Microcontroller Based Interface Design

Part 1

System Engineering Your Robot

Table of Contents

Introduction

In this post I am going to talk about the 3DoT Microcontroller Board and its integration with peripheral devices including sensors, actuators, and serial communications. A basic knowledge of programming in C++ is assumed.

Microcontroller Based Interface Design

Embedded Systems

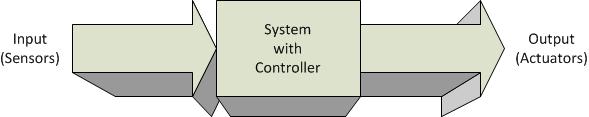

Engineers design systems. A system can be characterized by a box with an input and output. Typically the engineer is tasked to design the box with a given set of inputs and the desired output.

- When a controller “the brain” is part of the design solution, the design is known as an Embedded System.

- The controller may be implemented using an ASIC (Application Integrated Circuit), FPGA (Field Programmable Gate Array), or in most cases a Microcontroller. A combination of the above on a single IC, is known as a System on a Chip (SoC).

- For this discussion, the input device is by definition a Sensor, and the output device an Actuator.

In this post we look at the microcontroller based system design used by our robots. It is hoped that by looking at this specific example you will be able to apply the lessons learned to the design of other microcontroller-based systems.

Robot Microcontroller Based System Design

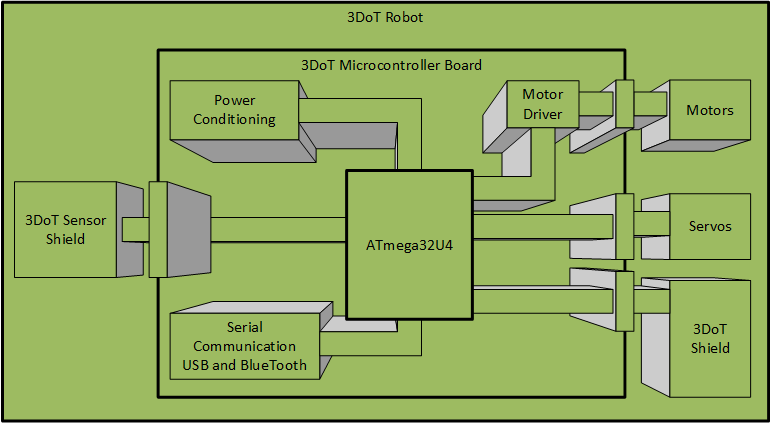

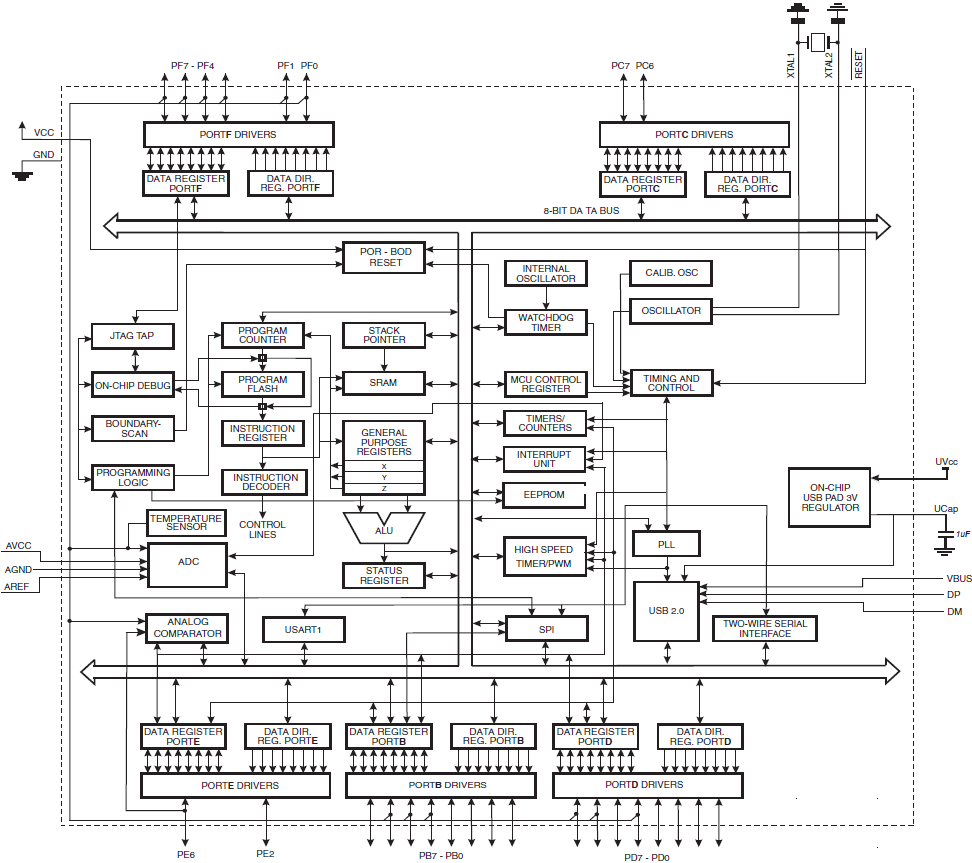

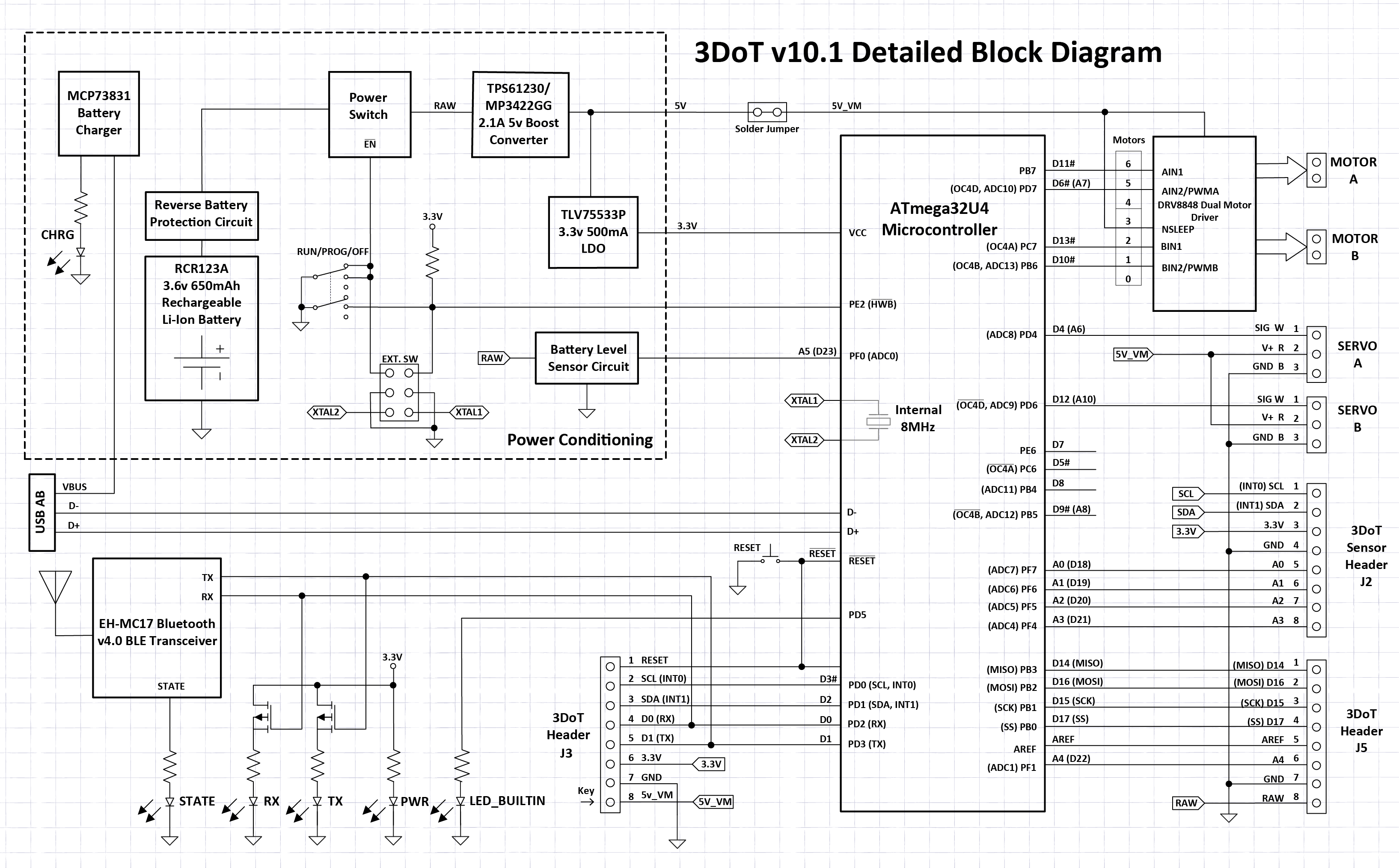

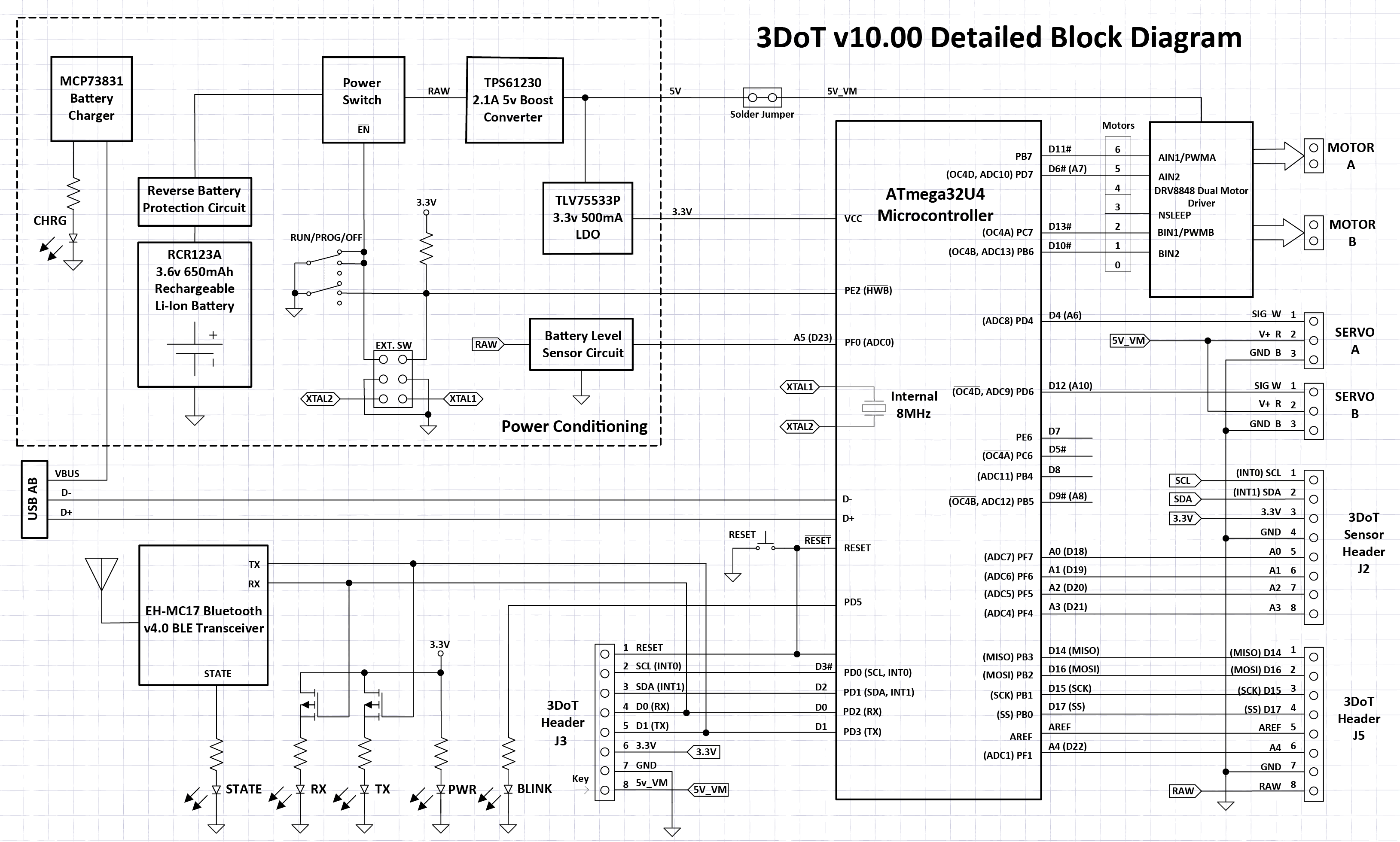

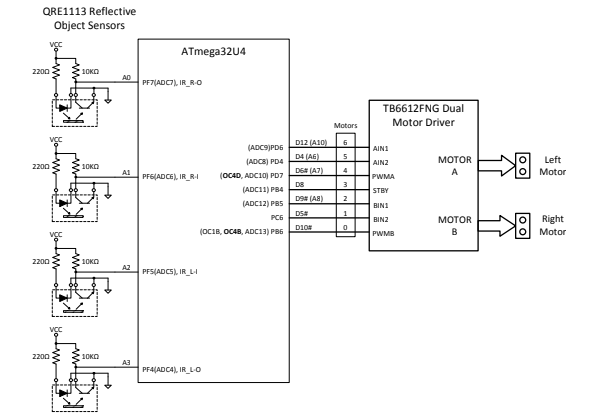

Figure 2.0 illustrates our robot design from a generic capabilities perspective. At the heart of our embedded system is an ATmega32U4 Microcontroller.

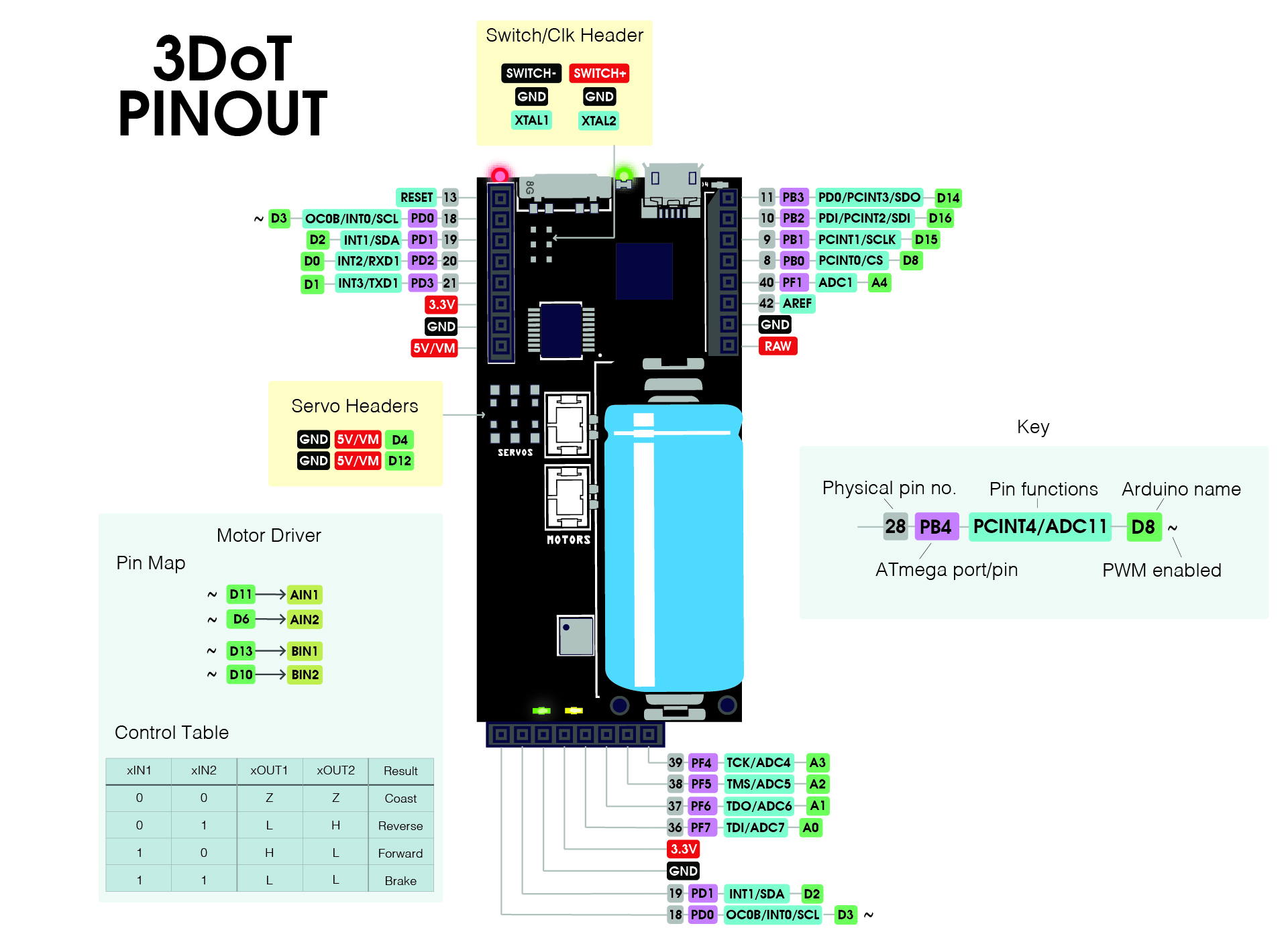

The ATmega32U4 is built into the Arduino compatible 3DoT (3D of Things) Board. Let’s take a closer look at the hardware and software built into the 3DoT board.

Hardware

The 3DoT board is a micro-footprint 3.5 x 7 cm all-in-one Arduino compatible microcontroller board, that integrates all the components needed to create a small autonomous, RC controlled, or telepresent robot.

- Microcontroller: At the heart of the 3DoT board is an Arduino Leonardo based microcontroller unit (ATmega32U4), featuring an 8 MIPS (Millions of Instructions Per Second) 2-stage pipelined AVR RISC processor.

- USB (Universal Serial Bus) serial communications circuitry allows you to upload your programs and download data.

- An FCC-certified BLE 5.0 module (optional) allows wireless communication with the ArxRobot Android/iPhone App and Arxterra control panel.

- Power Management: Power for the 3DoT board is provided by an RCR123A LiPo 650 mAh rechargeable battery with associated power protection, switching, and conditioning circuitry (3.3v and 5v). Plus, an integrated 3.7v Li-ion battery charger with battery level sensor circuit. You also have access to an external battery connector – for input voltages between 4 – 18 V.

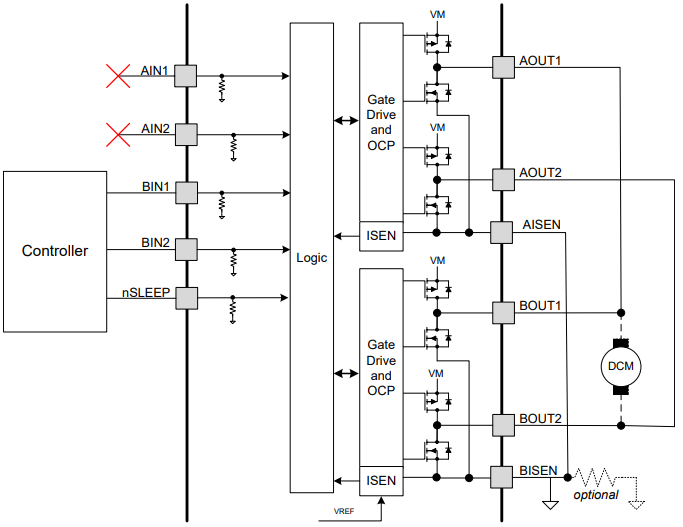

- Motors & Servos: To control your robot’s motors the 3DoT board includes a DRV8848 Dual Motor Driver. JST Connectors are provided for up to two (2) DC Motors and two (2) Micro or Ultra-Micro Servos.

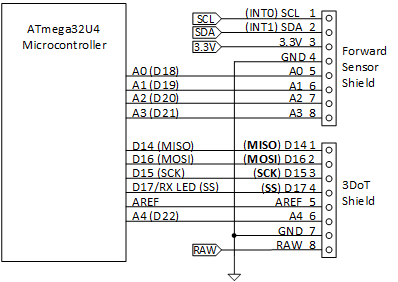

- Expansion: Customize your robot with 8-pin forward sensor and 16-pin 3DoT Shields, also known as daughter boards.

- 16-pin top female headers for shields – providing I/O, I²C, SPI, USART, 3.3 V and 5 V.

- The forward-facing 8-pin female header for sensor shields – providing 4 analog pins, I²C, and 3.3 V power – for sensor shields like infrared or metal-detecting shields. Great location for headlights, lasers, ultrasonics, etc.

- Programming switch: Three-position switch for easy programming

- No more double-tapping a button and rushing to program your board, or your robot trying to drive away while programming. Set the switch to PRG to program, RUN to execute your code.

Software

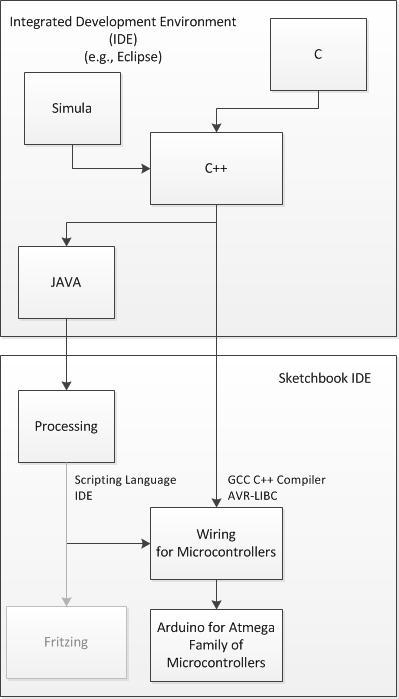

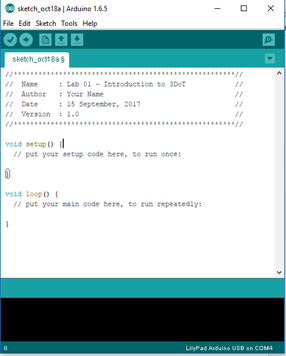

- Programs are written in the Arduino IDE (Integrated Development Environment).

- Pre-installed Arxterra 3DoT bootloader plus Robot3DoTBoard library – fully customizable for your robot

- Together this software suite running on the ATmega 32U4 microcontroller allows you to control a 2-wheel robot out-of-the-box using the FREE ArxRobot Android/iPhone App.

- If the robot can hold your phone, then you can remotely control your robot from anywhere with an internet connection from the Arxterra Control Panel.

Document Objective

The objective of this document is to teach you how to interface peripheral devices to a microcontroller based system. We first…

- Allocating the resource of our MCU (Micro-Controller Unit).

- Look at how sensors and actuators could be incorporated into this design

- Present the reference design as an example.

Allocating MCU Resources

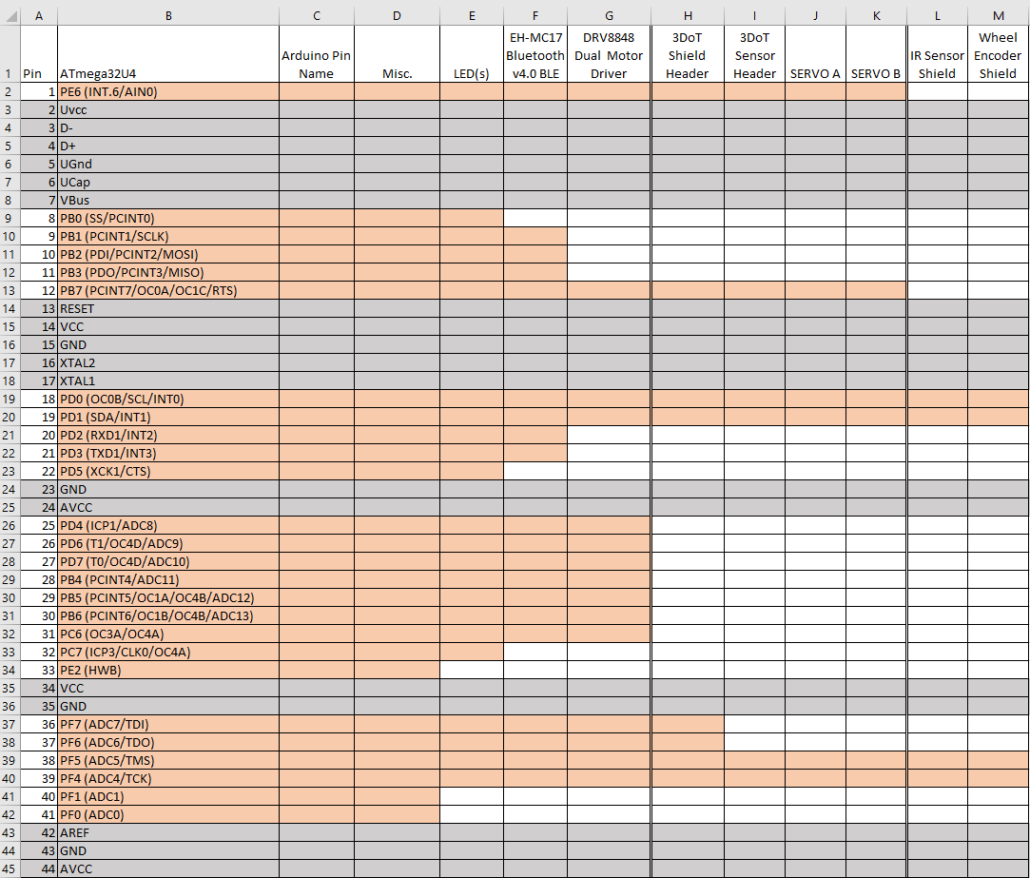

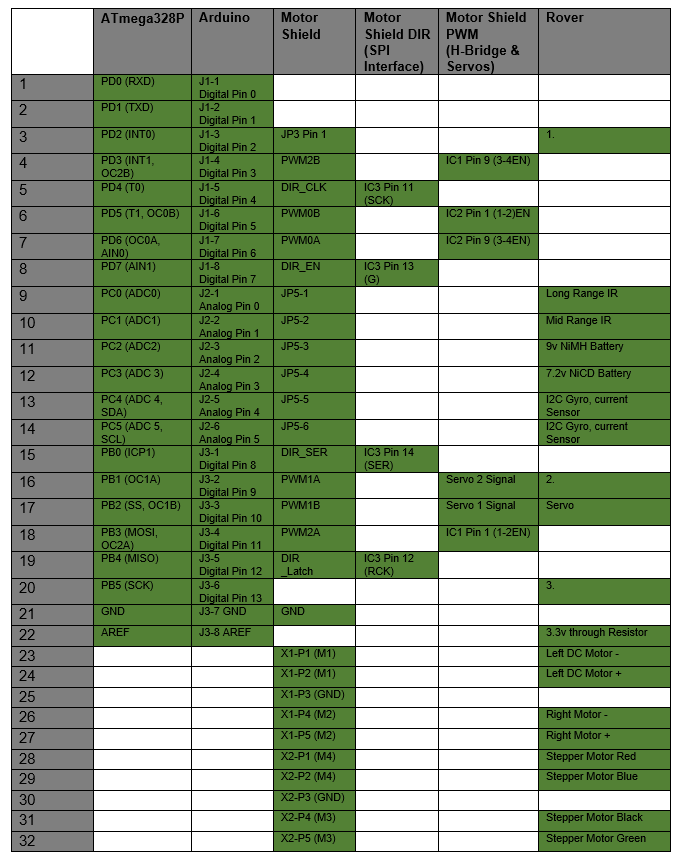

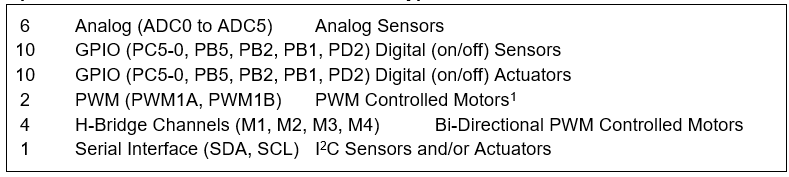

Our embedded system is comprised of a 3DoT Microcontroller Board. At the heart of the system is the ATmega32U4 microcontroller. The 3DoT board consumes some of the resources of the ATmega32U4 in exchange for extending the capabilities of the integrated system. Table 1 provides a mapping of these resources and ultimately the interface resources available to the sensors and actuators of your robot in columns G through K. Columns L and M show how the 16-pin 3DoT and 8-pin sensor headers can be used to add an IR sensor and wheel encoder shields.

ATmega32U4 I/O pins (columns A and B)

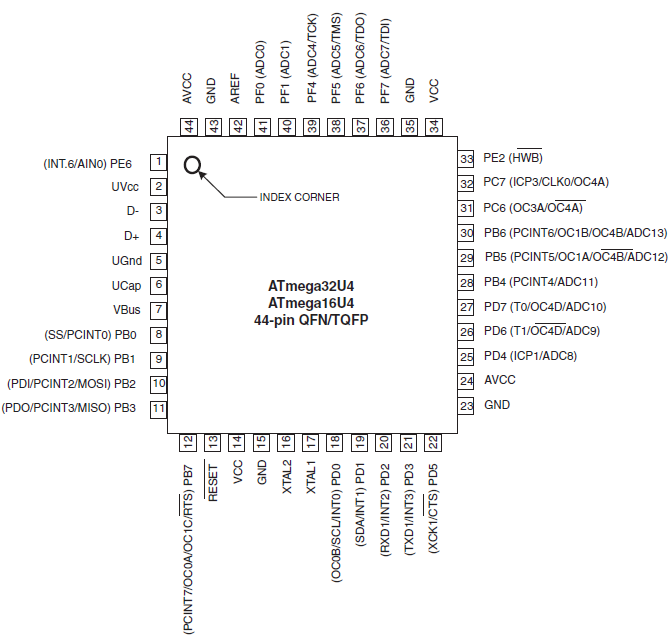

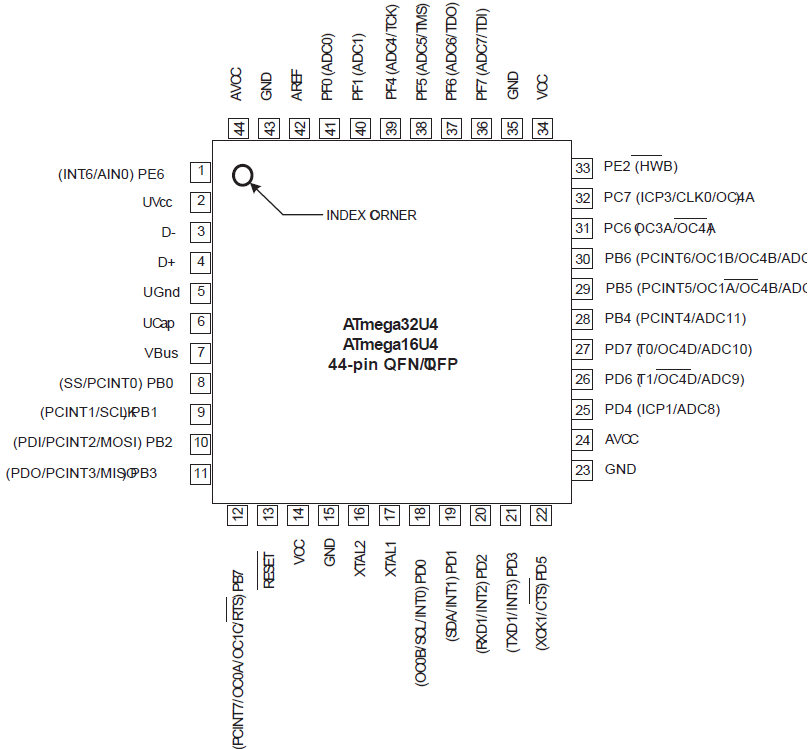

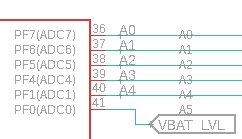

The ATmega32U4 comes in a 44-pin QFN (Quad Flat No-leads) and a TQFP (Thin Quad Flat Package). The arrangement of these pins around the QFN or TQFP IC is shown in Figure 3.0. Each pin is assigned both a number and a name.

Due to pin-out limitations of the IC package (QFN and TQFP), most I/O pins of the ATmega32U4 are multiplexed. Specifically, they can be programmed to provide different interfaces to the system. For example, pin 41 PF0 (ADC0) can be wired to a digital I/O device like a button or and LED. Conversely it could be wired to an analog input to measure a voltage output by an IR sensor.

Figure 3.0 ATmega32U4 Pin-out

Table 3.0 allows us to place the ATmega32U4 within the context of our design. Specifically, how are we going to wire up all the actuators and sensors to our microcontroller IC. We begin by adding each pin number and its name to columns 1 and 2 respectively.

As shown in Table 3.0 most but not all rows may be assigned as I/O pins. For example the VCC, GND, USB, XTAL (crystal) and reset pins are not available. These non-I/O pins appear as Gray rows in the table. What this means to the system designer instead of having 44 Multiplexed I/O pins you now only has twenty twenty-six (26). All 26 of these multiplexed pins may be used as digital I/O pins (PB7-0,PC7-6,PD7-0,PE6 and PE2, PF7-4 and PF1-0). These I/O pins appear as Orange rows in the table. When one of these I/O pins is consumed, the remainder of the row is White.

Arduino I/O Pins (column C)

The Arduino was designed as a tool for introducing students to embedded systems. To a student unfamiliar with peripheral subsystems like GPIO (General Purpose Input Output) ports and an ADC (Analog to Digital Converter), the names assigned to the pins of the ATmega32U4 can be intimidating. Instead, the creators of the Arduino realized that these complex electronic systems could be introduced in a step-by-step fashion by starting with the function to be performed. Put another way, students new to engineering are more interested in “what” the pin can do, rather than “how” it does it. For this reason, the Arduino creators renamed the pins by function. For example, pins that work with digital binary inputs and outputs start with the letter D and are numbered sequentially (D0 to D23). Pins that work with Analog inputs start with the letter A and are again numbered sequentially (A0 – A10). Along with these “functional” names came simple program instructions, like digitalRead(D0) and digitalWrite(D1) for digital signals and analogRead(A0) for analog inputs.

The 3DoT instruction set builds on this functional vs. technical philosophy by allowing you to control your robot’s movements with a single move() instruction.

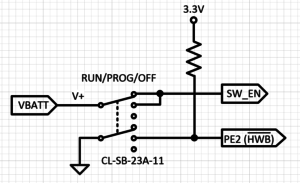

Table 1.0 Column C shows the Arduino names assigned to each ATmega32U4 I/O pin (orange rows). Specifically, digital pins D0 to D23 and analog inputs A0 to A11. The single exception is pin 33 PE2 (HWB) which is set to 0 (wired to ground) for Arduino ATmega32U4 microcontroller boards. The 3DoT board wires this pin to its ON/PROG/RUN switch. This change was made to make the 3DoT board easier to program than its Arduino cousins.

3DoT

To build an Arduino-based telerobotic Robot, in addition to the microcontroller board you would need a battery, charger, Bluetooth shield, motor shield, and a breadboard containing miscellaneous parts. The 3DoT board integrates all these components on a single 3.5 cm x 7 cm board. As a part of your robot, all these built-in functions consume microcontroller pin resources as defined in columns D, E, and F. In most instances, once used these resources are no longer available to implement other functions.

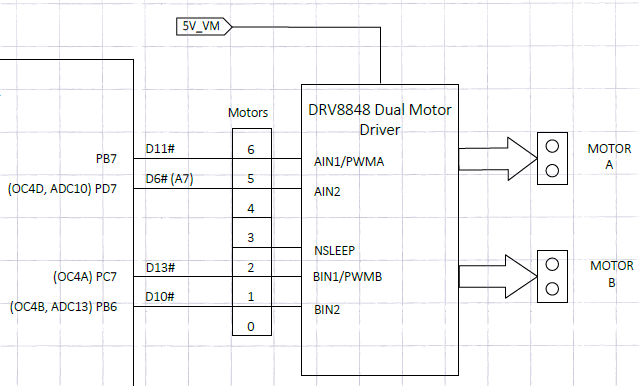

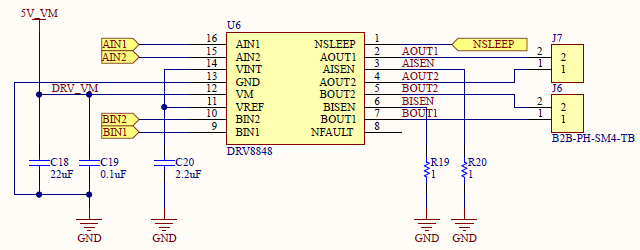

DRV8848 Motor Driver (column F)

Figure 3.1 shows how the DRV8848 Dual Motor Driver is wired to a typical MCU. Looking at Table 3.0 column F we see that our motor driver is wired to pins pin 25 to 31 of the ATmega32U4 MCU. Also notice that after this column these rows are colored white indicating that the resources are no longer available to the system.

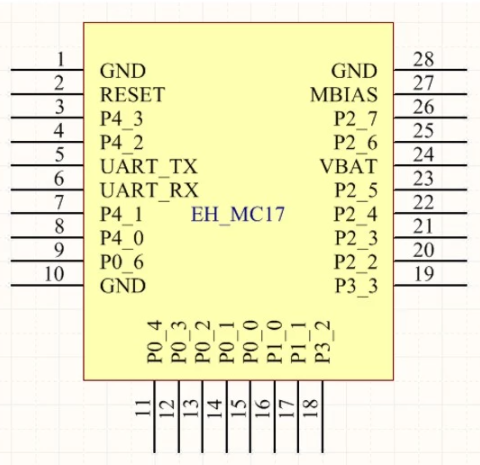

EH-MC17 Bluetooth Module (column E)

The EH-MC17 (Figure 7) sends and receives data to the USART peripheral subsystem of the MCU. The USART serial interface only needs 2 wires (RX and TX) to physically implement this interface. As shown in column B of Table 3.0 the TX1 and RX1 pins are internally routed from the USART peripheral subsystem to pins 20 and 21 of the ATmega32U4 IC. A few additional things are of note here.

- To add this Bluetooth module we need to sacrifice Arduino digital pins D0 and D1.

- Unlike the motor driver, these two rows do not immediately show these pin resources as being consumed. Specifically, they are brought out to the 3DoT Shield Header J1 (column G). The reason is simple. The addition of the HM-11 module to the 3DoT board is optional. If the robot designer chooses to not solder the HM-11 module to the bottom of the 3DoT board, then they are free to use these pins to implement a different serial communication standard (e.g. XBee, WiFi) or for a fully autonomous robot, Arduino digital pins Do and D1 are again available.

- It is curious to note that the MCU d0/RX1 pin is wired to the HM-11 TX pin and that the MCU d1/TX1 pin is wired to the HM-11 RX pin. Confusing isn’t it and also a very common wiring error. You can think of it this way; one person’s output is another person’s input.

LEDs, Switch, and Battery Level Circuit (column D)

Beyond the Motor Driver (Table 3.0 column F) and the HM-11 Bluetooth module (Table 3.0 column E) the 3DoT Board uses a few additional MCU pin resources for LEDs (Light Emitting Diodes), the ON/PROG/OFF Switch, and the Battery Level circuit. Let’s take a closer look at column D of Figure 3.0.

LEDs

RX LED 4 and TX LED 6 are wired to pin 8 (Arduino pin D17/RXLED) and pin 22 (Arduino pin TXLED). The famous Arduino on-board LED typically uses by the BLINK script, is wired to pin Port D bit 5, not Arduino digital pin 13.

DP3T OFF/PROG/RUN Switch

The Arduino Leonardo and in fact all Arduino 32U4 based boards have a peculiar problem as a result of the ATmega32U4 incorporating the USB peripheral system as part of the MCU. On “traditional” Arduino boards, like the UNO, a separate ATmega MCU is dedicated to implementing the USB interface. As a result, ATmega32U4 based Arduinos must juggle between the user uploading programs and acting as a USB port for the user’s program. You need the first function when you are programming and the second if you want your program to interface to the computer. For example, if you want your program to output to the Arduino IDE’s Serial Monitor. The Arduino developers solved this problem by having the Arduino upon reset look for the user to upload a program and after a few seconds, if the user does not start the upload process then it switches to running the currently loaded program. In many cases, the user can not initiate this upload process fast enough for the Arduino’s liking resulting in the “double-tap” solution which only works part of the time. To solve this problem 3DoT developers implemented a different solution. The 3DoT board has a DP3T (Double Pole Triple Throw) Switch. As the name implies this switch has three positions (OFF/PROG/RUN). Now the ATmega32U4 bootloader, by interrogating pin Pin 33 PE2 (HWB), can directly determine if you want to upload a program (PROG) to the ATmega32U4 or RUN your program.

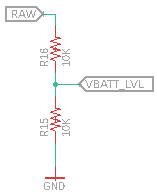

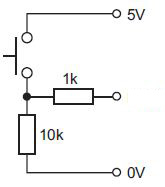

Battery Level Circuit

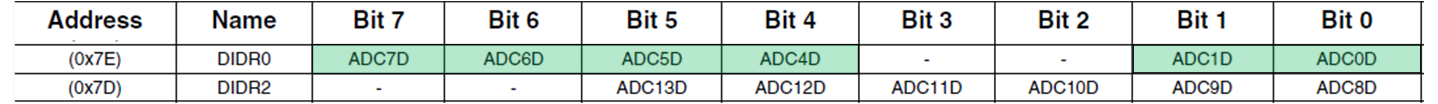

Going back to Table 3.0 column D row/pin 41 we see VBATT_LVL. Which is short for “Voltage Battery Level.” As the name implies the function of this pin is to read the current battery voltage. A simple voltage divider is all it takes to implement the battery level circuit, with the top of the voltage divider wired to the positive lead of the battery and the center of the divider wired to pin 41. The output of this circuit is an analog voltage typically between 2.1 and 1.2 volts. Going back to pin 41 we see that the ATmega32U4 names this pin PF0 (ADC0), while the Arduino names the pin A5/D23. The key here is that the pin can be both an analog input or digital input or output. So to implement this function, we will be using the Analog to Digital (ADC) peripheral subsystem of the ATmega32U4 and not the General Purpose I/O (GPIO) port used for digital inputs and outputs.

Robot

In this section we are going to look at the MCU resources available for customizing your robot. As already mentioned the 3DoT board directly supports a robot with two (2) DC motors and two (2) micro-servos. The DC motors are controlled by the TB6612FNG motor driver IC whose pins have already been allocated. The micro-servos have their own dedicated connector J7 (Figure 4.1), and wire directly to the ATmega32U4 through limiting resistors. The limiting resistors protect the MCU from damage in the event of an accidental short for the V7 boards.

Customization of your robot is afforded by three 8-pin connectors J1, J2, and J3. Daughter boards that plug into connectors J1 and J2 will be called “3DoT Shields.” Daughter boards that plug into connector J3 will be called “3DoT Sensor Shields.”

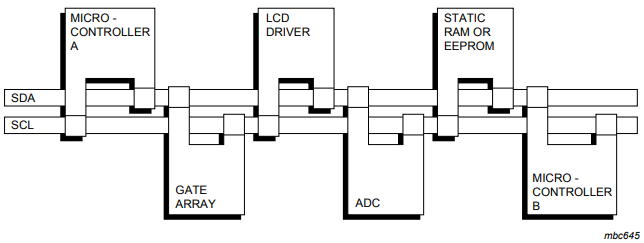

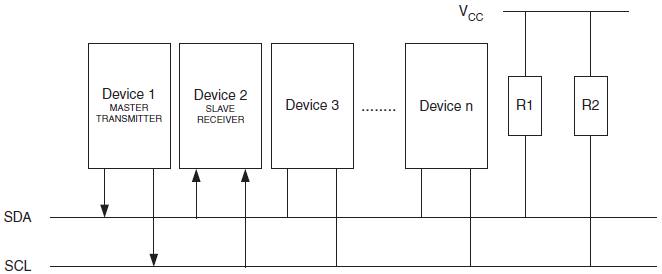

3DoT Shields

Connectors J1 and J2 are located on the top of the board in a fashion similar to the Arduino UNO, and like the UNO can support one or more stackable 3DoT Shields. This is especially true of the 3DoT board, whose J1 and J2 connectors support three (3) different serial communication protocols: I2C, SPI, and USART. To take this to the extreme, you could theoretically stack 127 I2C shields without even mentioning SPI and USART shields. In addition, the J2 pins 5 and 6 support one (1) Analog signal with an associated reference voltage (AREF). To avoid conflicts with 3DoT Sensor Shield (connectors J3) on the bottom of the board, do not wire digital I/O to I2C pins SDA and SDL (D2, D3). In addition, if your robot comes with the HM-11 Bluetooth module do not wire digital I/O to USART pins RX and TX (D0, D1).

As we have seen, the multiplexing of the I/O pins immediately forces the system engineer to make trade-offs in the design of their shields. For example, If your making a fully autonomous robot (no HM-11 Bluetooth module), you do not need the single analog input A4 on connector J2, and are your forward 3DoT sensor shield is not using I2C pins SDA and SCL, then your 3DoT Shield could have a maximum of nine (9) digital I/O signals. In most designs all those conditions will not be met, and you will have to trade-off one MCU peripheral subsystem (see Figure 4.2) against another (GPIO Port, A/D Converter, I2C, SPI, and USART).

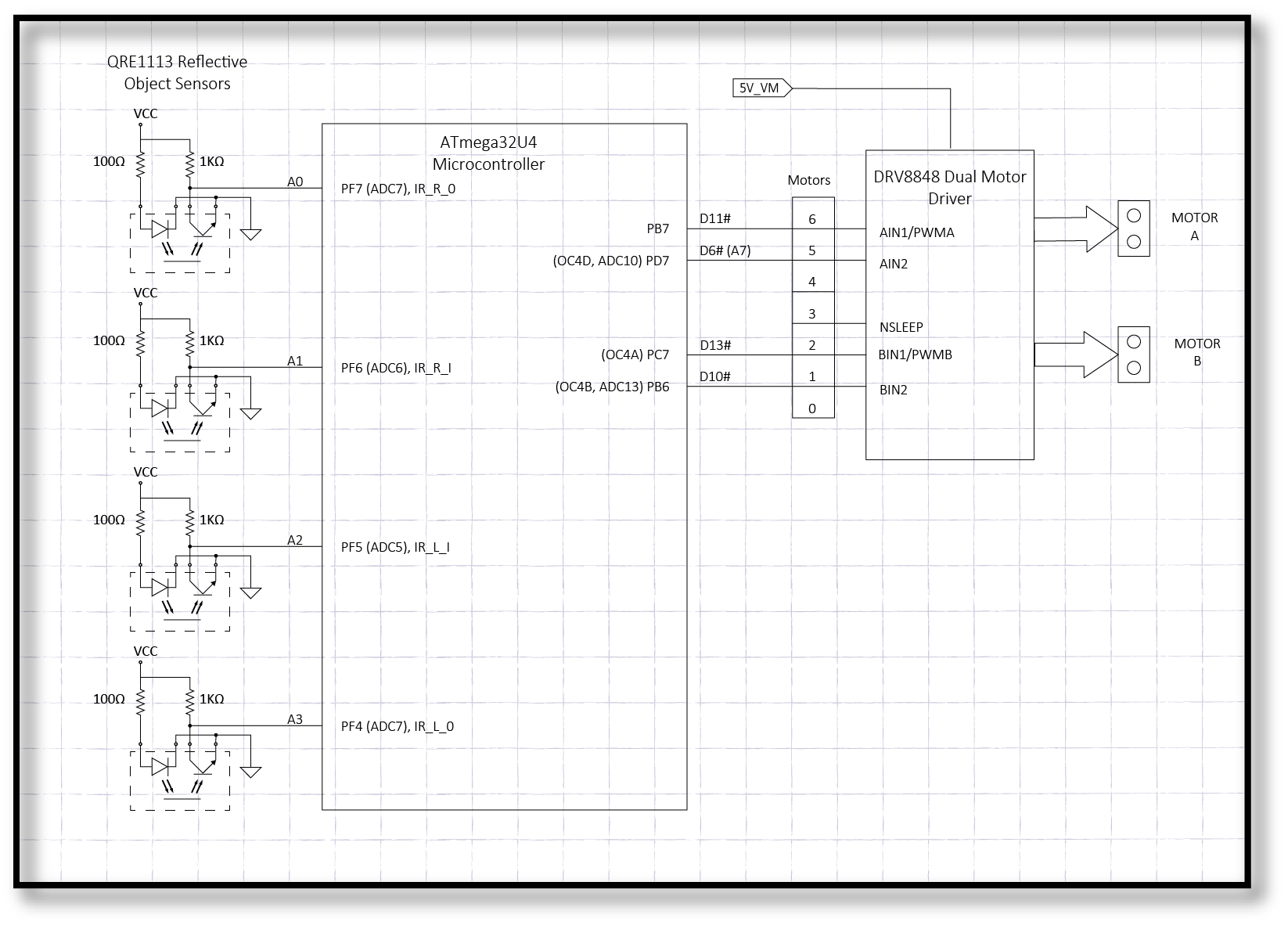

3DoT Sensor Shields

Connector J3 is an 8-pin connector located on the front bottom of the board. This connector is designed for “sensor shields” located on the front of the robot. Typical applications would include line following robots. With sensors in mind, the connector includes four analog inputs (A0 to A3) and support for the I2C serial communication protocol (SCL, SDA). For sensor shields requiring digital I/O lines it is recommended that one or more of the analog pins (D18 to D21) be utilized. As mentioned in the previous paragraph, to avoid conflicts with 3DoT Shields (connectors J1 and J2) on the top of the board, do not wire digital I/O to the I2C pins (D2, D3).

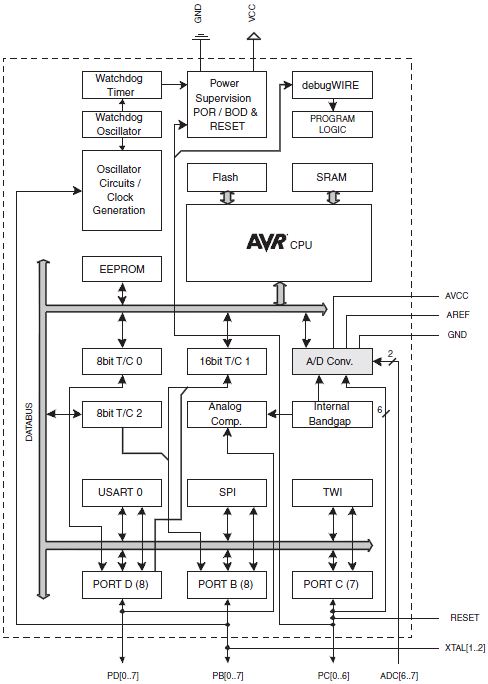

Figure 4.2 ATmega328P Block Diagram

| In the future when I talk about Arduino peripheral subsystems, as I did in the previous paragraph, I will show the ATmega328P Block Diagram in place of the ATmega32U4 processor used on the 3DoT board. The ATmega328P microcontroller was used on the original Arduino UNO and is far simpler than the ATmega32U4. Therefore, I can make the same points using the ATmega328P, without adding unnecessary complexity to the topic under discussion. |

Next Step

Applying what you learned here, in “Microcontroller Based Interface” Design Part 2 we will look at how sensors and actuators can be incorporated into your robot.

Lecture 2 – Robot Sensors and Actuators

System Engineering Your Robot

Table of Contents

Interfacing Sensors and Actuators

Reading

- Microcontroller Interfacing Circuits by Revolution Education Ltd.

- For help with a specific interface, or just to look for ideas, visit the related Arduino Forum.

- A detailed discussion of Pulse Width Modulation is beyond the scope of the document. We will be covering PWM in more detail later in the semester. For now you may want to read this nicely illustrated article: Working with Atmel AVR Microcontroller Basic Pulse Width Modulation (PWM) Peripheral

Introduction

In Part 1 we developed a Resource Map for our rover (Table 1.0). In this section we look at how sensors and actuators could be incorporated into the design of our rover. Specifically, we will map our sensors and actuators to our I/O pins.

Table 1.0 Rover Resource Summary

Table 1.0 Rover Resource Summary

While Part 1 of this System Interface Design discussion was from the perspective of the ATmega328P; Part 2 will be presented from the perspective of the I/O device.

A detailed discussion of the ATmega328P subsystems, along with the software required to run them, is outside the scope of this document and will be covered in future lectures (hopefully).

Sensors

Digital Interface

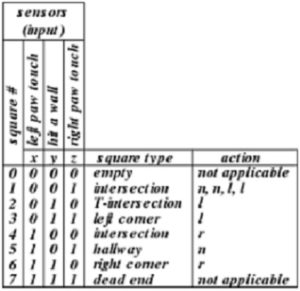

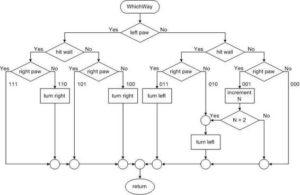

Design Example: DIP Switch

A DIP switch is an example of a digital sensor which you could add to your design. For example to allow your robot to discover its mode of operation upon reset.

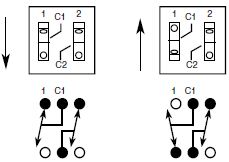

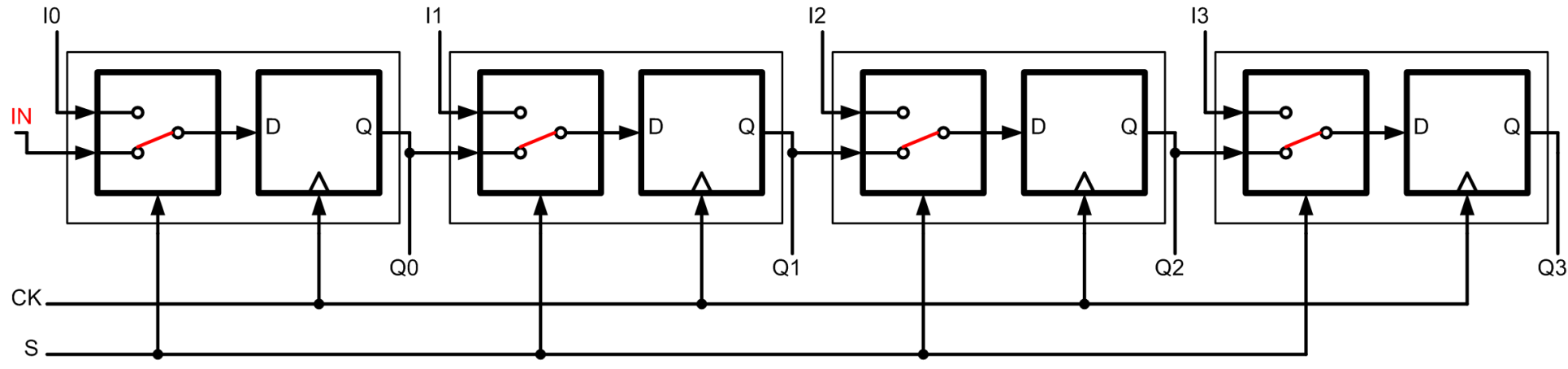

If you are not planning to implement the SPI interface and you do not have any Analog inputs, then working from the schematic of the device and the interface matrix, I would recommend wiring the four (4) Single Pole Double Throw (SPDT) DIP switch, shown in 1.0, to GPIO Pins (PF1, PB1, PB3, PB2, and PB1) of the ATmega32U4 or in Arduino parlance digital pins D22, D14, D16, D15. Button resources (Figure 2.1) would be allocated in a similar fashion.

Figure 1.0 Two SPDT DIP Switches

Figure 1.1 SPST Button Schematic

Parallel Interface

For our robots we are limited to no more than 9 digital inputs (see Section “3DoT Shields” in Part 1 of this series). Consequently, while wiring 1 button to the ATmega32U4 is not a problem, wiring a parallel device with a large word size is not directly possible. For example an 8-bit A/D converter would consume 89% of our available I/O resources. A much better solution would be an A/D converter that supports the I2C interface. Here we could get a 12-bit A/D converter with no loss in pin count.

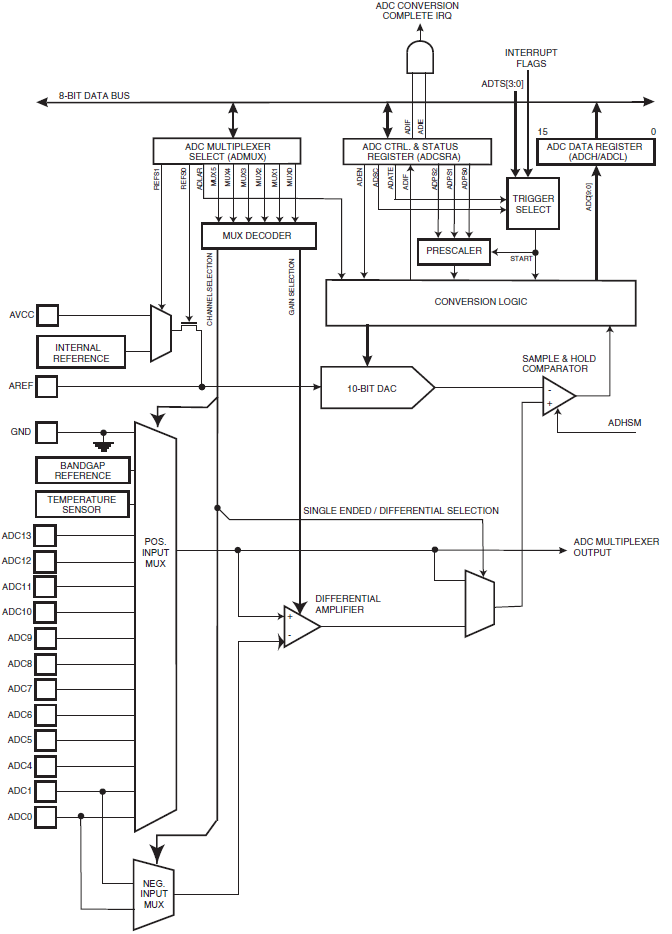

Analog Interface

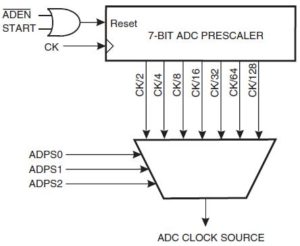

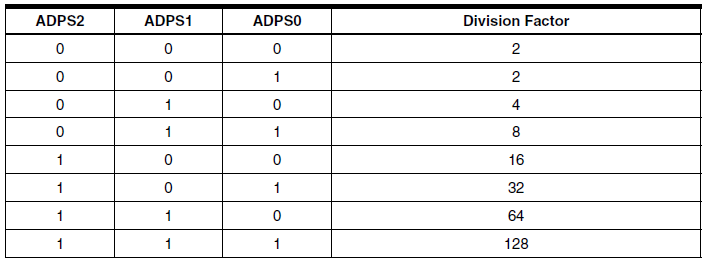

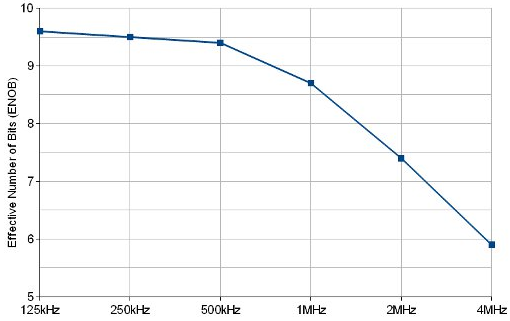

Many sensors output an analog voltage, including our IR sensors. The ATmega32U4 has a single ADC subsystem whose input can come from up to 6 multiplexed channels (ADC0 to ADC5). The reference design preserves all 6 of these analog channels. From a practical standpoint, the term multiplexed means that although our design can support up to 6 analog sensors, we can only read one at a time.

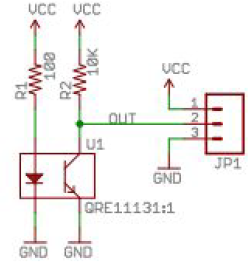

Design Example

As with all devices, start with a schematic

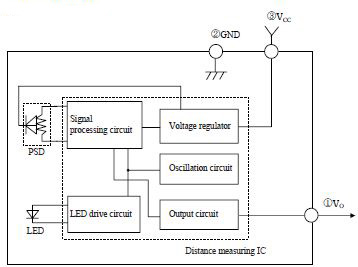

Figure 2.3 Medium Range IR Sensor Block Diagram

From the block diagram it is seen that the interface of an IR sensor is a single analog wire. In the absence of any other resource requirements, we are free to wire this sensor output to any one of our six analog inputs (ADC0 to ADC5).

Voltage Range and Electromagnetic Interference (EMI)

When working with any analog interface you should be sensitive to the output swing of the analog signal and to the introduction of noise.

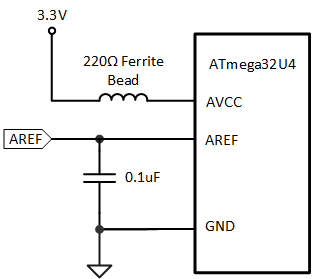

For our medium range IR sensor, the Voltage Output peaks at around 3.1 V. That means to maximize our resolution we will want to use an external voltage reference of 3.3V. The full scale reading of the ADC can be set to the AVCC (5 v), AREF, or an internal 1.1v reference voltage. So in this case we will want to wire a 3.3v reference source to AREF. In a future lecture you will also find we need to place a limiting resistor between the our reference source and AREF.

Noise is almost always a concern when working with an analog signal. For our IR sensor the data sheet recommends a 10 uF capacitor be placed as closely as possible to the sensor. In addition, analog signals are often sent over a twisted and shielded cable.

Actuators

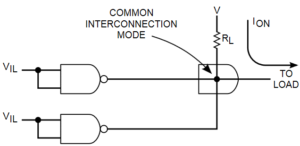

Digital Interface

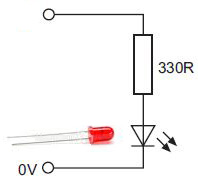

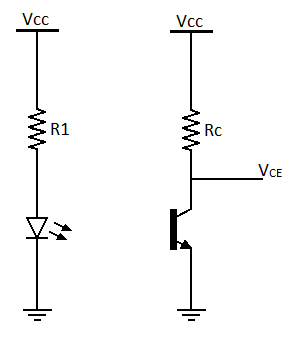

All ten available General Purpose I/O (GPIO) pins may be configured as outputs. The output circuit of the ATmega328 can sink or source a respectable 20 mA. This means that the ATmega328P can directly turn on/off LED indicators, without the need for an external driver (you will still need a limiting resistor).

Figure 3.0 Diode Circuit

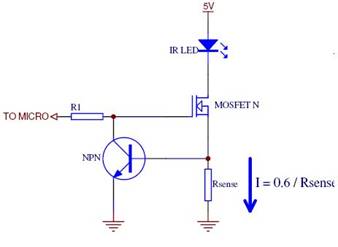

Another, digital actuator is our 650nm 1mW 8x13mm Laser Module. Once again before you purchase a device, make sure you have a datasheet. In the case of an laser, you need to know if it includes a current source, in which case you only need to turn the laser on/off, Otherwise, you will need to design in your own current source..

Figure 3.1 Laser Diode constant Current Circuit (source: Sparkfun Forum)

Motor and Pulse Width Modulation (PWM ) Interface

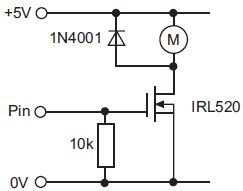

Motor On/Off

Change Motor Direction

Change the Speed of a Motor

A simple variable resistor is all you need if you want to control the speed of a DC motor manually. To control the speed of a DC motor with a microcontroller you will use one of our six PWM channels (e.g., PWM1A, PWM1B).

Figure 3.4 A simple method to generate the PWM pulse train corresponding to a given signal is the intersective PWM: the signal (here the red sinewave) is compared with a sawtooth waveform (blue). When the latter is less than the former, the PWM signal (magenta) is in high state (1). Otherwise it is in the low state (0).: Wikipedia

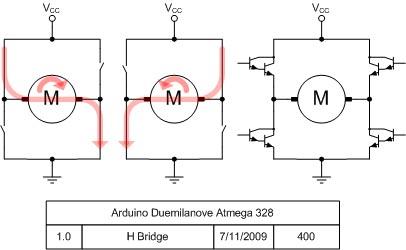

All the Above

If you want to turn your DC motor on/off, change direction, and control the speed of the motor you will need two (2) GPIO pins to configure the H-Bridge and a single PWM channel to control the speed. Without the Adafruit motor shield, If you wanted to control 4 DC motors (or 2 DC motors and a Bi-polar stepper motor) you would need eight (8) GPIO pins plus 4 PWM channels. With the motor shield we only lost 4 GPIO pins – we still need 4 PWM channels.

Attaching a DC motor to the Adafruit motor shield is as simple as wiring your DC motor to one of the four (4) Motor control connector pairs.

Servos

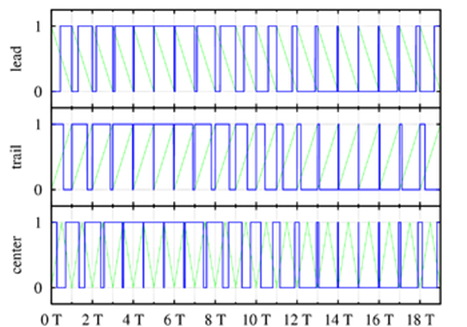

Reprinted from : Microcontroller Interfacing Circuits by Revolution Education Ltd.

A typical servo has just three connection wires, normally red, black and white (or yellow). The red wire is the 5V supply, the black wire is the 0V supply, and the white (or yellow) wire is for the positioning signal. The positioning signal is a pulse between 0.75 and 2.25 milliseconds (ms) long, repeated about every 18 ms (so there are roughly 50 pulses per second). With a 0.75ms pulse the servo moves to one end of its range, and with a 2.25ms pulse the servo moves to the other. Therefore, with a 1.5 ms pulse, the servo will move to the central position. If the pulses are stopped the servo will move freely to any position. Unfortunately servos require a large current (up to 1A) and also introduce a large amount of noise on the power rail. Therefore as with all motors, the servo should be powered from a separate power supply. Remember that when using two power supplies the two ground rails must be joined to provide a common reference point.

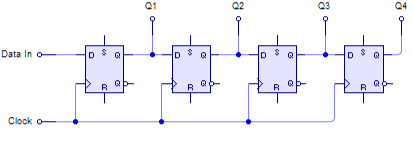

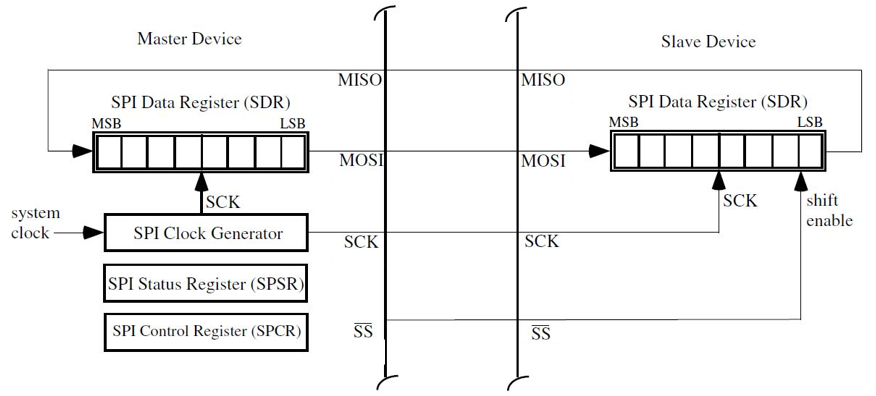

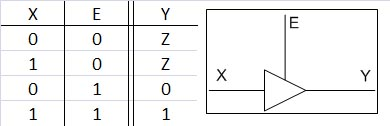

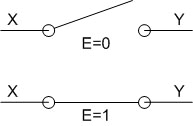

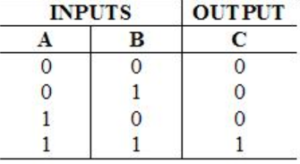

Serial Interface

The ATmega328P supports three serial interface protocols: Universal Asynchronous Receiver/Transmitter (USART), Serial Peripheral Interface (SPI), and Inter-Integrated Circuit (I2C). All three support two-way communications. This means that all three serial subsystems of the ATmega328P can work as easily with actuators as sensors (see Section 2.1) which implement one or more of these interface types.

Universal Asynchronous Receiver/Transmitter (USART)

For the purposes of this study, the USART will be reserved for communications between the rover and the PC. As we learned in Part 1, the USART subsystem uses two IC pins (TXD and RXD).

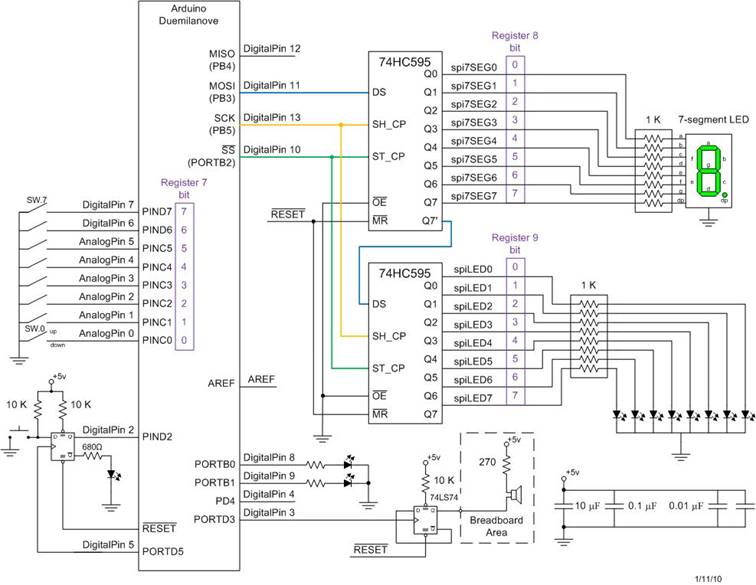

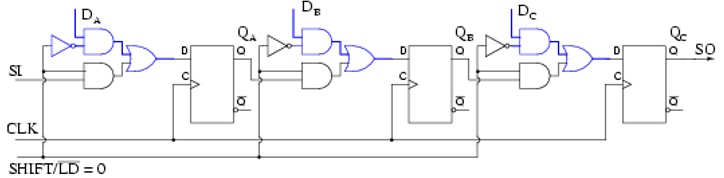

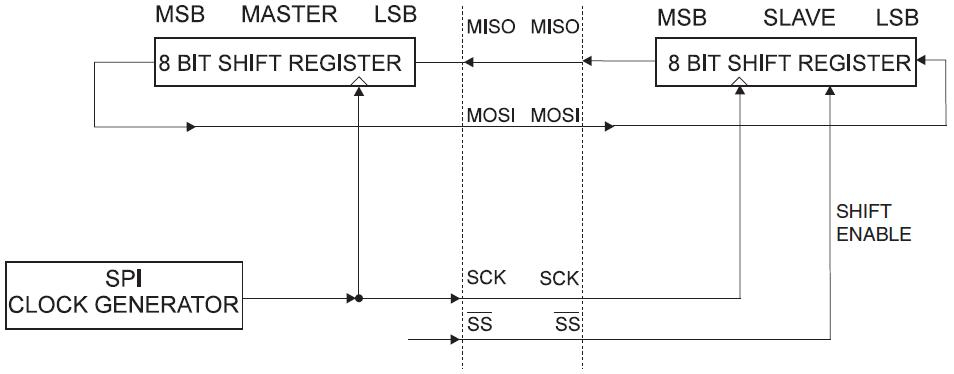

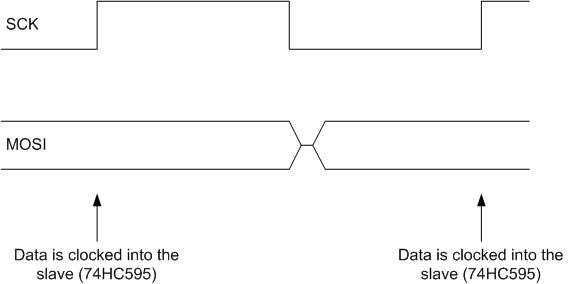

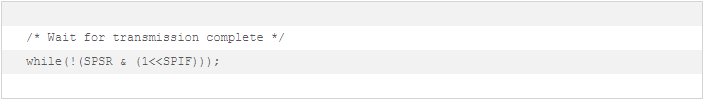

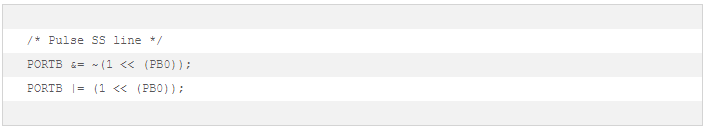

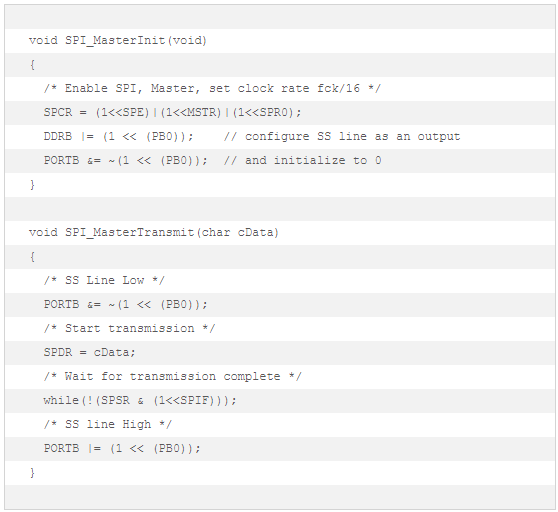

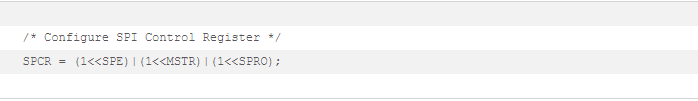

Serial Peripheral Interface (SPI)

The SPI Subsystem of the ATmega328P requires four pins to implement 2-way serial communications (SCK, MISO, MOSI, SS). These lines are are wired to pins PB5 (SCK/PCINT5), PB4 (MISO/PCINT4), PB3 (MOSI/OC2A/PCINT3), and PB2 (SS/OC1B/PCINT2). Of interest here are Output Compare signals OC2A and OC1B. These signals are from the 8-bit Timer 2 and 16-bit Timer 1 subsystems. Both timer subsystems are used by the Adafruit motor shield to generate Pulse Width Modulated signals PWM2A and PWM1B. Pulse Width Modulation is critical for controlling the speed of DC motors (PWM2A) and setting the angle of a servo (PWM1B). Consequently, Adafruit implemented their SPI interface with General Purpose I/O (GPIO) ports and software. In this way they were able to maximize the number of PWM signals available to the shield, while sacrificing the SPI subsystem of the ATmega328P.

So what if you are working with a peripheral device that implements the SPI serial communications protocol? First, you can follow the Adafruit path and implement your SPI interface in software. Second, the SPI subsystem can be recovered at the cost of some functionality or the time sharing of shared resources. An example of the last case would be to communicate with your SPI device only when the shared motor control signal was not required (motor is off).

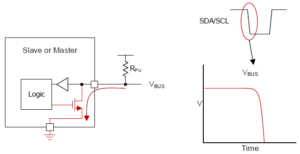

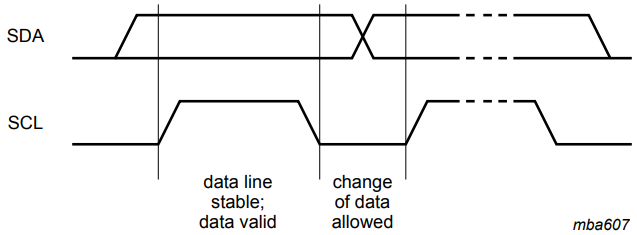

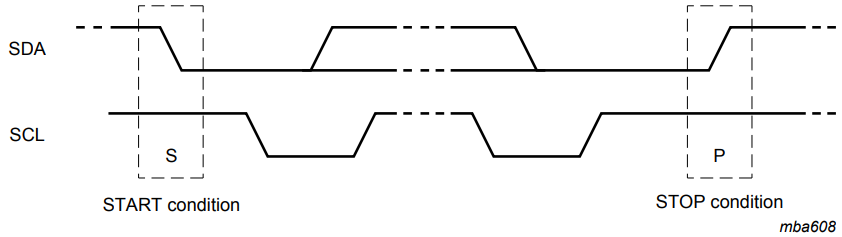

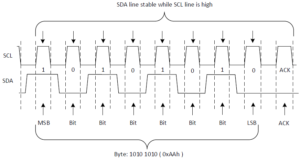

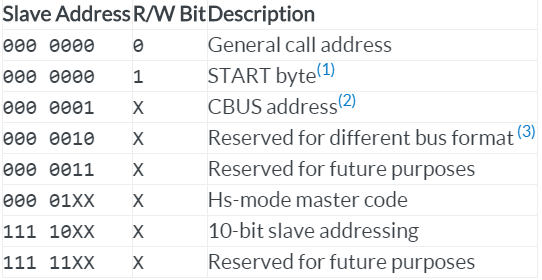

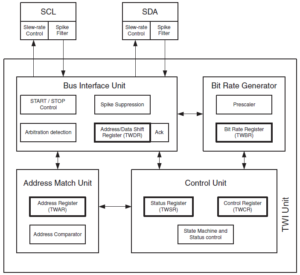

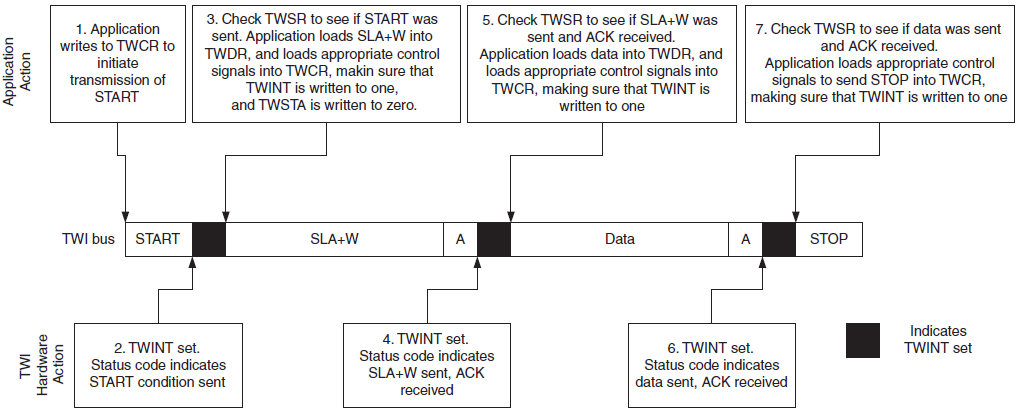

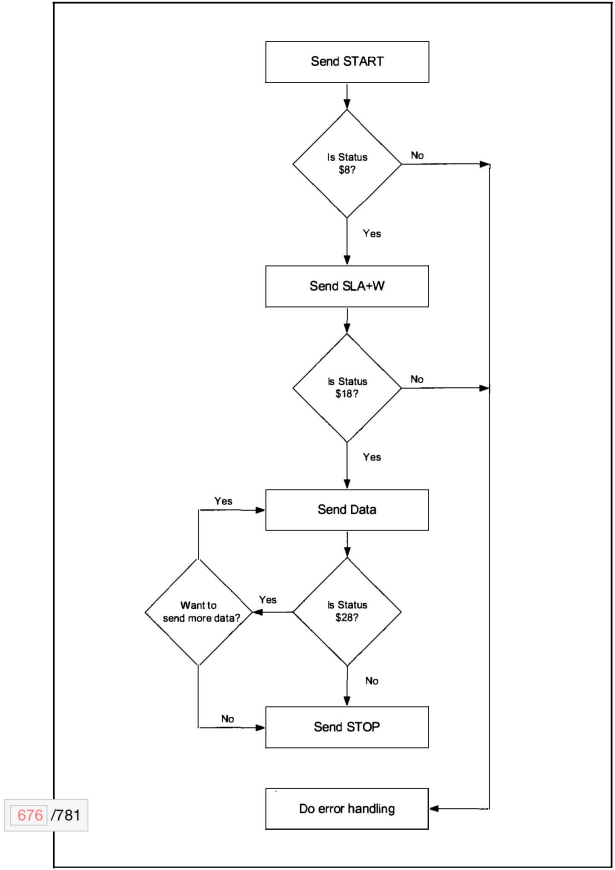

Inter-Integrated Circuit (I2C)

The I2C or TWI in Atmel speak, is a serial communications protocol with similar functionality to the SPI communications protocol. However, unlike the SPI which requires 4 pins to implement two-way communications, the I2C needs only two pins (SDA, SCL). The trade-off here is in the added complexity of the I2C interface. Today many intelligent sensors and actuators support both the I2C and SPI interface. This is the case with our L3G4200D 3-Axis Gyro Carrier with Voltage Regulator. As illustrated in Table 1.0 , the pins of the ATmega328P I2C subsystem are available for our sensors and actuators.

It should be noted that the I2C interface supports up to 128 devices without the need for any additional I/O pins.

Recovering I/O Resources

TBS

Rover Example

For our Rover we have the following Sensors and Actuators.

Sensors

I2C serial interface communicating with 3-Axis Gyroscope

I2C serial interface communicating with Current Sensor (optional)

I2C Arduino Nano (optional)

Analog input from Mid Range IR

Analog input from Long Range IR

Analog input from RC Circuit to 7.2V NiCD Battery – Dirty Power

Analog input from RC Circuit to 9V NiMH Battery – Clean Digital

Analog input from RC Circuit to 9V NiMH Battery – Camera

Four (4) Digital inputs from two (2) Shaft Encoders. Assumes full resolution of quadrature shaft encoders.

Actuators

Two (2) PWM outputs to H-Bridges controlling bipolar Stepper Motor – Adafruit Motorshield

Two (2) PWM outputs to H-Bridge controlling two DC Motors – Adafruit Motorshield

One PWM output to Servo – Adafruit Motorshield

One Digital output thru a Transistor circuit to turn the Laser on/off

One Digital output thru a Transistor circuit to turn the Camera on/off

(One or more Digital outputs to address bits of a 4051 Analog MUX for camera battery)

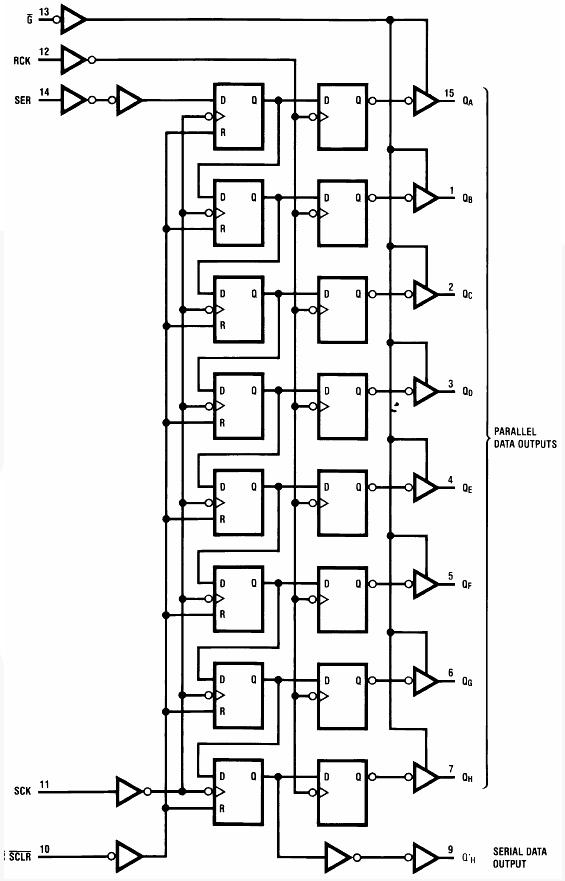

For our example we begin by allocating resources interfaced to ATmega328P peripheral subsystems requiring the use of only one set of pins. In this case the I2C serial interface. Looking at the matrix we see that this first step removes two Analog inputs leaving us with four (4). We need five (5) Analog Inputs so we are already in trouble. We will leave the sensors and actuators wired to the GPIO peripheral subsystem to the end. This is because these are the simplest to assign.The PWM channels are output from the Adafruit Motor Shield and so easily assigned. Once again we have very few options with respect to which pins can be used. We are now left with 4 Digital Input and 2 Digital Output pins to be connected to the GPIO peripheral subsystem of the ATmega328P. So we need to find 6 (4 inputs + 2 outputs) GPIO pins. Looking at the matrix we see that we have 3 GPIO pins left. So we are three (3) I/O pins short. How we find the 1 analog and 3 GPIO pins is left up to you. Hint: Look-up 4051, 74HCT595, and parallel shift registers like the 74HC166, 74HC194, and CD4014.

Rover with Arduino Nano Example

In this design example to the chassis mounted Arduino Uno we add a Arduino Nano to the scan/tilt platform.

Scan / Tilt Platform

Sensors

Analog input from Mid Range IR

Analog input from Long Range IR

Analog input from RC Circuit to 9V NiMH Battery – Camera

Actuators

One PWM output to Servo – Adafruit Motorshield

One Digital output thru a Transistor circuit to turn the Laser on/off

One Digital output thru a Transistor circuit to turn the Camera on/off

Serial Communication

For our example we begin by allocating resources interfaced to ATmega328P peripheral subsystems requiring the use of only one set of pins. In this case the I2C serial interface. Looking at the matrix we see that this first step removes two Analog inputs leaving us with four (4). We need two (2) Analog Inputs so we have two (2) pins which may be used for sensors and actuators to be wired to the GPIO peripheral subsystem (PC 2 – 5). Four (4) of our six (6) PWM channels are required by the Adafruit Motor Shield. This leaves us with two (2) more pins which may be used for sensors and actuators to be wired to the GPIO peripheral subsystem. Looking at the matrix we see that we have 2 GPIO pins PD2 and PB5 which are unused, giving us a total of six (6) pins available to the GPIO peripheral subsystem. We only need four (4) for our two shaft encoders which means we have two (2) spare pins.

Table 3.0 System Resource Map for Chassis Mounted Arduino Uno

Table 3.0 System Resource Map for Chassis Mounted Arduino Uno

Software Programming in C++: Introduction

PDF Lecture http://web.csulb.edu/~hill/ee444/Lectures/02%20C++%20Introduction.pdf

READING

The AVR Microcontroller and Embedded Systems using Assembly and C

by Muhammad Ali Mazidi, Sarmad Naimi, and Sepehr Naimi

Sections: 7.1, 7.3, 7.4, 7.6

Here is a fun tool to translate your C++ code into Assembly

https://godbolt.org/

Table of Contents

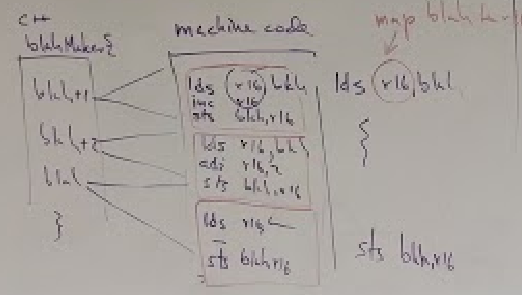

Assemblers, Compilers, and Interpreters

Language Levels

- Scripting Arduino, Matlab

- High-Level JAVA, PYTHON

- Mid-Level C/C++

- Low-Level Assembly

From Humans to the Machine

Reference: https://en.wikipedia.org/wiki/Interpreted_language

Assembly 1:1

Machine Code

Compilers 1:X

Machine Code

Language examples = C/C++, Python, BASIC

Interpreters 1:1

bytecode

Language examples = C#, Java, Python, BASIC

Examples of Languages which may be Compiled or use an Interpreter

Most interpreted languages use an intermediate representation, which combines compiling and interpreting.

- JavaScript

- Python

- Ruby

VARIABLE PROPERTIES

- Data Type

- Scope

Scope

Scope allows the compiler to help us from making mistakes (overwriting the value of a variable) & allows us to help the compiler optimize the code (manage SRAM resources).

Reference: https://andrewharvey4.wordpress.com/tag/avr/

Supplemental figure for Volatile

The key here may be the destruction of the mapping of variables to registers in the interrupted program.

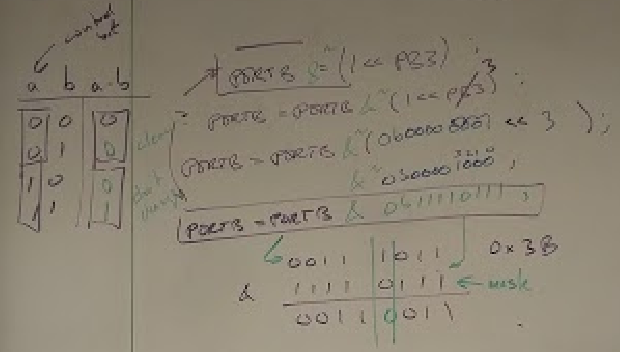

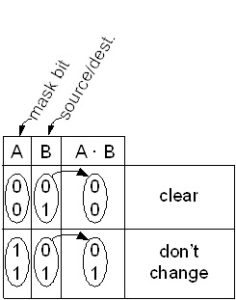

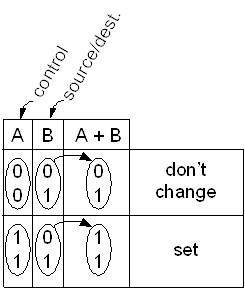

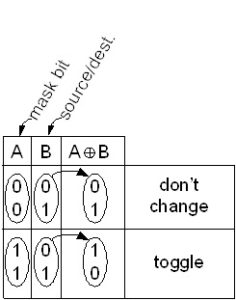

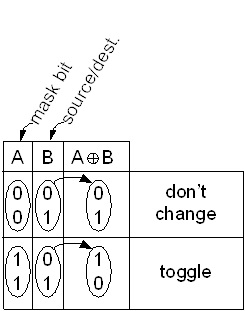

Supplemental figure for setting and clearing bits

Reference: http://web.csulb.edu/~hill/ee346/Lectures/14%20AVR%20Logic%20and%20Shift.pdf

Data Types

Explicit Data Types

source: Wikipedia stdint.h

- The C standard library introduced in the C99 standard library (stdint.h) allows programmers to write more portable code by allowing them to specify exact-width integer types, together with the defined minimum and maximum allowable values for each type.

- This new library is particularly useful for embedded programming which often involves considerable manipulation of hardware specific I/O registers requiring integer data of fixed widths, specific locations and exact alignments.

- The naming convention for exact-width integer types is intN_t for signed integers and uintN_t for unsigned integers. For example

uint16_t revsteps; // # steps per revolution

uint8_t steppernum;

uint32_t usperstep, steppingcounter;

Implicit and Architecture Dependent Data Types

| Data Type | Size in Bits | Data Range / Usage |

|---|---|---|

| void | ||

| boolean | ||

| char | 8 | -128 to +127 |

| unsigned char | 8 | 0 to 255 |

| byte | 8 | 0 to 255 |

| int | 16 | -32,768 to +32,767 |

| unsigned int | 16 | 0 to 65,535 |

| word | 16 | 0 to 65,535 (Arduino) |

| long | 32 | -2,147,483,648 to +2,147,483,648 |

| unsigned long | ||

| float | 32 | +/-1.175e-38 to +/-3.402e38 |

| double | 32 | +/-1.175e-38 to +/-3.402e38 |

| string – char array | ||

| String – object | ||

| array |

Utilities

sizeof()

The sizeof operator returns the number of bytes in a variable type, or the number of bytes occupied by an array.

VARIABLE SCOPE

Variable Scope

- Variables in the C programming language, which Arduino uses, have a property called scope.

- A Global variable is one that you can access anywhere in a program. Local variables are only visible to the function in which they are declared. In the Arduino environment, any variable declared outside of a function.

- Local variables insure that only one function has access to its own variables. This prevents programs from inadvertently modifying variables used by another function.

- A variable declared inside brackets {} can only be accessed within said brackets.

Source: Arduino – Variable Scope

uint gPWMval; // any function will see this variable

void setup()

{

// …

}

void loop()

{

int i; // “i” is only “visible” inside of “loop”

float f; // “f” is only “visible” inside of “loop”

// …

for (int j = 0; j <100; j++){

// variable j can only be accessed inside the

// for-loop brackets

}

}

QUALIFIERS

Static

- The static keyword is used to create variables that are visible to only one function. However unlike local variables that get created and destroyed every time a function is called, static variables persist beyond the function call, preserving their data between function calls.

- Variables declared as static will only be created and initialized the first time a function is called.

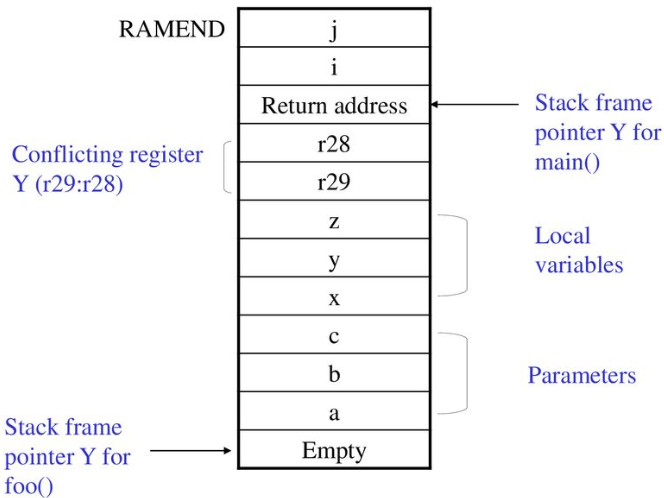

source: COMP2121: Microprocessors and Interfacing

http://www.cse.unsw.edu.au/~cs2121

int randomWalk(int moveSize){

static int place; // variable to store value in random walk,

// declared static so that it stores

// values in between function calls, but

// no other functions can change its value

place = place + (random(-moveSize, moveSize + 1));

// check lower and upper limits

if (place < randomWalkLowRange){ place = randomWalkLowRange; } else if(place > randomWalkHighRange){

place = randomWalkHighRange;

}

return place;

}

Volatile

- The volatile qualifier directs the compiler to load the variable from RAM and not from a general purpose register (R0 – R31),

- A variable should be declared volatile when used within an Interrupt Service Routine (ISR).

- For more on Interrupts visit Gammon Software Solutions forum

// toggles LED when interrupt pin changes state

int pin = 13;

volatile int state = LOW;

void setup()

{

pinMode(pin, OUTPUT);

attachInterrupt(0, blink, CHANGE);

}

void loop()

{

digitalWrite(pin, state);

}

void blink()

{

state = !state;

}

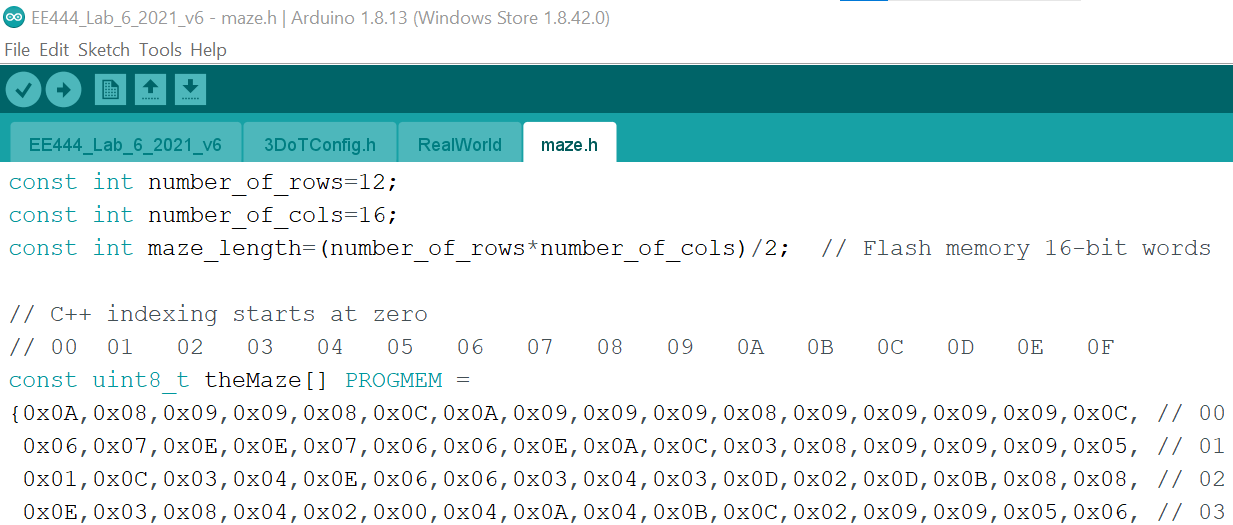

Const

Reference: The C++ ‘const’ Declaration: Why & How

- The const qualifier declares a variable as a constant.

Example

// create integer constant myConst with value 33

const int myConst=33;

- Such constants are useful for parameters which are used in the program but do not need to be changed after the program is compiled.

- It has an advantage over the C preprocessor ‘#define’ command in that is understood and used by the compiler itself.

- Use of constant checked for scope.

- Use of constant checked for datatype.

- As a result error messages are much more helpful.

- Example usage is in the definition of a base pointer to an array

Example

// The compiler will replace any mention of

// ledPin with the value 3 at compile time.

#define ledPin 3

- Constants are saved in SRAM not in Flash Program Memory (C was originally designed for Princeton based Machines). Click here to learn how to save data to Flash Program Memory.

Arduino Scripting Language

Reference

Arduino Language Reference

Arduino programs can be divided in three main parts: structure, values (variables and constants), and functions.

Structure

Control Structures

Further Syntax

- ; (semicolon)

- {} (curly braces)

- // (single line comment)

- /* */ (multi-line comment)

- #define

- #include

Arithmetic Operators

Comparison Operators

- == (equal to)

- != (not equal to)

- < (less than)

- > (greater than)

- <= (less than or equal to)

- >= (greater than or equal to)

Boolean Operators

Pointer Access Operators

Bitwise Operators

- & (bitwise and)

- | (bitwise or)

- ^ (bitwise xor)

- ~ (bitwise not)

- << (bitshift left)

- >> (bitshift right)

Compound Operators

- ++ (increment)

- — (decrement)

- += (compound addition)

- -= (compound subtraction)

- *= (compound multiplication)

- /= (compound division)

- &= (compound bitwise and)

- |= (compound bitwise or)

When we start constructing compound assignment statements in order to assign values to fields within a peripheral subsystem register, also known as a special function register (SFR), it is important to remember operator precedence.

| Level | Operator | Description | Grouping |

| 1 | :: | scope | Left-to-right |

| 2 | () [] . -> ++ — dynamic_cast static_cast reinterpret_cast const_cast typeid | postfix | Left-to-right |

| 3 | ++ — ~ ! sizeof new delete | unary (prefix) | Right-to-left |

| * & | indirection and reference (pointers) | ||

| + – | unary sign operator | ||

| 4 | (type) | type casting | Right-to-left |

| 5 | .* ->* | pointer-to-member | Left-to-right |

| 6 | * / % | multiplicative | Left-to-right |

| 7 | + – | additive | Left-to-right |

| 8 | << >> | shift | Left-to-right |

| 9 | < > <= >= | relational | Left-to-right |

| 10 | == != | equality | Left-to-right |

| 11 | & | bitwise AND | Left-to-right |

| 12 | ^ | bitwise XOR | Left-to-right |

| 13 | | | bitwise OR | Left-to-right |

| 14 | && | logical AND | Left-to-right |

| 15 | || | logical OR | Left-to-right |

| 16 | ?: | conditional | Right-to-left |

| 17 | = *= /= %= += -= >>= <<= &= ^= |= | assignment | Right-to-left |

| 18 | , | comma | Left-to-right |

Values

Constants

Data Types (see above)

Functions – Scripting Language

Digital I/O

- pinMode() // Writes to GPIO DDR register

- digitalWrite() // Writes to GPIO Port register

- digitalRead() // Reads GPIO Pin register

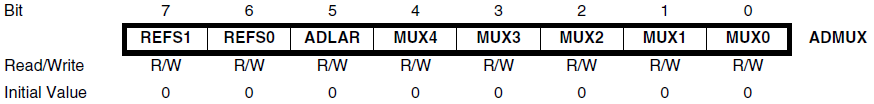

Analog I/O

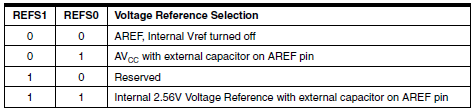

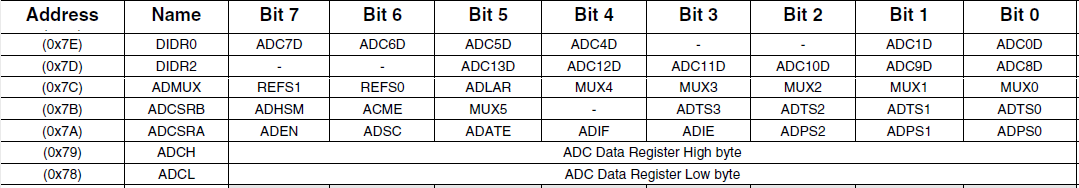

- analogReference() // Writes to bits REFS1:REFS0 of ADMUX register

- analogRead() // Reads ADC Data register (ADCH/ADCL)

- analogWrite() // Writes to OCRnA or OCRnB registers of Timers

Advanced I/O

- tone()

- noTone()

- shiftOut() // Software implementation of SPI MOSI interface

- shiftIn() // Software implementation of SPI MISO interface

- pulseIn()

Time

- millis()

- micros()

- delay()

- delayMicroseconds()

Math

Trigonometry

Random Numbers

- randomSeed()

- random()

Bits and Bytes

External Interrupts

- attachInterrupt() // Configures external interrupt pins INT1 and INT0

- detachInterrupt() // Clears EIMSK register bits INT1 and INT0

Interrupts

- interrupts() // Sets SREG I bit

- noInterrupts() // Clears SREG I bit

Communication

WORKING WITH BITS IN C++

Resources

1. Arduino

2. AVR-libc

Set/Clear a Bit

Assembly

GPIO Port (first 32 I/O addresses)

| sbi PORTB, PB3 | cbi PORTB, PB3 |

IO Address Space

| in r16, PORTB sbr r16, 0b00001000 out PORTB, r16 |

in r16, PORTB cbr r16, 0b00001000 out PORTB, r16 |

| // Set a Bit | // Clear a Bit |

| digitalWrite(MOTORLATCH, HIGH); | digitalWrite(MOTORLATCH, LOW); |

| // Set a Bit | // Clear a Bit |

| PORTB |= _BV(PB3); or sbi(PORTB, PB3); // deprecated |

PORTB &= ~_BV(PB3); or cbi(PORTB, PB3); // deprecated |

The AVR C library includes the following definition

#include

// _BV Converts a bit number into a Byte Value (BV).

#define _BV(bit) (1 << (bit)) // : Special function registers

C/C++

| // Set a Bit | // Clear a Bit |

| PORTB |= (1 << (PB3)); | PORTB &= ~(1 << (PB3)); |

Set a Bit Pattern

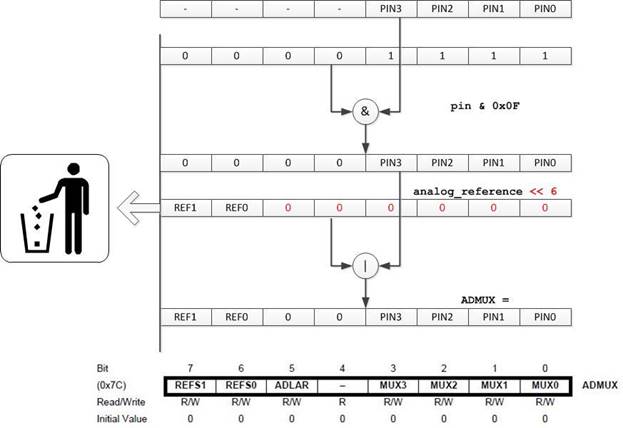

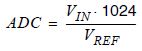

ADC Subsystem ADMUX Register Example

In this example we set/clear 2 fields within a byte. Undefined bits are cleared.

ADMUX = (analog_reference << 6) | (pin & 0x0f); // analogRead

Test Your Knowledge 1: Assume a function of type uint16_t. What would be returned if high = A and low = 3?

return (high << 8) | low;

0x0A03

Test Your Knowledge 2: How could you modify the ADMUX example to allow the programmer to set or clear the ADC Left Adjust Result ADLAR bit? Answer

ADMUX = (analog_reference << 6) | (pin & 0x0f) | ((left_adjust & 0x01) << 5);

note: if left_adjust is zero ADLAR bit stays at zero.

Program Example:

Here is my Arduino Test Script ported to AVR Studio so I could use the simulator: ArduinoToAVRStudio-Blink ****

In our first example “ADC Subsystem ADMUX Register” we assumed where each field was located within the register. In the next example we do not presuppose the location of the fields. This allows our program to adapt to different microcontroller register definitions. The downside is that, while in the first example the fields could be defined on the fly by the user (for example as arguments to a function), in this next example they must be predefined.

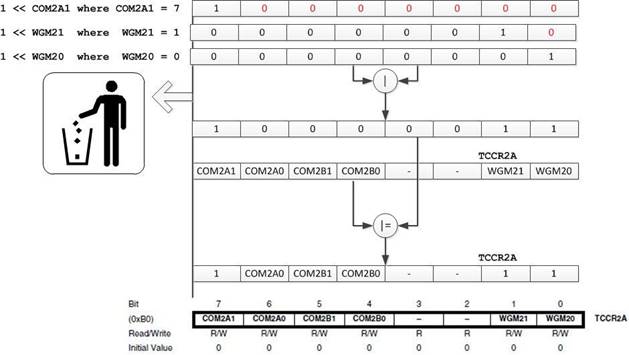

Timer/Counter 2 Control Register A Example 1

In this example, the wave generation mode of Timer/Counter 2 (WGM21:WGM20) is set to Fast PWM (0b11), the compare match output A mode (COM2A1:COM2A0) is configured to set on compare match (0b10), while the configuration bits for output compare register B are not modified (COM2B1:COM2B0).

#define _BV(bit) (1 << (bit))

TCCR2A |= _BV(COM2A1)|_BV(WGM21)|_BV(WGM20); // fast PWM, turn on oc0

Test Your Knowledge 3: At reset TCCR2A is cleared so our C++ example would result in COM2A1:COM2A0 = 0b10. What if another piece of software had set COM2A0 to 1 before this initialization routine was called. In this case our C++ code would not configure the register as expected. How could you solve this problem? Tip: Because of operator precedence (see Compound Operators earlier in this document) you will need to use a simple assignment operator or write two lines of code.

AnswerTCCR2A &= ~_BV(COM2A0)

Timer/Counter 2 Control Register A Example 2

In this example, the wave generation mode of Timer/Counter 2 (WGM21:WGM20) is set to Phase Correct PWM (0b01). The compare match output A mode (COM2A1:COM2A0) is configured to set on compare match, while the configuration bits for output compare register B are not modified (COM2B1:COM2B0). This example makes no assumption about the state of the bits within the WGM or COM2A bit fields.

TCCR2A &= ~_BV(COM2A0) & ~_BV(WGM21); // clear bits

TCCR2A |= _BV(COM2A1) | _BV(WGM20); // set bits

Test Your Knowledge 4: Can you combine these two expressions into one?

AnswerTCCR2A = TCCR2A&~(_BV(WGM21) | _BV(COM2A0)) | _BV(WGM20) | _BV(COM2A1);

Test Your Knowledge 5: If you are allowed to assume the location of the waveform generation mode (WGM2) and the compare match output A mode (COM2A) fields within the TCCR2A register, how would you write an expression that could set these two fields based on user defined variables output_mode and waveform? Hint: see the first example.

AnswerTCCR2A |= (output_mode << 6) | (waveform & 0x03); // analogRead

Test if a Bit is Set or Cleared

source: Special function registers

| #define | bit_is_set(sfr, bit) (_SFR_BYTE(sfr) & _BV(bit)) |

| #define | bit_is_clear(sfr, bit) (!(_SFR_BYTE(sfr) & _BV(bit))) |

| #define | loop_until_bit_is_set(sfr, bit) do { } while (bit_is_clear(sfr, bit)) |

| #define | loop_until_bit_is_clear(sfr, bit) do { } while (bit_is_set(sfr, bit)) |

ADC Subsystem ADMUX Register Example

// ADSC is cleared when the conversion finishes

while (bit_is_set(ADCSRA, ADSC));

What is _SFR_BYTE(sfr)?

Source: Playing with Arduino _SFR_BYTE() and PORT

The _SFR_BYTE() is a macro that returns a byte of data of the specified address. The _SFR_BYTE() is defined in hardware/tools/avr/avr/include/avr/sfr_defs.h as below.

#define _SFR_BYTE(sfr) _MMIO_BYTE(_SFR_ADDR(sfr))

The _SFR_ADDR() is a macro that expands the _SFR_MEM_ADDR(sfr) macro. Both are defined in hardware/tools/avr/avr/include/avr/sfr_defs.h as below.

#define _SFR_ADDR(sfr) _SFR_MEM_ADDR(sfr)

The _SFR_MEM_ADDR() is a macro that returns the address of the argument.

#define _SFR_MEM_ADDR(sfr) ((uint16_t) &(sfr))

The _MMIO_BYTE() is a macro that dereferences a byte of data at the specified address. The _MMIO_BYTE() is defined in hardware/tools/avr/avr/include/avr/sfr_defs.h as below. The input is mem_addr and dereferences its contents.

#define _MMIO_BYTE(mem_addr) (*(volatile uint8_t *)(mem_addr))

Putting it all together, this is how the compiler would expand _SFR_BYTE(sfr)

_SFR_BYTE(sfr) *(volatile uint8_t * uint16_t &(sfr))

Let’s take a closer look at this expanded macro definition. Starting from the inside and moving out. The ampersand sign (&) is known as a reference operator and lets the compiler know that “sfr” is to be interpreted as an address (i.e., a pointer). Specifically, a 16-bit address (uint16_t).

The asterisk (*) sign in the uint8_t declaration of the pointer does not mean “value pointed by”, it only means that it is a pointer (it is part of its type compound specifier). It should not be confused with the dereference operator, which come next, they are simply two different things represented with the same sign.

The final asterisk sign (*) at the beginning of the statement is a dereference operator. When the dereference operator is used you will get the “value pointed by” a pointer – the actual value of the register.

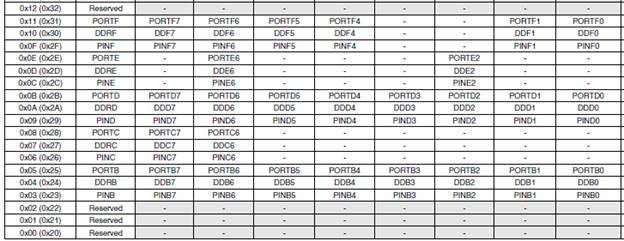

Mapping the 6-bit I/O address space into the 16-bit extended I/O address space

This works if the “special function register” is in the extended I/O address space but what if it is in the 64 byte I/O address space?

Let’s assume sfr is within the I/O address space of the ATmega microcontroller, for example a GPIO Port. Each GPIO Port includes three registers PINx, DDRx, and PORTx. For the ATmega32U4 “x” would be B, C, D, E, and F

To continue our example let’s assume we are going to write to one of the PORT registers (not to be confused with the PORT itself – see figure above). The PORTB, PORTC and PORTD registers are defined in hardware/tools/avr/avr/include/avr/iom32u4.h as below.

#define PORTB _SFR_IO8(0x05)

#define PORTC _SFR_IO8(0x08)

#define PORTD _SFR_IO8(0x0B)

Again looking at the figure, we see that arguments 0x05, 0x07, and 0x0A are the I/O addresses of PORTB, PORTC and PORTD respectively. They call _SFR_IO8(). The _SFR_IO8() converts the I/O address to the memory address. It is a macro that returns a byte of data at an address of io_addr + __SFR_OFFSET. The _SFR_IO8() is defined in hardware/tools/avr/avr/include/avr/sfr_defs.h as below.

#define _SFR_IO8(io_addr) _MMIO_BYTE((io_addr) + __SFR_OFFSET)

#define __SFR_OFFSET 0x20

Again, _MMIO_BYTE() is a macro that dereferences a byte of data at the specified address.

#define _MMIO_BYTE(mem_addr) (*(volatile uint8_t *)(mem_addr))

Putting it all together we have the equivalent macro.

#define _SFR_IO8(io_addr) (*(volatile uint8_t *)(mem_addr)) + 0x20

Appendix

Appendix A: The Arduino Family Tree

The Arduino language (based on Wiring) is implemented in C/C++, and therefore has some differences from the Processing language, which is based on Java.

A Visual Paradigm for Programming – Processing

Source: Wikipedia – Processing (programming language)

- Processing was designed to get non-programmers (originally electronic artists) started with software programming, using a visual context, and to serve as the foundation for electronic sketchbooks.

- The concept of “visual context” makes Processing comparable to Adobe’s ActionScript and Lingo scripting based languages.

- A “sketchbook”, is a minimal alternative to an integrated development environment (IDE)

- Processing is an open source programming language and integrated development environment (IDE)

- The project was initiated in 2001 by Casey Reas and Benjamin Fry, both formerly of the Aesthetics and Computation Group at the MIT Media Lab.

- The language builds on the Java programming language, but uses a simplified syntax and graphics programming model.

From Programming to Microcontrollers – Wiring

- Wiring was design to teach non-programmers (originally electronic artists) how to program microcontrollers.

- Wiring, uses the Processing IDE (sketchbook) together with a simplified version of the C++ programming language (gcc compiler)

- There are now two separate hardware projects, Wiring and Arduino, using the Wiring IDE (sketchbook) and language.

- Fritzing is another software environment of the same sort, which helps designers and artists to document their interactive prototypes and to take the step from physical prototyping to actual product.

From Programming Microcontrollers to the Arduino

Arduino is an open-source electronics prototyping platform based on flexible, easy-to-use hardware and software. It’s intended for artists, designers, hobbyists, and anyone interested in creating interactive objects or environments.

- The C/C++ language is the foundation upon which the Arduino language (like Wiring on which it is based) is built.

- The C/C++ language is implemented using the GCC Compiler and links against the AVR C library AVR Libc and allows the use of any of its functions; see its user manual for details.

- The AVR C Library has its own family tree (nongnu, gcc)

APPENDIX B: Standard Libraries

- EEPROM – reading and writing to “permanent” storage (EEPROM)

- Ethernet – for connecting to the internet using the Arduino Ethernet Shield

- Firmata – for communicating with applications on the computer using a standard serial protocol.

- LiquidCrystal – for controlling liquid crystal displays (LCDs)

- SD – for reading and writing SD cards

- Servo – for controlling servo motors

- SPI – for communicating with devices using the Serial Peripheral Interface (SPI) Bus

- SoftwareSerial – for serial communication on any digital pins

- Stepper – for controlling stepper motors

- Wire – Two Wire Interface (TWI/I2C) for sending and receiving data over a net of devices or sensors.

APPENDIX C: C++ OPERATOR PRECEDENCE

When we start constructing compound assignment statements in order to assign values to fields within a peripheral subsystem register, also known as a special function register (SFR), it is important to remember operator precedence.

| Level | Operator | Description | Grouping |

| 1 | :: | scope | Left-to-right |

| 2 | () [] . -> ++ — dynamic_cast static_cast reinterpret_cast const_cast typeid | postfix | Left-to-right |

| 3 | ++ — ~ ! sizeof new delete | unary (prefix) | Right-to-left |

| * & | indirection and reference (pointers) | ||

| + – | unary sign operator | ||

| 4 | (type) | type casting | Right-to-left |

| 5 | .* ->* | pointer-to-member | Left-to-right |

| 6 | * / % | multiplicative | Left-to-right |

| 7 | + – | additive | Left-to-right |

| 8 | << >> | shift | Left-to-right |

| 9 | < > <= >= | relational | Left-to-right |

| 10 | == != | equality | Left-to-right |

| 11 | & | bitwise AND | Left-to-right |

| 12 | ^ | bitwise XOR | Left-to-right |

| 13 | | | bitwise OR | Left-to-right |

| 14 | && | logical AND | Left-to-right |

| 15 | || | logical OR | Left-to-right |

| 16 | ?: | conditional | Right-to-left |

| 17 | = *= /= %= += -= >>= <<= &= ^= |= | assignment | Right-to-left |

| 18 | , | comma | Left-to-right |

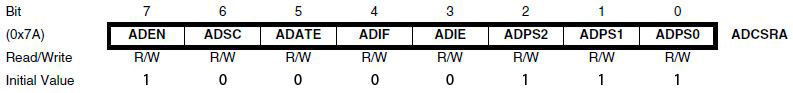

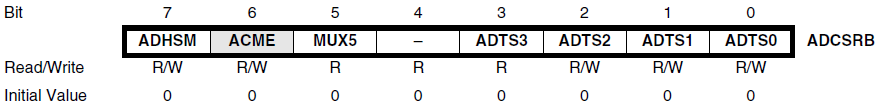

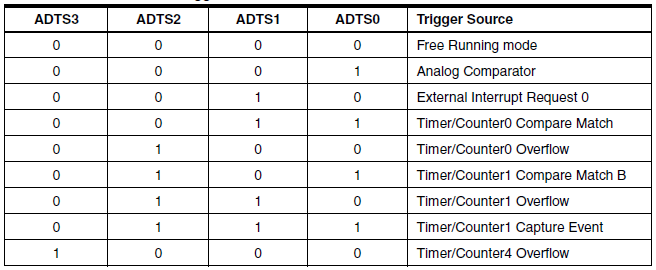

APPENDIX D: ARDUINO ANALOGREAD FUNCTION

int analogRead(uint8_t pin)

{

uint8_t low, high;

// set the analog reference (high two bits of ADMUX) and select the

// channel (low 4 bits). this also sets ADLAR (left-adjust result)

// to 0 (the default).

ADMUX = (analog_reference << 6) | (pin & 0x0f);

// without a delay, we seem to read from the wrong channel

//delay(1);

// start the conversion

sbi(ADCSRA, ADSC);

// ADSC is cleared when the conversion finishes

while (bit_is_set(ADCSRA, ADSC));

// we hto read ADCL first; doing so locks both ADCL

// and ADave CH until ADCH is read. reading ADCL second would

// cause the results of each conversion to be discarded,

// as ADCL and ADCH would be locked when it completed.

low = ADCL;

high = ADCH;

// combine the two bytes

return (high << 8) | low;

}

APPENDIX E: ADAFRUIT MOTOR SHIELD

Using the Motor Shield

DC Motors

#include

// motor is an instance of the AF_DCMotor class

AF_DCMotor motor(2, MOTOR12_64KHZ); // create motor #2, 64KHz pwm

void setup() {

Serial.begin(9600); // set up Serial library at 9600 bps

Serial.println(“Motor test!”);

motor.setSpeed(200); // set the speed to 200/255

}

void loop() {

Serial.print(“tick”);

motor.run(FORWARD); // turn it on going forward

delay(1000);

Serial.print(“tock”);

motor.run(BACKWARD); // the other way

delay(1000);

Serial.print(“tack”);

motor.run(RELEASE); // stopped

delay(1000);

}

Stepper Motor

#include

// motor is an instance of the AF_Stepper class

AF_Stepper motor(48, 2);

void setup() {

Serial.begin(9600); // set up Serial library at 9600 bps

Serial.println(“Stepper test!”);

motor.setSpeed(10); // 10 rpm

motor.step(100, FORWARD, SINGLE);

motor.release();

delay(1000);

}

void loop() {

motor.step(100, FORWARD, SINGLE);

motor.step(100, BACKWARD, SINGLE);

motor.step(100, FORWARD, DOUBLE);

motor.step(100, BACKWARD, DOUBLE);

motor.step(100, FORWARD, INTERLEAVE);

motor.step(100, BACKWARD, INTERLEAVE);

motor.step(100, FORWARD, MICROSTEP);

motor.step(100, BACKWARD, MICROSTEP);

}

Library Header

What is a Library?

// Adafruit Motor shield library

// copyright Adafruit Industries LLC, 2009

// this code is public domain, enjoy!

#ifndef _AFMotor_h_

#define _AFMotor_h_

#include

#include

//#define MOTORDEBUG 1

#define MICROSTEPS 16 // 8 or 16

#define MOTOR12_64KHZ _BV(CS20) // no prescale

#define MOTOR12_8KHZ _BV(CS21) // divide by 8

#define MOTOR12_2KHZ _BV(CS21) | _BV(CS20) // divide by 32

#define MOTOR12_1KHZ _BV(CS22) // divide by 64

#define MOTOR34_64KHZ _BV(CS00) // no prescale

#define MOTOR34_8KHZ _BV(CS01) // divide by 8

#define MOTOR34_1KHZ _BV(CS01) | _BV(CS00) // divide by 64

#define MOTOR1_A 2

#define MOTOR1_B 3

#define MOTOR2_A 1

#define MOTOR2_B 4

#define MOTOR4_A 0

#define MOTOR4_B 6

#define MOTOR3_A 5

#define MOTOR3_B 7

#define FORWARD 1

#define BACKWARD 2

#define BRAKE 3

#define RELEASE 4

#define SINGLE 1

#define DOUBLE 2

#define INTERLEAVE 3

#define MICROSTEP 4

// Arduino pin names

#define MOTORLATCH 12

#define MOTORCLK 4

#define MOTORENABLE 7

#define MOTORDATA 8

class AFMotorController

{

public:

AFMotorController(void);

void enable(void);

friend class AF_DCMotor;

void latch_tx(void);

};

class AF_DCMotor

{

public:

AF_DCMotor(uint8_t motornum, uint8_t freq = MOTOR34_8KHZ);

void run(uint8_t);

void setSpeed(uint8_t);

private:

uint8_t motornum, pwmfreq;

};

class AF_Stepper {

public:

AF_Stepper(uint16_t, uint8_t);

void step(uint16_t steps, uint8_t dir, uint8_t style = SINGLE);

void setSpeed(uint16_t);

uint8_t onestep(uint8_t dir, uint8_t style);

void release(void);

uint16_t revsteps; // # steps per revolution

uint8_t steppernum;

uint32_t usperstep, steppingcounter;

private:

uint8_t currentstep;

};

uint8_t getlatchstate(void);

#endif

Adafruit Private Functions

latch_tx

#define _BV(bit) (1 << (bit))

/*

Send data located in 8-bit variable latch_state

to the 74HC595 on the Motor Shield.

*/

void AFMotorController::latch_tx(void) {

uint8_t i;

//LATCH_PORT &= ~_BV(LATCH);

digitalWrite(MOTORLATCH, LOW); // – Output register clock low

//SER_PORT &= ~_BV(SER);

digitalWrite(MOTORDATA, LOW); // – Serial data bit = 0

for (i=0; i<8; i++) { // – Shift out 8-bits

//CLK_PORT &= ~_BV(CLK);

digitalWrite(MOTORCLK, LOW); // – Shift clock low

if (latch_state & _BV(7-i)) { // – Is current bit of

//SER_PORT |= _BV(SER); latch_state == 1

digitalWrite(MOTORDATA, HIGH); // – Yes, serial data bit = 1

} else {

//SER_PORT &= ~_BV(SER);

digitalWrite(MOTORDATA, LOW); // – No, serial data bit = 0

}

//CLK_PORT |= _BV(CLK);

digitalWrite(MOTORCLK, HIGH); // – Shift clock high, rising edge

} // shift bit into shift register

//LATCH_PORT |= _BV(LATCH);

digitalWrite(MOTORLATCH, HIGH); // – Output register clock high, rising

} // edge sends the stored bits to the

// output register.

enable

/*

Configure DDR Registers B and D bits assigned to

the input of the 74HC595 on the Motor Shield. Output

all zeros and enable outputs.

*/

void AFMotorController::enable(void) {

// setup the latch

/*

LATCH_DDR |= _BV(LATCH);

ENABLE_DDR |= _BV(ENABLE);

CLK_DDR |= _BV(CLK);

SER_DDR |= _BV(SER);

*/

pinMode(MOTORLATCH, OUTPUT);

pinMode(MOTORENABLE, OUTPUT);

pinMode(MOTORDATA, OUTPUT);

pinMode(MOTORCLK, OUTPUT);

latch_state = 0;

latch_tx(); // “reset”

//ENABLE_PORT &= ~_BV(ENABLE); // enable the chip outputs!

digitalWrite(MOTORENABLE, LOW);

}

Adafruit Motor Public Functions

run

void AF_DCMotor::run(uint8_t cmd) {

uint8_t a, b;

/* Section 1: choose two shift register outputs based on which

* motor this instance is associated with. motornum is the

* motor number that was passed to this instance’s constructor.

*/

switch (motornum) {

case 1:

a = MOTOR1_A; b = MOTOR1_B; break;

case 2:

a = MOTOR2_A; b = MOTOR2_B; break;

case 3:

a = MOTOR3_A; b = MOTOR3_B; break;

case 4:

a = MOTOR4_A; b = MOTOR4_B; break;

default:

return;

}

/* Section 2: set the selected shift register outputs to high/low,

* low/high, or low/low depending on the command. This is done

* by updating the appropriate bits of latch_state and then

* calling tx_latch() to send latch_state to the chip.

*/

switch (cmd) {

case FORWARD: // high/low

latch_state |= _BV(a);

latch_state &= ~_BV(b);

MC.latch_tx();

break;

case BACKWARD: // low/high

latch_state &= ~_BV(a);

latch_state |= _BV(b);

MC.latch_tx();

break;

case RELEASE: // low/low

latch_state &= ~_BV(a);

latch_state &= ~_BV(b);

MC.latch_tx();

break;

}

}

setSpeed

void AF_DCMotor::setSpeed(uint8_t speed) {

switch (motornum) {

case 1:

OCR2A = speed; break;

case 2:

OCR2B = speed; break;

case 3:

OCR0A = speed; break;

case 4:

OCR0B = speed; break;

}

}

initPWM1

This is a brief excerpt of the AF_DCMotor constructor (subroutine initPWM1(freq)), which is initializing speed control for motor 1:

// use PWM from timer2A

TCCR2A |= _BV(COM2A1) | _BV(WGM20) | _BV(WGM21); // fast PWM, turn on oc0

TCCR2B = freq & 0x7;

OCR2A = 0;

DDRB |= _BV(3);

break;

General Purpose I/O Ports

Table of Contents

Source: ATmega328P Data Sheet http://www.atmel.com/dyn/resources/prod_documents/8161S.pdf page 5

ATMEGA GENERAL PURPOSE DIGITAL I/O PORTS

Reading: Section 6.1.1 Introduction

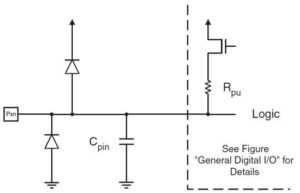

- The ATmega32U4 has 26 General Purpose Digital I/O Pins assigned to 5 Ports (8-bit Ports B, D, 2-bit Port C,E, and 6-bit Port F)

- Each I/O port pin may be configured as an output with symmetrical drive characteristics. Each pin driver is strong enough (20 mA) to drive LED displays directly.

- Each I/O port pin may be configured as an input with or without a pull-up resistor. The values for the pull up resistor can range from 20 – 50 K ohms.

- Each I/O pin has protection diodes to both VCC and Ground

PIN DESCRIPTION OF THE ATMEGA32U4

Reading: Section 6.1.3 Pin-Muxing

I/O Ports B, C, D, E, and F

Ports B (PB7..PB0), C (PC7,PC6), D (PD7..PD0), E (PE6,PE2), F (PF7..PF4,PF1,PF0) are bi-directional I/O ports with internal pull-up resistors (selected for each bit). The Port output buffers have symmetrical drive characteristics with both high sink and source capability.

Interrupts

External Interrupts are triggered by the INT0 to INT3 and INT6 pins or any of the PCINT7..0 pins associated with Port B. Observe that, if enabled, the interrupts will trigger even if the pins are configured as outputs. This feature provides a way of generating a software interrupt.

Analog Voltage (AVCC)

AVCC is the supply voltage pin for the A/D Converter. It should be externally connected to VCC. If the ADC is used, it should be connected to VCC through a low-pass filter.

Analog Reference (AREF)

AREF is the analog reference pin for the A/D Converter.

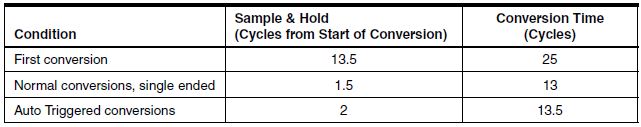

Analog to Digital Converter (ADC)

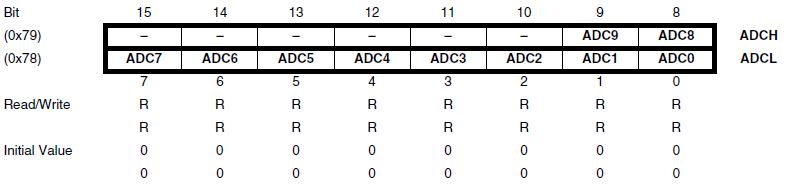

The ATmega32U4 includes a 10-bit ADC. The ADC is connected to a analog multiplexer with six single-ended voltage input (ADC0, ADC1, ADC4 to ADC7) channels. The device also supports differential inputs, with the positive input terminal selectable between ADC4 to ADC7, and negative input terminal selectable between ADC0 and ADC1. The output of the differential amplifier goes to a gain stage, with four (4) programmable amplification steps of 0 dB (1x), 10 dB (10x), 16dB (40x), and 23dB (200x). If 1x, 10x, or 40x gain is used, 8-bit resolution can be expected. If 200x gain is used, 7-bit resolution can be expected.

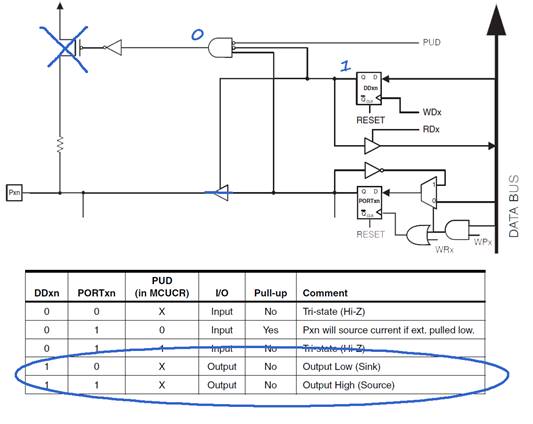

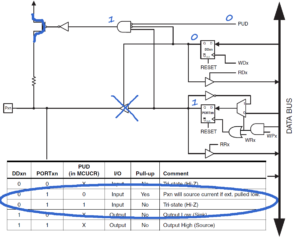

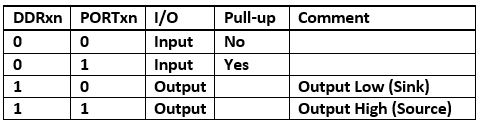

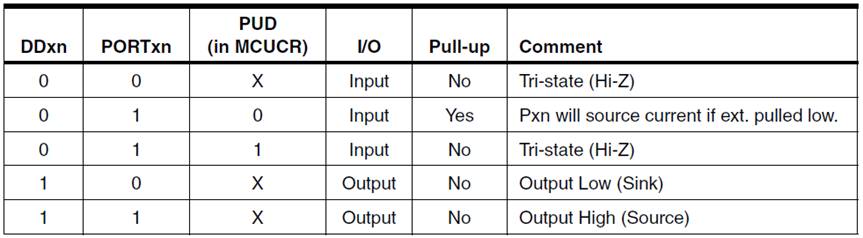

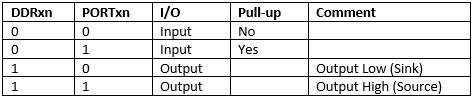

I/O PORT PIN AS AN OUTPUT

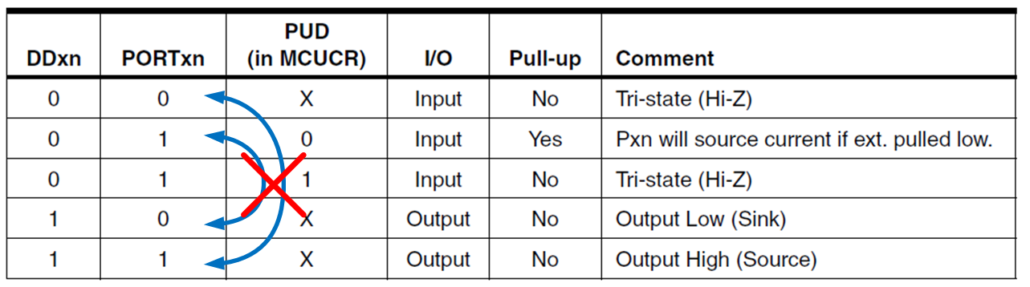

Reading: Section 6.1.2 Basic Operation

- To configure a Port (x) pin as an output set corresponding bit (n) in the Data Direction Register (DDxn) to 1. Once configured as an output pin, you control the state of the pin (1 or 0) by writing to the corresponding bit (n) of the PORTxn

- Writing (signal WPx) a logic one to PINxn toggles the value of PORTxn, independent on the value of DDxn. Note that the SBI instruction can be used to toggle one single bit in a port.

I/O PORT PIN AS AN INPUT

Reading: Section 6.2 Input

- To configure a Port (x) pin as an input set corresponding bit (n) in the Data Direction Register (DDxn) to 0. To add a pull-up resistor set the corresponding bit (n) of the PORTxn register to 1 (see illustration).

- You can now read the state of the input pin by reading the corresponding bit (n) of the PINxn

ACCESSING GPIO LINES IN ASSEMBLY and C++

DESIGN EXAMPLE 1 – Initialize 3DoT

Problem: When power is applied to the ATmega32U4 on the 3DoT board, it needs to be configured. However, because the 3DoT board, like the Arduino UNO, is itself integrated into another system, it is not completely aware of its environment. Therefore, pins allocated to the shields should not be modified.

The following tables show how the code should configure Ports B (PB7..PB0), C (PC7,PC6), D (PD7..PD0), E (PE6,PE2), F (PF7..PF4,PF1,PF0).

Port B

| PIN | PB7 | PB6 | PB5 | PB4 | PB3 | PB2 | PB1 | PB0 |

| J5-1 | J5-2 | J5-3 | J5-4 | |||||

| NET | AIN1 | BIN2 | NC | NC | MISO | MOSI | SCK | SS |

| DDRB | 1 | 1 | 0 | 0 | X | X | X | X |

| PORTB | 0 | 0 | 1 | 1 | X | X | X | X |

/* undefind pins are not changed */ /* pins that are not connected are defined as inputs with pull-up resistors */ DDRB &= 0x0F; // clear most significant nibble DDRB |= 0xC0; // set bit pattern PORTB &= 0x0F; // clear most significant nibble PORTB |= 0x30; // set bit pattern

Port C

| PIN | PC7 | PC6 | PC5 | PC4 | PC3 | PC2 | PC1 | PC0 |

| NET | BIN1 | NC | – | – | – | – | – | – |

| DDRC | 1 | 0 | – | – | – | – | – | – |

| PORTC | 0 | 1 | – | – | – | – | – | – |

DDRC &= 03F; // clear most significant 2 bits DDRC |= 0x80; // set bit pattern PORTC &= 03F; // clear most significant 2 bits PORTC |= 0x40;

Port D

| PIN | PD7 | PD6 | PD5 | PD4 | PD3 | PD2 | PD1 | PD0 |

| Servo A | LED | Servo B | J1-5 | J1-4 | J3-3 | J3-2 | ||

| NET | AIN2 | SIG | BUILTIN | SIG | TX | RX | SDA | SCL |

| DDRD | 1 | 1 | 1 | 1 | X | X | X | X |

| PORTD | 0 | 0 | 0 | 0 | X | X | X | X |

DDRD |= 0xF0; // set most significant nibble PORTD &= 0x0F; // clear most significant nibble

Port E

| PIN | PE7 | PE6 | PE5 | PE4 | PE3 | PE2 | PE1 | PE0 |

| S-1 | ||||||||

| NET | – | NC | – | – | – | SW | – | – |

| DDRE | – | 0 | – | – | – | 0 | – | – |

| PORTE | – | 1 | – | – | – | 0 | – | – |

DDRE &= 0xBB; // clear bits 6 and 2 PORTE &= 0xBB; // clear bits 6 and 2 PORTE |= 0x40; // set bit pattern

Port F

| PIN | PF7 | PF6 | PF5 | PF4 | PF3 | PF2 | PF1 | PF0 |

| J2-5 | J2-6 | J2-7 | J2-8 | J2-6 | ||||

| NET | A0 | A1 | A2 | A3 | – | – | A4 | BATT |

| DDRF | X | X | X | X | – | – | X | 0 |

| PORTF | X | X | X | X | – | – | X | 0 |

DDRF &= 0xFE; PORTF &= 0xFE;

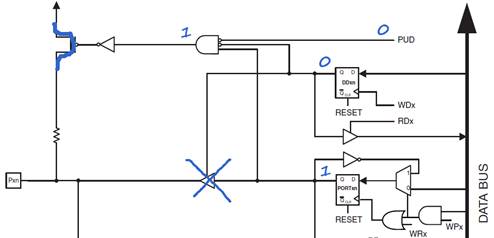

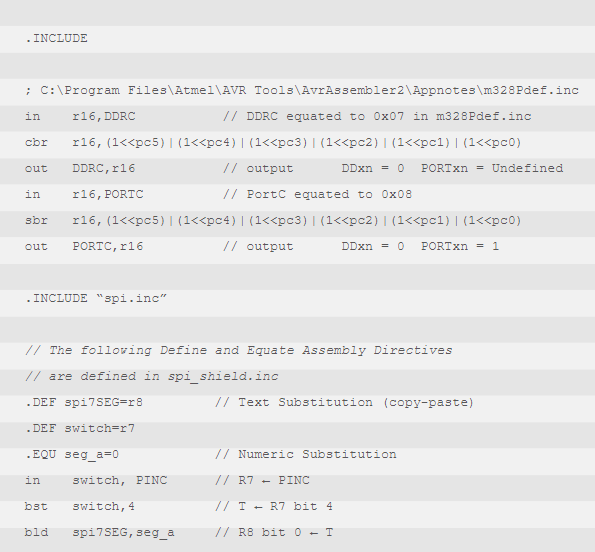

DESIGN EXAMPLE 2 – CSULB Shield Read Switches

Arduino Script

// Analog pins0,1,2,3,4,5 map to Digital pins 14, 15, 16, 17, 18, 19 pinMode(14, INPUT_PULLUP); // set pin to input with pullup resistor

Repeat this 1 line for pins 15, 16, 17, 18, and 19.

C++

DDRC &= ~0b00111111; PORTC |= 0b00111111;

Assembly

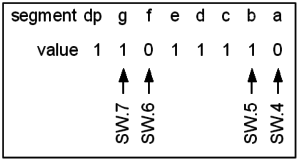

; Initialize Switches with Pull-up resistors in r16, DDRC // Port C DDR for switches 5 to 0 cbr r16,0b00111111 // define bits 5 to 0 as input (clear) out DDRC,r16 // output DDxn = 0 PORTxn = Undefined in r16,PORTC // PORT C Register for switches 5 to 0 sbr r16,0b00111111 // add pull-up resistors (PUR) out PORTC,r16 // output DDxn = 0 PORTxn = 1 Main: : in r7,0x06 // R7 ← PINC bst r7,4 // T ← R7 bit 4 bld r8,0 // R8 bit 0 (seg_a) ← T

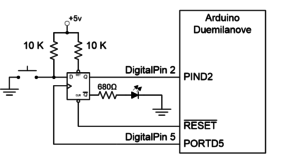

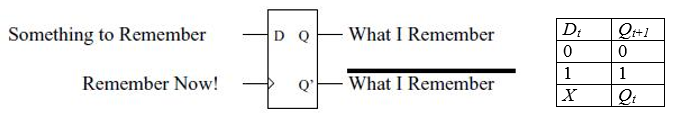

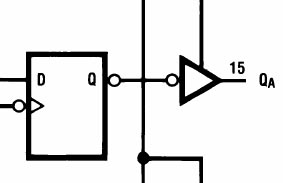

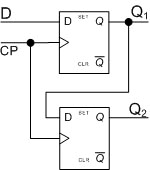

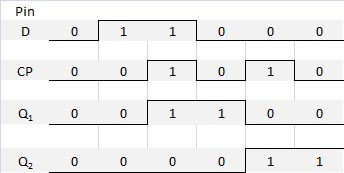

DESIGN EXAMPLE 3 – CSULB Shield Configure D Flip-Flop

Arduino Script

// Variable definitions const int dff_clk = 5; // D flip-flop clock wired to digital pin 5 const int dff_Q = 2; // D flip-flop Q output wired to digital pin 2 // Initialize digital pin 5 (dff_clk) as an // output and digital pin 2 (dff_Q) as an input pinMode(dff_clk, OUTPUT); // set pin as output digitalWrite(dff_clk, LOW); // initialize to zero pinMode(dff_Q, INPUT); // set pin as input

C++

// Preprocessor directives #define dff_clk PORTD5 #define dff_Q PIND2 // Initialize push-button debounce circuit DDRD |= 1 << dff_clk; // define bit 5 of Data Direction Register //(DDR)PORT D as an output PORTD &= ~(1 << dff_clk); // initialize to zero DDRD &= ~(1 << dff_Q); // define bit 2 of Data Direction Register //(DDR)PORT D as an input PORTD &= ~(1 << dff_Q); // without a pull-up resistor

Assembly

; Assembly directives .EQU dff_clk=PORTD5 .EQU dff_Q=PIND2 ; Initialize push-button debounce circuit sbi DDRD, dff_clk // flip-flop clock, DDRD5 = 1 PORTD5 = Undefined cbi PORTD, dff_clk // DDRD5 = 1 PORTD5 = 0 cbi DDRD, dff_Q // flip-flop Q DDRD2 = 0 PORTD2 = Undefined cbi PORTD, dff_Q // DDRD2 = 0 PORTD2 = 0

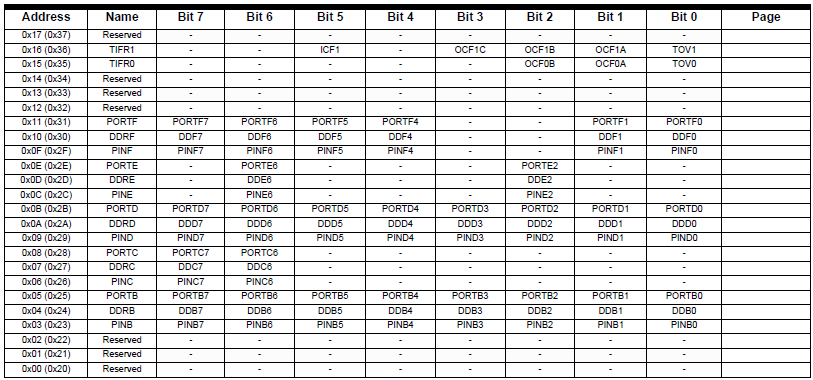

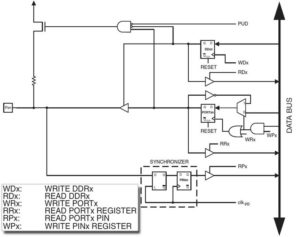

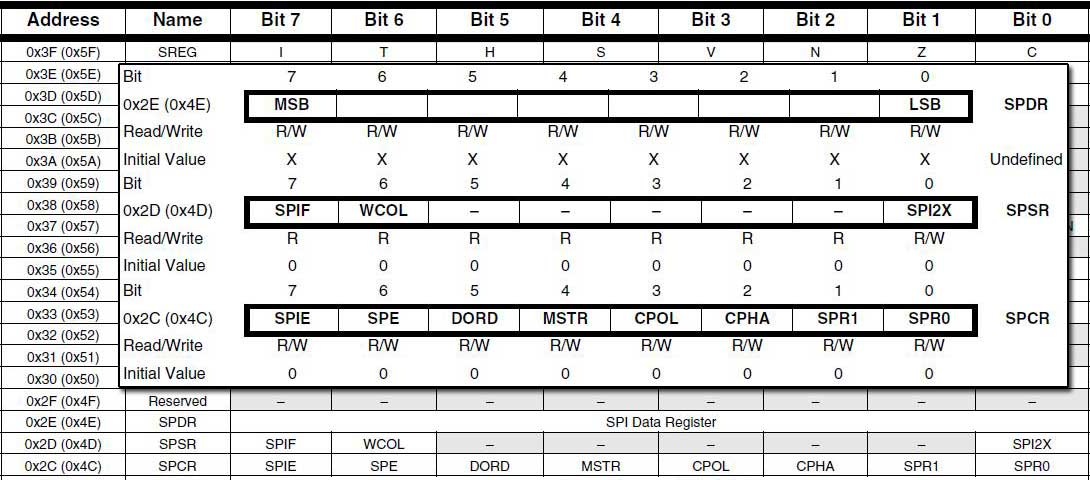

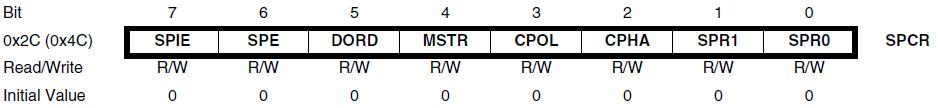

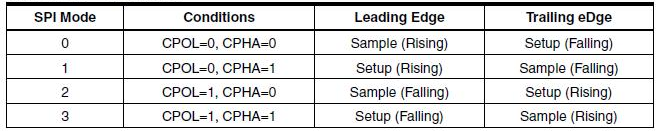

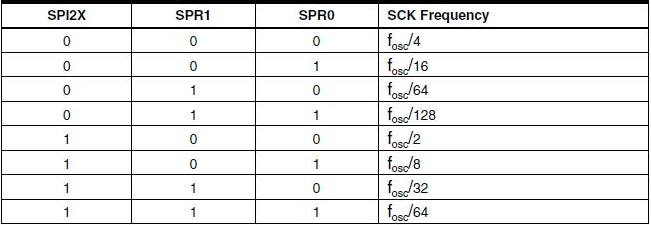

ATmega32U4 Register Summary and the I/O Port

- Three I/O memory address locations are allocated for each port, one each for the Data Register – PORTx, Data Direction Register – DDRx, and the Port Input Pins – PINx.

- The Port Input Pins I/O location PINx is Read Only, while the Data Register and the Data Direction Register are read/write.

- However, Writing a logic one to a bit in the PINx Register, will result in a Toggle in the corresponding bit in the Data Register.

- In addition, the Pull-up Disable – PUD bit in MCUCR disables the pull-up function for all pins in all ports when set.

I/O PORT PIN SCHEMATIC

I/O PORT PIN CONFIGURATIONS

Appendix A – PROGRAM I/O PORT AS AN INPUT USING MNEMONICS

In the original Read Switches example, I programmed GPIO Port C bits 5 to 0 as inputs with pull-up resistors. Read GPIO Port C into register r7 and moved bit 4 to register r8 bit 0. In addition the program did not modify Port C bits 7 and 6. In this version, mnemonics and the shift operator are used to increase clarity (i.e., make the code more self documenting).

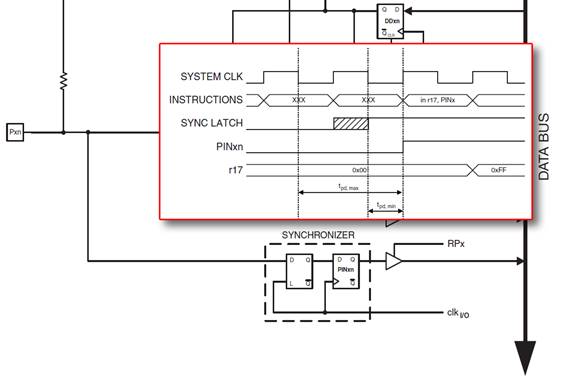

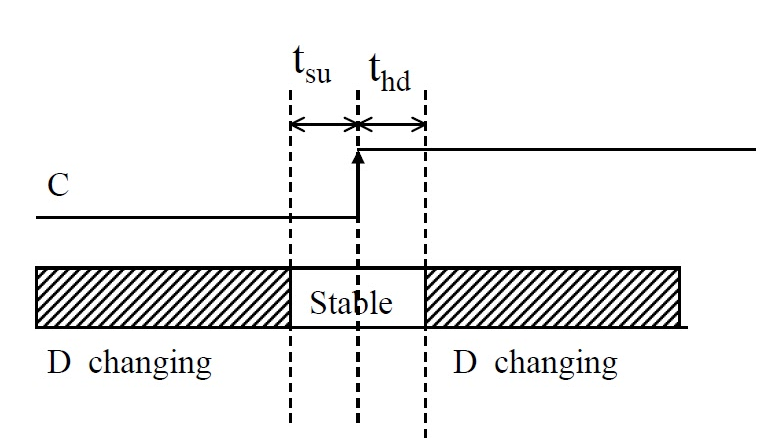

Appendix B – I/O PORT PIN “SYNCHRONIZER”

- As previously discussed, you read a port pin by reading the corresponding PINxn Register bit. The PINxn Register bit and the preceding latch constitute a synchronizer. This is needed to avoid metastability if the physical pin changes value near the edge of the internal clock, but it also introduces a delay as shown in the timing diagram.

- Consider the clock period starting shortly after the first falling edge of the system clock. The latch is closed when the clock is low, and goes transparent when the clock is high, as indicated by the shaded region of the “SYNC LATCH” signal. The signal value is latched when the system clock goes low. It is clocked into the PINxn Register at the succeeding positive clock edge. As indicated by the two arrows tpd,max and tpd,min, a single signal transition on the pin will be delayed between ½ and 1½ system clock period depending upon the time of assertion.

Appendix C – SWITCHING BETWEEN I/O PORT PIN CONFIGURATIONS

- When switching between tri-state ({DDxn, PORTxn} = 0b00) and output high ({DDxn, PORTxn} = 0b11), an intermediate state with either pull-up enabled ({DDxn, PORTxn} = 0b01) or output low ({DDxn, PORTxn} = 0b10) must occur.

- Switching between input with pull-up ({DDxn, PORTxn} = 0b01) and output low ({DDxn, PORTxn} = 0b10) generates the same problem. You must use either the tri-state ({DDxn, PORTxn} = 0b00) or the output high state ({DDxn, PORTxn} = 0b11) as an intermediate step.

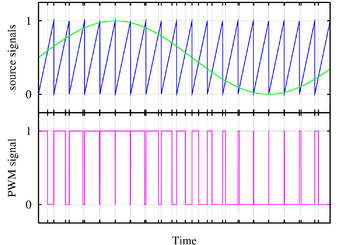

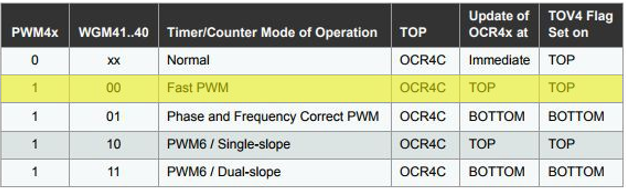

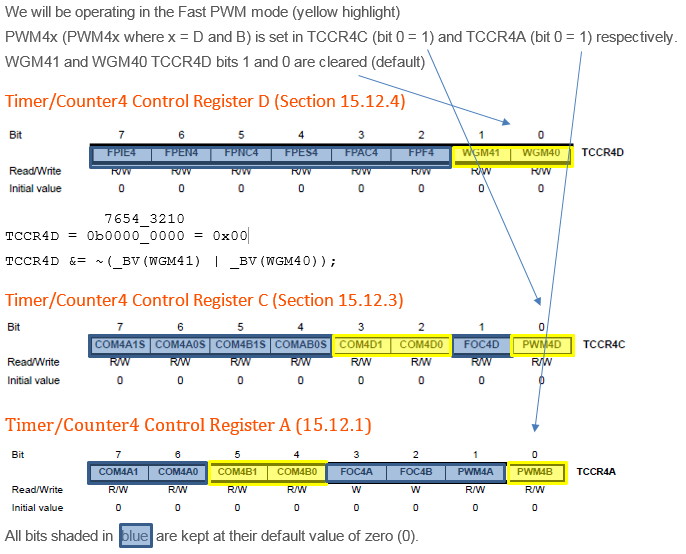

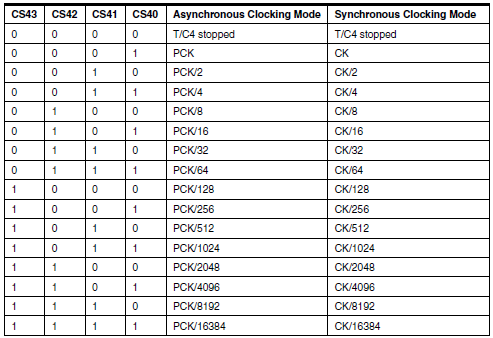

PWM Motor Speed Control using Timer/Counter 4

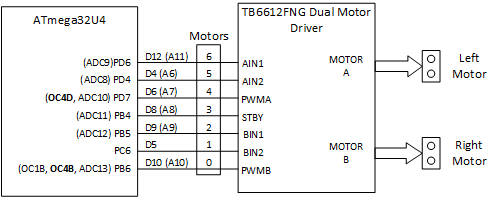

This article is on the motor control section of the 3DoT board using Timer/Counter 4 operating in Fast PWM mode.

For the remainder of this article use Figure 1 “Atmega32U4 to Motor Driver Interface” to help you cross-reference the tower of babel names used by Atmel, Arduino, and Toshiba (i.e., TB6612FNG).

The direction of motors A and B are defined by inputs AIN1, AIN2, and BIN1, BIN2.

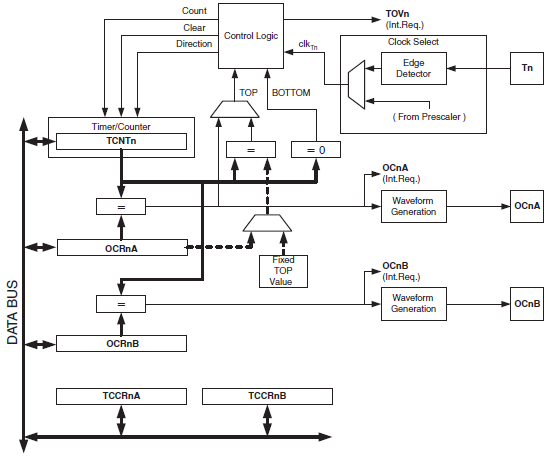

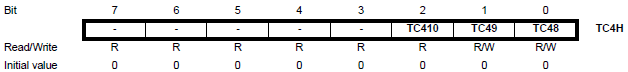

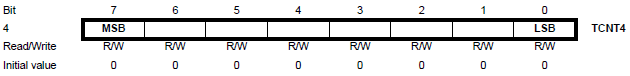

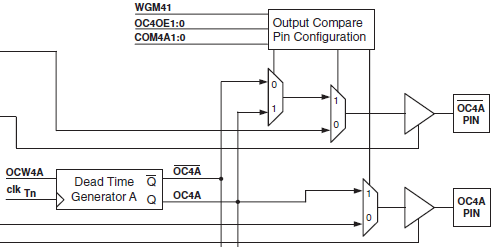

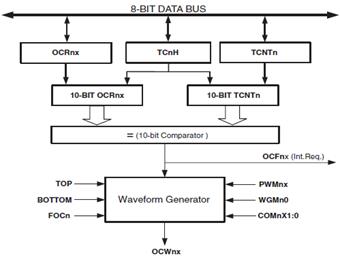

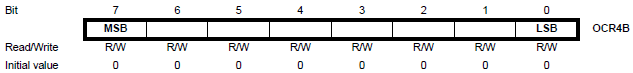

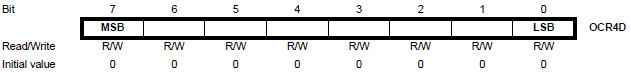

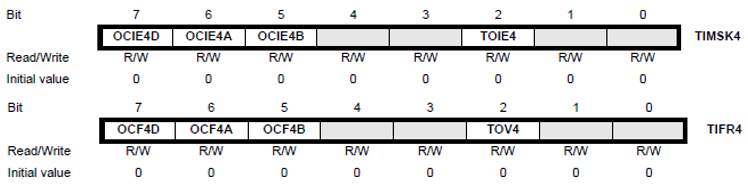

The speed of the motors A and B are controlled by changing the duty cycle of pins PWMA and PWMB respectively. With reference to Figure 1 “ATmega32U4 to Motor Driver Interface,” the speed of motor A will be controlled by Timer 4 register OC4D and motor B by Timer 4 register OC4B. The mnemonic OCnx stands for Output Compare register nx, where n is the Timer number (0, 1, 3, and 4) and x is the Compare register (Timer 4 has four (4) output compare registers designated A, B, C, and D). We will be operating our timer using “Fast Pulse Width Modulation.” I will tell you more about these registers and modes in the coming sections.

Table of Contents

Reference(s):

- The AVR Microcontroller and Embedded Systems using Assembly and C, by Muhammad Ali Mazidi, Sarmad Naimi, and Sepehr Naimi

Chapter 16: PWM Programming and DC Motor Control in AVR - ATMEL 8-bit AVR Microcontroller with 16/32K Bytes of ISP Flash and USB – ATmega32U4

Chapter 13 “8‑bit Timer/Counter 0 with PWM,” Chapter 14 “16-bit Timers/Counters,” and Chapter 15 “10-bit High Speed Timer/Counter4.”

Motor Direction Control

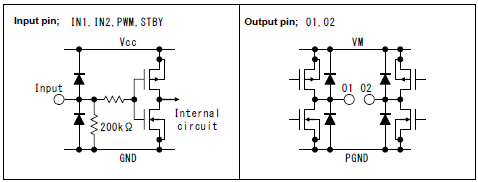

Figure 1 “Atmega32U4 to Motor Driver Interface” shows that we can configure 2 motors where each motor has 3 control pins and a standby (STBY) pin for the entire IC. If STBY is set low then the motors are not powered regardless of the state of the other two pins. The pins attached to AIN1/2 and BIN1/2 are digital outputs that control the rotation of the motor. The PWM inputs are connect to a pins capable of a PWM output to control the speed of the motor.

To prevent damage to the internal circuitry of the TB6612FNG, the IC includes clamping diodes on the inputs, a series resistor to limit in-rush current, and a weak pull-down resistor to keep the N-channel MOSFET OFF (Figure 2a Input Circuit). To prevent damage to the output circuitry internal flyback diodes are included (Figure 2b Flyback Diodes). Here is one of many articles on how to use a MOSFET as a Switch which goes into a little more details on these circuit elements.

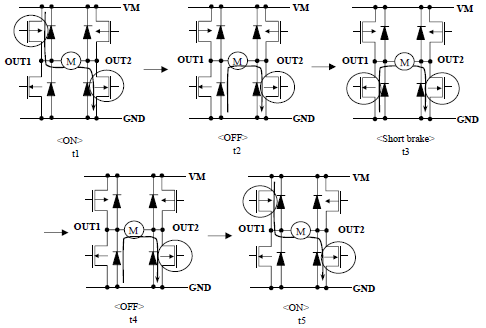

The direction in which the motors turn are defined in Table 1.

To turn clockwise (CW) you would want to set the H-Bridge to state t1 (see Figure 3 state t1). This would be accomplished by setting PD6 (AIN1) = 1 and PD4 (AIN2) = 0.

PORTD |= _BV(PD6) ; PORTD &= ~(_BV(PD4));

For a simple “toy” brushed DC motor the magnetic field of the rotor is generated by copper wire wound around a steel-laminate core. The magnetic field is switched by a commutator located on the shaft. The stator uses fixed magnets. The rotor’s copper winding from an electrical perspective is an inductor. During normal operation the back emf generated by the rotor’s winding (an inductor) as it is switched off is routed through a flyback diode (aka flywheel, free wheeling, snubber, suppresser, catch, clamp, kick back).

When switching the motor from CW to CCW care must be taken to not short the MOSFET switches on both legs of the H-bridge while also dissipating the current generated by the collapsing magnetic fields. To solve this problem a Finite State Machine (FSM) is implemented. The controlled transition from one state to the next of the FSM is illustrated in Figure 2 “TB6612FNG H-Bridge states t1 to t5” and Figure 4 “How to program switching between states to prevent short circuit conditions.”

These figures are taken from the TB6612FNG datasheet, and it is the author’s belief that the Toshiba editors made a copy-paste error for states t4 and t5 in Figure 3.

Sample C++ Code to Configure GPIO Ports

Figure 1 is duplicated here for reference purposes.

// MOTOR PINS // Motor A AIN1,AIN2,PWMA = PD6,4,7 DDRD |= _BV(PD7) | _BV(PD6) | _BV(PD4); // 0xD0 // Default to low output PORTD &= ~(_BV(PD7) | _BV(PD6) | _BV(PD4)); // Motor B BIN1,PWMB = PB5,6 and STBY = PB4 DDRB |= _BV(PB6) | _BV(PB5) | _BV(PD4); //0x70 PORTB &= ~(_BV(PB6) | _BV(PB5 | _BV(PD4))); // and for motor B BIN2 = PC6 DDRC |= _BV(PC6) ; //0x40 PORTC &= ~(_BV(PC6));

Motor Speed Control

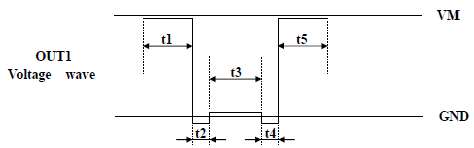

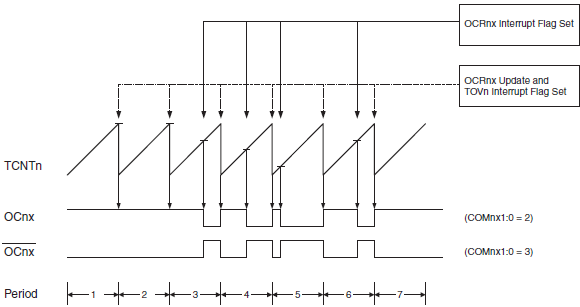

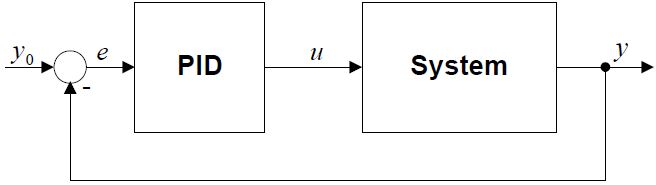

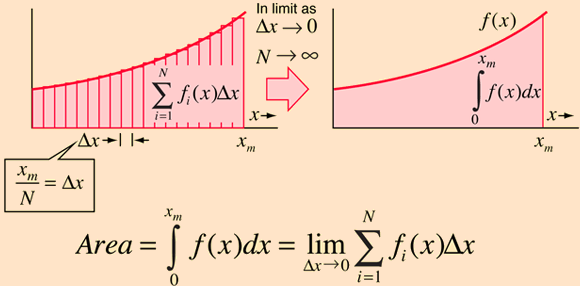

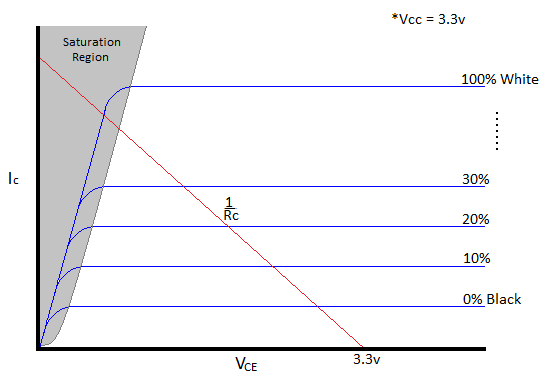

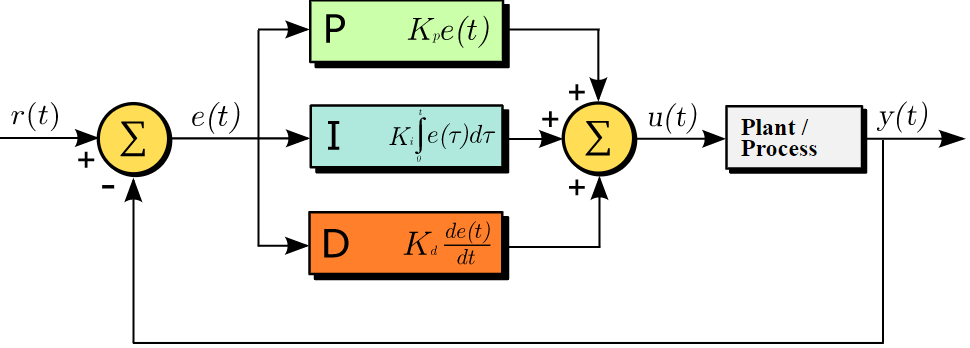

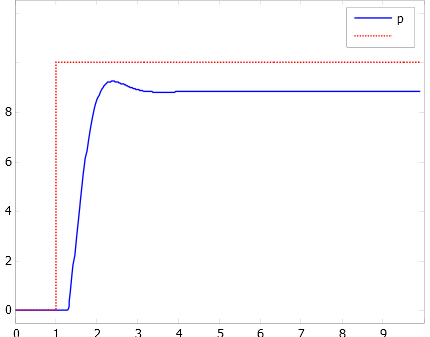

Several modulation methods have been developed for applications that require a digital representation of an analog signal. One popular and relevant scheme is pulse width modulation (PWM) in which the instantaneous amplitude of an analog signal is represented by the width of periodic rectangular wave. For example, consider the signals depicted in the figure below. Notice, the PWM version of the signal has a fixed frequency defining the point when a pulse begins. During the period of an individual pulse, the signal remains high for an amount of time proportional to the amplitude of the analog signal.

The speed of our DC motors is controlled using pulse-width-modulation (PWM). But, unlike the sinewave above, where the duty cycle changes after each cycle, we will be controlling the speed of our motors by setting a fixed duty cycle for a given speed. When the rectangular wave signal is high the motor is powered ON, and when the signal is low the power is turned OFF. The speed of the motor is controlled by the fraction of time the controlling signal is ON (duty cycle = Th/Tp %, where Th = time high and Tp = clock period).

ATmega Timer Modes