Lab 0 – Line Sensing QRE1113 Reflectance Sensor

Table of Contents

Overview

By Miki

IR sensors are commonly used in robotics to detect obstacles and for line following applications. We are using IR sensors for our robots to detect the lines along the 2D maze surface. If our robots can detect a range of grayscale values, so they can navigate the maze. With our current parameters, the IR sensors cannot detect a large range of grayscale values (i.e. low resolution detection).

Goal: Design a circuit that maximizes the resolution of the IR sensors for our robots to navigate through the maze.

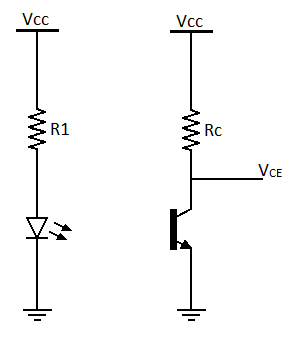

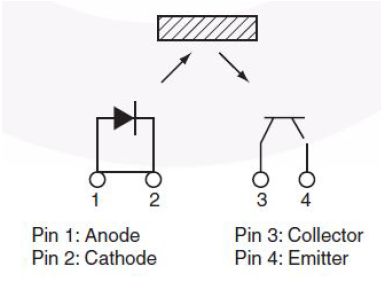

The QRE1113 sensor consists of an IR emitting photo diode and an IR sensitive phototransistor. The photodiode emits IR light that gets reflected back to the sensor when an object is in the light’s path.

.

The phototransistor inside the sensor detects the reflected IR light. The base of the phototransistor is open (not connected – floating). When the reflected IR light enters the base of the phototransistor, the light is converted into a base current that controls the collector current of the transistor (EE330 comes in handy here).

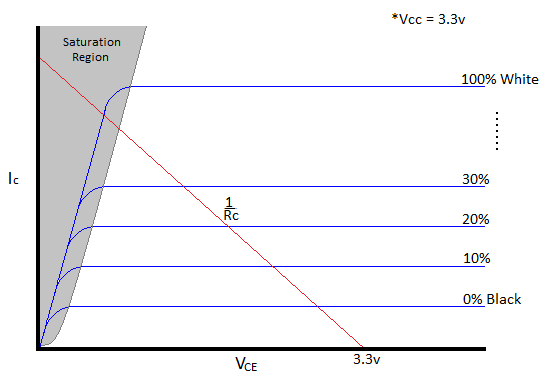

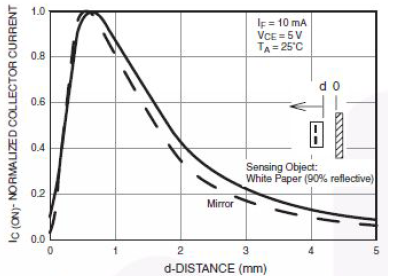

The intensity of reflected IR light determines the curve for the current flowing into the collector, as shown in the following graph (Ic vs. Vce). When the intensity of reflected IR light into the base increases, the collector current will increase (i.e. move to a higher curve).

We then place a load line across the graph. The load line represents Vce, the voltage across the

transistor (from collector to emitter). This is the voltage that is read by the ADC in the microcontroller.

We can derive the load line using simple KCL:

Solve for to get the equation of the load line:

In order to maximize resolution, we need to choose the best load line. We therefore need to design a circuit that uses the best value for Rc.

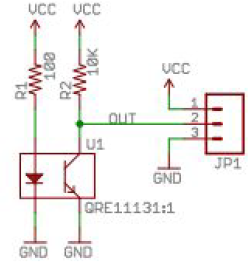

Here is link to the QRE1113 Miniature Reflective Object Sensor used in the SparkFun Analog (Figure 1) and Digital Line Sensor Breakout boards. Here is a short tutorial on the Line Sensing QRE1113 Reflectance Sensor + Arduino , which explains the difference between the Analog and Digital signal conditioning circuits used with the QRE1113. In this lab we will breadboard the “discrete” version of the SparkFun breakout board as shown in Figure 2.

Figure 1 QRE1113 Miniature Reflective Object Sensor

Figure 2 Schematic of SparkFun Analog Line Sensor

Experimentally it has been shown that resistors R1 and R2 used in the Sparkfun “Analog Line Sensor” circuit (Figure 2) do provide a linear output across a uniform grayscale. One of the objectives of this lab is to experimentally determine the optimal resistor values for R1 and R2. To accomplish our objective we will conduct a series of experiments.

From Figure 3 below we see that there are four (4) independent variables

1. Grayscale target

2. Distance to target (variable d )

3. LED current (variable IF )

4. Phototransistor bias (DC load line)

Lab Supplies

● QRE1113 Miniature Reflective Object Sensor (provided)

● 47 ohm resistor and Set of Resistors

● Multi-turn variable resistor – anything above 100 ohms and less than 1K ohm

● Mini , half, or normal breadboard with Jumpers

● Multimeter

● Cables with alligator clips for ECS-314 lab equipment

● Large Post-it Notes or Yellow Pad (may be provided)

● Large Binder Clip(s)

● Hole punch and/or X-Acto knife, a steel ruler, and a cardboard surface to cut on. ( See Note 1 )

● Micrometer (optional)

● Sparkfun ATmega32U4 Pro Micro – 3.3V/8MHz , Arduino Leonardo , or Arduino UNO.

Note 1: One group will be running the labs in ambient light. This group not need the a hole punch or X-Acto knife.

Arduino Code

//Code for the QRE1113 Analog board

//Outputs via the serial terminal – Lower numbers mean more reflected

int QRE1113_Pin = 0; //connected to analog 0

void setup () {

analogReference(EXTERNAL);

Serial.begin (9600);

// See Note 2

}

void loop () {

int QRE_Value = analogRead (QRE1113_Pin);

Serial.println (QRE_Value);

}

*Source: Line Sensing QRE1113 Reflectance Sensor + Arduino

Note 2: As shown in Figure 3 “Experimental Circuit” the circuit is powered from a 3.3v source (Vcc = 3.3v). If you are using a 3.3v Arduino (3DoT or ProMicro 3.3v/8MHz) then no action is required. If you are using a 5v Arduino then power the circuit from the 3.3v output pin and wire a jumper from 3.3v through a 5kΩ resistor to the AREF input pin. Make sure to include the resistor, or you will risk potential damage to the microcontroller. In addition before taking any measurements be sure to set the reference voltage to AREF. This AREF voltage must be present at the reset of the microcontroller and remain the same throughout the experiment. In other words, AREF cannot be set dynamically. Consequently, all analog measurements with be taken with the reference voltage set to 3.3v.

Information about using the analogReference() function can be found here.

Arduino Output using Serial Monitor (Print) and Serial Plotter

.

Excellent Video tutorials on Arduino Print function ( Part 1 and Part 2 ), analogRead ( Part 1 and Part 2 ). Here is documentation on using the Arduino Serial Plotter (Arduino IDE versions 1.6.7 and later).

● Arduino Forum

● Instructables

Bonus Points: You may want to also export your data and plot in Excel or Matlab.

The QRE1113 Sensor Jig

Details

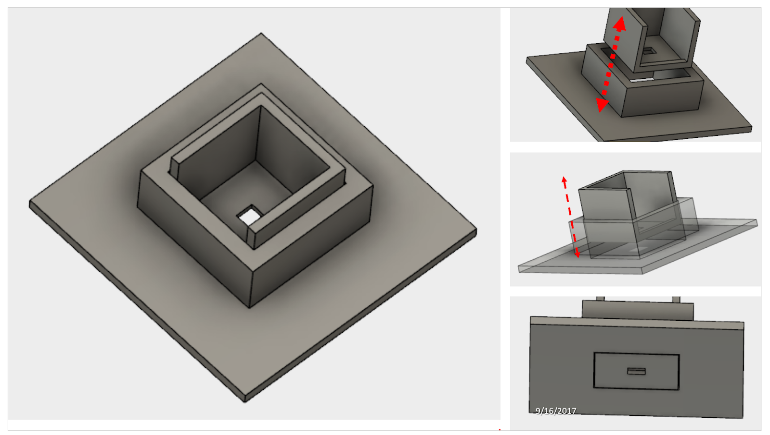

This device was first designed by Roy Benmoshe. It has two main features that make it useful during this lab. First, it blocks out almost all ambient light that could get between the sensor and the surface and possibly skew data results. Its second purpose is to provide a simple, consistent means of adjusting the sensor’s height.

The jig consists of a baseplate supporting a square column. A smaller, four-sided cube slides inside the column. From the picture above, we can see how the cube is able to be slide up and down within the cutout while remaining level. The QRE1113 reflective sensor is positioned so that its viewing window is directly over the small hole in the bottom of the cube.

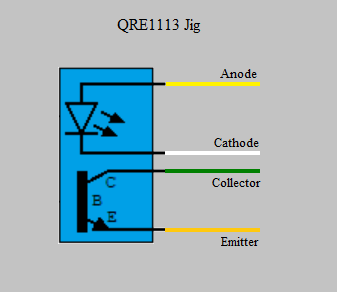

The sensor has been permanently “potted” inside the square column leaving only four wires exposed. Below the wiring diagram for the jig can be seen.

WARNING: Inaccurately connecting the wires to your circuit could permanently damage and/or destroy the sensor. The voltage source powering your sensor should be 3.3v, NOT 5v. Also be sure to check that you have placed a limiting resistor ( at least 47Ω) in addition to your potentiometer between Vcc and the anode of the LED before any power is introduced to the circuit.

Use

- Place the baseplate onto the testing surface with the sensor facing down

- With the sensor connected to your circuit, slide the small cube containing the sensor into the baseplate (see top right picture above) until both bottom surfaces become flush. Note that the top of the cube will still sit slightly above the top surface of the baseplate (see left picture above).

- Adjust the height of the sensor by sliding the small cube away from the testing surface in 0.2mm increments.

3a. This can be done multiple ways however, the easiest way we found was to cut a square section (roughly 1.5 cm X 1.5 cm) out of an entire standard pad of sticky-notes. Note this section must be smaller than 2 cm X 2 cm, so it can fit inside the square column.

3b. This sticky-note pad can then be placed between the small cube that houses the sensor and the testing surface. You can then push slightly on the baseplate, so its bottom face returns to the testing surface and the cube is displaced the exact distance of the sticky-note pad thickness.

3c. Once the cube has been displaced to the appropriate height, the sticky-note pad is removed and, due to the friction between the cube and the baseplate, the displacement distance will remain the same.

3d. The distance of the displacement (i.e. distance between the sensor and the surface) can be adjusted by peeling off a predetermined number of sticky-note sheets (1 sheet ≃ 0.09 mm). For this reason it would most likely be easiest to start with the maximum height desired (5 mm) during the test, then peel off sticky notes in 0.2 mm intervals until the minimum desired height was reached.

Experiment 1 – Optimum Distance to Target

.

1. Grayscale target – White Paper

2. Distance to target – independent variable [0.2mm steps, 0 – 5mm ]

3. LED current = 20 mA

4. Phototransistor bias (DC load line) = 10K

Experimental Setup

As discussed in lab. You will need the following.

● Notebook paper

● Voltmeter and variable resistor – record voltmeter accuracy

● Arduino microcontroller board (3DoT, Sparkfun ProMicro 3.3v, Leonardo, Uno)

Important Notes:

- As shown in Figure 3 the circuit is powered from a 3.3v source (Vcc = 3.3v). If you are using a 3.3v Arduino (3DoT or ProMicro 3.3v/8MHz) then no action is required. If you are using a 5v Arduino then power the circuit from the 3.3v output pin and wire a jumper from 3.3v to the AREF input pin.

- All experiments should not allow room lighting to reach phototransistor.

Experimental Output

For each experimental step d = 0 – 5mm, in ≃ 0.2mm steps take readings using a voltmeter and as read from the Arduino serial output port (analogRead ).

Solving the equation provided in the Analog-to-Digital lecture and provided here for VIN , convert the Arduino ADC output (units are a Digital Number – DN) into its corresponding voltage ( VIN ).

, where

= 3.3v

Using Ohm’s law, and measured value for R2 (≃ 10KΩ), calculate Ic . On one graph using two different notations (ex. X = Voltmeter, O = Arduino) plot your experimental results. Using Excel, Matlab, etc. curve fit your experimental results for both sets of readings (again on a single plot). Your resulting plot should take the form shown in Figure 4. Differences from this figure include IF = 20mA, VCE = 3.3v, TA = measured; Two plots (Voltmeter, Arduino) and no “Mirror” plot; Actual current (not Normalized).

Based on team assignment set d = [Optimum, 1, 2, 2.5, 3, 3.5, 4] mm

Experiment 2 – Optimum LED Current and R1

.

1. Grayscale target – White Paper

2. Distance to target d – Based on team assignment

3. LED current = independent variable IF = 0 – 40 mA, in 2 mA steps

4. Phototransistor bias (DC load line) = 10K

As in most engineering problems there is a tradeoff to be made. In this case we want to use the minimum amount of power, while also achieving the best resolution possible.

Experimental Output

For each experimental step IF = 0 – 40 mA, in 2 mA steps take readings using a voltmeter and as read from the Arduino serial output port (analogRead). Following the procedures outlined in Experiment 1, create a plot, which should take the form shown in Figure 5. Differences from this figure include Two plots (Voltmeter, Arduino).

As an ancillary objective measure the forward voltage ( VF ) drop at different forward current values ( IF ). For each experiment record the room temperature.

Based on IF current assigned [5, 10, 15, 20] to the team find R1

Experiment 3 – Optimum R2 based on Team Assignment

.

1. Grayscale target – White Paper

2. Distance to target d – Based on team assignment

3. LED current IF – Based on team assignment

Experimental Objective

One of the key objectives of this lab is to experimentally generate Figure 4 “Collector Current vs. Distance” between device and target and Figure 8 “Collector Current vs. Collector to Emitter Voltage” as shown in the QRE1113 Miniature Reflective Object Sensor datasheet.

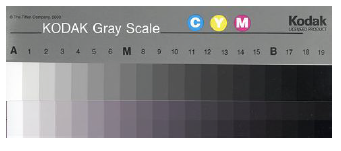

The characteristic curve for the Phototransistor (Figure 8) will be generated from a gray scale as provided here. Base on experimental results you may be required to focus on additional gray scale images.

Figure 7 Sample Gray Scale Page

Figure 7 Sample Gray Scale Page

Experimentally, once an optimum distance has been experimentally determined, the transistor characteristic curve will be generated using a load line for each gray scale target (see Figure 9 ”Sample transistor characteristic curve with load line”).

Use the above information and your EE330 “Transistor Characteristic Curve Lab” to complete this lab. As before please collect data using a multimeter and your Arduino.

Based on experimental results calculate R2

Reference Lab Experiments

● Photo Transistor Characteristics by Dr. Gabriel M. Rebeiz

● Lesson 1452, Optoelectronics Experiment 6, Photodiode and Phototransistor Current Measurements

● http://inst.eecs.berkeley.edu/~ee105/sp11/labs/Lab3.pdf

● http://archivio.iav.it/Doc/Vanni_Paolo/5CNT/EE332LE1rev3.pdf

Lab Report

Introduction

The introduction essentially summarizes the entire experiment. It defines the purpose of the lab and explains the goals and/or what one is trying to learn in the process. It should also present any concepts (scientific theories, previous experiments etc.) that act as background information, which would be crucial to understanding the lab.

Materials/Setup

This section should, as the name implies, include a list of all materials used to complete the lab. It will also explain how each of these items were prepared in order to obtain the results of the experiment. It is important to be as detailed as possible here, both to eliminate procedural ambiguity and to increase the lab’s ability to be reproduced.

For this lab specifically, all three experiments will share a materials section however, each will have its own setup procedures. Also, many students have found it easier to include pictures of their setup with only a brief description.

Discussion

The discussion is the main section of the lab report, where the data from the experiment is presented and both it and the lab itself are reviewed. This includes any challenges encountered during the procedures, as well as reaction to the data. Interpretations of the results themselves should be avoided in this section, and discussion should instead be limited to answering questions such as how successful the experiment was and how the data compared to the expected outcome.

In this specific lab, experimental data must be presented using graphs. Since there are three separate parts to this experiment, there should also be three subsections under the main discussion section, each presenting its corresponding data. Graphs can be generated in a number of ways however, the most common forms seen in this class are MATLAB and Microsoft Excel.

Conclusion

The conclusion section elaborates on the claims made during the discussion. It seeks to provide an explanation as to why the results appear the way they do, and whether or not they make sense in the context of the initial goal of the experiment. It is important to state if the goal was achieved, as well as what was learned during the course of the lab.

Appendix

The appendix section is where all code used during the lab should go. For this experiment, that includes both the Arduino code for reading the sensor, as well as any code used to generate the graphs (MATLAB, Python etc.). Each block of code should have a corresponding subsection within the appendix. For example, all of the Arduino code might be labeled as subsection “A”, while the entire MATLAB code could be labeled as “B”.

.

.

Lab 0 Deliverable(s)This lab requires a full, written lab report. Only one report per team is required, which will be submitted via the “Dropbox” folder in Beachboard. The outline and requirements for this report can be found above in the section labeled “Lab Report”. All lab reports should represent your own work – DO NOT COPY. |

Checklist

- Your lab report follows the format listed above under the “Lab Report” section, including an abstract, introduction, materials/setup, discussion, conclusion and an appendix

- Graphs have been generated for each of the three experiments

- A graph of “IC vs VCE” is included

- A graph of “IC vs Distance” is included

- A load line is included on the appropriate graph

Appendix

C++ Robot Lab 1 – An Introduction to 3DoT & C++

Table of Contents

Introduction

This lab training sequence is designed to introduce you to the 3DoT Board. the Arduino Integrated Development Environment (IDE), C++ programming, and the methodology used to navigate the maze. Plus, you will learn about the power of library files. Library files are simply files that you instruct the Arduino IDE to include in your program. In this lab, you are going to create a library file called 3DoTConfig.h that handles all of the initialization and configuration for your robot.

What Is New

New terminology and concepts are listed below under “Bit/Byte Operations” and “Pin Configuration & Control”. If you have any questions on this information, refer back to the lectures on the introduction to C++ and configuring the GPIO registers.

C++ Essential Training (Required)

This Linda tutorial provides a comprehensive review of the basics of C++.

Getting Started in Embedded Systems (Required)

This Linda tutorial offers a nice introduction to C++ and embedded systems.

Please download certificates when you have completed the tutorials and submit them on Beachboard.

Please download certificates when you have completed the tutorials and submit them on Beachboard.

Data Types

uint8_t variable // Define variable data type as an unsigned 8 bit integer (0-255) uint16_t variable // Define variable data type as an unsigned 16 bit integer (0-65,535) int8_t variable // Define variable data type as a signed 8 bit integer (-128 to 127) int16_t variable // Define variable data type as a signed 16 bit integer (-32,768 to 32,767) const uint8_t variable // Qualify variable as a constant static uint8_t variable // Qualify variable that will persist after a function return

C++ Code

Preprocessor Directives

#define Name Text // Replace every occurrence of Name with Text. #include// Include avr/io.h library located in the Arduino program folder #include “filename” // Include library located in the sketch (i.e., program) folder

Bit / Byte Operations

variable = byteValue << numberOfShifts; // Left shift byte value by specified number of bits. variable = _BV (bitNumber); // Create a byte with specified bit set to 1. variable |= _BV(bitNumber); // Set specified bit within a byte variable. variable &= ~_BV(bitNumber); // Clear specified bit within a byte variable variable = !another_variable // C++ Boolean NOT operator

Arduino Built-In Functions

Pin Configuration & Control

pinMode(pin_number, TYPE); // Define digital pin and set type as INPUT, OUTPUT, or INPUT_PULLUP digitalRead(pin_number); // Read digital value from specified digital INPUT or INPUT_PULLUP pin. digitalWrite(pin_number, value); // Write digital value to specified digital OUTPUT pin.

3DoT Overview & Mission

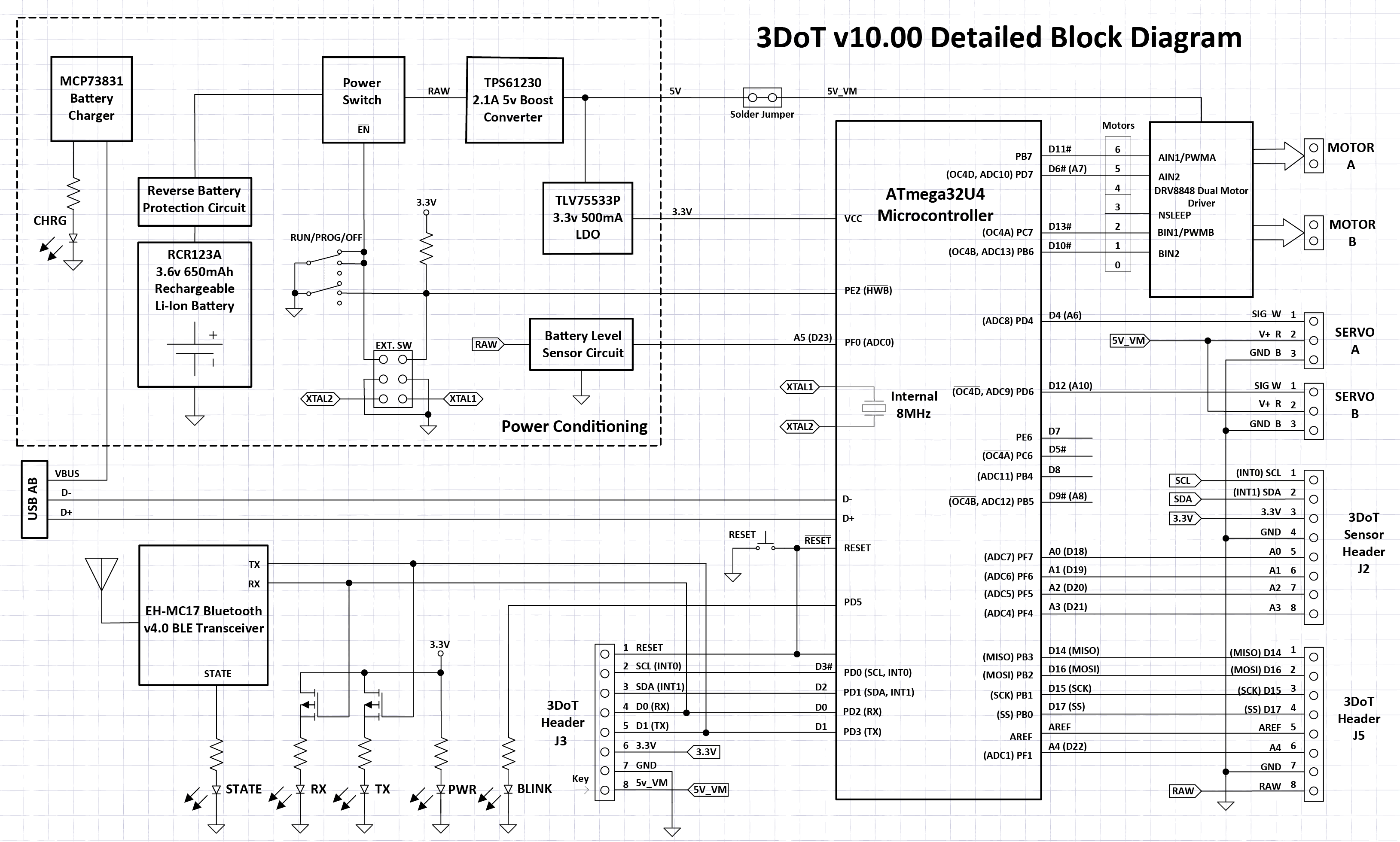

The end goal of these labs is to program a robot utilizing the 3DoT board and be able to navigate a maze autonomously. Shown below are the major features of the 3DoT board and the block diagram of the latest version.

3DoT is a micro-footprint 3.5 x 7 cm all-in-one Arduino compatible microcontroller board designed for robot projects.

- Microcontroller: ATmega32U4

- Bluetooth: FCC-certified BLE 5.0 module

- Power Management:

- RCR123A battery holder

- Included 600 mAh rechargeable battery

- Microchip MCP7383 battery charge controller

- External battery connector – for input voltages between 4 – 18 V

- Reverse polarity protection – plug in the battery backward? No problem

- Motors & Servos:

- 2x JST motor connectors

- 2x standard servo connectors

- Expansion:

- 16-pin top female headers for shields – providing I/O, I²C, SPI, USART, 3.3 V, and 5 V.

- The forward-facing 8-pin female header for sensor shields – providing 4 analog pins, I²C, and 3.3 V power – for sensor shields like infrared or metal-detecting shields. Great location for headlights, lasers, ultrasonics, etc.

- Programming switch: Three-position switch for easy programming

- No more double-tapping a button and rushing to program your board, or your robot trying to drive away while programming. Set the switch to PRG to program, RUN to execute your code.

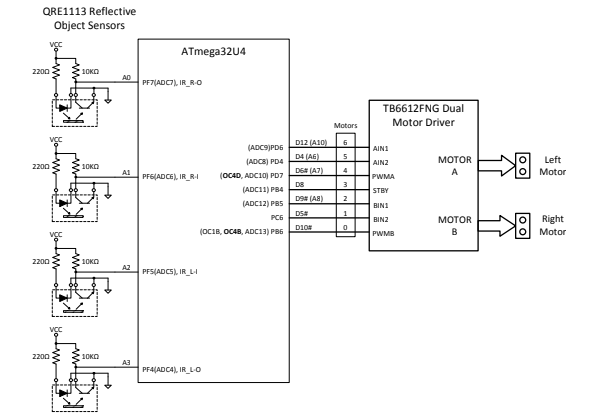

It would be ideal to spend some time analyzing the block diagram to get a better understanding of the capabilities of the 3DoT board but we will focus on the connections between the motor driver and IR sensors for Lab 1. Figure 3 provides an isolated view of those connections.

3DoT Block Diagram v10 3DoT v10 Detail Block Diagram 201215

.

Errata: AIN1, AIN2/PWMA,BIN1,BIN2/PWMB,NSLEEP wired to 5V_VM

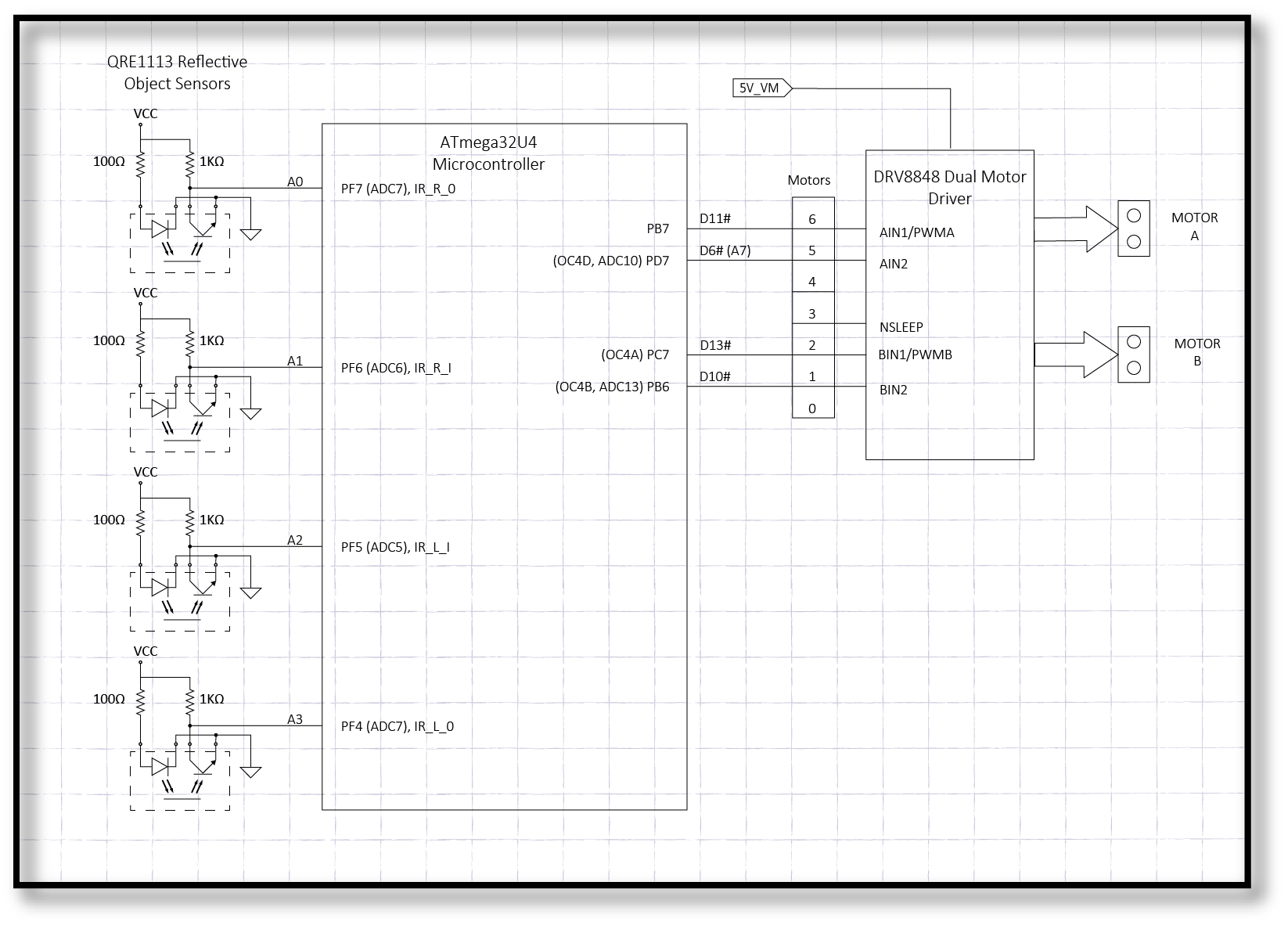

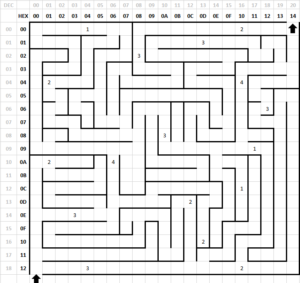

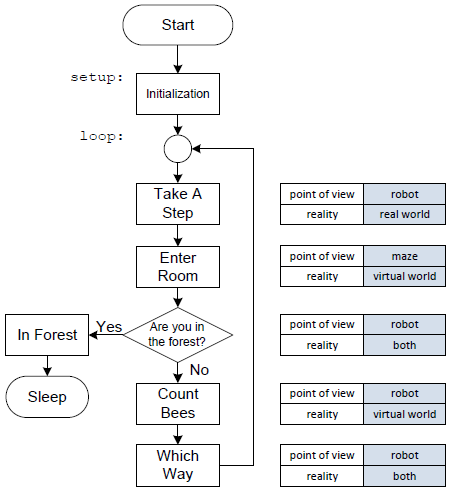

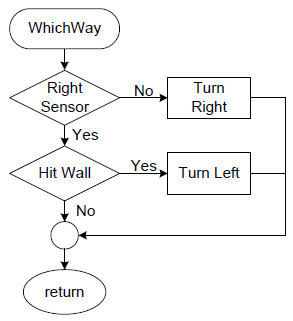

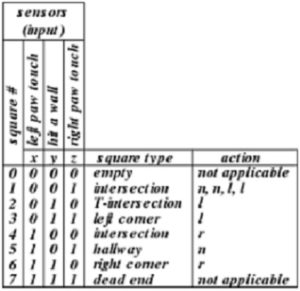

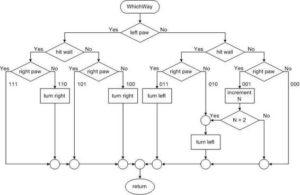

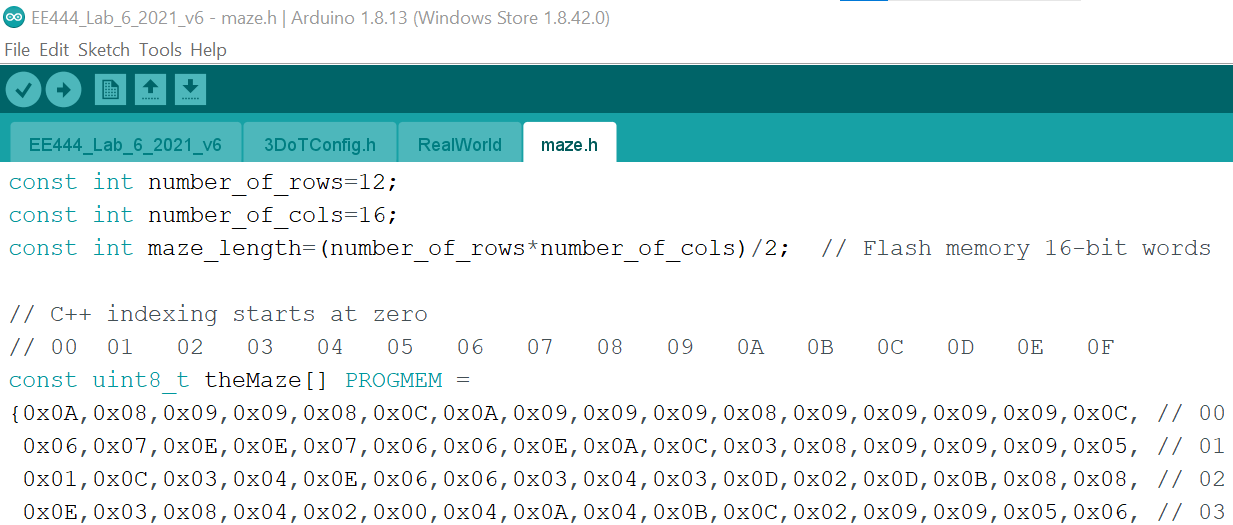

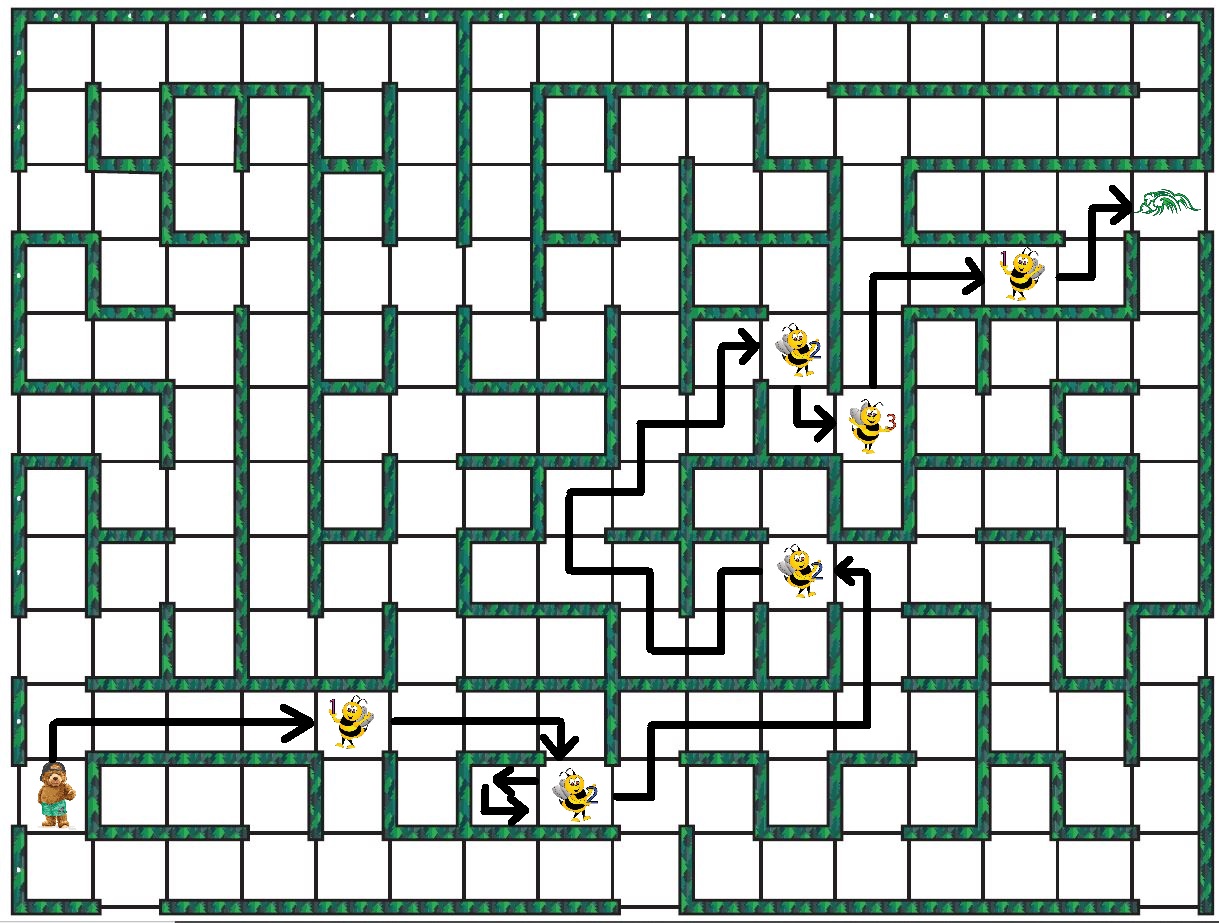

The main objective of Lab 1 is to develop the path following logic for your robot to move through the maze shown in Figure 4 “The Maze.” We will handle what to do at intersections in later labs. The path following algorithm reads data from two of the four IR sensors and decides how the control signals being sent to the motor driver need to change based on that information. The outside IR sensors provide the most relevant data about your robot’s position as it follows the path and is what we will be focused on. You can read the two inside sensors to verify the robot has not left the path. To start developing this code, you will need to configure the input and output pins.

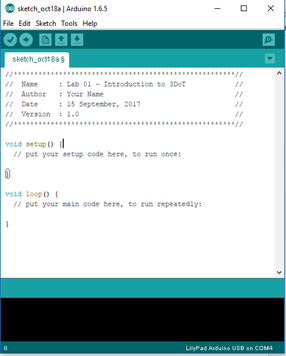

Introduction to the Arduino IDE

In the lab, you will be spending most of your time working within an Integrated Development Environment (IDE). For our labs, we will be working in the Arduino IDE. The IDE lets us write our program in a human-readable form (C++) and then translate it into a machine-readable form understood by the ATmega32U4. There are many other types of IDEs for C++ programmings such as Eclipse and Atmel Studio 7 that allow us to create very complex projects. The focus will be on the Arduino IDE because of how easy it is to learn and use.

Before continuing complete the ARDUINO IDE 3DOT TUTORIAL, up to and including and running the BLINK test script.

Before continuing complete the ARDUINO IDE 3DOT TUTORIAL, up to and including and running the BLINK test script.

Creating A New Sketch In Arduino IDE

To start, create a new sketch in the Arduino IDE. When the Arduino IDE launches, it should open a blank sketch. If you do not see a blank sketch, click File > New as shown in the figure below.

The first thing you will be adding is a title block to describe the purpose of the sketch and the author. This will go before the setup function and should look something like this.

Next, you will need to rename the sketch to a more descriptive name. Click on File -> Save and type in the name you want to save it as such as Lab01. The application will create a folder for your sketch in the location you have designated for all sketches (Default is in the Arduino folder located in My Documents). Now let’s take a look at the hardware before developing the code to control it.

Making the 3DoTConfig.h Library File

Libraries allow us to place useful definitions and initialization code outside our main program. Once created and included, the user can still call these functions and reference these definitions in their main .ino file. Libraries make the main program much cleaner and simpler to understand.

A C++ library file typically includes a header file (.h) that provides the prototypes of the functions in the library and a .cpp file that has all of the C++ code. For Lab 1 the library header file will include the actual C++ code and be used to configure the robot. First, a new header “.h” file will need to be created. Click on the icon and select “New Tab” as shown in Figure 7 below. Name the file 3DoTConfig.h

Simply copying and pasting the following HTML text may insert hidden characters into your code, resulting in multiple compiler errors. The author recommends manually typing in the following material.

Simply copying and pasting the following HTML text may insert hidden characters into your code, resulting in multiple compiler errors. The author recommends manually typing in the following material.

Place the following include directives at the beginning of your sketch. The quotes (“) around “3DoTConfig.h” instructs the application to look in the folder containing the program (your .ino file).

#include "3DoTConfig.h"

void setup() {...

Using #define to Create Descriptive Names

The #define preprocessor directives (or macro) instructs the compiler to replace an identifier with its associated text string.

Unlike C++ instructions, preprocessor directives do not end with a semicolon (;).

For this series of lab, the #define preprocessor directive, associates an Arduino pin name with its 3DoT equivalent as defined in Figure 3 “Reflective IR Sensor to Motor Driver.” For example, this #define macro will replace every occurrence of the text string IR_R_O (i.e., the outside IR sensor trace) with the text string A0 (i.e., it Arduino pin name).

#define IR_R_O A0 // IR_R_O = analog pin A0

Place the #define macro preprocessor definitions for IR sensor traces IR_R_O, IR_R_I, IR_L_I, and IR_L_O in the newly created 3DoTConfig.h file.

The same can be done for the control signals to the motor driver so that each motor and its associated pins can be clearly distinguished from the other. Add #define macro preprocessor definitions for AIN1, AIN2, NSLEEP, BIN1, and BIN2.

In addition, define synonyms PWMA and PWMB.

// Synonyms #define PWMA AIN2 #define PWMB BIN2

To provide visual feedback for future tests, we will be using the built-in LED wired to ATmega32U4 Port D pin 5. Physically, the LED is located between the switch and the micro USB port (Figure 1). See if you can find the built-in LED on the schematic in Figure 2 “3DoT Detailed Block Diagram.” Add a #define preprocessor directives for the built-in LED.

#define LED_BUILTIN PD5 // Built-in led is wired to ATmega Port D pin 5

Unlike the previous definitions which used the Arduino naming convention. The LED_BUILTIN definition uses the ATmega32U4 naming convention.

An alternative approach

For digital pins, this can also be done by creating a variable that is set to the pin number. Since these values will never change, a const qualifier is added. This new form has the advantage that it allows the compiler to check scope and datatype. It has the disadvantage that it uses SRAM to save these constants. Our first #define example could therefore be replaced with the variable definition

const uint8_t IR_R_O = A0;

In this instance, the author recommends the #define directive over a constant variable based on the savings in RAM.

Quick Check

The 3DoTConfig.h file should contain twelve (12) #define preprocessor directives.

Configuring the Input and Output Pins

The first thing that needs to be done is to define what pins are going to be used for the Atmega32U4. Just because components have been hardwired to specific pins does not mean the microcontroller knows what they are being used for. You will need to configure the input and output pins. In the next section, the Arduino’s built-in functions are used to configure the input and output pins. In the design challenge, you will apply what you learned in the lecture to directly modify the GPIO registers (DDRX and PORTX) in C++.

Add the following function definition to the 3DoTConfig.h file after the last # defines statement.

void init3DoT() { // add code here };

Place the following line of code in the setup() function.

void setup() { init3DoT(); }

In a previous section, pins were assigned to the IR shield and motor driver. Once the Arduino preprocessor knows the name of a pin, the program can configure the pin as an input or output, using the pinMode() function. Once a pin has been configured, the program can read or write to the pin using the Arduino digitalRead() and digitalWrite() functions.

Initialize the Motor Driver

Start the initialization of the ATmega32U4 by defining Motor Drive pin AIN1 as an output and initializing it to zero (OFF).

void init3DoT() { pinMode(AIN1,OUTPUT); // Digital pin AIN1 is an output digitalWrite(AIN1,LOW); // Left Motor OFF }

Following the above example, configure motor driver pins AIN2, NSLEEP, BIN1, BIN2 as outputs and initialize to zero.

Initialize the IR Sensors

Next, initialize the right outside IR sensor as a digital input.

void init3DoT() { pinMode(AIN1,OUTPUT); // Digital pin AIN1 is an output digitalWrite(AIN1,LOW); // Left Motor OFF : pinMode(IR_R_O,INPUT); // Analog pin A0 }

Following the above example, configure IR pins IR_R_I, IR_L_I, IR_L_O as inputs.

Initialize the Built-in LED

Finally, initialize the Built-in LED pin as an output and initialize to zero. The Arduino reserved words LOW and HIGH are of datatype uint8_t and have values 0x00 and 0x01 respectively. Also note that like LOW and HIGH, LED_BUILTIN is colored cyan.

pinMode(LED_BUILTIN,OUTPUT); digitalWrite(LED_BUILTIN, LOW); // Turn the built-in led OFF

Reading and Interpreting the IR sensor Data

The IR sensors provide feedback as the robot follows a line. In this section, you will learn how to read the IR pins as digital inputs.

As a digital input, the input value read from the IR sensor when it is over a black line is HIGH (a value of 1), otherwise, it is LOW.

| white | 0 |

| black | 1 |

This is determined by the microprocessor’s own threshold for digital logic and cannot be modified. While there is no customization, it is very useful for situations that have only two states and is easy to implement. Within the Arduino IDE, this is done using the digitalRead()function.

IR Sensor Test

Before continuing, let’s do a quick check to see if the IR sensors are working. This test will also use the BLINK led to provide visual feedback as you debug your code. Place the following test code in the loop() section of the program.

void loop(){

int val = digitalRead(IR_R_O); // read IR sensor

digitalWrite(LED_BUILTIN, val); // display on blink led

}

To run the test you will need to upload the code to the robot. This is a two-step process after the hardware has been prepared. The first thing that needs to be done is to verify the code by clicking on the checkmark on the top left corner (the verify button). This will compile and check the code to see for any syntax errors. Any error messages will appear in orange at the bottom of the window and will need to be fixed before the program can be uploaded to the board. Once verified, upload the compiled code to the board using the right arrow button (upload button) that is next to the verify button. If everything went correctly, the led should turn OFF when the right outside IR sensor is over a white or reflective surface and ON otherwise. Tip: Placing and then slowly lifting your finger off the IR sensor will also turn it on and off.

Test the operation of the other IR sensors by replacing IR_R_I with the names of the other IR sensors (i.e, IR_R_O, IR_L_I, and IR_L_O), uploading, and rerunning the test.

Debugging Tips

If the output is always 1, this may be due to the sensor’s height off the path or the IR LED not being ON. First, try placing your sensor closer to the line. If this does not work, verify that the IR LED is ON by looking at the sensor with your cell phone camera. Some cell phone cameras have an IR filter that can block the light. Consequently, if your camera initially does not see the LED try another phone. If you still can not see the IR LED verify that the shield is powered (3.3v).

If the output is always 0. Stray light is probably saturating the photo-transistor. This problem may be solved by simply adding the paperBot shell or taping paper around the boot to block the light from entering the sensor.

If none of the above work, remove the IR shield and using a resistor and/or jumper, wire the analog pin to 3.3V and GND, and verify built-in LED turns ON and then OFF.

Controlling the Motors

Wiring the Motors

Now let’s teach the robot how to move forward. Verify that the robot’s motors are wired correctly as shown in the PaperBot Chassis Build Instructions video and Figure 8 “Wiring the Motors.”

Motor Control Settings

Figure 9 “3DoT Pinout and Motor Driver Truth Table” is a great resource that you will be using over the course of the semester.

Use the following truth table when programming your robots.

| Action | Input | |||

| Left Motor | Right Motor | |||

| AIN1 | AIN2 | BIN1 | BIN2 | |

| Motors OFF | 0 | 0 | 0 | 0 |

| Forward | 0 | 1 | 0 | 1 |

| Spin Right | 0 | 1 | 1 | 0 |

| Spin Left | 1 | 0 | 0 | 1 |

| Reverse | 1 | 0 | 1 | 0 |

Enable the Motors

In the “Configuring The Input and Outputs Pins” section you defined the ATmega32U4 pins controlling the motors as outputs using the Arduino pinMode() function. Whenever you define an output pin you must initialize it to some value. For the motors, this was done by setting all outputs to LOW using the Arduino digitalWrite() function or by modifying the PORTD and PORTB registers (design challenge). In other words, the robot was placed in a safe state (no running away). In this section, you teach the robot to move forward by editing the value parameters of the digitalWrite(pin, value) function calls.

Moving Forward

Add an initialization section to loop.

void loop() {

/* Initialization */

}

Add two (2) Arduino digitalWrite() functions to the Initialization section of loop(). Reading from Table 3 configure the robot to move forward (AIN1, BIN1). Now let’s do a quick check to see if our motors work. Add the following test code to the loop() section of your program.

void loop(){

/* Initialization */

:

/* Test code */

digitalWrite(PWMA, HIGH);

digitalWrite(PWMB, HIGH);

}

Verify that both PWM pins have been configured as outputs within the /*Initialization*/ block.

pinMode(PWMA,OUTPUT); // PWMA is mapped to AIN2

pinMode(PWMB,OUTPUT); // PWMB is mapped to BIN2

Upload the code to your robot. If everything went correctly, your robot should start to run away.

Quick Check

At this point in the lab the init3DoT() function should be complete; containing ten (10) pinMode and six (6) digitalWrite instructions. Specifically, all ATmega32U4 IR sensor inputs and motor outputs should be configured (Figure 3).

The initialization section of the loop() function should contain four (2) digitalWrite instructions.

Path Following Algorithm

Now that you have the robot moving forward, let’s incorporate the IR sensors to provide feedback as your robot tries to follow a path. Replace your test code in loop() with the following code after your digitalWrite() function calls in the initialization section.

void loop() { /* Read the IR sensors */ int sensorLeft = digitalRead(IR_L_O); // White = 0, LOW int sensorRight = digitalRead(IR_R_O); // Black = 1, HIGH /* Run the path following algorithm */ int motorLeft = !sensorRight; // we invert and cross the wires int motorRight = !sensorLeft; /* Write to the motors */ digitalWrite(PWMA, motorLeft); digitalWrite(PWMB, motorRight); }

How it Works

The first block reads the two outer IR sensors as digital inputs. In fact, the output from these sensors is an analog signal. As digital signals, anything below 0.56 V will be interpreted as logic 0 (LOW) and above 1.56 V as logic 1 (HIGH). These are in compliance with the LVTTL JEDEC standard and defined in Section 29.2 DC Characteristics of the Atmel-7766J-USB-ATmega16U4/32U4-Datasheet_04/2016 Document. Clearly, these may not be the optimal threshold settings for these IR sensors. In addition, when an analog signal drifts between these two threshold values, the input transistors can inject noise into the chip, which can result in excessive current consumption, heating, and ultimately failure of the device. So why did we do this? The short answer is to keep this early lab as simple as possible. A more technically correct answer is that the ATmega32U4 includes input circuitry to protect against drifting signals from damaging the device. This potential problem will be corrected by reading each IR signal as an analog input in Lab 3.

The second block of code runs the line following algorithm. To help understand how this works, visualize the robot traveling down the path. When the robot starts to veer off the path towards the left, it means that the right motor is rotating faster than the left motor. This may be due to differences in friction within the gearbox and/or the DC motor. At some point, the left IR sensor will detect the black line on the left side of the path, and sensorLeft = 1. In order to adjust and get the robot back on the path, the algorithm will stop the right motor (motorRight = 0) until the left outside IR sensor is back on the white surface of the maze. In summary, when input sensorLeft = 1, we want the output motorRight = 0 and visa-versa, something easily accomplished using the C++ Boolean NOT operator (!) and swapping the inputs. The same logic applies when it veers to the right. While this simple algorithm is good enough for following a path and stopping at an intersection, it is not intelligent enough to teach the robot how to actually take a step (takeAStep) or turn in the maze. This problem will be addressed by writing a more advanced algorithm in Lab 4.

Like the IR sensor, using binary signals to control the motors (ON/OFF) is sub-optimal. So why did we do this? The short answer is again to keep this early lab as simple as possible. This problem will be corrected by writing a Pulse Width Modulated (PWM) signal to the motors, approximating an analog output in Lab 2.

Design Challenge

You can skip the remainder of this lab if you are happy receiving a passing or even a good grade on the lab. If you want to receive an excellent grade you will need to accept the challenge(s). Specifically, the maximum grade you can receive on the prelab 1 plus lab 1 if you do not accept the challenge(s) is 20 points out of 25 (80%).

Working with the GPIO Registers

The Arduino IDE is designed for non-engineers and therefore, as much as possible, it hides what is going on within the MCU. As engineers, we would like to understand how the MCU really works and for this lab how the registers within the General Purpose Input/Output (GPIO) peripheral subsystems can be programmed to work with digital pins.

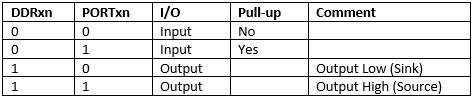

In order to configure a pin as an input, the corresponding bit position in the DDRX register needs to be cleared to 0. If that input pin needs to use a pull-up resistor, the corresponding bit position in the PORTX register needs to be set to 1. Obtaining the value that is being detected on that input is done by reading the corresponding bit position in the PINX register. For an output pin, the value in the DDRX register needs to be set to 1. You have to write the value that is to be outputted in the PORTX register. This information is summarized in Table 4.

From figure 5 you will notice that our input pins for the IR sensors are PF7, PF6, PF5, and PF4. The output pins that go to the DRV8848 motor driver are PB7, PD7, PC7, and PB6. It is possible to define each pin individually but it would be more efficient to develop an expression to get the final value that needs to be written to each 8-bit register. It is also important to preserve the values of the other bits in the GPIO register because that would change the functionality of those pins. This can be done with a combination of the bit/byte operations that were introduced earlier.

As an example, let’s set Port B bits 6, 5, and 4 to logic 1 without modifying the other bits in PORTB. If you were to configure them individually, you might start with the following instruction.

The right-hand side of the expression can be read as; take 0b00000001 and shift it to the left 4 times, where PB4 is defined as equal to ‘4’. The resulting binary value is 0b0001000. You can say the same thing by using the bit value macro _BV(bit), included in the avr/io library. A bit-wise OR (=|) is then performed with DDRB and this binary value. Recalling that 1 OR anything is 1 and 0 OR anything is anything, this expression will set only bit position 4, defining that pin as an output.

That right-hand side of the equation can set a single bit, or again by application of the bit-wise OR operation, multiple bits. This means we can set DDRB bits 6, 5, and 4 in a single line of code.

For clearing values, the following instruction would be used. It is performing the bit-wise AND operation on the original value of DDRD and the complement of the expression.

The ChallengeTurn the Arduino functions you wrote in 3DoTConfig.h into Comments (//), and replace them with their C++ equivalent. One advantage of working directly with GPIO port registers (DDRX and PORTX) is that one line of C++ will replace multiple Arduino lines of code, which work with one pin at a time. |

Lab 1 Deliverable(s)

|

All labs should represent your own work – DO NOT COPY. Submit all of the files in your sketch folder. Make sure that the code compiles without any errors. Do not forget to comment your code. Lab 1 Demonstration

|

Checklist

Remember before you turn in your lab…

- The configuration of the robot is written in the 3DoTConfig.h file.

- All of the configuration is done in the init3DoT() function.

- The init3DoT() function should be called in the setup() function.

- The robot should move forward and use the IR sensors to follow a line

C++ Robot Lab 2 – Motor Control and Fast Pulse Width Modulation

Table of Contents

Introduction

This lab is designed to introduce you to how pulse width modulation (PWM) is used to control the speed of an electric motor, how the timers of the Atmega32U4 can be configured for fast PWM mode to produce a desired PWM signal, and how to apply that to your line following algorithm.

What is New?

C++ Flow Control

To the C++ terminology and concepts learned in Lab 1; Lab 2 adds flow control using if-else statements. Before you begin I would recommend watching Lynda’s Fun with C++, part of the Learning C++ lecture series.

if (condition) {

statement block

} else {

statement block

}

Arduino Built-In Functions

To the terminology and concepts learned in Lab 1; Lab 2 adds the following Arduino Built-in function. If you have any questions on this information, refer back to my lecture on Pulse Width Modulation and Lynda’s lecture on Arduino Pulse Width Modulation. If you decide to do the first of the recommended “Power Tips” you should also read up on Arduino Serial Communications.

analogWrite(pin_number, PWM-value); // Define timer pin and output PWM digital waveform. Serial.println(val, format); Serial.read();

Improving Control of the Motors

Up to this point, you have been simply turning the motors ON and OFF. This is not the best solution for following a path and results in the robot ping-ponging from one side of the path to the other or more likely driving off the path entirely. In this lab, our main goal is to get better control of our robot by applying what we learned in the Pulse Width Modulation lecture.

Using the Timers in Fast PWM Mode

As you learned in the lecture, the timers can be configured to generate the desired PWM values and output them on specific pins. Those pins are indicated in Figure 1. If you plan to use this feature for the timers, you must use one of the five available PWM pins. You will notice that we are already using PD7 and PB6 (Arduino pins D6 and D10) for our PWM 3DoT v10 Block Diagram control signals for the motor driver.

Errata: AIN1, AIN2/PWMA, BIN1, PIN2/PWMB, NSLEEP wired to 5V_VM

The Timer with PWM lecture goes into detail about how this entire system works and you should understand that before we move forward. For the actual implementation, you can use the built-in function of analogWrite(). All of the configurations that were described in the lecture are handled for you in the analogWrite() function and the specific limitations are described here.

takeAStep

Open Lab1 in the Arduino IDE. Save As Lab 2. At the end of loop(), create a new function named takeAStep(). Move your path follower code into this new function. To the now-empty loop() function add a call to takeAStep(). Your program should now look something like this.

void loop() {

takeAStep();

}

void takeAStep() {

// path follower code from Lab 1

}

At the present time, your robot can follow a path. You may have also discovered that it also slows down at an intersection. This follows from your algorithm which stops a motor when its associated sensor is over a line. At an intersection, both sensors at some point will detect a line and therefore stop their respective motors momentarily, with the other motor taking the robot over the line.

If you have not done so already, verify that your robot slows down at an intersection.

Find the Maximum Speed

There is a high probability that your two motors are not equal. This is typically due to a difference in the internal friction of the gears and motors, which translates into a difference in the speed of rotation at a given voltage or duty cycle. This will cause your robot to veer towards the right or left. In order to address this issue, we will start by finding the ideal maximum speed for the fastest motor such that the robot travels in a straight line (or at least as close as possible).

This portion of the lab involves a lot of trial and error. With a pencil and yardstick, make a light straight line on a white surface that is about three feet long (i.e., the back of your maze). You will be manually controlling the speed of each motor using the analogWrite() function.

Temporarily comment out the call to takeAStep() and add analogWrite() functions to control the motors.

Begin with both motors running at full speed (PWM value of 255) and record in which direction the robot drifts from the path. If it drifts to the right, then the left motor is faster than the right. Decrease the speed of the faster motor by lowering the duty cycle (PWM) of the faster motor. Repeat this process until the motors are in sync. Define the maximum speed for both motors as a constant integer in the 3DoTConfig.h file.

const uint8_t motorRightHIGH = ____; // Synchronize motors max const uint8_t motorLeftHIGH = ____;

Power Tips

If you want to save time you can also write a bit of code and simply use the Serial.read() and Serial.println() functions to find the maximum PWM value for the faster motor. As an alternative, you can use a potentiometer with the wiper (middle terminal) connected to analog pin A4 wired to connector pin 6 on 3DoT Header J5 and the outside leads to 3.3V and ground (GND) wired to connector pins 3 and 4 on 3DoT Header J2, you can find the maximum and minimum speeds quickly by adapting the example script provided for the analogWrite() instruction.

Find the Minimum Speed

The objective of this section is to find the minimum speed that will keep the motors synchronized and provide a safe margin above the stall speed for both. A motor will stall when there is insufficient power to the motor to overcome the internal friction of the gears and motor (i.e., nothing is moving). The motor is ON at this point and it is consuming power but there is no physical motion. This may damage the motor and should be avoided. By obtaining the minimum speed to get the motor moving, we can keep the motor ON and barely moving while the robot smoothly gets back on track.

Using trial-and-error determine the minimum speed for each motor. Specifically, slowly decrease the duty cycle (PWM value) until the minimum speed is reached with a margin of safety. If you want to save time you can again write a bit of code and simply use the Serial.read() and Serial.println() functions to find this minimum safe PWM value or use a potentiometer as described in the previous section.

Next, run both motors at their minimum speed and note how the robot deviates from the line. Increase the speed of the slower motor. Repeat this process until the motors are in sync. Define the minimum speed for both motors as a constant integers in the 3DoTConfig.h file.

const uint8_t motorRightMin = ____; // Synchronize motors min const uint8_t motorLeftMin = ____;

We will be experimentally determining the motorRightLOW and motorLeftLOW constants in the next section.

A More Majestic Step

Now that you have identified all of the values that are needed to synchronize the speed of the motors, you can update the path following the algorithm to have the robot follow a path with fewer corrections. In a perfect world, the robot should move forward and never veer off a straight line with this change. We do not live in a perfect world.

Delete the analogWrite() functions and restore the call to takeAStep() in the main loop.

void loop() {

takeAStep();

}

/* Write to the motors */

In takeAStep(), replace the digitalWrite(PWMA, motorLeft); and digitalWrite(PWMB, motorRight); functions with the corresponding analogWrite() calls.

/* Write to the motors */

analogWrite(PWMA, motorLeft);

analogWrite(PWMB, motorRight);

Integer variables motorLeft and motorRight, which in lab 1 were assigned values of simple LOW (i.e., 0) and HIGH (i.e., 1) will now contain PWM values between 0 and 255.

/* Run the path following algorithm */

Replace the two (2) assignment statements in the “Run the path following algorithm” block with if-else conditional expressions setting each motor’s max (motorLeftHIGH, motorRightHIGH) and min (motorLeftLOW, motorRightLOW) PWM value as a function of its’ corresponding sensor input value (sensorLeft, sensorRight).

/* Run the path following algorithm */

if (condition) {

// Statement(s) to execute if condition is true

} else {

// Statement(s) to execute if condition is false

}

:

Binary Search Algorithm

In lab 1 we simply changed direction by turning a motor off. In this section, we want to experimentally determine the speed to set the motor that was previously turned off to a value that will make the most gentle correction possible. If the value is too low then the robot will continue to ping-pong as it moves along the line; too high and the robot could not correct its’ course in time and may leave the path. Once experimentally determined these values will be assigned to integer constants motorLeftLOW and motorRightLOW in the 3DoTConfig.h file. These constants will have values between their HIGH and MIN values. The fastest way to experimentally determine the optimal speed is to use a binary search algorithm. Start by setting the motor LOW constants to a value between their HIGH and LOW values.

guess low = (max + min)/2

const int motorRightHIGH = ____; // Synchronize motors max const int motorLeftHIGH = ____; const int motorRightMin = ____; // Synchronize motors max const int motorLeftMin = ____; const int motorRightLOW = ____; const int motorLeftLOW = ____;

Upload and run the line following code. If the robot leaves the path then you need to decrease the LOW value. Guess a value between your last guess and the minimum value. If the robot stays on the path then you need to increase the LOW value. Guess a value between your last guess and the maximum value. Repeat these steps until you find the speed that results in the most gentle correction possible without leaving the path. If you want to save even more time you can again write a bit of code and simply use the Serial.read() and Serial.println() functions or use a potentiometer as described earlier.

Design Challenge – pwmWrite

You can skip the remainder of this lab if you are happy receiving a passing or even a good grade on the lab. If you want to receive an excellent grade you will need to accept the challenge(s). Specifically, the maximum grade you can receive on lab 2 if you do not accept the challenge(s) is 20 points out of 25 (80%).

The Arduino IDE is designed for non-engineers and therefore, as much as possible, it hides what is going on within the MCU. As engineers, we would like to understand how the MCU really works and for this lab how the registers within the Timer 4 peripheral subsystems can be programmed to replace the analogWrite() functions.

Open the 3DoTConfig.ino tab and add the following function definition.

void initTimer4(){

// add code to initialize timer 4 here.

};

Add a call to the initTimer4() function to the init3DoT() function.

void init3DoT() {

// initialization code from lab 1.

initTimer4();

}

Write a function named pwmWrite(motor, value) to replace your analogWrite(pin, value) calls. Place this function after the takeAStep() function definition.

Lab 2 Deliverable(s)

| This lab will be turned-in with Lab 3. |

C++ Robot Lab 3 – Sensor Data as an Analog Input

Table of Contents

Introduction

While a single binary number (1 or 0) makes it easy to make decisions (true or false) in your C++ code, you must rely on the digital input logic to determine what analog voltage will be a interpreted as a 1 and or a 0. This may not result in the best choice for your IR sensors which output an analog value. Now that you have gotten the robot to move forward we will use the IR sensors analog inputs to make decisions.

What Is New

C++ Data Type Qualifier

The static qualifier instructs the compiler to save a variable into SRAM memory and not to destroy it at the end of a block of code; where a block of code is defined by curly brackets {}.

static datatype var;

Arduino Built-In Functions

To the terminology and concepts learned in the previous labs; Lab 3 adds the following Arduino Built-in function. If you have any questions on this information, refer back to the lecture on Analog-to-Digital Conversion.

analogReference(type); // DEFAULT=3.3V, INTERNAL=2.56V, EXTERNAL=AREF analogRead(analog_pin); // Read 10-bit analog value.

Find HIGH and LOW

The analog-to-digital converter (ADC) peripheral subsystem of the ATmega32U4 translates an analog voltage on an input pin into a digital number within the range of 0 to 1023. Within the Arduino IDE, this is done using the analogRead()function.

To convert an analog voltage into a digital number (DN) the ADC needs a reference voltage. By default, the reference voltage is equal to VCC (i.e., 3.3V). In most cases, the voltage from the IR sensors will not exceed 2 V. Therefore, to increase the range of DNs read, we will switch our reference voltage from 3.3V to a 2.56V reference source generated internal to the ATmega32U4.

Once converted to a 10-bit unsigned integer, your challenge is to create an algorithm to determine what that value represents (HIGH or LOW). For example, if the value is less than 50, it could mean that you are detecting the white part of the maze. If the value is greater than 50 but less than 700, it could be some shade of grey (you are on the border of the line). If it is above 700, it could mean that black is detected and you are over the line.

Using the Serial.println() function and the following test script, determine the threshold values that will work best for your robot. Try viewing the output both on the text-based Tools > Serial Monitor and graphical Tools > Serial Plotter

You will find the color key for the four (4) plots on the upper left-hand side of the graph.

void setup(){

Serial.begin(9600); // setup serial

analogReference(INTERNAL); // reference voltage = 2.56v

}

void loop(){

uint16_t val = analogRead(analogPin); // read the input pin

Serial.print(analogRead(IR_R_O));

Serial.print(" ");

Serial.print(analogRead(IR_R_I));

Serial.print(" ");

Serial.print(analogRead(IR_L_I));

Serial.print(" ");

Serial.println(analogRead(IR_L_O));

delay(50); // waits for 50 milliseconds

}

sensorRead()

Open Lab2 in the Arduino IDE. Save As Lab3. Here is a template for your to be written sensorRead() function.

uint8_t sensorRead(uint8_t sensor_pin, uint8_t current_level) { 1. read analog value 2. conditional expressions set return logic_level based on analog value read and trigger points. 3. if the analog value is in the undefined region (no mans land) then logic_level equals the current_level argument. return logic_level; // return HIGH or LOW }

The sensorRead function returns HIGH if the analog value is greater than or equal to trigger1, and LOW if the analog value is less than or equal to trigger0. When the analogRead() function returns any value that is neither (gray area), your function should return the current logic level (HIGH or LOW). This is known as hysteresis and will keep your robot from reacting too quickly to changes in the input (noise). To implement hysteresis, your function receives as its’ second argument (current_level) the last returned value.

To determine my trigger points I followed these steps.

- hysteresis = (high value – low value)/2

- trigger1 = high value – hysteresis/2

- trigger0 = high value + hysteresis/2

For my IR sensors when over black the recorded digital numbers were very volatile but usually over 300. When over white the recorded value was fairly stable at 79. Although, if I simulated going over a bumpy surface this value could spike up wildly. So a hysterics value of 221 DN seemed like a reasonable number with trigger1, therefore, set to 245 and trigger0 set to 135. Based on your experiments, you may want to implement a different set of criteria for setting your trigger points and possibly even use the runningAverage script found in the StatPak tab to remove high-frequency noise from your sensor readings. Open the 3DoTConfig.h tab and set the trigger points where an analog reading; a digital number (DN) between 0 and 1023 is translated to a digital HIGH or LOW value

/* IR sensor constants */ const uint16_t trigger1 = ____; // IR values 1023 to ____ = 1 (black) const uint16_t trigger0 = ____; // IR values ____ to 0 = 0 (white)

Return to the home tab. If you have not done so already, complete writing the sensorRead() function.

To maintain compatability with the Arduino digitalRead() function, your sensorRead() function will return a data type uint8_t with values HIGH or LOW. If you are converting your Arduino script to a C program, then I would recommend switching to a bool datatype, with a value of true or false.

Now that you have identified your trigger points and written the sensorRead() function, you are ready to update the “Read the IR sensors” block within takeAStep to improve your robot’s ability to follow the path.

In takeAStep() within the “Read the IR sensors” block, replace the digitalRead() Arduino functions with your new sensorRead() function. Add this new function at the end of takeAStep(). Your program should now look something like this. Observe that sensorLeft and sensorRight are both arguments sent to and returned from sensorRead. Therefore, they must be defined as static uint8_t data types before the call to sensorRead. The subject of the next section.

void loop() {

takeAStep();

}

void takeAStep(){

/* Read the IR sensors (lab 3) */

uint8_t sensorLeft = LOW; // initial value white, motor ON

uint8_t sensorRight = LOW;

sensorLeft = sensorRead(IR_L_I,sensorLeft); // White = 0, LOW

sensorRight = sensorRead(IR_R_I,sensorRight); // Black = 1, HIGH

/* Run the path following algorithm */

Remainder of path follower code from Lab 2

}

A Memory Bug

The sensorRead function takes as its second argument the current value of the sensor (current_level). To add hysteresis to the function, we simply return this value, if the sensor reading (analog_value) does not meet the HIGH or LOW threshold values. So for our solution to work, the variables sensorLeft and sensorRight need to be remembered between calls to takeAStep. Unfortunately, that is not how local variables work. To save memory, local variables are destroyed at the end of the subroutine. If you want the subroutine to remember the value of a local variable you need to add the static qualifier as shown here.

void takeAStep() { /* Read the IR sensors */ static uint8_t sensorLeft = LOW; // initial value white, motor ON static uint8_t sensorRight = LOW; :

Design Challenge

You can skip the remainder of this lab if you are happy receiving a passing or even a good grade on the lab. If you want to receive an excellent grade you will need to accept the challenge(s). Specifically, the maximum grade you can receive on the prelab 3 plus lab 3 if you do not accept the challenge(s) is 20 points out of 25 (80%).

In lab 3 you have the opportunity to accept one or both of the following challenges. Completing one challenge may result in a perfect score. Accepting a second challenge will be rewarded with bonus points. Bonus points are added to your overall lab grade in the course. Your overall lab grade may not exceed 100%. In other words, by accepting a second challenge you may be able to skip a future challenge or make-up for points lost in previous labs.

Design Challenge 1 – getAnalog()

Write new functions initADC() and getAnalog(). The initADC() function should be called from setup() and initialize the ADC peripheral subsystem of the ATmega32U4. The getAnalog() function should replace all Arduino analogRead() function calls. Both functions must be written in C++ (no Arduino functions).

Design Challenge 2 – Interrupt Service Routine

Write an interrupt service routine (ISR) to read the analog signal from the IR sensors, replacing the existing ADC polling based solution. The solution, should operate the ADC in “3DoT Mode 8” as defined in the “C/C++ Arduino Robots” class lecture on “Analog to Digital Conversion.” In addition the initialization routine should disable the corresponding digital input pins, shared with the IR sensors, as discussed in the “DIDRn – Digital Input Disable Register 0 and 2” section of the same lecture.

Design Challenge 3 – PID Controller

Please talk to the instructor before attempting this design challenge. This challenge may be completed at any time during the semester.

Apply material in the PID Controllers lecture to add a PID controller to help your robot follow the line. In other words, you will now work with the native analog value of the sensor inputs (i.e., not digital values). The error input to the PID controller should be the difference between the analog readings between the left and right sensors.

Lab 3 Deliverable(s)

|

All labs should represent your own work – DO NOT COPY. Submit all of the files in your sketch folder. Make sure that the code compiles without any errors. Do not forget to comment your code. Lab 3 Demonstration

|

C++ Robot Lab 4 – Take A Step

.

Table of Contents

Introduction

Your robot can now follow a path. In this lab, we are focusing on developing the code to detect a room boundary and continue until the robot’s wheels enter the next room (hop). When this lab is completed, you will be ready to develop the control algorithm for turning in the maze. The critical issue for the takeAStep algorithm is keeping track of the robot’s position with the sensor data that is available. This requires readings from the sensor(s) and implementation of a Finite State Machine (FSM) using a C++ switch-case statement. Your FSM will have three (3) states.

- walk

- hop

- stop

What is New

C++ Code

switch(expression) {

case constant:

statement(s);

break;

case constant:

statement(s);

break;

...

default: //optional

statement(s);

}

Arduino Built-In Functions

millis() // number of milliseconds since program started running.

Walk

Open Lab3 in the Arduino IDE. Save As Lab 4. Create a new function named walk. The walk will allow us to reduce the path following code to only the two lines as shown. For reference, my lab 3 “path following algorithm” originally used 16 lines (9 C++ statements) of code.

void takeAStep() {

/* Initilization */

:

/* Read the IR sensors */

:

/* To follow a path the ir sensor controls the opposite motor */

analogWrite(AIN1, 0); // left motor

analogWrite(AIN2, walk(sensorRight,motorLeftHIGH, motorLeftLOW));

analogWrite(BIN1, 0); // right motor

analogWrite(BIN2, walk(sensorLeft,motorRightHIGH, motorRightLOW));

/* Write to the motors */

:

}

int walk(uint8_t sensor, uint8_t motorHIGH, uint8_t motorLOW) {

uint8_t motorSpeed;

:

return motorSpeed;

}

The new walk function accepts three arguments and returns the PWM signal to be sent to the left or right motor (motorLeft or motorRight). The first walk argument is sensor which is either the left or right sensor reading (LOW or HIGH). With one exception; the structure of walk is functionally equivalent to your original algorithm, with the sensor value used in a conditional expression setting the speed (motorSpeed) of the opposite motor to its corresponding motorHIGH (parameters motorLeftHIGH, or motorRightHIGH) or motorLOW (parameters motorLeftLOW, or motorRightLOW) value accordingly. The one exception is how the new walk function, operates at the end of a room. Before the robot would only slow down as it passed over a room boundary. We now want to detect a room boundary using one of both of our inner IR sensors and once detected pass over the room boundary and then stop inside the next room.

Before you continue, verify that your robot’s performance has not changed.

Build the Framework

To take a step, we are going to upgrade our path following algorithm to a three (3) state, finite state machine (FSM). We will be using a C++ switch-case statement to implement the FSM. An if-else-if construct could have been used just as easily. A simple switch-case contains a variable (the switch) which is compared to a series of constants (the cases). The block of statements within a case is run on a match. For reasons, that date back to antiquity, statement blocks after the case are also run. To prevent this unfortunate behavior case statements nearly always end with a break instruction.

void setup

void setup(){ : delay(5000); // 5 second delay to set robot in the maze } : void takeAStep() { /* Initialization */ : /* Finite State Machine */ static int state = 0; // fsm state /* Read the IR sensors */ : /* Run the path following algorithm */ switch(state) { /* follow path until room wall (i.e., inner IR) detected */ case 0: // walk statements break; /* move forward (open loop) until inside room case 1: // hop statements break; case 2: // stop } // end switch /* Write to the motors */ : }

Text in gray is from the previous labs. Let’s take a closer look at each section.

/* Initialization */

As you write your code for each case, within the line following the algorithm you may need to declare a few new variables. Place these declaration statements in the initialization section of takeAStep.

/* Finite State Machine */

The beginning of the finite state machine section initializes the FSM and switches state to zero.

/* Run the path following algorithm */

To complete a single step the FSM sequentially moves through two states (or cases), to be defined in the following sections.

- state 0: walk

- state 1: hop

- state 2: stop

Variables sensorLeft,sensorRight,motorLeft, and motorRight typically hold the input (sensor) and output (motor) values for each case.

state 0: walk

Write the code needed to teach your robot to walk until the end of a room is reached; the inner sensor(s) reads white. Before the end of a room is reached you can simply re-purpose your original walking code. This is the path following block-of-code from Section 3 without the definition of motorLeft and motorRight (both were defined as integers in the header block). Unlike the previous version, where your robot kept walking down the hallway, instruct your robot to proceed to the next state.

if (inner sensor(s) in the room){ // walking code : } else { // start hopping analogWrite(AIN1, 0); // "true" A ==> left motor (simply a convention) analogWrite(AIN2, motorLeftHIGH); analogWrite(BIN1, 0); // right motor analogWrite(BIN2, motorRightHIGH); state = 1; }

state 1: hop

At the end of the last state, the motors were set to their ON position. During the hop state, your robot should proceed in an open-loop fashion. Continue doing nothing, until the inner sensor(s) detects the next room (white).

if (inner sensor(s) in the next room){ switch to state 2 }

state 2: stop

At the end of the last state, the motors were still in their ON position. In this final state, end the mission by turning off the motors (brake) and turn ON the LED_BUILTIN led.

analogWrite(AIN1, 255); // left motor analogWrite(AIN2, 255); analogWrite(BIN1, 255); // right motor analogWrite(BIN2, 255);

Test Your Code

Upload your code. Verify that the robot follows the path and hops into the next room – BLINK led turns ON.

Lab 4 Deliverable(s)All labs should represent your own work – DO NOT COPY. Submit all of the files in your sketch folder. Make sure that the code compiles without any errors. |

Checklist

Remember before you turn in your lab…

- FSM sketch with explanatory comments.

C++ Robot Lab 5 – Turning Algorithm

Table of Contents

Introduction

Your robot can now follow a path and stop at the start of a room (takeAStep) by implementing a simple algorithm that controls the motors based on inputs from the sensors. In this lab, we are focusing on how to turn the robot to face the desired direction. When this lab is completed, you will be able to control your robot for all situations it can encounter in the maze and will be ready to develop the control algorithm for navigating your path through the maze in Labs 6, 7, and 8. The critical issue for the turning algorithm is keeping track of the robot’s position with the sensor data that is available. This requires continuous readings from the sensor(s) and implementation of Finite State Machines (FSMs). Along the way we will write three (3) new functions:

- turnLeft()

- turnRight()

- turnAround()

What is New

Data Types

const uint8_t variable // Qualify variable as a constant static uint8_t variable // Qualify variable that will persist after a function return

C++ Code

do {

statement

statement

. . .

statement

} while (expression); // Repeat while expression remains true

Serial Monitor Commands

Serial.begin(9600); // Configure baud rate Serial.print(“text”); // Print the text to the serial monitor Serial.println(variable); // Print the variable to the serial monitor and start a new line

Timing Control

delay(time_value); // Delay program execution by the time_value milliseconds

Build the Framework

Open Lab4 in the Arduino IDE. Save As Lab 5. At the end of takeAStep() add the following three (3) functions.

void loop() { takeAStep(); } void takeAStep(){ // code from lab 1, 2, 3 and 4 } void turnLeft(){ /* Initialization */ /* Turn algorithm */ /* Write to the Motors */ } void turnRight(){ } void turnAround(){ } int sensorRead(int sensor_pin, int current_level){ // code from lab 3 }

takeAStep

You have now completed the education of your robot in how to take a step. Now it is time to teach it how to turn. Unfortunately, although yes, your robot can take a step it will not play nice with any new functions called from within loop. To solve this problem, in this section you will “encapsulate” the takeAStep function within a do-while loop.

The takeAStep() function works because it is continuously called from within loop. put another way, we are calling and returning from the takeAStep() function until the step is completed. This causes a problem if we want to add additional functionality to our robot. In this instance functions turnLeft, turnRight, and turnAround – and that is the problem. If for instance, we were to follow takeAStep with turnRight, the program would run the line following algorithm once, then run the turnRight once, resulted in a really confused robot. Before we solve the problem, lets take a closer look at what is happening. If we were to tunnel down into the C++ code which implements the loop method from within the Arduino scripting language, we would find this while statement.

while(1) {

loop();

}

Because the while condition is always true (1), the statements within the while block, in this case loop(), will be repeatedly called until the Arduino is reset. And here in lies the solution to our problem. To keep our takeAStep function from returning, we can “encapsulate” it within its’ own loop. However, in place of a condition which is always true, we will add a condition that will allow our function to return when the robot has completed a single step. Lets take a look at the solution.

void takeAStep() { /* Initialization */ : /* Finite State Machine */ static int state = 0; // fsm state do { /* Read the IR sensors */ : /* Run the line following algorithm */ switch(state) { : /* Write to the motors */ analogWrite(PWMA, motorLeft); analogWrite(PWMB, motorRight); } while(state != 0); }

The do-while looping construct works best for our solution, because we want to make at least one pass through the FSM. On that first pass we move from state 0 to state 1, this means that the while test will fail (we will loop) until state 3 is completed and we return to state 0.

Add the do-while loop to the takeAStep() function.

Test Your Code

Before you added the do-while loop, your robot could take a step. Your robot should now be able to do exactly the same thing, so how do you know if your program is working? The answer is pretty simple. Move your test code in state 2: // hop, which turns ON the BLINK led after your call to takeAstep(). If everything is working the led will stay OFF until the robot completes the first step and then will turn ON. Once you know your code is working you may comment out (//) or delete the test code.

Configure Motors

It is finally time to start teaching your robot how to turn. First, review “Controlling the Motors” in Lab 1. Up to this time, the DRV8848 motor driver has been configured for the right and left motor to move the robot forward. In the Initialization section of functions turnLeft() and turnRight(), configure the motors for the desired turn as defined in Table 1 “Motor Control Setting.”

| Action | Input | |||

| Left Motor | Right Motor | |||

| AIN1 | AIN2 | BIN1 | BIN2 | |

| Motors OFF | 0 | 0 | 0 | 0 |

| Forward | 0 | 1 | 0 | 1 |

| Spin Right (CW) | 0 | 1 | 1 | 0 |

| Spin Left (CCW) | 1 | 0 | 0 | 1 |

| Reverse | 1 | 0 | 1 | 0 |

| Brake | 1 | 1 | 1 | 1 |

Spin Test

Unless you add a sensor (one of the design challenges) your robot will be executing an open-loop turn. Consequently, your robot will need to be able to turn about a point without drifting in any one direction. The tuning of the motors to eliminate drift is the objective of the spin test.

In setUp(), comment out takeAStep()and add a call to turnLeft(). Add the following code to turnLeft().

void turnLeft() { /* Initialization */ : /* Turn algorithm */ : /* Write to the motors */ analogWrite(AIN1, motorLeftHIGH); analogWrite(AIN2, 0); analogWrite(BIN1, 0); analogWrite(BIN2, motorRightHIGH); }

Compile and upload your code. Your robot should start spinning counter-clockwise. If your robot can complete at least two (2) revolutions without drifting then you can skip to the next section, otherwise, you will need to tune your motors employing the techniques learned in Lab 2 “Motor Control and Fast Pulse Width Modulation.”

Replace motorLeftHIGH and motorRightHIGH with numerical values that keep your robot spinning in place. To discover these numerical values, using one of the techniques you employed in Lab 2, to tune the motors to track in a straight line, teach your robot to spin in place. These techniques included: trial-and-error, wheel encoder, a potentiometer, and binary search.

If you are unable to tune your robot to spin about a point, you may need to implement one of the hardware sensor solutions discussed in the design challenge section of the lab.

Finite State Machine Turning

In Lab 4 you implemented a four (4) state FSM to teach your robot to walk, hop, and skip. In this lab, you will again implement a four (4) state FSM to teach your robot how to turn. Implement the following pseudo-code. I would recommend looking to your takeAStep FSM for help.

/* Turn left algorithm */

switch (state) {

case 0:

/* hold in reset state for some period of time */

delay(2000); // robot moved to maze

state = 1; // continue to state 1

break;

case 1:

/* loop on this state until right sensor enters the room in front of the robot */

case 2:

/* continue rotation through the room */

case 3:

/* rotation is complete when the right sensor enters the room to the left of the robot */

} // end switch

Once you have your robot turning left, encapsulate your finite state machine within a do-while loop. Enable (remove comments) takeAStep and run your code. Your robot should now take a step and then turn left. After a short delay between actions (takeAStep – turnLeft – takeAStep …) your robot now autonomously walks around in circles (well actually squares). should traverse a square.

Repeat the steps above to teach your robot to turn right.

Turn Around