Goliath Spring 2018 – PCB Test

By: Milton Ramirez (E&C Engineer)

Verified By: Ernie Trujillo (Project Manager)

Approved By: Miguel Garcia (Quality Assurance)

Table of Contents

Introduction

This blog post will detail our testing procedures to determine whether the goliath PCB board works as intended.

Body

We first tested the PCB with a continuity test. We first checked if the SDA and SCL pins were connected to the multiplexer, gyro, and the rangefinder connectors. Then we checked the continuity of voltage and ground which worked fine. The problem occurred when we finally tried to run the code. We ran a gyro code to check if the gyro worked properly, but we didn’t get any readings.

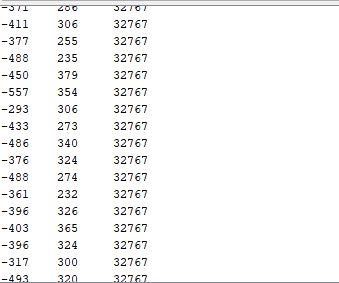

Figure 1. The output that we got when we ran the code as it can be seen the gyro was giving back no readings.

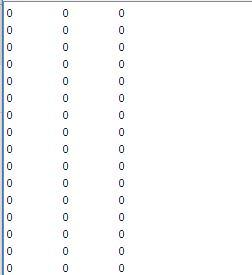

Then looking back at the hookup of the Gyro sensor I overlooked that the Vlogic pin was suppose to be connected to the 3.3V pin . So to confirm that this was the problem, we connected a wire from the 22nF capacitor that went from the Vlogic pin to the 3.3V pin. We got the following figure.

Even though we were getting the pro micro to finally display values these values where not the ones that were desired. So we proceeded to test the UV sensors with the code as well . These were also not responding. Here we realized that it wasn’t the UV sensor that wasn’t working but the PCA9540BD Multiplexer was not responding. At this point, we had to cut our losses and just use the breakout boards that this PCB consisted of which were the Si1145 UV sensor, ITG-3200 Gyro breakout, and the multiplexer.

Lessons Learned

It is crucial to check the hookup guides for some of these breakout board if provided and most of the companies that sell these breakout boards do provide this. Since most of these PCB boards will be designed to work for the 3DoT board, a lot of these breakout board specific pins will not be included.