 1 assignment.

Begin by making a copy (electronic or paper) of the maze and drawing your bear’s path through the maze. When you are happy with your new path, follow the methodology previously discussed to build your truth table. Verify that your path meets the design criteria (passes through target square while encountering the minimum number of bees and getting lost once). Remember, your target square may not be along the original solution path.

It is now time to teach your bear how to navigate the new path by writing a flow chart. To accomplish your goal, you will need to apply everything you have learned so far plus add a few Notepad operations. The notepad pages (i.e., variables) are used to determine which path your bear should take when he enters an intersection in which more than one action is possible. For, example the first time he enters intersection 1 you may want the bear to go straight, while the second time he encounters intersection 1 you want him to turn left. To resolve this conflict you would record in your notepad how many times intersections 1 had been encountered and then check your notepad before taking any action.

In addition to previously stated conditions, your solution must also meet the following negative criteria.

- Your solution may not use a variable (notepad) to simply count how many steps the bear has taken in order to make a decision.

- Your solution should use a variable(s) and not the number of bees encountered to help it make a decision.

Deliverables for Prelab 1

Turn in the following material on the following pages (i.e., no more, no less). All work must be typed or neatly done in ink.

Title Page (Page 0)

The title page (Page 0) includes your picture (one that will allow me to match a name with a face), the lab number, your name, today’s date, and the day your lab meets.

Page 1

At the top of the page provide the last four digits of your student ID and describe how you calculated your target square. Include in your discussion how the resulting path met the design requirements defined in the pre-lab. For example how many paths did you consider before choosing your final path – how close did you come to 15.

Page 2

Next, using your favorite illustration (Visio, Illustrator, or Photoshop) program or the drawing tools included with your favorite Office program (PowerPoint, Excel, and Word), mark your target square with an X and illustrate your bear’s path through the maze just like Figure 3. Include a second illustration that marks all of the intersections that the bear will need to make a decision at. Make sure to number your intersections (but not corners or hallways) as illustrated in Figure 5. You may remove / white out the bees that were placed throughout the maze in order to clearly show the numbers.

The last thing to include is the truth table for your path as explained above with a format similar to Table 2. If you do not have access to any of those programs, there is a free online website called www.draw.io that works just fine. Please make sure everything is legible. You may use more than one page for this if there is not enough room.

Page 3

Again using your favorite drawing program, draw the flowchart for your path. It should be based on the truth table from Page 2 and look similar to Figure 9.

Your flowchart should resemble the one included with the lab and only use the provided instructions. Artwork of the sample flowchart can be found here.

Page 4

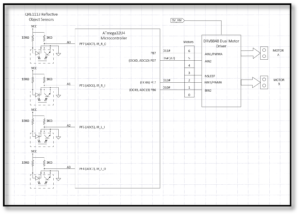

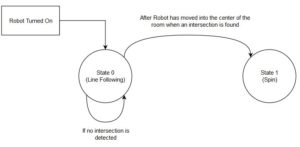

The goal of Lab 1 is to use two of the four input object sensors to control the motors in such a way that the robot will follow a black line. We will spend some time discussing how each part operates and start with a couple of questions to see how much you already know. Provided below is a diagram of how the IR sensors and motors are connected to the microcontroller.

Question 1: How many connections need to be made based on the the objective described? For example, will it be 1 to 1, 1 to 4, etc?

Question 2: Based on Figure 11, how should the input and output signals be connected so that the robot can follow a line. Hint: Read Lab 1. For example, should AIN1 be connected to IR_R_I (the inner right IR sensor) or the other way around?

All labs should represent your own work – DO NOT COPY.

Checklist

- Your pre-lab report includes a title page (Page 0) with your picture (one that will allow me to match a name with a face). Title information includes lab number, your name, today’s date, and the day your lab meets (Monday or Tuesday)

- Pages are in the order specified (see Deliverable)

- You do not have any extra pages

- You describe how you arrived at your path.

- Maze is not copied from another student (zero points)

- Path is computer drawn.

- Maze Path meets specified requirements.

- Intersections are not drawn by hand and appear as shown in the example.

- Intersection are numbered

- Intersections are numbered correctly

- Truth table

- Truth table is on the same page as the maze

- Truth table is typed

- Truth table matches the maze

- Flowchart

- Flowchart matches your truth table

- Flowchart is correct

- Question(s) are answered with all work shown.

Assembly Robot Lab 1 – An Introduction to 3DoT & Assembly

Table of Contents

Introduction

This lab is designed to introduce you to the 3DoT Board, Microchip’s Integrated Development Environment (IDE), and AVR Assembly Language programming. Plus, you will learn about the power of library files. Library files are simply files that you instruct AVR Studio to include in your program. In this lab you are going to include two library files. One is named m32U4def and the other is robot3DoT. By the end of this lab, you will be able to make the robot execute simple movements and understand how that was done.

What Is New

The following instructions and assembly directives are used in Lab 1. If you have any questions on any instructions or assembly directives a nice source of information, in addition to your textbook, are AVR Instruction Set Manual and the Atmel AVR Assembler User Guide.

AVR Assembly Instructions

Data Transfer

in r7, PINC // Input port C pins (0x09) into register R7 out PORTB, r7 // Output to Port B from register R7 mov r8, r7 // Move data from register r7 into register r8

Arithmetic and Logic

clr r16 // Clear Register R16 ser r17 // Set Register R17

Control Transfer

call Init3DoT // Subroutine Call rjmp loop // Jump to the label named loop

AVR Studio Assembly

Directives

.INCLUDE < m32u4def.inc > // < > means the file is in the AVR Studio folder .INCLUDE "robot3DoT.inc" // " " means the file is in the project folder .ORG 0x0000 // Code Origin

Labels

loop: // Links the next assembly instruction or piece of data to the

term used. (loop in this case).

Comments

;

//

/* */ <- Used for large blocks of text. Must indicate the

start and end with these symbols

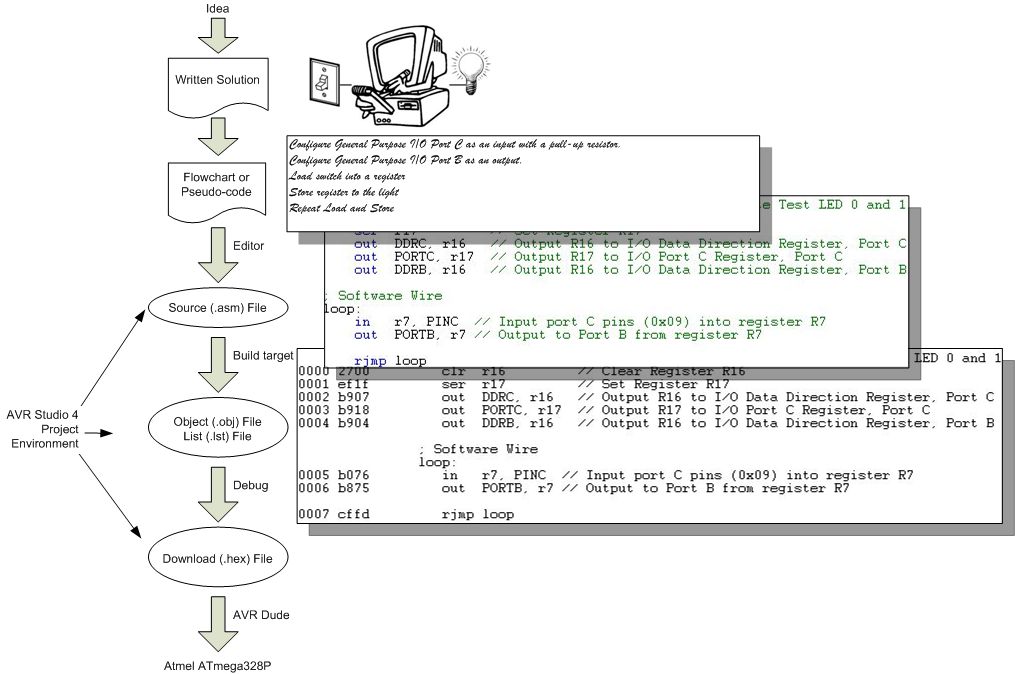

Introduction to Programming

Before you start writing your first assembly program, it is crucial to go over the core concepts that will be influencing how the programs are written. There are several misconceptions that can severely limit a student’s programming capabilities as they attempt to memorize how the code is written or the exact structure to use. It may feel overwhelming with the amount of new material to understand and learn but these core concepts should help with that.

- Recognize that the programmer is responsible for everything.

- It is common for new programmers to think that the microcontroller is smart enough to do certain things on its own given how technology has advanced and how the example programs shown in lecture do everything without any errors. This is not true. The only thing that a microcontroller / computer / laptop will do is follow the instructions provided by the programmer. It is the programmer’s responsibility to plan out the logic of how the program will run, anticipate any issues or errors that could occur, and provide any relevant information or resources for the microcontroller to use while executing the program.

- Understand that the programmer has relative freedom within the bounds of that specific architecture.

- You may have noticed that many example programs follow a consistent structure. This is to make it easier to teach and ensure that students have a general understanding. However, this does not mean there is only one way to write the program. If you fully grasp the way things are done on a specific microcontroller, it is possible to develop the code in various ways. This depends on the microcontroller because there are differences in how they work depending on the manufacturer. It requires an understanding of how to use labels, subroutines, etc but it highlights how the programmer can be creative with how the task is accomplished. Keep that in mind when attempting to create your own programs for the labs.

- The general structure for a section of code is to (1) Load the values or variables that are needed, (2) Do / Execute the action needed, and (3) Store the results or variables accordingly. This can be applied to a complex application by breaking it down to the individual parts and handling them separately. Be aware that each part could be one instruction or multiple instructions depending on what is needed for the program.

Keeping these concepts in mind should help when creating assembly programs for a specific application. We can now move onto the more technical details of writing the code.

Introduction to AVR Studio

In lab, you will be spending most of your time working within an Integrated Development Environment (IDE). For our labs, we will be working in the AVR Studio IDE. As shown in the figure below and discussed in the next few sections, the IDE lets us write our program in a human readable form, known as assembly, and then translate it into a machine readable form understood by the ATmega32U4.

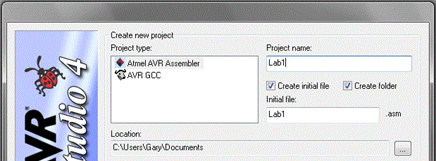

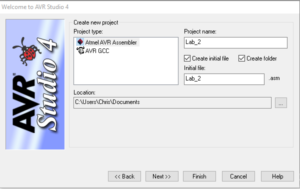

Create a New Project

The best way to learn about the AVR Studio IDE is to start playing with it. So let’s get things started by launching AVR Studio and Opening a New Project.

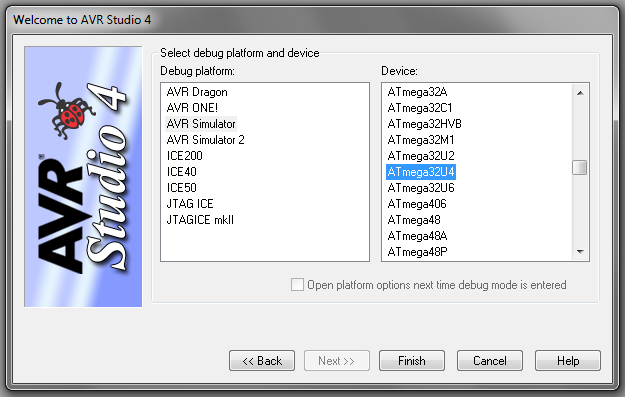

Select Atmel AVR Assembler and check both check boxes(Create initial file and Create folder). Name your project (Lab1) and browse to location where you want it saved. Click Next >>.

In the next window select AVR Simulator. For the Device, select ATmega32U4. Click the Finish button.

Congratulations, you are ready to start programming within the AVR Studio IDE!

Assembly Directives

All assembly programs contain assembly directives and assembly instructions. Assembly directives are instructions to be read by the assembler. In our lab, the assembler is included with AVR Studio IDE. As you have seen, AVR Studio is a program that runs on your computer and is responsible for translating your human readable assembly program into the machine language of the microcontroller.

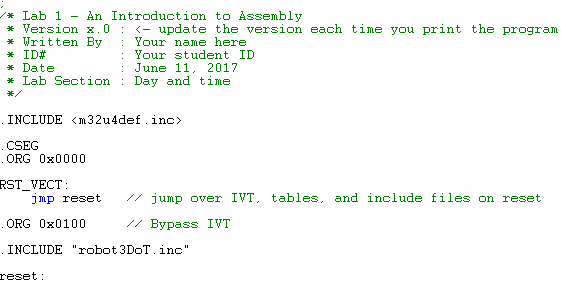

We begin our program with an Assembly Directive. First, locate the program window within the IDE. This is the blank window in the center of your AVR Studio application. The title bar should include the location of your program and end with the name of your program and the “.asm” extension. Enter the following lines into the program window.

You can probably guess that here we are telling the assembler that we would simply like to include some comments for the individual reading our code. To include comments, you can use the C language notation // comment line and /* block comment */ or unique to assembly a semicolon ; character.

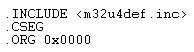

Now let’s add some code which intended strictly for the assembler, not the reader or the microcontroller. The difference is important.

The “dots” tell the assembler that these lines are talking to the assembler and not to be turned into machine instructions.

Without overly complicating our first program, I will just note that the INCLUDE assembly directive tells the assembler to copy into our program all the text contained in a file named m32u4def.inc. For now, we do not need to know what is in this file, other than to note it will help us in writing a more human readable program.

The CSEG statement tells the AVR Studio Assembler to place the following material in the Code SEGment of memory. For the ATmega32u4, this means Flash Program Memory. The ORG statement tells the assembler to start placing code at this address in Flash Program memory.

Programming Convention Because it is so important to remember when a line is intended for the Assembler (Assembly Directive) and when a line is to be converted to a machine instruction intended for ATMega32u4 microcontroller (Assembly Instruction), I always capitalize Assembly Directives and place in lower case letters Assembly Instructions. AVR Studio is not case sensitive, so this convention is not required for your assembly program to assemble correctly – it is however required by the instructor.

Now let’s add our first label. Enter the following line after the .ORG 0x0000 assembly directive:

RST_VECT:

The label RST_VECT stands for ReSeT VECTor and is only there as a point of programming style (i.e., it helps the reader know that the code to be executed on reset follows). What the assembler does is quite a different story. Whenever the assembly sees a label, it places the label name and its corresponding address, in this case we know it is 0x0000, into a look-up table.

| Label Name | Program Address |

|---|---|

| RST_VECT | 0x0000 |

Now if you ever want to reference this location in your program, you can use the name and let the assembler worry about the address.

Congratulations, you have for now completed your initial conversation with the assembler. You have asked it to include some comments, include more assembly directives located in another file, setup to write some code at address at 0x0000 in program memory, and finally to associate this address with the name RST_VECT. What you haven’t done is write anything that the AVR microcontroller will ever read. Once again it is important to know when you are talking to the assembler and when your code will be used to generate machine instructions to be run by the microcontroller. So let’s start generating assembly instructions intended for the microcontroller.

Assembly Instructions

Just as you are reading the step-by-step instructions on this page so you can write your first program, the microcontroller in Figure 5 reads the step-by-step instructions contained in the program to learn what is intended by the programmer. This is the “Machine Language” of the computer. This language is comprised of only ones and zeros. For example, this binary sequence 0010011100000000 tells the AVR computer (aka microcontroller) to set all the bits in register 16 to zero. All these 0’s and 1’s are not very easy for us humans to understand. So instead we humans have created a human like language comprised of abbreviations (known as mnemonics). This is known as Assembly Language. By definition then, there is a one-to-one correspondence between a machine instruction and an assembly instruction. For our machine code example, the equivalent assembly instruction is clr r16.

Registers Our microcontroller contains 32 general purpose registers labeled R0 to R31. For now you can think of registers like variables which can hold up to 8-bits of information (000000002 = 010 to 111111112 = 25510). To learn more about number system read Chapter 1 “Introduction” in your textbook or Appendix A – Number Systems in my Lecture 1 notes.

It is finally time to write our first assembly instruction. Add the following assembly instructions to your program.

rjmp reset // jump over the IVT, tables and include file(s)

The assembly instruction rjmp reset instructs the microcontroller to jump to the yet to be defined label named “reset”. You will also see I have included a comment. The meaning of this comment will become more clear over the remainder of the semester.

The Anatomy of an Assembly Instruction

Each assembly instruction is defined by an operator and one or two operand fields. For our clr r16 example, the clear instruction’s operator is clr and it has one operand r16. Our first program line also contains a single operand instruction. In this case, the operator is rjmp and the operand is reset.

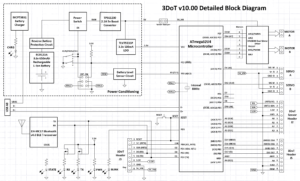

3DoT Board Schematic & Block Diagram

The end goal of these labs is to program a robot utilizing the 3DoT board and be able to navigate a maze autonomously. Shown below are the major features of the 3DoT board and the block diagram of the latest version.

3DoT is a micro-footprint 3.5 x 7 cm all-in-one Arduino compatible microcontroller board designed for robot projects.

- ATmega32U4 Microcontroller Unit (MCU)

- Power from a single CR123A 650mAh rechargeable Li-ion battery

- Integrated 3.7v Li-ion battery charger

- All digital logic powered from Low Dropout (LDO) 3.3v regulator with power and ground output header pins provided.

- Battery Level Sensor

- DRV8848 Dual DC Motor Driver

- 5.0v Turbo Boost for driving DC and servo motors

- Reverse voltage and overvoltage protection circuitry

- Android and Apple iOS application software (HM‑11 Bluetooth BLE module required)

- 2×8 pin Arduino-like shield connectors

- One 8-pin forward-facing sensor shield connector

- Two 100 mil standard Servo connectors

It would be ideal to spend some time analyzing the block diagram to get a better understanding of the capabilities of the 3DoT board but we will focus on the connections between the motor driver and IR sensors for Lab 1.

The main objective of Lab 1 is to understand the different components of the EE 346 robot and start to develop some basic control schemes. We will focus on understanding how the robot takes in sensor readings and can use them to drive the motors in a specific way. The end goal of all of the labs is to be able to program the robot to automatically navigate your path from prelab 1.

The Robot3DoT.inc Include File

To simplify your life – it is after all the first lab – I have already written all the assembly code you need to work with the two DC motors included with your CSULB 3DoT board. This code is contained in a separate file named robot3DoT.inc. We will add this file to our program in the same way we included the m32U4def.inc “include” document in an earlier part of the lab. Let’s begin.

- Download the file from BeachBoard. Make sure to place it within your Lab1 project folder or else you will get some errors when compiling.

- Unlike, the m32u4def.inc file which contains equate assembly directives, the robot3DoT.inc file includes subroutines which need to be run by the microcontroller.

- Add the following lines of code to your Lab1 project file.

.ORG 0x0100 // Bypass IVT .INCLUDE "robot3DoT.inc" reset:

Quick Review and New Directives to the Assembler

Here is what your program should look like now.

- Can you identify the comments?

- Can you tell which lines contain Assembly Directives and which contain Assembly Instructions? Remember assembly directives typically, but not always start with a period and use upper case letters; while assembly instructions use lower case letters.

Do you remember the first INCLUDE assembly directive from earlier in the lab? The m32u4def.inc library is written by Atmel and allows you to use names in place of numbers. In the following example the mnemonic PINC is “equated” to the number 0x06 in the library. If you like, you can open the m32u4def.inc file in AVR Studio and using the find tool, locate this directive.

.EQU PINC = 0x06

Up to this point our program has only contained comments, assembly directives, and labels. The first actual instruction is the previously discussed rjmp reset. So when you press the reset button, the AVR processor will first run the rjmp reset instruction. The rjmp instruction tells the processor to jump to the code starting at the reset label. This means the program will jump over (bypass) a table known as the IVT (to be covered later in the semester) and all the code included in m32u4def.inc. Which is a good thing; because we do not want to run any of the included programs until we are ready.

I wrote the robot3DoT.inc library. This library includes subroutines like Init3DoT, and ConnectToMotors which allow you to work with the 3DoT board without knowing the details of how it works.

Why are the two include files placed at different locations in the program?

The m32U4def.inc library is written by Atmel and allows us to use mnemonics (abbreviations like PINC) in place of numbers (like hexadecimal 6). To allow us to use these mnemonic names as quickly as possible we insert this library at the beginning of the program. The Init3DoT library is written by the instructor and contains instructions. This code must not be executed at reset so the library is inserted after the first jump instruction (rjmp reset) and above the label reset.

If you have played around with the Arduino IDE, you know that all Arduino programs have an initialization section named setup() and a looping section named loop(). Our assembly program written within the AVR Studio IDE will be configured in a similar fashion. In our case, the initialization section is labeled reset: and the looping section is again named loop:. In the next section you will write the initialization section to be used throughout the semester.

Initialization Section

How to Initialize the Stack

To accomplish almost anything useful in assembly you write a subroutine. To allow us to work with the 3DoT board I have written a number of ready-made subroutines for you to use. When you call a subroutine you need to save your current location on a stack. All computers have built-in hardware stack support. However, before we can save our return address on the stack we need to initialize our stack pointer (SP) register. You will learn more about stacks as the semester progresses. Add the following lines of code to your program right after the reset label.

reset: ldi r16, HIGH(RAMEND) out SPH, r16 ldi r16, LOW(RAMEND) out SPL, r16

How to Use the Init3DoT Subroutine

We are now ready to call our first subroutine. Add the following line to your program.

call Init3DoT // Initialize 3DoT board with both motors OFF

The Init3DoT subroutine takes care of all the initialization required to use the 3DoT board. This includes defining the various input and output pins for the major subsystems, preparing the motors, and putting the robot into a waiting state before the user commands it to do something. You only need to call it once at the beginning of your program, just after stack initialization. That is it, you are now ready to work with the 3DoT board – allowing you to read IR sensors, run the motors, and more. We will go over this initialization process in more detail throughout the semester.

Understanding How The Infrared Sensors Work

As we start working with the robot, it is crucial to understand how it receive inputs and utilizes them to determine the appropriate output such as moving forward or turning. The 3DoT Robot has four infrared sensors located on the IR shield that are used to detect information about its surroundings. If you are not familiar with this type of sensor, it will be covered in more detail in lab 3. For now, the core concepts to remember are that the IR sensors are used as inputs to determine what is below the robot, different values are returned based on the material or color of the surface the robot is on top of, and the program that you write will determine what to do with that information.

With this in mind, we will be performing an exercise to show how the IR sensors can be linked to both motors by creating “software wires” with our code. What this means is that depending on the value returned by the IR sensor, something could occur such as the motors turning or stopping. You may print out a page with a couple of black lines spaced apart by about a quarter inch to experiment with what the sensors will read. A simpler way is to use your fingers to cover the sensors entirely. Covering the sensors will imitate the robot being on white paper, so keep that in mind. We will be using different combinations to see their effects if each sensor was connected to one of the four motor driver pins shown in the diagram below. Refer to the following table and diagram to understand what each sensor is controlling and what the different combinations should do. Keep in mind that the black lines will be detected as values of 1 and the white space will be values of 0. Of the 16 possible combinations, all repetitions and unnecessary results are omitted.

| PF7 | PF6 | PF5 | PF4 | Expected Result |

| 0 | 0 | 0 | 0 | No movement. |

| 0 | 0 | 0 | 1 | Motor A is moving while Motor B is stopped |

| 1 | 0 | 0 | 1 | Both motors are moving. |

| 1 | 0 | 0 | 0 | Motor A is stopped while Motor B is moving. |

| 1 | 1 | 1 | 1 | Both motors are stopped. |

At this point, we are ready to write the code for our main program. This is indicated with a new label called loop. The purpose of this section is to have the code that will be continuously executed, which is separate from the initialization section that was focused on the setup of everything. Please add the following lines of code after the call Init3DoT instruction as shown.

....Previous Code....

call Init3DoT // Initialize 3DoT Board with both motors off

loop: // Start of main program

in R24, PINF // Take in inputs from IR sensors

rcall TestMotors // Run subroutine that will connect sensor values to motor driver pins

rjmp loop // Go back to the beginning of this section (repeat main program)

Let’s analyze what each instruction does.

- The instruction in R24, PINF will take the values from the I/O register PINF and copy them to general purpose register 24. This effectively brings in the values from the IR sensors for the microcontroller to work with. The reason the I/O register PINF is used comes from the fact that the IR sensors are connected to PF7 – 4, which are part of the Port F pins.

- The rcall TestMotors instruction will take the final values in register 24 and copy them to the motor driver pins. You will notice that the four pins are all located on different ports such as B, C, and D. Rather than overwhelm you with multiple lines of code, the TestMotors subroutine has been provided to handle this for you. The rcall instruction functions just like the call instruction where it will execute a subroutine that has been defined or provided from an include file.

- Finally, the rjmp loop instruction will cause it to go back to the beginning of the loop section and repeat the code continuously.

Assemble and upload the code to the robot. Test all of the combinations and make sure you understand what is occurring. After this, we are ready to move onto the next step of using the IR sensors to control both motors to move in a straight line.

Controlling the Motors

Given the quick introduction during the exercise with the IR sensors, it is a good time to go into more detail about the input and output ports. The General Purpose Input and Output (GPIO) ports of a microcontroller (MCU) allow you to read pins and write to the pins of the MCU. To read a pin means – to record if the voltage on the pin corresponds to a logic 0 (Low) or logic 1 (High). To write to a pin means – output a voltage to the pin corresponding to a logic 0 (Low) or logic 1 (High). Figure 6 is a close-up picture of the interface between the ATmega and it GPIO ports and the DVR8848 Motor Driver. The mnemonics inside the ATmega32U4 correspond to the GPIO port bits. The numbers outside the box correspond to the Arduino naming convention. We will be working directly with the GPIO ports. Instead of mapping it to just one motor, we will not be configuring it as shown in figure 6.

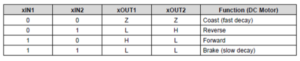

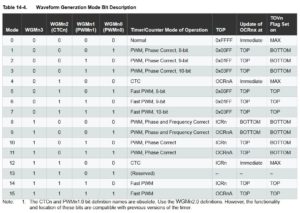

Figure 7 is the truth table for the DVR8848 Motor Driver taken from the datasheet. As a practicing engineer, much of your time will be spent reading datasheets and translating that information into a schematic and software.

Ultimately, we want to know what settings make our robot go forward, backward, turn right, and turn left. Because of how the motors sit inside the robot, one of the motors will be going in the opposite direction of the other. Keeping in mind that the USB connector and switch are the back of the robot, the left motor must be plugged into slot A and the right motor is plugged into slot B. With that convention, the robot will move forward if the right motor goes clockwise and the left motor is counter clockwise. If you followed the video for assembling the 3DoT robot, it will simplify to 0b01 for going forwards and 0b10 for going in reverse. If that is not the case, please discuss the issue with your lab instructor before moving forward.

| AIN1 | AIN2 | BIN1 | BIN2 | Effect |

| 0 | 1 | 0 | 1 | Robot moves forward |

| 1 | 0 | 1 | 0 | Robot moves backwards |

Feel free to test the other combinations to get the robot to spin left, right, or around given the table below. The reason we chose to spin the robot instead of turning is to keep the movement consistent.

| Action | Input | |||

| Left motor | Right Motor | |||

| AIN1 | AIN2 | BIN1 | BIN2 | |

| Motor Off | 0 | 0 | 0 | 0 |

| Forward | 0 | 1 | 0 | 1 |

| Spin Left | 1 | 0 | 0 | 1 |

| Spin Right | 0 | 1 | 1 | 0 |

| Reverse | 1 | 0 | 1 | 0 |

As you may have noticed, we do not need to connect all four IR sensors to the motor pins directly. If we do, there will be major issues with getting the motors to move the way we want to within the maze. For this reason, we will only be using the two outer IR sensors for the rest of the semester. They will be used to detect the walls if the robot starts to deviate from moving in a straight line, which is more common than you might think. This is because of various factors such as the motors not outputting the same number of rotations when operating at the same voltage, differences in friction for the gear train, and the battery draining over time as it is being used. They all interfere with the assumption that it would be easy to get our robot to keep moving forward in a straight line.

For all future labs, this will be how the information for controlling the motors will be formatted. Using register 24 as an arbitrary register to hold the information, it will look like the following:

| R24 | Bit 7 | Bit 6 | Bit 5 | Bit 4 | Bit 3 | Bit 2 | Bit 1 | Bit 0 |

| X | X | X | X | AIN1 | AIN2 | BIN1 | BIN2 |

The X indicates that we do not care what their value is because it is not being utilized for anything. By default, you can set that to 0 to make it easier to manage. At this point, you should notice that only one of the bits from each pair will need to be a 1 in order to get the robot to move. At this point, we want to directly control the motors and ignore the IR sensors. It is possible to link the IR sensor to the motor driver pin but that implementation leads to more problems than it resolves. We will be handling the IR sensors in a slightly different way in future labs. We will want to directly control which direction the motors are going, so you will want to get used to this format and using the WriteToMotors subroutine.

....Previous Code....

call Init3DoT // Initialize 3DoT Board with both motors off

loop: // Start of main program

ldi R24, 0x05 // Test combination to get robot to move forward (01) for both motors

rcall WriteToMotors // Run subroutine that configures motors based on input given

rjmp loop // Go back to the beginning of this section (repeat main program)

It may seem like a very minor change but the most important idea to take away from this is that it is crucial to understand what each subroutine you are using will do. You may take a look at the robot3DoT.inc file to see all of the code involved.

Directly Controlling Both Motors

Now, you may be wondering how we will be controlling the robot to perform turns while navigating the maze. The ConnectToMotors subroutine is only meant to make the robot move forward based on what the IR sensors are detecting (should be white paper). In order to properly control the robot, we will be using another subroutine called WriteToMotors in future labs. This will use a value that has been formatted properly to get the motors in a specific way. For example, if you want the robot to start spinning to the left, the value that needs to be set in a register is 0b00001001. This will be combined with another subroutine that will adjust the speed of the motors to accurately control how the robot traverses the maze.

With that, we are now done with Lab 1. The rest of the time will be spent exploring the simulator / debugger within AVR Studio 4 and understanding what was accomplished. For those of you that are interested in going further, please take a look at the design challenge described below.

Design Challenge – Wall Following Algorithm (5 points)

You can skip this section if you are happy receiving a passing or even a good grade on the lab. If you want to receive an excellent grade you will need to accept the challenge. Specifically, the maximum grade you can receive on the prelab 1 plus lab 1 if you do not accept the challenge is 25 points out of 30 (83%).

To accomplish this challenge you will need to learn a few new instructions: com, bst, and bld. A nice source of information on assembly instructions is the AVR Instruction Set Manual.

The objective of the design challenge is to teach your robot how to follow the walls and adjust appropriately to stay within the maze boundaries. This requires a different solution to what has been covered in the lab so far. Instead of using the sensors to control a single motor or loading a value to be used with the WriteToMotors subroutine, we will be using the two outer IR sensors to detect when the robot strays from the path. You should be using the maze from the kit that you ordered. If it has not arrived yet, you may print out a test setup with two black lines that are spaced apart about 2.5 inches. For this scenario, the robot will need to keep moving forward as long as it detects white and adjust the motors in a way that it will correct itself if a wall is encountered on either sensor. In order to make sure that we consider all possible situations and what needs to be done, fill out the following table.

| Input | Condition | Action | Output to Motor | ||

| IR_L | IR_R | Motor A | Motor B | ||

| PF5 | PF6 | Bit #? | Bit #? | ||

| 0 | 0 | Walking down the path | forward | ||

| 0 | 1 | Right sensor over the path | veer right | ||

| 1 | 0 | Left sensor over the path | veer left | ||

| 1 | 1 | Next Room / Wall | stop | ||

If you understand the table correctly, you should discover that all you need to do to implement the truth table is wire the complement of the input with its corresponding motor driver bit. Keep in mind that we want the robot to keep moving forward, so choose the appropriate bit to work with.

Now all we need to do is wire the complement of each object IR sensor input to its corresponding motor output. As a load-store architecture, we will need to input our sensor inputs into a register, wire them up, and then output to the motors. Using any of the provided subroutines will interfere with what we are trying to do, so refer back to figure 6 for an idea of how the data needs to be handled.

Test your code and if everything is working correctly, your robot should adjust itself when it hits either of the vertical walls on the maze. For the lab assignment submission, please indicate on the title page that you are attempting the design challenge. Insert the design challenge code where it is appropriate in the base lab. You do not need to create a separate project just for the design challenge.

Uploading the Code

At this point, you are ready to test the code with the robot. To do this, there are a few things that need to be prepared.

- Make sure to have assembled the program and that the hex file that is created is the latest version.

- Connect the 3DoT board to your computer and take note of which COM port it is using while in PROGRAM mode. You can find that information by running the device manager and expanding the Ports and COMs category.

- Create a batch file with the following command.

-

- You can make a batch file by opening Notepad and pasting the command below.

- When saving the file, make sure to change the file type from Text document to All Files under the Save As Type option.

- Erase everything in the file name area and make sure that it is exactly upload.bat

-

avrdude -v -p atmega32u4 -c avr109 -P \\.\COM9 -b 57600 -D -U flash:w:Lab1Test.hex pause

Keep in mind that you will need to make adjustments to the command based on the file name and COM port being used. In this example, the file name is Lab1Test and the COM port used is 9. You can make copies of the batch file and edit it by right clicking and selecting the edit option.

Once that is all prepared, make sure the upload.bat file is in the same folder as the hex file for the lab you want to upload. In this case, it should be in the Lab 1 folder. With the 3DoT board connected and set to PROGRAM mode, run the upload.bat file. If everything goes well, it should successfully upload and start executing when the board is put into RUN mode.

Lab 1 Deliverable(s)

|

All labs should represent your own work – DO NOT COPY. Submit your list file as defined below. Make sure that the code compiles without any errors. Do not forget to comment your code. Lab 1 Demonstration

|

How to Create and Print-out a List (.lst) File

At the end of each lab, you will turn in a List file version of your program. A list file contains both your assembly program and the machine program generated by the assembler. First let’s verify that AVR Studio is set to generate a List file. In the menu bar select Project and then Assembler Options

Now whenever you assemble your program, a file with a .lst extension will be created in your project folder. Assemble your program and then open the generated list file.

You will see that along with your program the list file includes a lot of other stuff. Most of this is the text from the included m328pdef.inc document. This is the document that includes all the equate Assemble Directives which allow us to use mnemonics for all our registers in place of their actual addresses. If you have not done so already browse this material to see how AVR Studio does it. You should see something like the following.

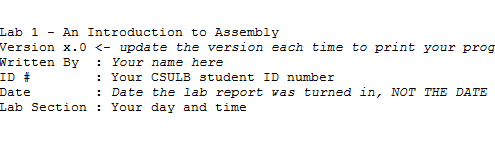

AVRASM ver. 2.2.7 c:usersDocumentsLab1Lab1.asm Tue Aug 21 13:05:53 2019 [builtin](2): Including file 'C:/Program Files (x86)AtmelStudio7.0PacksatmelATmega_DFP1.2.209avrasmincm328pdef.inc' c:usersDocumentsLab1Lab1.asm(10): Including file 'C:/Program Files (x86)AtmelStudio7.0PacksatmelATmega_DFP1.2.209avrasmincm328pdef.inc' c:usersDocumentsLab1Lab1.asm(16): Including file 'c:usersDocumentsLab1spi_shield.inc' /* Lab 1 - An Introduction to Assembly * Version x.0 <- update the version each time to print your program * Written By : Your name here * ID # : Your CSULB student ID number * Date : Date the lab report was turned in, NOT THE DATE DUE * Lab Section : Your day and time */ ;***** Created: 2011-02-19 12:03 ******* Source: ATmega328P.xml ********** ;************************************************************************* ;* A P P L I C A T I O N N O T E F O R T H E A V R F A M I L Y ;* ;* Number : AVR000 ;* File Name : "m32U4def.inc" ;* Title : Register/Bit Definitions for the ATmega32U4 ;* Date : 2011-02-19

There is a lot of extra material that is not useful, so there are several things to remove. Everything that comes from any include file must be removed since it is not a part of the main code. Delete material from this line…

;***** Created: 2019-12-11 15:36 ******* Source: ATmega32U4.xml ********** ;************************************************************************* up to and including this line. ; ***** END OF FILE ******************************************************

Your list file must include the AVR Studio Assembler version and time stamp!

AVRASM ver. 2.1.42 Tue Aug 23 16:57:15 2019

The “Resource Use Information” should also be deleted before you print out your list file.

Delete material from this line…

RESOURCE USE INFORMATION ------------------------

up to, but not including this line.

Assembly complete, 0 errors, 0 warnings

You can clean up and format the final version of your file in AVR Studio or your favorite text editor. Regardless of the text editor your final document should be formatted as follows.

Font: Courier or Courier New

Size: 9 or 10 point

Paragraph Spacing: 0 pt before and after

Line Spacing: Single

Page Layout: Landscape

Next, clean up unwanted spaces so your code is aligned and easy to read. DO NOT FORGET THIS STEP. Your touched up list file should now look something like this template.

AVRASM ver. 2.1.42 Tue Jan 10 11:24:47 2019 /* Lab 1 - An Introduction to Assembly * Version x.0 <- update the version each time to print your program * Written By : Your name here * ID # : Your CSULB student ID number * Date : Date the lab report was turned in, NOT THE DATE DUE * Lab Section : Your day and time */ .CSEG .INCLUDE .ORG 0x0000 RST_VECT: 00000 c131 rjmp reset // jump over IVT, tables, and include files .ORG 0x0100 // place all the code that follows starting at the address 0x0100. .INCLUDE "robot3DoT.inc" reset: // Initialize the stack pointer 000132 e008 ldi r16, HIGH(RAMEND) // IO[0x3e] = 0x08 000133 bf0e out SPH, r16 000134 ef0f ldi r16, LOW(RAMEND) // IO[0x3d] = 0xFF 000135 bf0d out SPL, r16 000136 940e 0100 call Init3DoT // Initialize 3DoT Board with both motors off. loop: //in r16, PINF //cbr r16, 0x0F //out PORTD, r16 0001c0 e20c ldi r16, 0x2C 0001c1 2f80 mov r24, r16 0001c2 940e 016f call ConnectToMotors 0001c4 cffb rjmp loop Assembly complete, 0 errors, 0 warnings

NOTE: THIS IS JUST AN EXAMPLE. YOUR LIST FILE SHOULD CONTAIN THE CODE FOR THE LAB YOU ARE SUBMITTING.

Finally, if you have not done so already, set your printer page layout to landscape mode. Preview your printout before you actually print it out to save paper. Double check your document to make sure there is no word wrap. Your printout should never include word-wrap. If you do see a line wrapping in the print-out, go back and correct the line and re-print your list file.

Lab 1 Deliverable(s) / Checklist

STOP Read the Lab READ ME document contained in the Labs Folder. Be absolutely sure you have followed all instruction in the “Lab Formatting” section of this document. Points will be deducted if you do not follow these instructions. You have been warned.

If you have not done so already, please purchase a Lab Notebook. Follow the guidelines provided in the “Lab Notebook” section of the Lab READ ME document.

Make sure you have read and understand the “Plagiarism” section of the Lab READ ME document.

All labs should represent your own work – DO NOT COPY.

Remember before you turn in your lab…

- Did you convert your code for the exercise with controlling a single motor into comments?

- Your lab report includes a title page with your picture (one that will allow me to match a name with a face), lab number, your name, today’s date, and the day your lab meets

- The above information is duplicated in the title block of your assembly program as described in the lab. Do not forget to include the first line of your program containing the title of the lab. If you are not careful this line may be deleted and points deducted.

- Your list file should include the AVR Studio Assembler version and time stamp.

- Your list file should not include material from the m328pdef.inc or spi_shield libraries or Resource Use Information.

- Include the Assembly line indicating that your Assembly program contains no errors or warning in syntax.

- Your list file should be formatted as defined here.

Font: Courier or Courier New

Size: 9 to 10.5 point

Paragraph Spacing: 0 pt before and after

Line Spacing: Single - All fields within the program area (address, machine instruction, label, operand, destination operand, source operand, comment) must be aligned.

- Your list file printout should be in landscape and not have any lines wrap from one line to the next.

- Never turn in a program that is not debugged (i.e., contains logical errors).

Assembly Robot Prelab 2 – Understanding the Robot’s motion

Table of Contents

Introduction

The focus of this prelab is to help you understand how the robot will be navigating through the physical maze, provide details on the new subroutines that will be used in Lab 2, and cover some of the general rules about subroutines. While you may have felt overwhelmed with all of the information provided in Lab 1, all subsequent labs and prelabs will be focused on one or two key topics that should be more manageable. For example, instead of worrying about how to program the robot to maneuver the path defined from prelab 1 right away, we will break it down into the basic, repeatable actions and combine those together.

Details about the Physical Maze

At this point, you should be fairly familiar with the printed maze that is part of the kit for the labs. The finer details about its design were omitted to keep things simple at the beginning of the semester. By the end of the semester, you will be expected to demonstrate the robot going through the maze in two different ways. The first way is to have it go through the physical maze and the second way is to show the program going through the virtual maze in the simulator.

The physical maze is made up of the artwork for the the walls (hedges) in the maze and the grid of intersecting lines to show the boundaries of each room. Figure 1 provides a closer look at some of the possible room configurations the robot will encounter. The walls of the room are in a different color (green in this case) and it is surrounded by a black outline in order to help the robot navigate properly.

In order to keep things simple and cost effective, the robot will be using a wall detecting algorithm to navigate through a 2D maze that is printed on paper. The algorithm will keep the robot moving in a straight line as it transitions to the next room and make sure that it moves away from a wall if it deviates to the left or right. This design was finalized after several different methods were considered such as using ultrasonic sensors to detect the nearby surroundings. The following questions are meant to help emphasize that different types of programs could be developed to solve the same problem.

Question 1 – What are some of the issues that will need to be resolved if the robot is using a wall detecting solution? Consider what else the robot will encounter as it navigates the maze.

Question 2 – How many ultrasonic sensors would be required if the maze was 3D instead of 2D (physical walls made instead of printed on paper)? Provide your reasoning for that amount.

Question 3 – Should the ultrasonic sensors be continuously on while the robot is moving through a 3D maze? Why?

Subroutine Basics

So far, the term subroutine is probably still pretty vague. In Lab 1, Init3DoT and WriteToMotors were introduced with a brief description of what they did. You were told to simply use the call instruction with them and move on. As we continue through the semester, you will be creating your own subroutines and understand how to utilize them properly.

The term subroutine refers to a programming methodology that can help improve the structure and efficiency of your code. There are several rules to follow to ensure that things will work properly. We will cover those in later labs. The main focus for now is recognizing what they are used for and how we define the names. Subroutines are a group of instructions that achieve a specific result and has been given a unique name/label by the programmer. For example, the Init3DoT subroutine is composed of several lines of code that configure all of the input and output pins for the IR sensors and motor driver. Subroutines could be called once (as with Init3DoT) or multiple times (as with WriteToMotors if testing many configurations) depending on what the programmer is trying to do. All of these factors influence how the subroutines need to be handled.

For example, any data that needs to be provided (inputs) or received (outputs) from a subroutine is handled in a specific manner. That data is sent through designated registers in order to prevent chaos if an arbitrary register was being used to hold some other important piece of information. For this class, if the size of the data is one byte, the registers used are R24, R22, and R20 for one input/output, two inputs/outputs, and three inputs/outputs respectively. Also, the registers are not restricted to just one input or one output. If a subroutine has two inputs and one output, R24 and R22 will be used to send data in and R24 is used to take data out. The reason that R24 can be used twice is that both R24 and R22 were designated for transferring data, so it is not locked to any specific input or output. It is dependent on the programmer to recognize how the data is moving. This is why you were told to load the value for the motor driver configuration into register 24 before calling WriteToMotors in Lab 1.

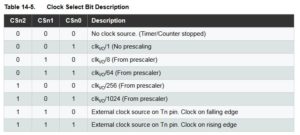

Understanding AnalogWrite

The new subroutine that is being introduced in Lab 2 is called AnalogWrite. It is meant to be identical to the analogWrite function that is used in the Arduino IDE. The primary objective of the subroutine is to set the speed for each motor with two values provided by the user. The range of acceptable values is from 0 to 255, where 255 represents the maximum speed the motor can go. In order to prepare for using this subroutine, you will need to practice converting from decimal to hexadecimal. Answer the following questions for the prelab. Make sure to show your work for the conversions.

Question 4 – Convert the value 216 into hexadecimal.

Question 5 – Convert the hexadecimal value 0xAE into decimal.

To make our programs more readable, subroutine names we start with a capital letter, otherwise the first letter of a label will be in lower case.

Prelab 2 Deliverables

For Prelab 2, make sure that you have the following:

Page 1 – Title page with photo, name, ID#, and assignment #.

Page 2 – Answers to five questions. Show work when necessary.

Assembly Robot Lab 2 – Setting the motor speed and introduction to subroutines

Table of Contents

Introduction

This lab is focused on accurately controlling the speed of the motors in order to improve the maneuverability of the robot. The ideal result from this lab is that your robot should be able to move in a straight line without veering off of the path and having to correct itself. This will reduce the issues that you may run into once we start testing the robot with the physical maze. You will also learn more about subroutines and how we will be handling them in this course.

What Is New

The following instructions and assembly directives are introduced in Lab 2. If you have any questions on any instructions or assembly directives a nice source of information, in addition to your textbook, are AVR Instruction Set Manual and the Atmel AVR Assembler User Guide.

AVR Studio Assembly

Directives

.EQU Name1 Value1 // Tells the assembler to equate Name1 with Value 1 throughout the program .DEF Name2 Name3 // Tells the assembler to use Name2 to replace Name3 (Name 2 is defined as Name3) throughout the program

Improving Control of the Motors

Up to this point, you have been simply turning the motors ON and OFF without regard to the speed. By default, the motors have been operating at full speed and you could have seen the robot veering to one side instead of going straight. This is not the best solution for navigating a maze and will require the development of an algorithm that will automatically correct the robot’s movement. In this lab, our main goal is to get better control our robot by addressing the possible mechanical issues like friction or component quality with adjustments to the speed of each motor. We will do this by using another subroutine that was included in robot3DoT.inc called AnalogWrite.

Creating Lab 2

To start, create a new project in AVR Studio 4.

- Give the lab an appropriate name and make sure the options to create the initial file and folder are selected.

- Select AVR Simulator from the list of Debuggers and Atmega32U4 from the list of devices.

- Copy all of the code from the Lab1.asm file to the empty Lab_2.asm file.

- Copy the robot3DoT.inc file and upload.bat file from the Lab 1 folder to the Lab 2 folder.

- Assemble the code to make sure that it builds with zero errors and zero warnings.

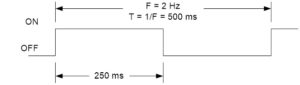

How the AnalogWrite Subroutine Works

As mentioned in Prelab 2, the AnalogWrite subroutine is meant to be equivalent to the analogWrite() function used in the Arduino IDE. It is used to configure the speeds of each motor based on inputs provided by the user. The range of acceptable values used to represent the various speeds are from 0 to 255. While 255 corresponds to the fastest the motors can turn, 0 does not necessarily correspond to the motor moving at the lowest speed. It is more accurate to say that 0 would be equivalent to the motor being off and that there is a range of values where the motor is on but unable to turn. This is because those values represent the pulse width modulation duty cycle with 0 being 0% and 255 being 100%. It translates into a voltage being applied to the motors between 0 V and 5 V.

As this is a new subroutine, there are a few things to keep in mind. Unlike WriteToMotors, AnalogWrite requires two inputs and does not have any outputs. You will need to provide the two input values through registers 24 and 22 respectively. The values for each of these will have to be in hexadecimal. R24 is assigned to Motor A (left motor) and R22 is assigned to Motor B (right motor). If the values are not prepared properly before calling AnalogWrite, the subroutine will use whatever values were in those registers at the time and could result in unexpected results. That is why one of the rules for subroutines is to always load the arguments before calling the subroutine. More information about these rules that have not been covered so far are listed in Appendix A.

With this information, we can move onto the main focus of Lab 2.

Find the Maximum Speed

There is a high probability that your two motors are not equal. This is typically due to a difference in the internal friction of the gears and motors, which translates into a difference in the speed of rotation at a given voltage or duty cycle. This will cause your robot to veer towards the right or left. In order to address this issue, we will be start by finding the ideal maximum speed for the fastest motor such that the robot travels in a straight line (or at least as close as possible).

This portion of the lab involves a lot of trial and error. We will be placing the robot on the printed maze and verifying if it is moving in a straight line. If it reaches the room boundary without moving towards a side wall, then you have found the appropriate speed on each motor. If not, try changing the speed of one of the motors and check the result. You will be manually controlling the speed of each motor using the AnalogWrite subroutine. Add the following lines of code to the main loop.

...Previous Code...

ldi r24, 0x05

call WriteToMotors

ldi r24, 0xFF // value for speed of Motor A, left motor

ldi r22, 0xFF // value for speed of Motor B, right motor

call AnalogWrite // sets speed of both motors using inputs r24 and r22.

rjmp loop

Begin with both motors running at full speed (PWM value of 255) and record in which direction the robot drifts towards. If it drifts to the right, then the left motor is faster than the right. Decrease the speed of the faster motor by lowering the duty cycle (PWM) of the faster motor. Repeat this process until the motors are in sync. Define the maximum speed for both motors as RightHIGH and LeftHIGH respectively with the following assembly directives. Make sure these directives are added before RST_VECT and after .INCLUDE < m32u4def.inc >.

.EQU RightHIGH = 0x____ (Fill in with the value that you determined. It should be between 0 and 255). .EQU LeftHIGH = 0x____

With this, you will be able to use the terms RightHIGH and LeftHIGH instead of values that were determined in the exercise. For example, ldi r24, 0xFF would become ldi r24, LeftHIGH.

Find the Minimum Speed

Now that you have found the maximum speed, the next step is to find the minimum speed that will keep the motors synchronized and provide a safe margin above the stall speed for both. A motor will stall when there is insufficient power to the motor to overcome the internal friction of the gears and motor (i.e., nothing is moving). The motor is ON at this point and it is consuming power but there is no physical motion. This may damage the motor and should be avoided. By obtaining the minimum speed to get the motor moving, we can keep the motor ON and barely moving while the robot smoothly gets back on track. Make sure to find a speed that has the wheel moving at a reasonable pace. We do not need it to be barely moving but it should be distinguishable from the maximum speed. Feel free to go about 10 or 15 more than the lowest value that satisfies these conditions.

Using trial-and-error, determine the minimum speed for each motor. Specifically, slowly decrease the duty cycle (PWM value) until the minimum speed is reached with a margin of safety. If you pick a value where the motors are not turning, turn off the robot immediately to prevent damage. This should never happen as the AnalogWrite subroutine will default to a value of 0x50 if anything lower is inputted. If it seems like the value could go lower than 0x50 for your motors, please inform your lab instructor.

Next, run both motors at their minimum speed and note how the robot deviates from the line. Increase the speed of the slower motor. Repeat this process until the motors are in sync. We are not looking for just the minimum speed of each motor but the minimum speed for both to still move in a straight line. Define the minimum speed for both motors as RightLOW and LeftLOW. If you have the time and want your robot to move through the maze in a reasonable amount of time, the motors should be set to a value in between the maximum and minimum that is able to move in a straight line. This is optional as the minimum speed is enough to make it through the maze.

Once you have defined all of these values, Lab 2 is complete.

Lab 2 Deliverable(s)

|

All labs should represent your own work – DO NOT COPY. Submit your list file as defined below. Make sure that the code compiles without any errors. Do not forget to comment your code. Lab 2 Demonstration

|

Appendix A: Rules for Working with Subroutines

In the last lab I introduced three steps for writing a program for a load-store RISC based architecture.

- Load the data (lds),

- Do something (typically an arithmetic or logical instruction), and then…

- Store (sts) the result.

When working with subroutines an analogous set of steps applies.

- Load argument(s) into input registers (parameters) specified in the header of the subroutine. Following the gcc C++ calling convention, this would be register r24 if only one calling argument is specified (lds r24, myData).

- Call the Subroutine

- Do something with the return value(s) stored in the output register(s) specified in the header of the subroutine. Following the gcc C++ calling convention, this would be register r24 if a single byte value is returned. In most cases you will storing this return value(s) into SRAM data memory (sts myData, r24).

You call a subroutine using the rcall or call assembly instruction and return using the ret instruction. Here are a few rules to remember when writing your main program and subroutines.

- Your subroutine should always include a header block. As a minimum, the header must define the input arguments to the subroutine, the values returned, and what if any registers are modified by the subroutine.

- Always initialize variables and registers at the beginning of your program. Do not re-initialize variables or registers within a loop or a subroutine. For example, you only need to configure the port pins assigned to the switches once.

- Never jump into a subroutine. Use a call instruction to start executing code at the beginning of the subroutine.

- Never jump out of a subroutine. Your subroutine should contain a single return (ret) instruction as the last instruction.