Fall 2016 Velociraptor (W): Material Trade-Off Study

By Aaron Choi (Manufacturing Engineer)

Approved by Tim Haddadian (Manufacturing Division Manager) and Lam Nguyen (Project Manager)

Table of Contents

Requirements

Level 1-1 The 3rd generation Velociraptor (W) budget shall not cost more than $102. This estimate is based upon the customer and project team agreement on October 7th, 2016.

Introduction

For the materials, cost and mass of the materials were taken into consideration to meet the Level 1-1 cost requirement.

Materials

For choosing the material, cost and mass of the material should be considered to meet cost budget. The materials chosen for trade-off are the following: aluminum sheets, birch plywood, polylactic acid (PLA), acrylonitrile-butadiene styrene (ABS), and acrylic sheets. Since it is difficult to compare materials that are sold in different sizes, a set dimension is chosen, a volume of 6 inch by 3 inch by 0.125 inch. The reason for the 0.125 inch thickness is due to 3mm thickness limitation for 3D printing. The size 6 inch by 3 inch is chosen for further stress test to analyze which material is the strongest and which is best utilized for maintain the structure of the robot without breaking.

Calculations

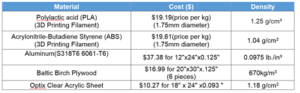

Using the set volume, the mass of the volume of material is calculated given the density of the material and cost per cubic inch. The table below shows the given cost and density of the materials.

Calculations document

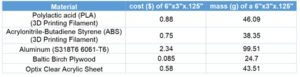

From the given cost and density, the cost and mass of the volume is calculated. The work shown for the calculations are also linked below.

Table 2. Calculation Results

Link: Material Cost and Mass Calculations

Conclusion

In conclusion, Baltic birch plywood is the lightest and cheapest material calculated. This would require laser cutting for the designing components of the Velociraptor. If components are too complex to laser cut, then 3D printing will be used. For the 3D printing filament, ABS will be chosen over PLA. Further stress tests will be completed through experimentation.

Resources

[1] http://www.3ders.org/pricecompare/ [2] https://www.metalsdepot.com/catalog_search.php?search=s318T6 [3] http://www.woodworkerssource.com/shop/product/18balpack3.html [4] http://www.homedepot.com/p/OPTIX-18-in-x-24-in-x-0-093-in-Clear-Acrylic-Sheet-Glass-Replacement-MC-05/202038047 [5] https://www.botfeeder.ca/abs-vs-pla/ [6] http://www2.glemco.com/pdf/NEW_MARTERIAL_LIST/Alumina%206061-T6.pdf [7] http://www.engineeringtoolbox.com/wood-density-d_40.html [8] http://www.plaskolite.com/Media/Get/144?inline=True