Class Topics

Expand a topic for assignments and linked lectures.

#1: Welcome to TRC “The Robot Company”

Quote of the Day

“…I hit the interview with Northrop-Grumman out of the park. I had the one interviewer leaving the room saying he wanted his money back from his undergrad after hearing about the content I learned being in EE400D.”

Lab Task

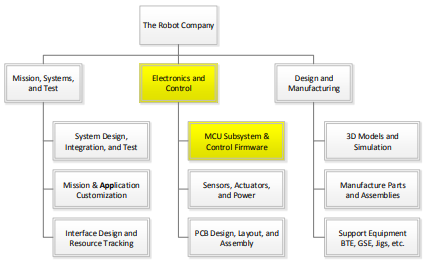

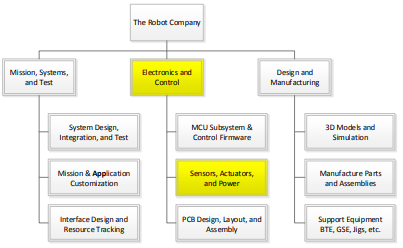

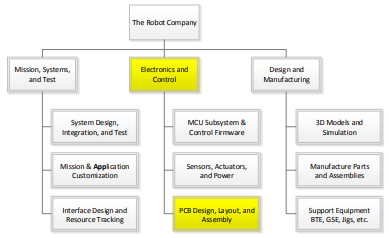

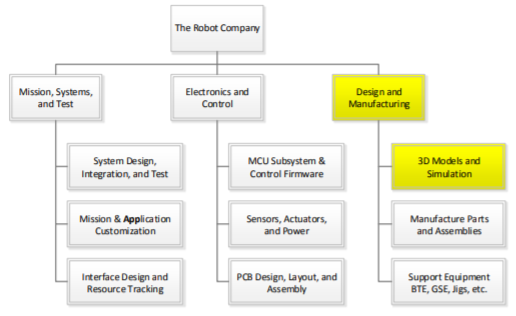

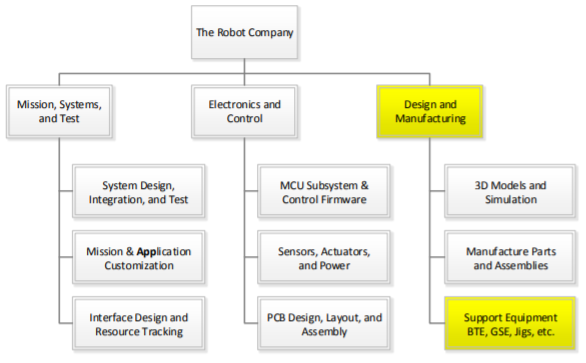

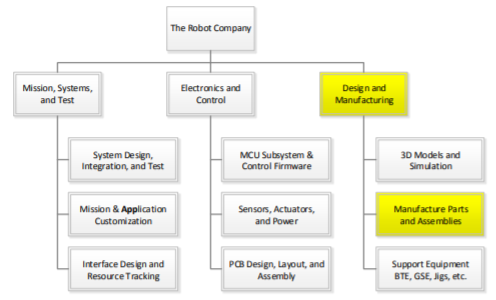

1. The Robot Company Work Breakdown Schedule

- Over the semester it is important that you understand what your responsibilities are within the project. Just as important is an understanding of the roles and responsibilities of your fellow engineers. To gain this knowledge and to help you find your place in the class, please read The Robot Company Job Descriptions.

2. Write and Submit Cover Letter and Resume

Your first writing assignment is to generate and submit a Job Application to The Robot Company. This will be great practice for the cover letters and resume you will be writing for the upcoming job fairs. The hyperlinked document includes everything you will need to get started, including:

- Functional versus Written Cover Letter

- Tips from real companies, like Beckman Coulter on Resume Writing and Interview Skills

- What we at The Robot Company are looking for in your cover letter and resume.

- Sample Cover Letters and Resumes

- How to submit your cover letters and resume to The Robot Company.

- Your cover letter and resume should be in a single pdf document. The Name of the Document should be your name, Joe Smith.

- Submit your cover letter and resume in your EE400D Beachboard Dropbox, no later than Friday 6:00 p.m.

- Grading Rubric

#1.5: The Engineering Method

Quote(s) of the Day

“Each week (day, hour,..) is less important than the week (day, hour,…) before.”

Corollary

- Choose the difficult tasks to do first.

- Do not wait for instructions. Apply your critical thinking skills to work independently.

Old Business

New Business

Assignment Due Dates

Lab Task

Research

Research Presentation Template

“Engineers should always try to build on what has already been done before. Information on related problems that have been solved or unsolved may help engineers find the best solution.”

- Working from your job description, research similar work reported on the web and for legacy robots review Blogs from earlier generation robots. In the latter case consider the quality of the post.

|

- It is hard to overstate the value of this initial research. If you are in doubt, as a cautionary tale, I recommend reading the following Case Studies.

Research Case Studies

- Case Study – Pick and Place

- After a suggestion was made that a Makeblock XY – Plotter could be an excellent platform on which to build a pick and place machine, the team immediately purchased the plotter and modifying it to be a pick and place machine. In the end the project achieved all its goals.

- Lesson: While it is hard to argue with success, and in this case showing the initiative to move forward as quickly as possible, two problems present themselves. The purchase of this $300 dollar plotter was not approved by the department and therefore the students may have had to fund the project. If the plotter did not meet design requirements, and in multiple instances it did not, the students again would have had to fund the project. Instead of focusing on the strawman solution the students may have wanted to do their homework, and may have found in less than an hour, the PP4 – SMD-Pick and Place Machine and Paste Dispenser. This DIY project includes a pdf file listing all the components needed to make the project.

- Case Study – Project BiPed Robot

- For 12 weeks the software engineer was stopped by a single broken link on the Project BiPed website. After the Critical Design Review (CDR) and a few minutes of detective work the Project BiPed RoFi software download page was found.

- The software plus documentation was also found on the previous semester’s last blog entry – the first one the software engineer should have read.

- Lesson: First, do your homework and then if you still need help getting past a problem talk to your management team.

- Case Study – Velociraptor

- The core software engine used by walking robots like Biped and Velociraptor are the same. For 15 weeks these two teams never spoke to each other.

- Lesson: This exactly why we have Division meetings.

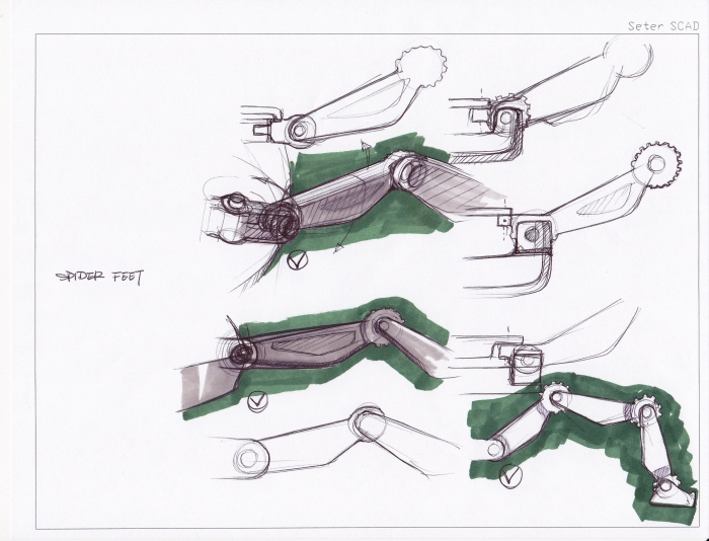

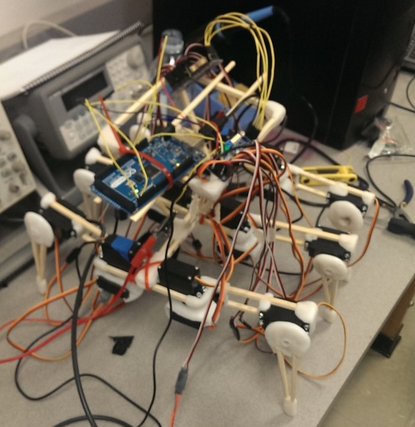

- Case Study – SpiderBot

- After being given a HEXBUG robot, the spider robot team took the HEXBUG apart, rendered all the parts in Solidworks and then after 12 weeks of hard work, realized it could not be duplicated using available 3D printers. After a few minutes on the internet, three 3D printable spiders designed by Jerry Mantzel, Joe Klann, and Theo Jansen were located. Ultimately, an original design was implemented in only a few weeks.

- Lesson: First, do not focus on the first “strawman” solution presented to you. Follow the engineering method beginning with doing your homework. Second, the whole team needs to sign-off on the final design concept. In this example, the mechanical engineer should have understood the limitation of the fabrication tools available to his/her project and brought these limitations to the attention of the team.

- Case Study – Rover

- The sum total of the design at CDR was two 3D printed sheets of plastic – one included two bends. Further, the prints were not coordinated with the Division manager or was funding approved by the department.

- Lesson: The mechanical engineer did not do their homework, which after only 15 minutes research would have found reference models. Next, the wrong machine (3D printer) was used. In addition, the engineer should have requested help from the Division manager in locating the correct machine (laser cutter). Finally, without approval, the student may have had to pay for these 3D prints.

#2: Stakeholder Expectations

Lab Task

- The Task Matrix

- Creativity Exercise

- Creativity Presentation Example

- Remember…

- The presentation should illustrate the evolution of a “crazy” idea (Hover Board” to a practical solution (magnetic levitation).

- All creativity methods (Dunker diagram, attribute listing, and lateral thinking) should be integrated into Brainstorming Approach (not assigned to individuals)

- Tour of the Cabinets

Creativity Exercise

- Applying what you learned in the Creativity lecture to help the customer define the mission. Develop your creative solutions using the following methods.

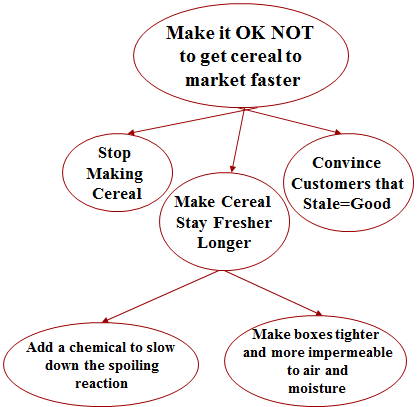

- Dunker Diagram

- Brainstorming Approach

- Attribute (Properties) Listing

- Lateral Thinking

- Forced Relationship Technique

- Different Point of View

- Assign one team member to be the moderator for one of the creativity tools. The entire team must participate with different team members trading off as the moderator.

- The creative process is iterative, with one idea (often impractical) leading to another. For example; Create an innovative alternative to IR lights used to reflow solder surface mount devices (SMDs) onto a printed circuit board (PCB). This traditional approach does not provide uniform heating of the board, resulting in burnt boards on one side to cold solder connections on the other side of the board. Camp Fire – used to fire clay over 16 thousand years ago, lead to kilns lined with fire bricks, use fire bricks with electric heating elements to generate a uniform IR source for reflow soldering.

- Identify representative solutions developed by the group which are out-there and innovative. Avoid existing “known” solutions for solving the problem. If applicable, highlight (star) two (2) and not more than four (4) promising design solutions for each problem.

- Do not be concerned that you will be required to implement these solutions. Consider these alternatives ideas to be weighed against more traditional non-innovative solutions (see next bullet point).

- Make a list of questions/experiments that might help you determine the best solution for each problem. This list should contain both innovative and traditional non-innovative solutions.

- Document your work in a PowerPoint presentation to be given next week. The moderator should talk about the creativity tool for which he/she was the moderator. Grades will be assigned on an individual basis.

Presentation Outline

Prepare 1 slide per subject, with the total not to exceed 8 slides and take no more than 8 minutes to present.

For grading purposes, please follow this outline exactly, do not deviate.

- Candidate and Selected Problem(s)

- Dunker Diagram

- Brainstorming Approach

- Attribute (Properties) Listing

- Lateral Thinking – Forced Relationship Technique

- Lateral Thinking – Different Point of View

- Promising innovative alongside traditional solution(s).

- Questions/experiments that might help you determine the best solution(s).

Case Studies

- Prosthetic Arm

The Prosthetic Arm used the Dunker method to discover the VA hospital solution (do not have an amputee, do have an amputee)

- Pathfinder Solar Panels

Make solar panels lighter (based on incorrect problem statement), make solar panels heavier – move cg lower so it does not tip over. In this case study, the Dunker method helped the team discover the real problem.

#3: High Level Requirements

Old Business

New Business

Assignment Due Dates

Lab Task

- Customer Objectives

- Draft of Level 1 Requirements

- Divison Resources

- Robot Kit (Shared Google Document)

- Review of the reference blog posts

Requirement Evaluation Rubic

- Is the requirement, Quantitative, Verifiable, and Realizable?

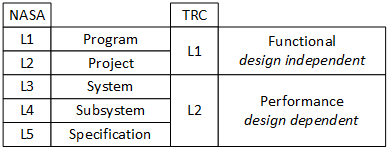

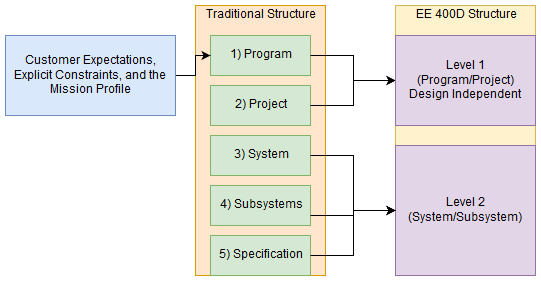

- Is the requirement located at the correct level (1 – Program/Project, 2 – System/Subsystem)

- Is the requirement response to a higher level requirement or customer’s objective (Requirement Flow Down)? Is the linkage clearly defined?

- Does requirement provide links to the source material?

- Does the requirement move the design process forward?

- Are equations used to calculate a requirement provided and are answers correct?

- Is language in the form of a requirement?

- Avoid multiple requirements within a paragraph. (i.e., breakup statements that contain multiple requirements)

- The requirements that are missing are the hardest to discover and will be factored into your evaluation. Use your strawman design to help you find them.

#4: Derived Requirements and Modeling

Old Business

New Business

Assignment Due Dates

Lab Task

- Division Training

- Projects should continue to work on Task Matrix and Level 2 Requirements.

Design Process and Modeling

- Draw a preliminary sketch of the design

- Make a back of the envelope calculation

- Conduct a trade-off study

- Model the System

- Mathematical Model

- Computer Simulation

- Full-scale Prototypes

- Scale Model

#5: Realistic Constraints and Standards

Old Business

New Business

#6: Preliminary Design Review

Old Business

New Business

Assignment Due Dates

Lab Task

Project Meetings

- Assign due dates to all tasks and allocate points across the task matrix.

- Review of Research Projects/First Blog Post (see Preliminary Project Document outline)

- Work on assigned tasks (task matrix)

- Project managers should translate task matrix into a schedule.

- Generic Schedule

- Microsoft Project and Project Libre Burn Down

Division Meetings

MST

- Did you…

- Training Plan plus quiz schedule – 3DoT documentation quiz next week?

- Find common and unify Requirements/tasks across the projects

- Status of Collaboration between MST and E&C

- NASA System Engineering Handbook Appendix C: How to Write Good Requirement

- 3DoT – Training Documentation

- Simple Robot Project Folder

- Identification of custom PCB(s)

E&C

- Review of E&C Technical Training Plan (does it include the following)

Manufacturing

- Solidworks Strawman Models

Quality Assurance

- Make sure Blog is posted to the correct location on the website. Do not post to more than one area. If we cannot find it we cannot grade it.

- Clearly identify project member(s) who and how they contributed to the post. If this information is not included then no grade can be assigned.

- Do not plagiarize material. For example if you use a photo, as a minimum provide source. See University “Cheating and Plagiarism” policy for more on this topic.

- Failure to follow any of the following directions will result in an automatic grade reduction.

- Once posted only your “Introductory” paragraph should appear on the project page with a “Read more à” link.

- Blog post must include a square teaser photo.

- All blog post must include image(s) for illustrative purposes. See presentation and starter kit to learn how to format images for upload. Failure to “optimize” images result in long periods of time from upload to the photo appearing within your blog post. This often leads to multiple uploads, with the instructor spending time deleting photos in the media folder.

- Please use courier font and single spacing on Code examples.

#7: Career

Old Business

New Business

Assignment Due Dates

Lab Task

Project Meetings

- Review Project Budgets or How to lower cost

- PDR Debrief

Division Meetings

MST

E&C

Manufacturing

- Solidworks Cable Routing

- Madell Pick and Place

- MUSE Laser Cutter

#8: Preliminary Design Review (PDR)Preliminary

Announcements

Assignment Due Dates

Lab Tasks

PDR

- PDR Checklist

- Schedule

- 2 PM – ModWheels Starts

- 2:40 PM – ModWheels End

- 2:45 PM – 3DoT Chassis (Pete-Bot) Starts

- 3:25 PM – 3DoT Chassis End

- 3:30 PM – BiPed Starts

- 4:10 PM – BiPed End

- 4:15 PM – Goliath Starts

- 4:55 PM – Goliath End

- 5:00 PM – Sojourner Starts

- 5:40 PM – Sojourner Ends & Break Time Starts

- 5:50 PM – Break time Ends & ModWheels Demonstration Starts

- 6:00 PM – 3DoT Chassis Demonstration

- 6:10 PM – BiPed Demonstration

- 6:20 PM – Goliath Demonstration

- 6:30 PM – Sojourner Demonstration

- 6:40 PM – End

#9: Critical Design Review (CDR)

News and Announcements

Old Business

New Business

Assignment Due Dates

PDR Generic Comments

- Use material from previous semesters with extreme caution. Recommended that you do your own work and then check against previous work. Too much “incorrect” material taken from previous semesters.

- Division Management

- Division managers need to help and review work product of division members.

- Division Managers are reasonable for material covered by Division Members

- Division Manager grade may be based on Division Members grades on member’s work products (major reviews and blog posts).

- More Research…

- Use Rocker-Boogie as a model of how it is done.

- Requirements, Verification, and Validation

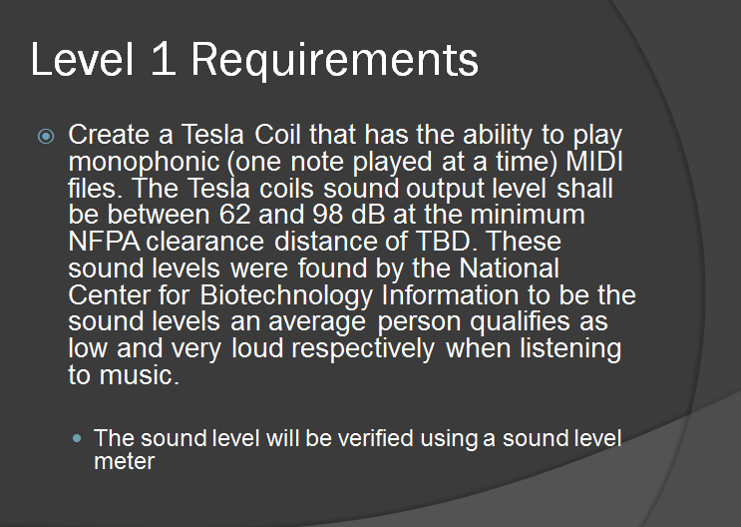

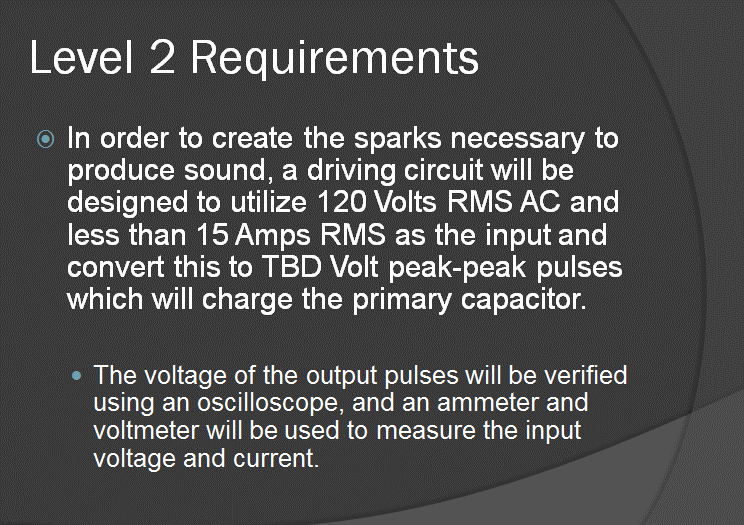

- L1 and L2 should be a more quantitative allowing easy verification testing. Verification is not during the mission which is validation.

- Qualitative using adjectives and TBDs

- Any visual inspection is a “will”

- Nothing is verified during the final. The mission is for validation Only.

- 3DoT Project Notes

- 3DoT robots are required to use the onboard battery only.

- 3DoT robot dimensions should match those of the 3DoT board

- 6 hour (2/2/2) Print Requirement

- Resource Management

- Mass and Power Project Allocation

- Other Resource example would be 3D Print Time

- Tasks

- Word “Trade-off study” used where MODEL should be

- Back of the Envelope does not equal Pencil Drawing with Dimensions.

- Avoid generic task descriptions on the project schedule. The schedule is a guide to the entire team.

- Project and Systems Design

- PBS (Product Breakdown Structure)

- Label axis on burndown with vertical line showing today

- If you are planning to use a 3D Printer versus a Laser Cutter, do not use outline and extrude with Solidworks add a third dimension (nut capture, ribs, …)

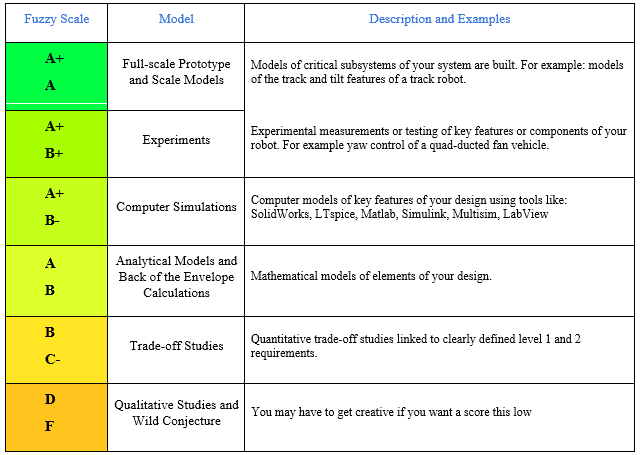

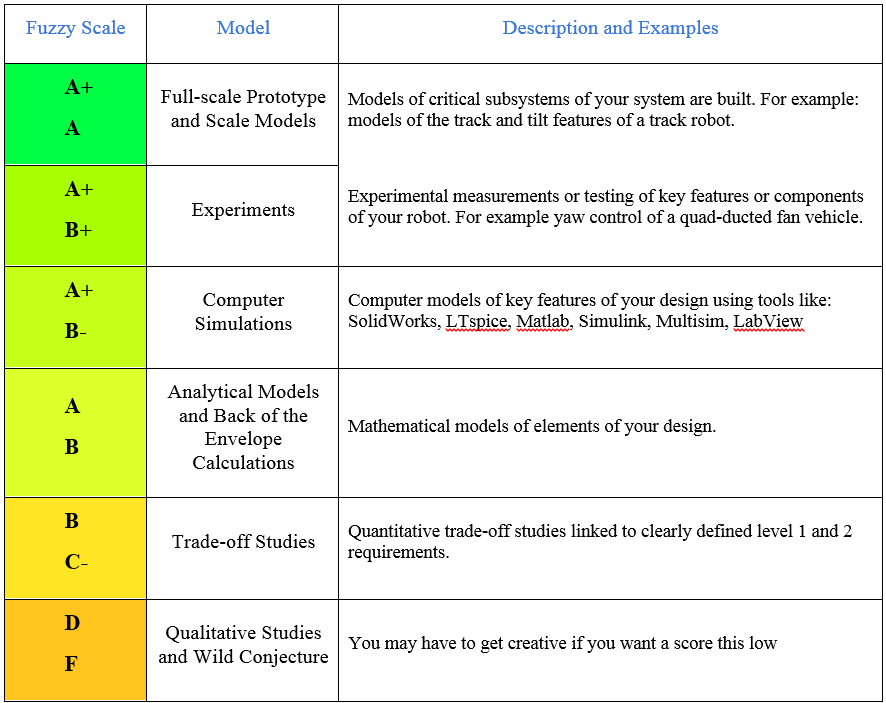

Model Grading Scale

- Here is a first draft of the grading scale we will use to evaluate the models you produce. Keep in mind that this is a fuzzy scale, and should not be taken as canon. Combining multiple modeling steps to address a particular design problem (for example a back of the envelope calculation –to- a computer simulation -to- an experiment –to- a full-scale prototype) increases the chance of getting many high grades.

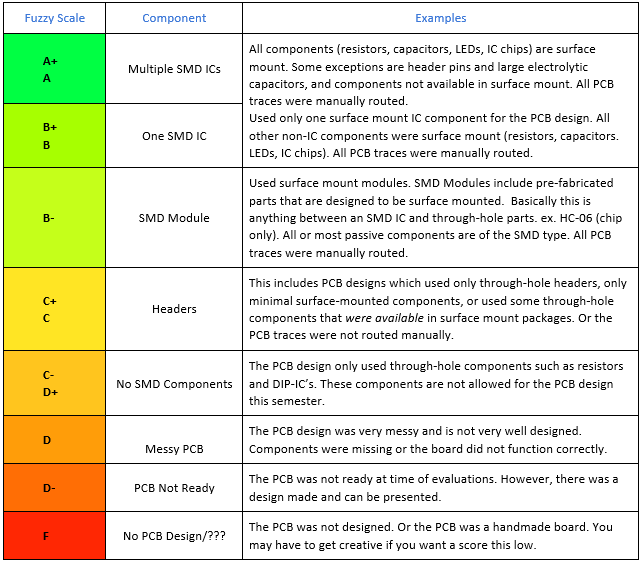

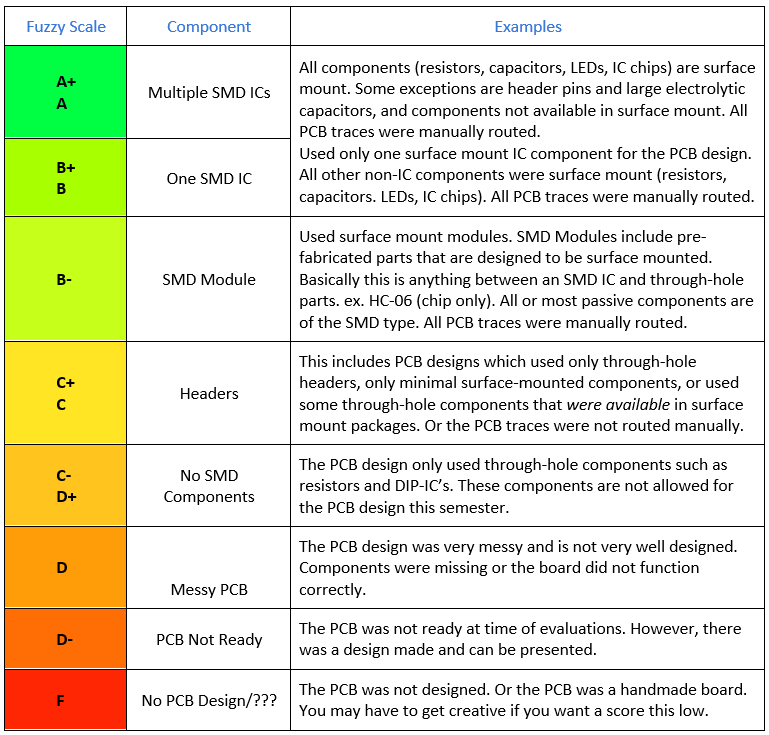

PCB Grading Scale

- Here is first draft of a grading scale we will use to evaluate the custom PCB you produce. Keep in mind that this is a fuzzy scale, and should not be taken as canon. Here are a few examples of what SMD ICs look like and here is a nice introduction to IC Packages from our good friends at SparkFun. Well-designed boards with using only surface mount components will achieve higher grades as outlined in the rubric below. Obviously, the PCBs and components you use need to be functional. No credit is given for chips laid down that serve no function or do not work.

#10: Critical Design Review (CDR)

News and Announcements

Old Business

New Business

Assignment Due Dates

CDR Debrief

- Do not blindly believe what the computer (or the internet) tells you. Use common sense.

- Requirement flow down ultimately is realized in the components selected.

- Please show how the engineering method resulted in the selection of key electronic and mechanical components.

- This may result in the generation of higher level requirements. If this occurs highlight these new requirements.

- For example, Pathfinders desert environment requirement needed to be factored into the selection and design of the rotary encoder.

- If your project has a user interface, (i.e. Arxterra Control App, etc.) make sure your images are screen captures of your original custom interface. Specifically, they should show the custom commands you have implemented.

- All allocation reports’ format should not change from PDR (Expected, Actual, Uncertainty, Margin, Source)

- Do not change “Expected” value to “Actual” value.

- Leave Expected at PDR values.

- Cost reports “Expected” should not change from PDR.

- Do not show only money spent to date.

- Table should clearly identify money spent to date and money to be spent.

- Other resources

- Do not forget to give allocation resource report for 3D printing time if applicable

- 3DoT projects must follow 2,2,2 = 6 hr. print time

- Multiple power reports are often required when using a 3DoT board

- 5v Boost current (mA)

- 3.7v Battery current (mA)

- 3.7 Battery capacity (Ahr)

- Charging time (hr)

- For battery capacity do not forget depth of discharge.

- Finally, get your units right!

- Do not forget to give allocation resource report for 3D printing time if applicable

- The best source of information is the datasheet, not a previous semester. For example, current capability of your battery.

- Listing tasks (and only those tasks) along the Critical Path is required on the second slide in the schedule section.

- Be on time to class (Your project team are counting on you).

- Presentation are due an hour before class. Place in BeachBoard drop box.

- Consult with your Management team (President, Project, and Division) on when they require your material so they can review.

- Keep you division management in the loop! Remember, their grades are also based on the material you present.

- This review material should allow time for the material to be revised if needed.

- Software detailed definition, for the most part, should be completed by CDR. Software coding should not be far behind.

- Clearly identify test versus actual mission ready code.

- Overly simplistic PCB designs.

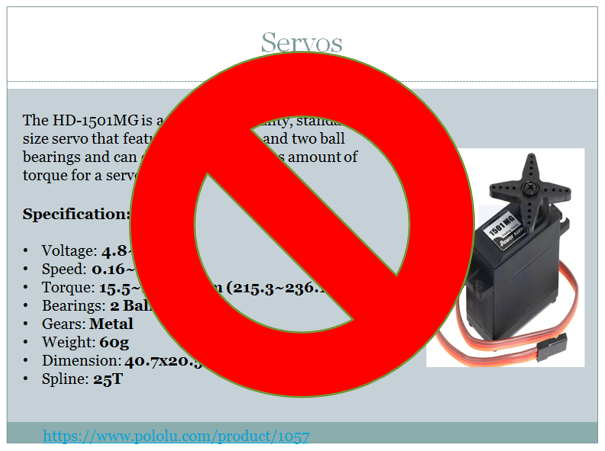

- Duplication of tests reflects poorly on Division communication and coordination. For example; servo testing with hanging weight.

- Design Process

- Draw a preliminary sketch of the design

- Make a back of the envelope calculation

- Conduct a trade-off study

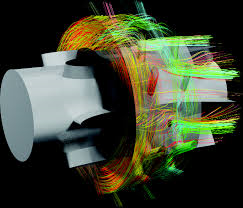

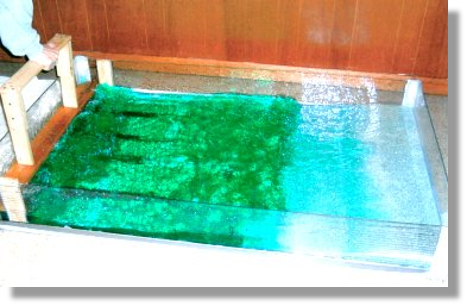

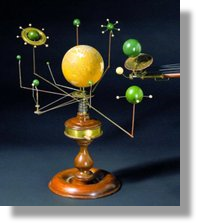

- Week 4: Design Process and Modeling – Models facilitate the design process. A model simplifies a system or process so that it may be better studied, understood, and used in a design. There are three common models used in engineering:

- Mathematical

- Computer Simulation

- Physical Models

- Full-scale Prototypes

- Scale Models

- Solidworks designs are not models unless applied to a simulation. For example load testing.

- Plagiarism from previous semesters leads to disaster.

- You do not understand material presented.

- Cable tree does not address plan for routing cables.

- Material is obsolete

- Resource reports, including power allocation

- 3DoT command software

#11: CDR Presentations and Project Demonstrations

News and Announcements

Assignment Due Dates

Lab Tasks

CDR Project Presentations and Demonstrations

- Schedule

- 2 PM – ModWheels Starts

- 2:40 PM – ModWheels End

- 2:45 PM – 3DoT Chassis (Pete-Bot) Starts

- 3:25 PM – 3DoT Chassis End

- 3:30 PM – BiPed Starts

- 4:10 PM – BiPed End

- 4:15 PM – Goliath Starts

- 4:55 PM – Goliath End

- 5:00 PM – Sojourner Starts

- 5:40 PM – Sojourner Ends & Break Time Starts

- 5:50 PM – Break time Ends & ModWheels Demonstration Starts

- 6:00 PM – 3DoT Chassis Demonstration

- 6:10 PM – BiPed Demonstration

- 6:20 PM – Goliath Demonstration

- 6:30 PM – Sojourner Demonstration

- 6:40 PM – End

#12: Final Documentation

Old Business

New Business

Assignment Due Dates

Lab Tasks

CDR Review

- CDR Debrief with each project

#13: Project Implementation

Old Business

New Business

Assignment Due Dates

Lab Tasks

- Start V&V Reviews

- Grade Status

#14: Housekeeping

News and Announcements

Old Business

New Business

Assignments and Due Dates

Lab Tasks

- Review of Verification and Validation Plans and Reports

- I recommend returning parts on loan, except those integrated into the project, today – avoid the crunch.

- Get projects mission ready.

Mission Accomplished

- Verification and Validation Reports

- Updated and Printed Verification and Validation Checklists and associated Test Reports are Due at the time of the Demonstration

- Updated Checklist broken out by Division and Type (Will, Shall, Should). Unless otherwise directed (approved), verification will be at the system level.

- Request waivers on tests you are not planning on conducting. It never hurts to ask.

- Provide link to PDR System Level Requirements Do not include unlinked requirements. In other words, a system level requirement which is not linked to a project requirement. Again, unless approved, subsystem verification is not factored into your grade.

- Include a “Change Control Page” at the beginning of the Test Report. See SMD Pick and Place for excellent example.

- Checklist may include percent complete versus a simple Yes or No.

- Common mistakes: quantitative (no sharp edges), missing requirements (flight time, safety).

- Grading Note(s)

- Points deducted for use of glue gun and other adhesives like epoxy, twisted non-soldered wires, poor workmanship, tape, zip ties, etc.

- Non-mission Critical Parts

During the final week of class (not during final’s week) teams will return parts on loan or purchased with University funds and not required in support of the demonstration. Please bring paper versions of all relevant emails and receipts to expedite the process.

Promotional Video on the Engineering Method

- The objective of the video is to provide a fun and positive overview of the engineering method and project. The video may be used for promoting the electrical engineering department to the college and outside world (e.g. as a recruiting tool).

- Reference Video: You can view previous videos here.

- Time: Approximately 2 minutes

- Music: Non-copyrighted instrumental track. Here is a good source of non-copyrighted material http://www.mobygratis.com/catalog

- Voice Over: Optional but recommended

- Video: Please do not use copyrighted material (e.g. clips from movies)

- End Credits: Second to last clip should thank our sponsors (for example: 4PCB and Arxterra) including by name and corporate logo. The final clip must always show CSULB Emblem and give credit to the COE/EE department.

- Do not enable commercials on your YouTube videos. Here is a tutorial on how to “Turn Off Ads on YouTube Videos.”

- Grading

- Points will be deducted if the video is not turned in on time and the above instructions are not followed.

- Do not forget to illustrate the Engineering Method through your Project Video with voice-over and/or text overlays.

- Please provide in your accompanying email, who participated in the creation of the video and to what extent.

Blog Posts - Common Errors

- Blog Posts should have a descriptive title, show a square teaser photo plus a short introductory paragraph with Read More à tag.

- Post should indicate semester

- Title should describe content

- Teaser photo must be square

- Verify short summary paragraph is on project home page. (prosthetic arm/hand)

- If missing “Read More” tag you probably have the complete blog post on the project page.

- Code must include helpful comments and should be single spaced done in Courier font

- Too much space between paragraphs

- Image Size and Number

- Images should be under 200 Kbytes. See “How to Blog Post – 101”. And only upload once (Arxterra/public_html/www.arxterra.com/wp-content/uploads/2017/01 – 04). All of these files are over 400K. Interesting that the biggest files are also uploaded multiple times – which should tell you something!

#15: Final Information Filing

Assignments and Due Dates

Additional Information

Do Not Forget

Verification Report

- Updated and Printed Verification and Validation Checklists and associated Test Reports are Due at the time of the Demonstration. Verification will be at the L1 level (minimum) and L2 on a time available basis. Request waivers on tests you are not planning on conducting. It never hurts to ask.

- Provide link to PDR System Level Requirements Do not include unlinked requirements. In other words, a system level requirement which is not linked to a project requirement. Again, unless approved, subsystem verification is not factored into your grade.

- Include a “Change Control Page” at the beginning of the Test Report. See SMD Pick and Place for excellent example.

- Common mistakes: quantitative (no sharp edges), missing requirements (flight time, safety).

- Checklist may include percent complete versus a simple Yes or No.

- Grading Note(s)

- Points deducted for use of glue gun and other adhesives like epoxy, twisted non-soldered wires, poor workmanship, tape, zip ties, etc.

- Non-mission Critical Parts

During the final week of class (not during final’s week) teams will return parts on loan or purchased with University funds and not required in support of the demonstration. Please bring paper versions of all relevant emails and receipts to expedite the process.

Class Lectures

Organized list view of all lectures.

The EE400D Robot Company

Table of Contents

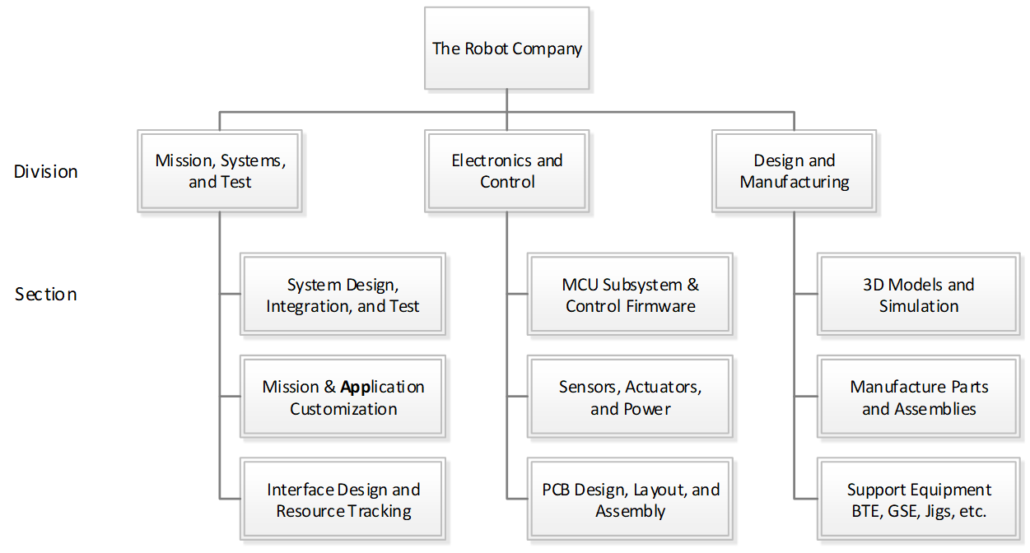

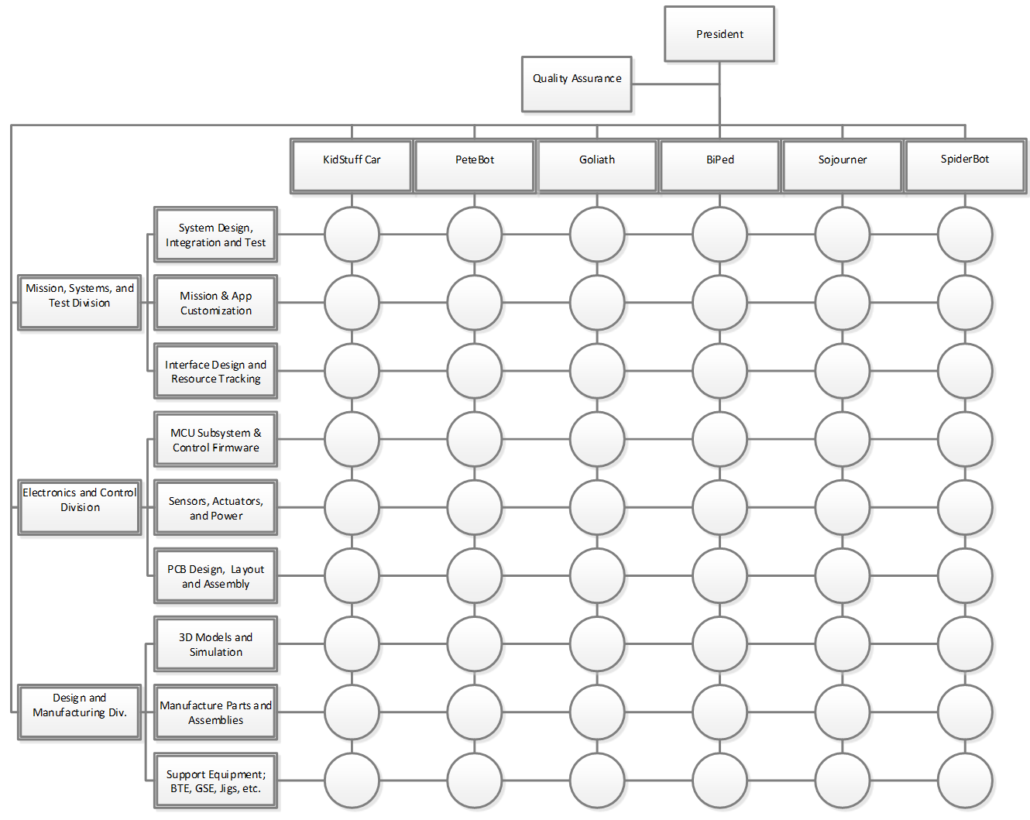

Three Project Management Structures

- Functional Organization

- Project Teams

- Matrix

Functional Organization

- Engineers working on the project work within the company’s existing functional organization.

- Coordination is maintained through existing company management structure.

- EE400D, a classroom of future electrical engineers, is not a real company and has no existing company management structure. Our functional organization will therefore reflect the common functional elements of our projects. This was a key consideration in the selection of our candidate set of projects.

Project Teams

- The company (instructor) assigns engineers to a project team which remains intact over the life of the project (the semester)

- This structure is simple, cohesive, and most important the one which you are most familiar.

- Unfortunately this structure has many disadvantages.

- No training. You are assumed to be technically proficient in your area of responsibility on day 1.

- No sharing of technology expertise or resources.

- Difficult post-project transition. A real problem in a company with thousands of engineers.

- For these reasons, the Matrix organization is the typical structure you will find in large organizations like NASA’s Jet Propulsion Laboratory.

Matrix Organization

- Our class is organized as a matrix type organization as defined in the following two articles. Note that the x and y axis of our matrix is reversed from the generic matrix organization cited in these articles.

|

In my experience, projects just seem to work best with a balanced matrix type of organization. This is because the resources of the company are permanent (or relatively permanent) and projects are not. A project is a temporary undertaking with a known ending. Project teams are formed for the life of a project. This means that we are able to bring the right resources together for a project and use them for the amount of time they are needed. Organizing the Organization for Project Management |

- The Matrix is a Hybrid organization where projects are overlaid on the company functional structure. For our class our functional organization is based on the common components of our robots.

- Notice that our functional organization forms the vertical axis of the matrix.

- In a matrix organization you report to both a project and a line manager.

Robot Company Matrix Organization

Line Management

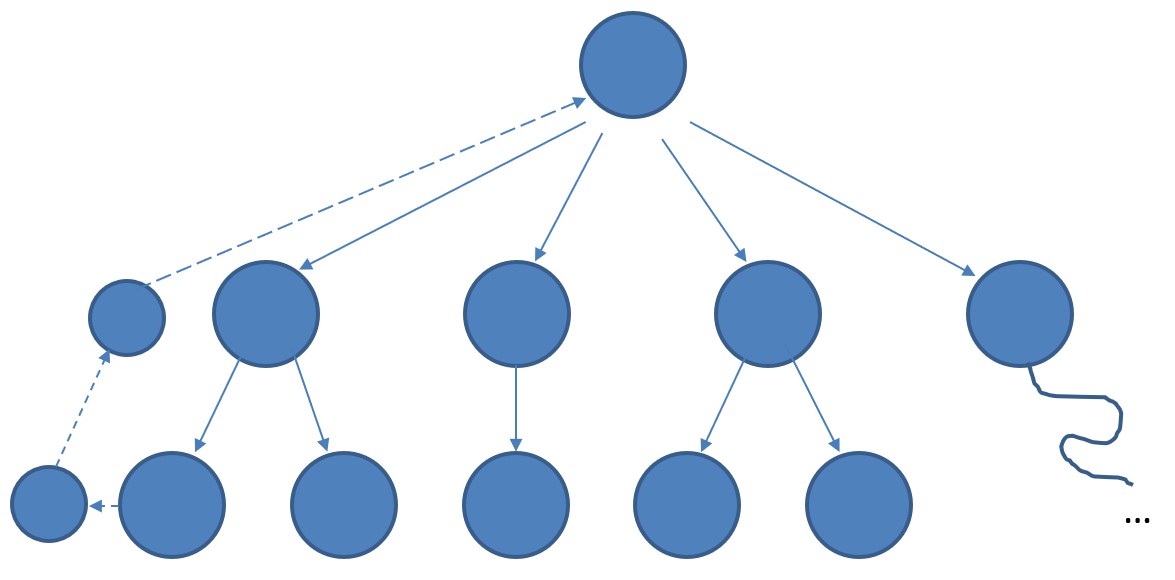

- From the perspective of the company matrix, the Functional Organization is the vertical axis and describes the division’s sections, and groups that make up the company.

- Using NASA’s Jet Propulsion Laboratory as an example each node (circle) is a group of engineers who report to a group supervisor. These group supervisors in turn report to a section manager, who are at the end of each horizontal line in the matrix. Also seen in the matrix, each section manager reports to a division manager who in turn reports to the president. This is the Line Management of the company.

Table of Contents

Suggested Reading

NASA System Engineering Handbook Section 6.1.2.1 “Work Breakdown Structure” and Section 4.3.2.1

“Product Breakdown Structure.” Also, review page 312 Figure G-1 where a PBS Example is provided.

The Robot Company WBS

This document describes how The Robot Company is structured technically known as the Company Work Breakdown Structure (WBS). From your perspective, the WBS describes your responsibilities within the company. In that spirit, I have worded the sections in the form of Job Descriptions and named the document accordingly.

|

As the names imply the WBS provides a breakdown of the work that needs to be accomplished to build the product, while the PBS provides a breakdown of the product ITSELF. |

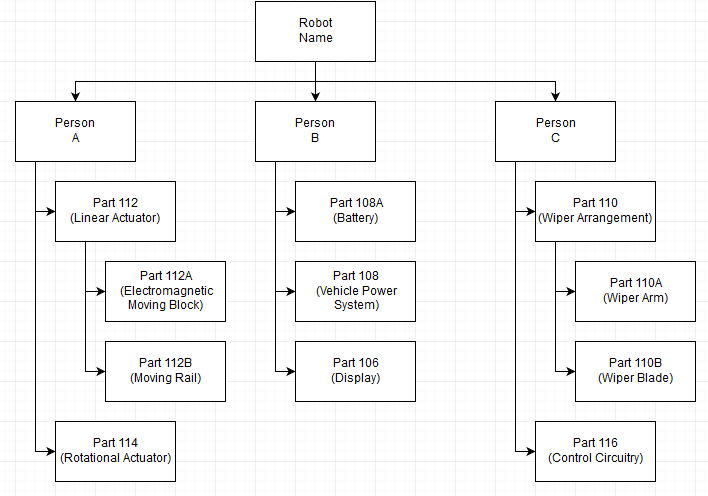

During the first phase of the project, your manager will create a project WBS, based on this one but adapted to your specific robot. Later in the semester, you will hear the term Product Breakdown Structure (PBS). The PBS describes the parts (functional blocks) of the robot. The PBS is the responsibility of the System Engineer.

To make sense out of the following material, please refer to the Company Matrix Organization Chart presented earlier and the Figure 1 Company Work Breakdown Structure. To learn more, read Section 6.1.2.1 “Work Breakdown Structure” and Section 4.3.2.1 “Product Breakdown Structure” in the NASA System Engineering Handbook. On page 312 Figure G-1 a PBS Example is provided.

Figure 1 Company Work Breakdown Structure

If the parts of an organization (e.g., teams, departments, or subdivisions) do not closely reflect the essential parts of the product, or if the relationship between organizations do not reflect the relationships between product parts, then the project will be in trouble … Therefore: Make sure the organization is compatible with the product architecture – Conway’s law

The Customer

Task Summary:

- Define mission objectives

- Set cost and schedule goals based on inputs for the project manager and Electrical Engineering Department chair.

- Validate project design

The Robot Company President

The president is responsible for the management of all Robot Company projects. Coordinate working from the customer’s mission objectives to develop the program requirements for each project. Will allocate limited financial resource between projects.

Task Summary- Work with the customer(s) to define Program/Project Level 1 Requirements

- Train Project and Division managers

- Ensure company meets cost and schedule goals set by the customer(s)

- Support project and division managers

- Look for synergy between projects

- Assess performance of Project and Division Managers

As the president, you will be responsible for the management of all Robot Company projects.

Working from the customer’s mission objectives, you will develop the program requirements for each project.

You will also work with the customer to allocate limited financial resources between the projects. You will be scheduling all project deliverables including the Project Plan, Preliminary and Critical Reviews and Associated Documents.

You will be working closely with our project managers helping them manage cost, schedule, and performance, including…

- Assisting the project managers in their preparation for reviews and written documents.

- Assisting the division managers in the development and execution of their training plans.

Working with the project and division managers, you will also identify areas of synergy between the projects allowing better utilization of limited engineering resources.

Keep close communication with joint projects (cross course integrated projects) to ensure each division manager, project manager and engineer are in agreement and compliance with the Interface Control Document (generated by Mission, Systems and Test Division). Requires close communication and collaboration with the presidential counterpart in second-course section.

Along with the customer and management staff, you will, on a periodic basis, assess each project and division manager’s performance.

Qualifications

An educational background in business and/or management experience, or a desire to learn is a plus.

Quality Control Engineer

The QA Engineer working with the project and division managers, will insure that project plans, documentation, presentations, and blog posts are consistent with those generated by working engineers and reflects well on the CSULB COE and EE department.

Task SummaryInsure quality is built into each project. For example, is the robot easily assembled and disassembled. Does the robot not undergo “Rapid Unscheduled Dissembly” RUD.

Cabling

Although, typically not the responsibility of the Quality Assurance Engineer, you will take the “interface definition” to the next level down by defining the “cable tree” for each project. To accomplish this task you will working with the system, electronics and control, and manufacturing subsystem engineers, from each project to specify analog/digital signal and power connectors, cables, and how they will be routed (the tree). Specifically, insure NO wires are exposed and all cabling includes connectors and routing is designed-in.

Factor in interference with other design elements and how to keep the overall cleanliness of the design. In other words, when assembled, the product should not look like a rat’s nest.

Blog Posts

Manage the class website. The QA engineer is the gate keeper insuring that all blog posts meet all requirements before posting.

- Blog is posted to the correct location on the website.

- Includes correctly formatted square teaser photo and “Introductory” paragraph with a “Read more à” link.

- Identifies project member(s) who created the post.

- All images are formatted for the web!

- Does not plagiarize material.

- All code examples use courier font and single spaced.

Make an effort to attend project and division meetings.

Project Manager

Define projects level 1 requirements, hold project meetings, manage and keep tasks on schedule. Working with your team to make your robot a success. Success will be defined by meeting cost, schedule, and performance requirements.

Task Summary- Build Project Team

- Define Project WBS and PBS

- Define Program/Project Level 1 Requirements

- Track and manage project budget and schedule

- Lead Weekly Project Meetings

- Report to the Company President

- Communicate with Division Managers

- Edit Project Documentation

- Project Video

- Assesses the contribution of Project Members

The successful candidate(s) will manage one of our Robot Projects. You will initially be negotiating with the division managers to build your project team.

Next, you work with the system engineer to define your project unique WBS. You will assist the System Engineer in developing the PBS.

Working with the customer, you will write the Level 1 Program requirements. Working with the System engineer, you will next write the Level 1 Project requirements. These requirements will be codified in the Project Plan.

You will then be working with your team to make your robot a success. Success will be defined by meeting cost, schedule, and performance requirements.

Qualifications

An educational background in business and/or management experience, or a desire to learn is a plus.

Assessment

During the semester, on a periodic basis, the project manager will assess the performance of each engineer within their project. At the same time, the president and management staff may also grade the members of your team. The instructor shall take these recommendations into consideration when assigning grades to engineers within your project.

Meetings

The Project Manager leads a weekly project meeting. As part of the meeting, the project manager should assign someone to take the meeting minutes. The project manager is responsible for editing these minutes and uploading them to BeachBoard in a timely manner. Keep president informed of weekly project meeting date, time and location for occasional attendance.

The Project Manager is responsible for scheduling a weekly meeting with the President. This meeting may be as short as 15 minutes. The meeting may occur during the lab time. The project manager is responsible for taking the minutes during the meeting. An edited version of the minutes are to be provided to the president and the instructor prior to the next meeting.

Project Video

The project video is the last deliverable provided by the project. Its objective is to act as a recruiting tool for high school students considering electrical engineering at CSULB. It should also showcase our work to the COE and its corporate sponsors. The video must also present the engineering process as applied to the design and construction of your project. Points earned are “bonus.” The project manager may want to assign video production to someone with video editing experience or a team member who could benefit from the “bonus” points assigned.

Final Documentation

Although Physical copies of reports are still alive and well in industry, to keep the instructor’s office as uncluttered as possible, we will be storing all our documents on the cloud.

The project manager is responsible for compiling, organizing, and editing the key documents and reports (selected blog posts) generated over the semester by the project into a Final Documentation Blog Post. This will ensure your documentation and videos are not lost over time.

Division Manager

Present training material to the division members in the form of hands-on lectures and assess learning with assignments and/or exams. Manage cross-links between projects and find and manage resources within your division.

Task Summary- Manages Division Engineering Resources

- Responsible for Training

- Leads Weekly Division Meetings

- Reports to the Company President

- Communicate with Project Managers

- Assesses the contribution of Division Members

The first task of the Division manager will be to assign engineers within his or her division to each project.

Division managers, at their discretion, may also assign an engineer to be a section manager. If not assigned, the Division manager will act as the section manager.

Over the course of the project, you may dynamically reallocate your engineering resources due to:

- Changing needs of a Project which may require additional help or temporary reassignment of an engineer with a unique skill set.

- Successful completion of a task

- Poor performance in support of a project

Present training material to the division members in the form of hands-on lectures and assess learning with assignments and/or exams.

During the semester, the division manager shall provide reading and/or homework assignment to help division members learn the material. On a periodic basis, no less than every 2 weeks, the division manager will assess the performance of each engineer within their division by giving a quiz. The quiz shall be over a set time limit, where the division members may, at the managers discretion be allowed a sheet of notes. It is important to distinguish between helping division members learn the material and assessing their mastery of the material.

Learning assessment grades shall form a part, but not the totality of this grade. At the same time, the president and management staff may also grade the members of your division members. The instructor shall take these recommendations into consideration when assigning grades to engineers within your division.

Meetings

The Division Manager leads a weekly division meeting. As part of the meeting, the division manager should assign someone to take the meeting minutes. The division manager is responsible for editing these minutes and uploading them to BeachBoard in a timely manner. Keep president informed of weekly division meeting date, time and location for occasional attendance.

The Division Manager is responsible for scheduling a weekly meeting with the President. This meeting may be as short as 15 minutes. The meeting may occur during the lab time. The division manager is responsible for taking the minutes during the meeting. An edited version of the minutes are to be provided to the President and the instructor prior to the next meeting.

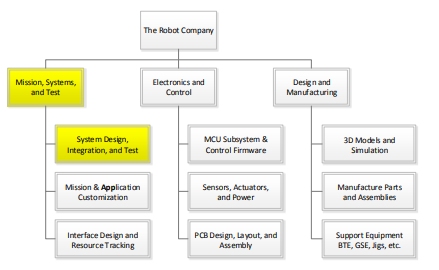

Mission, Systems, and Test Division

Divison Manager

Manage the Mission, Systems and Test Division and associated sections. See the Division Manager section for a general job description. Responsibilities of the engineers within this division are described in the following subsections.

System Design, Integration and Test

Resources:

- NASA Systems Engineering Handbook

- GSFC Rules for the Design, Development, Verification, and Operation of Flight Systems

Task Summary:

- Define WBS and PBS

- Define Level 2 System/Subsystem Requirements

- Interface Control Document (ICD) if applicable to your project

- System Electronic Interface Design

- System Software Interface Definition

- Cable Tree

- Grounding Strategy

- Manage system resources

- Generate verification and validation test plan

- Build summary verification and validation checklist

- Look for the Intangibles

System Design

First task will be to work with each project manager to define unique WBS for each project. Working from the WBS and subsystem engineers, define the PBS.

Requirements

Working with the project manager, help develop level 1 program and project requirements. The project manager is ultimately responsible for generating Level 1 program requirements. Working from the level 1 requirements, and with the subsystem engineers, write the level 2 system and subsystem design requirements. Subsystem engineers are ultimately responsible for the generation of subsystem requirements.

Integration and Test (Requirement Verification and Product Validation)

Working with customer and each system engineer, develop a product requirement verification and validation test plan. This plan includes the tests to be conducted to verify requirements and validate the design. Avoid qualitative definitions like “visual inspection.”

Part of the plan includes a summary verification/validation checklist. The checklist breaks down requirements by numbering them, stating the requirement, providing rationale for the requirement, and then breaking down the level of success of the requirement into a percentage.

Look for the Intangibles

Finally, a good system engineer looks at the project as a “complex system” and how it might fail or not meet customer expectations during the mission (Project Validation). This is a critical part of ConOps (Conceptual Operations) whose purpose is to discover holes in the definition of the design (the intangibles) before the start of the mission.

1.1.4.1 Case Studies

Here are some examples of ConOp failures.

A vacuum system for use in a lab might be defined in millimeters of mercury (mmHg), but once the machine is built the noise generated (decibels) makes it useless for use in a lab environment.

The stability of a walking robot might be defined by the impact of a rod of radius r (cm) located at a given distance d (cm) at height h (cm) from the robot, with mass m (kg) moving a velocity v (cm/sec) for a period of t seconds. The robot is designed to pass this test, only to fall over if a lesser force is applied. So the robot passes the defined test but fails the spirit of the requirements.

The field-of-view (FOV) of an articulating camera mirror system mounted on a rover is not defined. On the day of the final half of the camera’s FOV is the floor.

A pan and tilt subsystem is designed and tested to meet FOV requirements only to discover when mounted on the spider robot that the pan and tilt subsystem impacts the leg servos when panned down.

A large capacitor on a PCB was designed to close to an IR sensor connector preventing the sensor from being plugged into the robot.

Mission and Application Customization

Programming is not a traditional role for a system engineer, but moved to this level to focus additional attention onto this too often forgotten area.

Task Summary:

- Configure mobile device App

Configure the application software required to remotely control the robot. Control may be done from a PC and/or cell phone (Android or iPhone) application.

If no off-the-shelf application exists to remotely control your robot, it will be necessary to generate this code. If the project falls within this category, it will be useful to have a background in programming in one or more high-level scripting languages like Processing, HTML 5, Java, or MATLAB.

Interface Design and Resource Tracking

System Electronic Interface Design

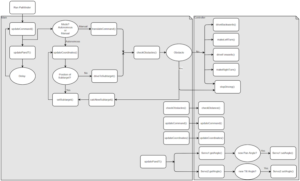

Working with the electronics and control subsystem engineer(s) within each project, document the System Interface Design, which includes the System Block Diagram and Interface Design Matrix.

Power Distribution Strategy

The system engineer, working with the electronics and control and manufacturing engineer, is responsible for defining the power distribution strategy (star and/or multipoint) at the PCB and System level.

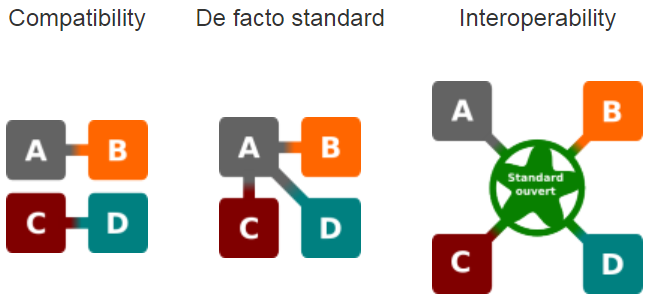

Interface Control Document (ICD)

In some cases, projects will be interfacing with another project. Fall ’16 examples include the Prosthetic Arm (Wednesday class) to the Prosthetic Hand (Thursday class) and the Pathfinder Solar Panels (Wednesday class) to the Pathfinder Chassis (Thursday class). For these projects, the systems engineers will work together to write an ICD documenting the electrical connectors and cabling, power, mechanical, and other interfaces associated with the integration of the two projects. Work closely with MST counterpart in other class section, project managers for each project, and president from each class to ensure ICD is being followed. Encourage joint project meetings throughout the life of the project to help maintain communication between groups.

System Resources

Manage all applicable system resources. Resource management typically includes, but is not limited to, mass and power. For example, on a spacecraft, Field-of-View is a resource. When reporting to management, please include margins and contingencies. Margins are applied based on uncertainty in a given line item. Contingency is applied across the resource and is a function of the system resource budget minus the expected value and total margin. Resource reports should be updated on a periodic basis, typically defined by the president. As a rule of thumb, resource reports should be updated every other week and included in the meeting minutes.

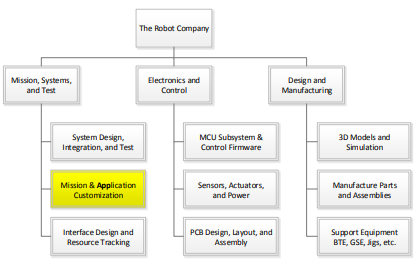

Electronics and Control Division

Division Manager

Manage the Electronics and Control Division and associated sections. See the Division Manager section for a general job description. Responsibilities of the engineers within this division are described in the following subsections.

MCU Subsystem and Control Firmware

Task Summary:

- Software Definition

- MCU Communication Firmware

- MCU Subsystem Command and Telemetry Firmware

- MCU Subsystem Control Firmware

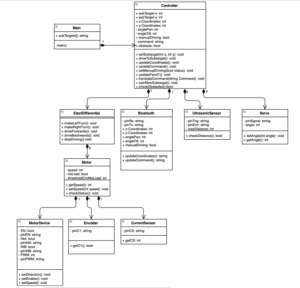

Write software subroutines and functions as defined by the software system block diagram. For robots implementing complex motion algorithms, this includes creating a data structure array in SRAM or Flash program memory to define the motion.

Specifically, responsibility of the electronics and control engineer will be to write the firmware required to translate commands into control signals to the actuators, read sensors and translate into data bytes, and implementation of any control algorithms. Communication with the Bluetooth module and decoding of command packets is the responsibility of the systems engineer. The systems engineer is also responsible for collecting and packetizing the data bytes and subsequently sending them to the Bluetooth module.

Qualifications

A background with embedded systems, the Arduino IDE, and the C++ programming language or a desire to learn is a plus.

Software Definition

Develop a software system block diagram. The description of the block diagram should define the function of each module and how they will communicate. For example, number of arguments and their data type, plus return value and data type.

MCU Communication Firmware

The Micro-Controller Unit (MCU) Communication firmware[1] receives and decodes commands and sends telemetry to the Bluetooth device on the robot. The software’s responsibility stops once a command is decoded. For most projects, the E&C engineer will adapt existing C++ programs written within the Arduino IDE for this purpose.

If the project does not fall within the category of having an off-the-shelf application to decode commands and send telemetry, then it would be necessary to have a strong background in programming in C++.

MCU Subsystem Command and Telemetry Firmware

To control actuators and read sensors, software will interface with the peripheral subsystems of the microcontroller including: Timers (e.g., Fast PWM mode), ADC, TWI, SPI, EEPROM, and USART. The Robot Company has developed extensive material on working with the ATmega328P and on how to program its subsystem modules in C++.

MCU Subsystem Control Firmware

The successful candidate(s) will be responsible for the onboard software associated with the stability and tracking control of the robot. Most robots will implement one or more PID control algorithms.

Control input will typically be from an IMU.

For this sub-task a background in embedded systems, C++ programming, and control theory (EE470 and EE471) or a desire to learn is a plus.

[1] Software located in Flash program memory.

Sensors, Actuators, and Power

Task Summary:

- Define sensor suite

- Define actuators including electromechanical devices and subsystems

- Define communications subsystem

- Define power subsystem

Electronics and control engineer is responsible for selecting and implementing the sensors, actuators and power subsystem to be carried on the robot.

Sensors

Sensors can be as simple as a resistor divider to measure battery voltage and as complex as a SLAM mobile device. In the following paragraphs, sensors typically found on a robot will be discussed.

For measuring target distance, a number of sensors need to be considered including IR, Lidar, Ultrasonic, or camera. Trade-off studies to select a sensor should consider how measurement errors are introduced by the environment (e.g. lighting, reflections, and target surface properties). Also consider the peripheral subsystem required by each sensor type. These may include the ADC or a serial peripheral interface like the I2C, SPI, 1-wire, and USART. A wealth of information can be found on the Internet and here.

For measuring the distance traveled by a robot, consider the addition of a shaft encoder. The trade-off study should investigate traditional (opto and hall effect sensors) and sensorless (commentator and back emf) solutions for measuring the rpms of a DC motor.

For measuring angular rotation and/or velocity to control the stability and tracking of the robot, consider gyro, accelerometer, and magnetometer or some combination of all three incorporated into an Inertial Measurement Unit (IMU). If an IMU is adopted, sensor data may be smoothed using a Complementary or Kalman Filter algorithm. Some commercially available modules incorporate both the IMU and filter.

For measuring battery state, purchase a fuel gauge or simply use a resistor voltage divider.

Actuators

An actuator is defined as any output device. This includes optical devices like LEDs and Lasers. It also includes electromechanical devices like solenoids, servos, and motors.

Electromechanical Devices

Specification of electromechanical devices, like servos and motors, should be based on quantitative system/subsystem design requirements. From these “specifications”, a trade-off study is typically conducted. The trade-off study usually takes the form of a table where the robot’s desired specification for the electrometrical part is in the first column. The subsequent columns contain the specifications gleaned from the datasheet of candidate commercial off- the-shelf (COTS) parts. The selected parts are then purchased and tested against the original robot specification. These tests should consider static and dynamic loads plus life-cycle testing under worst case load conditions.

Case Study

Up to the Spring 2016 Semester, no SpiderBot has ever completed its mission due to insufficient static and dynamic modeling (back of the envelope and at 3D modeling) at the system level, mass resource management, and life-cycle testing under load conditions.

Electromechanical Subsystems

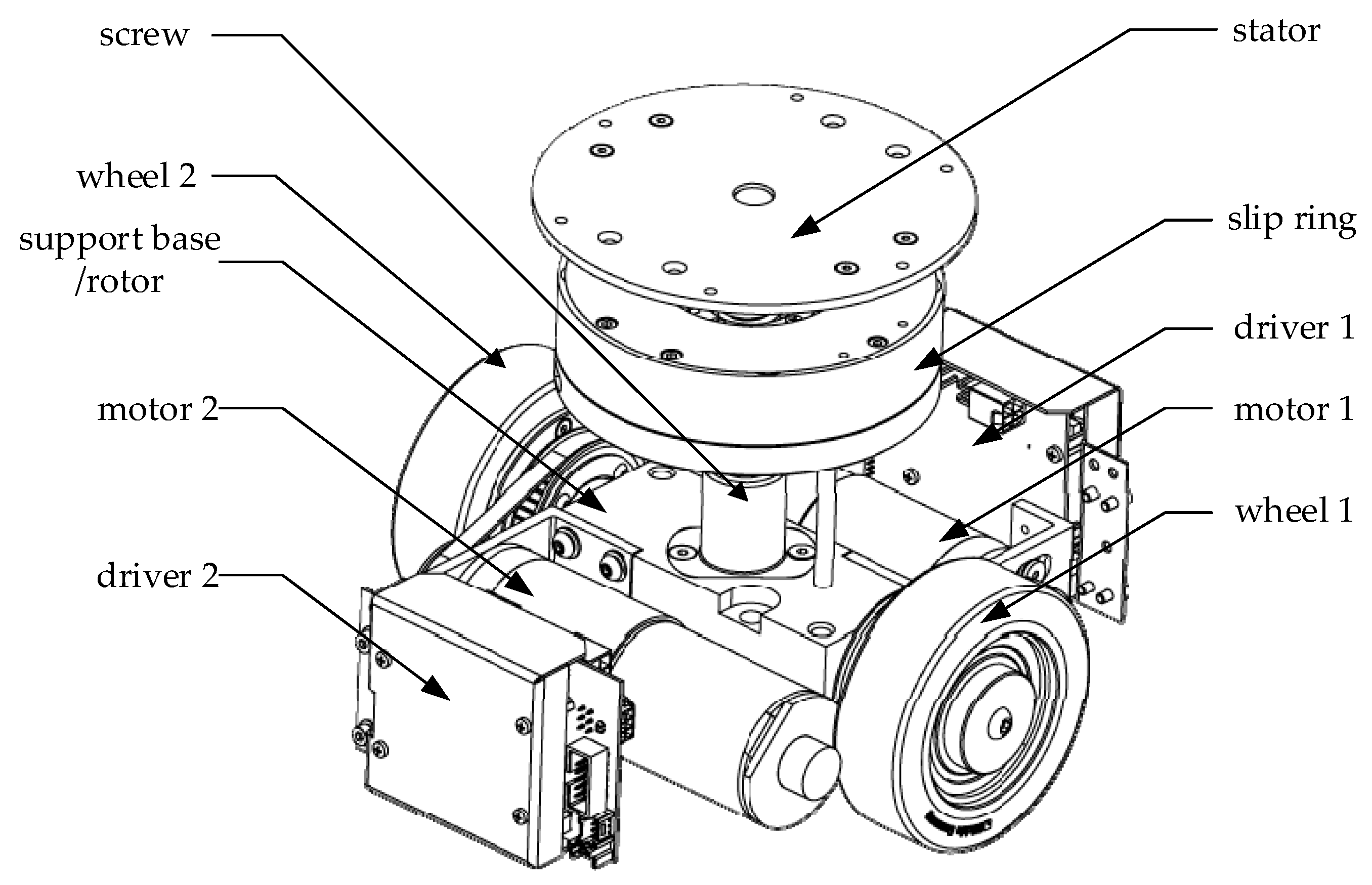

Electromechanical devices are often combined into subsystems. Robots’ subsystems may include the powertrain and a pan and tilt platform.

Powertrain

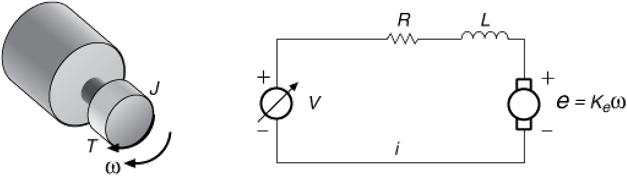

The powertrain includes: DC motors and/or servos, transmission (the “gearbox”), and drive electronics (H-Bridge, Shift Register, Power Transistors …). For this subsystem, an educational background in motors and motor control (EE451) or a desire to learn is a plus.

Pan and Tilt Platform

For the robots, the pan and tilt platform carry the mobile device (Android or iPhone). Actuators may include a stepper motor or servo for panning and almost always a servo for tilting.

Communications

For most robots, a Bluetooth module will be incorporated into the design.

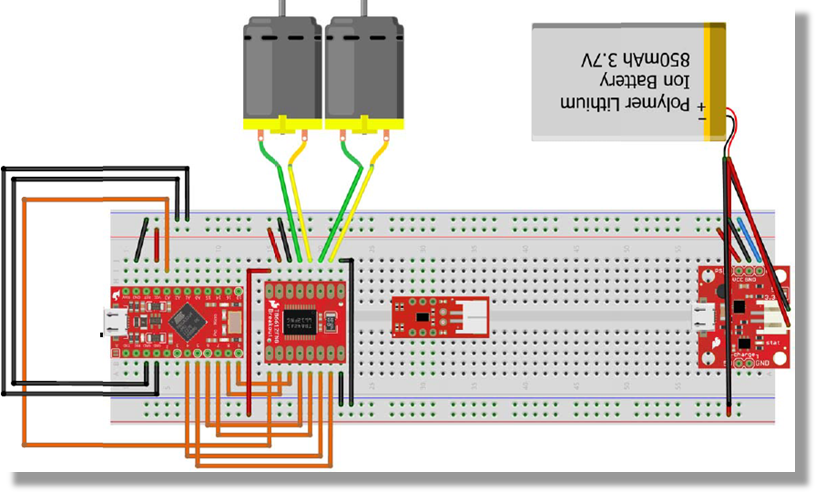

Power

The power subsystem may include batteries, charging circuits, DC-to-DC converters, and voltage regulators (linear and LDO). For some robots, consider the addition of solar panels.

DC-to-DC converters may step-down (buck) the input voltage, step-up (boost) the input voltage, and in some cases both. A step-down (buck) converter is also referred to as a UBEC which stands for “Universal Battery Eliminator Circuit”.

Research battery solutions based on quantitative subsystem requirements, resource reports (mass and power), and project requirements (mission duration, safety, etc.). Battery technologies include, but are not limited to, NiCD, Nimh , LiFePO4, and Li-Ion/Polymer. Based on requirements, other power sources may be investigated such as solar.

PCB Design

Task Summary:

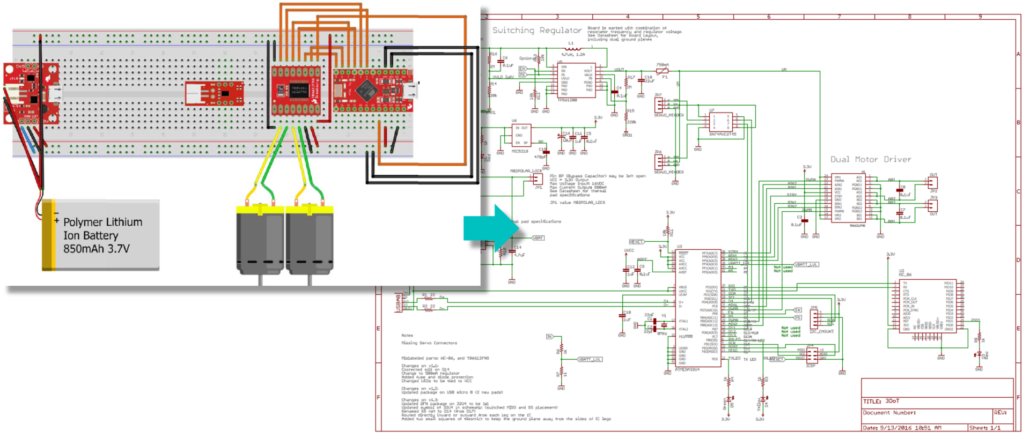

- Working from interface matrix, create a Fritzing diagram

- From fritzing diagram, build breadboard

- Write C++ test software programs both to control the actuators and collect data from the sensors

- Test breadboard

- Using Eagle CAD (schematic capture), create electrical schematic

- Test finished PCB

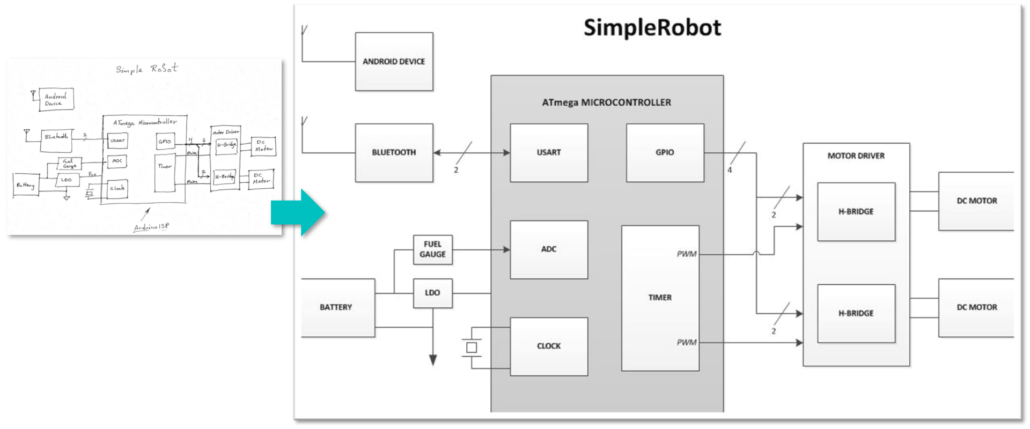

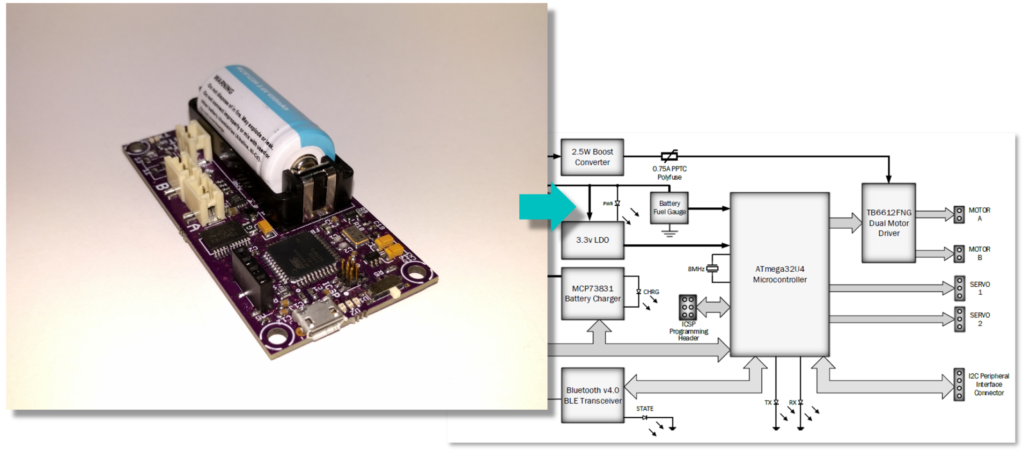

Working from the PBS, System Block Diagram, and Interface Matrix, provided by the system engineer, the electronics and control engineer designs the robot’s Printed Circuit Board (PCB). Working from the provided material, the electronics and control engineer also creates a Fritzing diagram, makes and tests the breadboard, and captures the design, in the form of a schematic, using CAD software (typically Eagle CAD). The manufacturing division is then responsible for laying out the PCB and providing to the Electronics engineer a completely assembled PCB. The electronics and control engineer is then responsible for testing the completed PCB.

PCB Layout and Assembly

Task Summary:

- Layout a PCB with Surface Mount Technology (SMT) discrete components and ICs

- Generate Gerber file and order a SMT solder paste stencil.

- Reflow and hand solder PCB

Working from a schematic, provided by the electronics and control engineer, the power distribution strategy, provided by the system engineer, and the physical constraints of the robot, the manufacturing engineer will design the printed circuit board (PCB), perform ERC and DRC checks, generate the CAM file and upload to a PCB house for fabrication. This process is typically carried out using Eagle CAD.

In addition to the PCB, it will be necessary to purchase the SMT solder paste stencil used for applying paste to the PCB as part of the reflow soldering process. The design of the stencil is generated in Eagle CAD and output as a Gerber file.

Once the PCB and stencil are received, the manufacturing engineer is responsible for reflow soldering of the SMT discrete components and ICs onto the board, as well as hand soldering through-hole discrete components. The board is then given to the electronics and control engineer for testing.

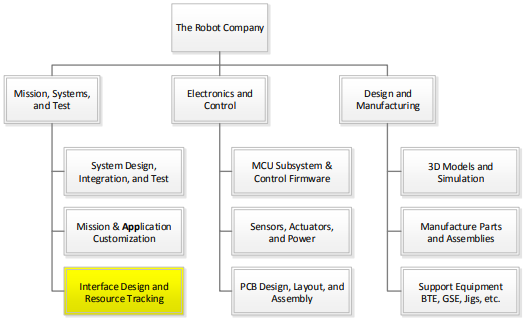

Design and Manufacturing Division

Division Manager

Manage the Design and Manufacturing Section. See the Division Manager section for a general job description. Responsibilities of the engineers within this division are described in the following subsections.

3D Models and Simulation

Task Summary:

- Use CAD/CAE software to design the robot

- Use CAD/CAE software to design the mechanical parts

- Run static and dynamic simulations

The successful candidate(s) will use a solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) software program, typically SolidWorks, to design the mechanical parts, sub-assemblies, and even the robot itself. The overall design must take into consideration all parts manufactured and purchased. The most commonly forgotten parts are the connectors and cabling.

Working with the systems engineer, determine the acceptability of the design by running simulations. These may be in the form of system level animations (e.g., for bipedal robots the walking motion while tracking center of mass), system level load and shear analysis (e.g., for spiders a stress analysis across the body-servo-leg interfaces), and others as seen appropriate.

Qualifications

Work experience with a 3D modeling program or a desire to learn is a plus. Preferred modeling program is Solidworks; however, a working knowledge of Blender, AutoCAD, SketchUp or any other CAD/CAE program will be taken into consideration.

Manufacture Parts and Assemblies

Task Summary:

- Manufacture mechanical parts

- Specify and order off-the-shelf parts

Parts may be fabricated using additive (3D printers), subtractive (CNC, laser cutter, lathe …), or other (vac-u-form, molds …) manufacturing techniques. It is important to work with the manufacturing Division Manager to find the manufacturing technology required for the project.

Off-the-Shelf Parts

Specify and order miscellaneous parts including:

- Fasteners – nuts, bolts, screws, washers…

- Adhesives and Sealants – tape, velcro, zip-ties, O-rings, weather stripping, silicone tube…

- Powertrain Components – belts, gears, bearings…

- Hardware – grommets, brackets…

The customer has a large number of fasteners, powertrain components, and other hardware. Otherwise, purchase such parts from Home Depot and McMaster-Carr among others.

Case Study

The manufacturing engineer of a robot has a friend with a 3D printer. He asks his friend if she will print the parts for their robot. The friend agrees, assuming that the STL files will be provided within a few weeks.

Case 1: Near the end of the semester, the friend receives the STL files and realizes that they simply do not have time to print the parts. What should the manufacturing engineer have done to avoid this problem?

Case 2: The STL files are provided within a few weeks. However, the friend says her 3D printer is broken and she simply does not have time to fix it. Because the engineer now has time to recover from this disaster, instead of running around asking everyone if they have a 3D printer or purchasing time on a 3D printer, he contacts the Division Manager for help. The Division Manager bring up the problem at the next division meeting and another 3D printer is located. This is the strength of the matrix organization!

Test Your Knowledge

Design

- Who is responsible for designing the cabling layout?

- You want to build a pan and tilt platform. Who is responsible for the specification of the servos?

- You want to build a pan and tilt platform. Who is responsible for the design of the brackets to hold the servos?

- Who is responsible for calculating the torque specification for the servo?

- Who is responsible for simulating the pan and tilt platform to insure it will meet FOV requirements.

- Provide one or more examples of a ConOps failure?

Testing

- Who is responsible for designing robot verification tests?

- Which division(s) are involved in testing the robot?

Printed Circuit Board

- Which division(s) are involved in the design, fabrication, and testing of the PCB?

- What part does the System Design engineer play in the design of the PCB?

- Who designs the circuit schematic?

- Who board layout of the Printed Circuit Board (PCB)

- Who is responsible for assembling the PCB?

- Who is responsible for testing the PCB?

Software

- Which division(s) are in involved in software development?

- Your project has decided to develop an iPhone powered spider robot. Who is responsible for customize the Arxterra application to control the spider robot?

- Who is responsible for implementing commands?

- Who is responsible for sending telemetry data packets to the Bluetooth module?

- Who is responsible for writing the firmware to translate sensor inputs into data bytes?

- In which computer can you find the MCU communication firmware?

Other

- Who is responsible for drafting the product breakdown structure (PBS)?

- Your project has decided to use a CNC machine to fabricate a part for your robot. Who should you look to for help?

- Who is ultimately responsible for assigning your grade?

- If you were going to fly a payload on the Space Shuttle, NASA Johnson Spaceflight Center (JSC) reassured you that all surface in the payload bay would be visually clean. Is this a quantitative requirement?

- How often should system resources be updated?

Table of Contents

First Writing Assignment – Job Application Cover Letter and Resume

- Your cover letter along with your resume will help me in assigning company responsibilities. Other direct input for assigning work is welcome.

- One page limit.

- How to write your Cover Letter and Resume

- Resume Format – Write your cover letter in paragraph form as shown in the second figure here. Please do not provide a “functional” cover letter (first example shown).

- Your Cover Letter should tell a story!

- Here are some tips on what Beckman Coulter (Biomedical Engineering) and Google are looking for in your Cover Letter and Resume.

- Finally, some sample EE400D Cover Letter.

- How to Send Me Your Cover Letter and Resume:

- Your cover letter and resume should be in a single PDF document. The name of the document should be your name Joe Smith.pdf.

- Place your Cover Letter with Resume in Beachboard Dropbox.

Job Application Cover Letter

In your job application cover letter please answer the following questions.

- Before you begin be sure you have read our company Job Descriptions. Read our company’s Blog Posts to learn more about each project.

- What Position(s) are you applying for? Start your cover letter with a short sentence that allows our recruiting department to send your cover letter and resume to the correct engineering department(s) for review and consideration.

- Introductory Paragraph(s):

- Next, introduce yourself by starting with the reason (e.g. motivation, goals) you chose electrical engineering.[1]

- Describe some significant engineering experience[2] and any access[3] you may have to resources which match the background requirements on the job posting.

- When describing your engineering experience, include any projects you have built.

4. EE400D Unique Career Path

- How many units are you taking this semester, including 400D? Do you have a job/internship and if yes, how many hours per week do you work?

- What career track would you like to be placed on? – Line (People) Management, Project Management, Technical Excellence

- If you had a choice, what project would you like to be assigned?

- Although the following material is optional, you may want to include it in order to help us place you within the company.

- What technical/project skills would you like to learn?

- What fellow students would you like to work with? Optional

[1] If you are not sure where to start see Appendix A Why Do Students Choose Engineering?

[2] If you do not have any work experience you may include relevant classes.

[3] For example, talent or machines you have access to on campus (e.g., mechanical engineering machine shop, on campus projects, organization like the IEEE, SWE, etc.), at work or home.

Cover Letter Rubric

- Did you follow instructions? For example, did you format and name the document correctly. Is there only one document.

- Strength of the cover letter.

- Glowing platitudes without backup are worse than nothing.

- Your resume is useless if I never read it.

- Grading is harder than normal to better reflect the real world.

- Rule of Thumb… D to C = skip cover letter, B = read resume,

A = job offer w/o even reading resume

- Did you address points in assignment? In are a few questions to ask yourself before you turn in your assignment.

- Did you indicate your career path and project(s) you are interested in working on.

- Did apply for a division with a project option. Did you get the Name of divisions correct?

- Did you define your school and outside workload?

- English Proficiency

Resume

- Create a resume that specifically applies your coursework and/or experience toward the position you are applying for at our company.

- Personalize your resume to the company with a few introductory sentences. Think of your cover letter crystallized into two or three sentences. The company should come away with the idea that this is your dream job and they would be crazy not to hire you.

- One page limit.

- Please see Chapter 3 of Finkelstein on ‘Technical Definitions’ and Chapter 18

- For help, try Resume Builder templates

Appendix A: Why Do Students Choose Engineering?

- Source: Stiquito An Inexpensive Robot by James M. Conrad, North Carolina State University

- Career counselor suggested, based on correct (or incorrect) perceptions of the field.

- A teacher suggested, because the student was good at math and science. (Note: teachers also discourage based on this and perception).

- Second hand knowledge, like from a neighbor, relative, friend, books, newspapers, magazines.

- Direct exposure with the field through work, workshops, class assignments.

Students rarely have direct exposure to engineering.

Table of Contents

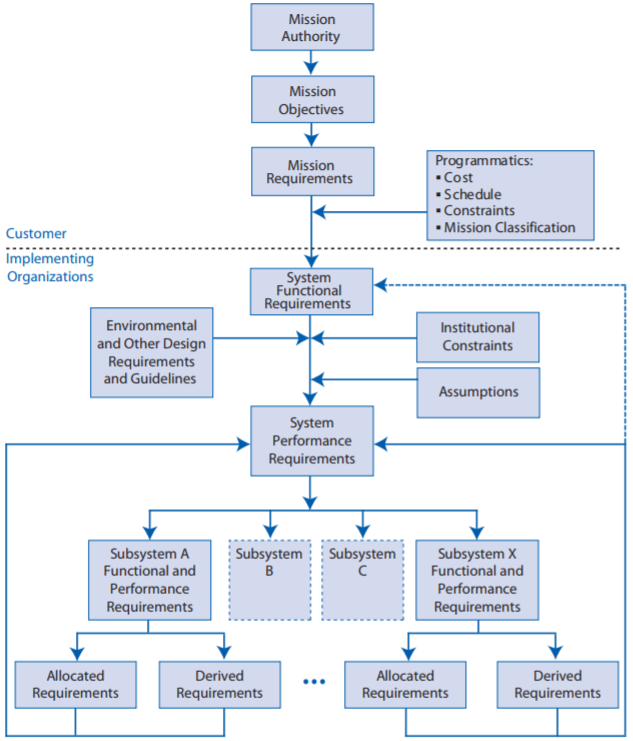

The following document paraphrases and quotes material originally contained in the NASA Systems Engineering Handbook NASA-SP-2007-6105-Rev-1 Section 4.0 System Design (page 31)

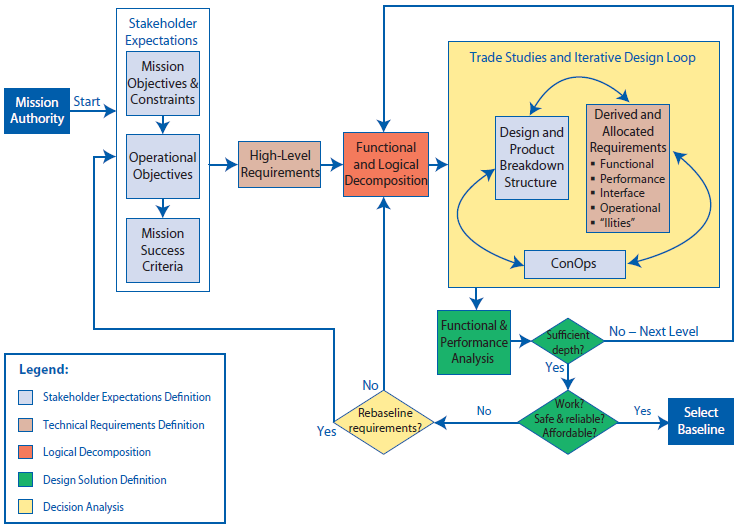

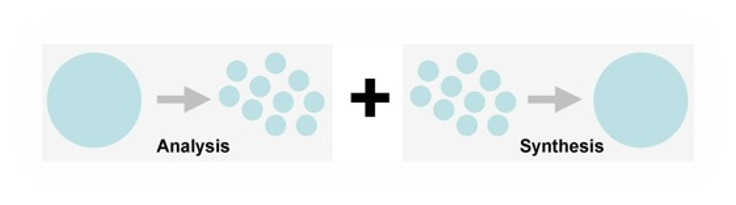

System engineering design is a highly iterative and recursive processes, resulting in a validated set of requirements and a validated design solution that satisfies a set of customer expectations.

- Customer[1] Expectations (Program/Project Objectives and Mission Profile) and Constraints (Stakeholders, Institutional, Professional, etc.).

- High Level Functional Requirements[2] (Level 1 Program/Project)

- Functional and Logical decompositions (Project WBS)

- Trade Studies and Iterative Design Loop

- Form Creative Design Solution (System PBS)

- Define Level 2 System and Subsystem Performance Requirements

- Make Hardware and/or Software Model(s) and Perform Experiments

- Organize and Analyze Data

- Does Functional & Performance Analysis show design will meet Functional Design and concept of operations (ConOps) Requirements?

- If additional detail need, Repeat Process

- Select a preferred design

- Does the system work[3] (functional and performance)?

- Is the system achievable within cost and schedule and other constraints?

- If the answer is no, reenter design loop (Step 4), reorganize project (Step 3), or adjust Customer’s Expectations and Constraints (Step 1) and start again.

- Preparing presentations (PDR and CDR)

- Communicate Results (PDR and CDR)

- Reports, plans, and specifications. (Project Planning)

- Implement, Verify, and Validate the design. (Project Implementation)

The Iterative Nature of the System Design Process

After Mission Authorization (i.e. funding), the process Starts with a study team collecting and clarifying the Customer’s Expectations, including the program objectives, constraints, design drivers, mission profile[2], and criteria for defining mission success.

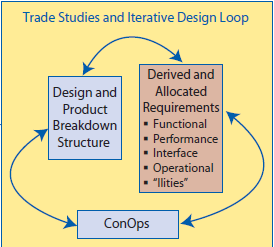

From the customer’s expectations high-level requirements are defined. These high-level requirements drive an iterative design loop where (1) creative “strawman” architecture/designs, (2) the concept of operations (ConOps), and (3) derived system and subsystem requirements are developed.

From the customer’s expectations high-level requirements are defined. These high-level requirements drive an iterative design loop where (1) creative “strawman” architecture/designs, (2) the concept of operations (ConOps), and (3) derived system and subsystem requirements are developed.

This process will require iterations and design decisions to achieve consistency (design loop blocks 1 – 3). Once consistency is achieved, analyses allows the project team to validate the design against the customer’s expectations. A simplified validation asks the questions:

- Does the system work (functional and performance)?

- Is the system achievable within cost and schedule constraints? [3]

The output of this step will typically result in modification of the customer’s expectations and the process starts again. This process continues until the system—architecture, mission profile, and requirements and stakeholder expectations achieve consistency.

The number of iterations must be sufficient to allow analytical verification of the design to the requirements.

The design process is hierarchical and recursive by nature with the same process applied to the next level down in the program – one person’s subsystem is another person’s project.

System Design Keys

- Successfully understanding and translation of the customer’s expectations into clear unambiguous quantitative, verifiable, and realizable program requirements

- Complete and thorough requirements traceability (including requirement flow-down)

- Document all decisions made during the development of the original design concept[4].

- Visualization of the product in use (ConOps) looking for missed level 1 requirements. Rapid Prototyping also helps us discover missing level 1 requirements (ex. ShopVac).

- Design validation is a continuing recursive and iterative process occurring over the entire life cycle of the product

| Note: It is extremely important to involve the customer in all phases of a project. Such involvement should be built in as a self-correcting feedback loop that will significantly enhance the chances of mission success. Involving customer in a project builds confidence in the end product and serves as a validation and acceptance with the target audience. |

ConOps Examples

Remember, validation occurs over the life of the product (from concept to retirement).

Design faults discovered before the operational phase of the project.

- On the prosthetic arm project, conOps showed that we had failed to conceptualize the soldier in McDonalds. Specifically, in appearance and the potential noise generated by the system. In both cases, unwanted attention of fellow customers would have been be placed on the soldier.

- On the solar panel project, conOps showed that we had failed to conceptualize operation of the rover remotely, in the desert or ultimately on Mars. Once discovered telemetry requirements were added to the project.

Design faults discovered during the operational phase of the project.

- After successful verification of the Pick and Place machine we tried to put it in a cabinet. Clearly, we did not conceptualize this step in the life-cycle of the product. All future projects now include this customer requirement.

- … it emerged that the design of Type 45 destroyers have faulty engines unable to operate continuously in warm waters. “The UK’s enduring presence in the Gulf should have made it a key requirement for the engines. The fact that it was not was an inexcusable failing and one which must not be repeated,” the MPs’ report said. Source: BBC “Royal Navy ‘woefully low’ on warships”

Customer Expectations (Project Objectives and Mission Profile)

Sponsor presents Program and/or Mission Objectives

- These are not requirements, but rather a statement of a problem to be solved. They may be qualitative in nature.

High Level Requirements (Level 1 Program/Project)

Reference: NASA Systems Engineering Handbook Section 4.2 Technical Requirements Definition Start (page 40) and Appendix C page A: 279

- Translate Program and/or Mission Objectives into Level 1 Program/Project Requirements.

- Work with and get the sponsors concurrence that these meet their Program and/or Mission Objectives.

- It is important to document all decisions made during these early phases of the project. Include links to source material and how decisions were made.

- Were the equations used to calculate a requirement provided and are the answers correct?

- Close attention to this process is the difference between the customer saying “you said” and your company paying to correct the problem within the agreed upon schedule, versus you telling the customer your new requirement is out-of-scope and your customer paying the increased cost with attendant schedule delay[1].

Form Creative Solutions

The word “creative” appears less than a half dozen times in the 360 page NASA Systems Engineering Handbook. I will therefore rely on outside sources.

Logical decompositions (Level 2 Systems)

The following document paraphrases and quotes material originally contained in the NASA Systems Engineering Handbook NASA-SP-2007-6105-Rev-1 Section 4.3 Logical Decomposition (page 49)