Gel Point Test Plan Excuted

By Omair Tariq

Purpose

The purpose of this test plan was to carry out the test plan here and determine the gel point of 1% Agarose gel. This test plan would also serve to verify the specification already provided by the manufacturer of the powder.

Equipment needed

|

Equipment |

Quantity |

|

Spatula |

1 |

|

Mesuring balance accurate to a 100th of a gram |

1 |

|

900 Watt Hot Plate |

1 |

|

100 ml beaker |

1 |

|

50 ml graduated cylinder |

1 |

|

Mercury-in-glass thermometer (Range: 0oC-110oC) |

1 |

|

Agarose gel Type A0169 by Sigma Aldrich |

See Table 2 |

|

Distilled water |

See Table 2 |

|

Safety Goggles |

1 per person |

|

Latex Gloves |

1 per person |

Table 1. Equipment needed for Gel Point Testing

The amount of Agarose gel and Distilled water is to be determined by the desired gel concentration.

Percent Gel Desired (concentration) =100 x (Amount of Agarose in grams) / (Amount of water in milliliters)

|

Concentration |

Agarose Gel Type A0169 (± 0.05g) | Distilled water ( ± 0.1 ml) |

|

1% |

0.50 g |

50.0 ml |

|

2 % |

1 g |

50.0 ml |

|

5 % |

2.5 g |

50.0 ml |

|

And so on… |

|

|

Table 2. Amount of agarose gel powder and water required to produce desired gel concentration for 3D bioprinter

For the purpose of the bio-printer the amount of distilled water is to be limited to 50.0 ml since the extruder is a 60 ml syringe. The maximum amount of water is limited to 50 ml rather than 60 ml to avoid spilling of the gel and consequently, the waste of valuable gel mixture.

Test Plan Instructions

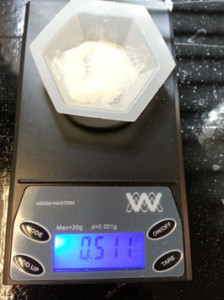

Note: This test plan can be carried out to determine the gelling point of any concentration of gel. 1 % gel concentration was chosen for the purpose of our bioprinter.

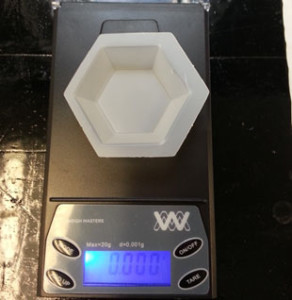

1.Put a 100 ml beaker on the weighing balance. This was not done due to the limitations of our weighing balance which had a maximum limit of 20 grams. Instead, a small plastic dish was used to weigh the powder.

2.Zero the balance so that the weight of the beaker does not hinder measurements.

3 Use a clean spatula to put 0.50 grams of Agarose gel Type A0169 powder by Sigma Aldrich into the beaker.

4.Measure out 50 ml of distilled water using a graduating cylinder.

5.Pour the 50 ml of distilled water into the beaker containing the 0.50 grams of Agarose powder.

6.Measure the weight of the solution using a measuring balance. It should weigh about 51 grams. This was not done due to our weighing balance having a maximum weight limit of 20 grams.

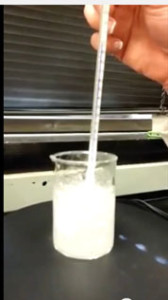

7.Mix the solution using a Mercury-in-Glass Thermometer or a spatula.

8. Put the beaker containing the mixture from Step 4 onto a hot plate.

9.Bring the solution to a boil and let it boil for 5 minutes.

10.At the same time, place the graduating cylinder filled with water on the hot plate.

11.Reweigh the solution after boiling.

12.Add enough hot water from the graduating cylinder, if necessary, to bring the total weight of the solution to 51 grams.

13.Allow the mixture to cool. Mix the solution continuously until the solution reaches a temperature of 50oC. At this point, further mixing might lead to problems in accurately determining the gelling temperature of the solution. Observe the viscosity of the solution every 10o C until the solution reaches a temperature of 40oC. Once the solution has reached a temperature of 40oC, or when the solution starts to gel, the viscosity of the solution must be observed every 1oC.

14.The viscosity is to observed using the following steps:

Take a small amount of solution on the spatula,

Raise the spatula about 12 inches above the beaker.

Carefully, drop the solution by tilting the spatula.

This happened when the solution was at a temperature of 36oC. Therefore, it was determined that 1 % agarose gel has a gel point of 36oC. At the gelling point, the solution turned rubbery. When it was attempted to mix the gel at the gel point, the gel broke into smaller pieces. The smaller pieces did not merge after sometime as they would if the gel was still a solution. This would not happen if the mixture were still a solution, thereby proving that the gelling point was reached.

The solution gelled at 36oC

The gel structure breaks into small solid pieces if mixed at a temperature below the gelling temperature

This test plan can be seen carried out here.

Conclusion

Through this test plan, it was determined that 1% agarose gel has a gelling point of 36 oC. This test also verified the values that were provided by the manufacturer of agarose powder. Therefore, the extruder temperature will be maintained at 38oC to ensure smooth extrusion of the gel.