Fall 2016 Solar Panels: The Solar Panel Sandwich (the “Encapsulation”)

By Ridwan Maassarani (Design and Manufacturing)

Approved by Inna Echual (Project Manager)

Table of Contents

Introduction

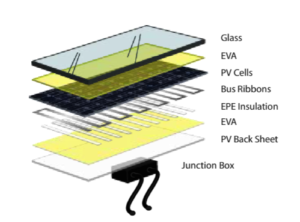

In order to secure the cells onto the panel, one must consider the way of “sandwiching” the cells onto place. A rubber substrate was used for insulating the solar cells from the aluminum sheet. Here, I will review the “sandwich” method of encapsulation.

PV Back Sheet [1]

The first substrate considered was PV Back Sheet, which can be bought from aliexpress. This could reduce the thickness of the overall layers and, as explained by Dunmore, a supplier of solar panel material, “the PV back sheet is a photovoltaic laminate that protects the PV module from UV, moisture and weather while acting as an electrical insulator. DUN-SOLAR™ PV back sheets are available in a variety of constructions for both traditional rigid PV modules, like the one shown above, as well as thin film PV modules and solar power concentrators.”

EVA Layer [1][2]

Next, there’s the EVA layer, and according to Dunmore is a “thermoplastic containing ethylene vinyl acetate which is used to encapsulate the photovoltaic cells.” EVA encapsulation might not be the way to go since it needs to be heated which renders the cells inaccessible. And the cells need to be serviceable as part of our project requirement. For our panels, I took a couple of sticker paper and laser cut individual square cut outs to place each cells in its cavity and then when the acrylic is attached, there would be not visual gap between the cells and the acrylic. This did not work since I did not make my sticker paper thick enough. I modeled the shape I needed using Solidworks to ensure every cell in our current design had a cavity to sit in. Then I generated the dxf file that would then be used by the laser machine to cut the sticker paper, as shown in Figure 1.

Figure 1: Sticker Paper

Then comes the EPE insulations which is an extra layer of insulation, protecting the PV cells from being damaged from additional voltage seeping into the cells and damaging them.

Finally, there’s glass, which was substituted with acrylic in our final product which based on a PDF document written by Arkema, a leading specialty chemicals and advanced materials company says that it transmits 92% of the suns light striking it at the perpendicular.

The entire sandwiching process can be seen in Figure 2.

Figure 2: Sandwich Process