Table of Contents

Reading

- NASA Systems Engineering Handbook NASA-SP-2007-6105-Rev-1 Appendix C: How to Write a Good Requirement, Use of Correct Terms

- NASA Systems Engineering Handbook NASA-SP-2007-6105-Rev-1 Appendix C: How to Write a Good Requirement, Requirements Validation Checklist, Clarity

- NASA Systems Engineering Handbook NASA-SP-2007-6105-Rev-1 Section 4.2 Technical Requirements Definition Start (page 40)

- Department of Chemical Engineering, University of Michigan, Ann Arbor, Chapter 5 “Problem Definition Techniques”

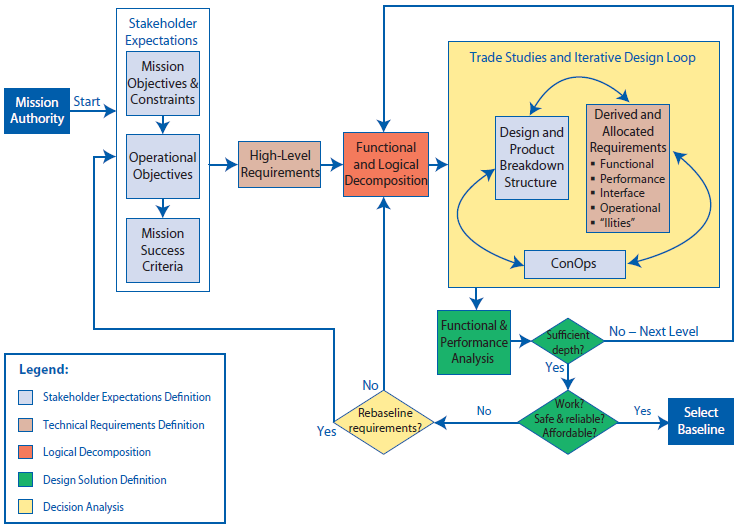

The Systems Engineering Method

- Customer[1] Expectations (Project Objectives and Mission Profile)

- High Level Requirements (Level 1 Program/Project)

- Functional and Logical decompositions (Project WBS)[2]

- Trade Studies and Iterative Design Loop

- Form Creative Design Solution (System PBS)

- Define Level 2 System and Subsystem Requirements

- Make Hardware and/or Software Model(s) and Perform Experiments

- Organize and Analyze Data

- Does Functional & Performance Analysis show design will meet Functional Design and concept of operations (ConOps) Requirements?

- If additional detail need, Repeat Process

- Select a preferred design

- Does the system work[3] (performance)?

- Is the system achievable within cost and schedule constraints?

- If the answer is no, adjust Customer’s Expectations (Step 1) and start again.

- Communicate Results (PDR and CDR)

- Preparing presentations (PDR and CDR)

- Reports, plans, and specifications. (Project Planning)

- Implement the design. (Project Implementation)

The System Engineering Design Method

Customer Expectations (Project Objectives and Mission Profile)

After Mission Authorization (i.e. funding), the process Starts with a study team collecting and clarifying the Customer’s Expectations (The Problem Statement), including the program objectives, constraints, design drivers, mission profile[1], and criteria for defining mission success.

- Include information on what you are to solve, and consider why you need to solve this problem.

- A conversation with Elon Musk about Starship from 4:50 to 6:21.

- Case Study – 1st Iteration

- Problem: People are being injured and dying in traffic accidents.

- Customer Objective: Decrease the number of traffic accidents

- Social Engineering Solution: Roll out a “Drive Safely” campaign with better driver education and traffic enforcement

[1] I will use the term Mission Profile in place of Operational Objectives

Customer Expectations May Change

As we have seen, the statement of the Customer’s Expectations may be modified as objectives are translated into requirements and the nature of the real problem is better understood.

After each iteration, make sure you are proceeding to solve the real problem as opposed to the perceived problem.

- Case Study – 2nd Iteration

- Problem: People are being injured and dying in traffic accidents.

- Customer Objective: Decrease the number of (injuries due to) traffic accidents

- Engineering Solution: Design a safer vehicle and roadways

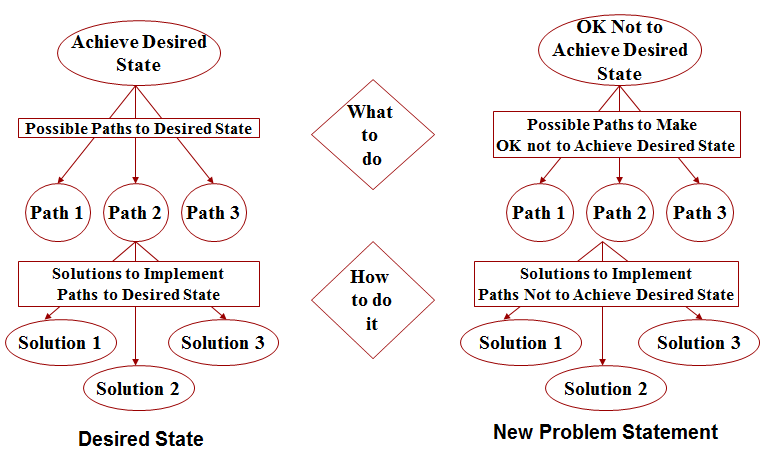

Duncker Diagrams

- As you explore the problem by translating into requirements, a step which includes design trade-off studies, simulation, modeling, experiments, and rapid prototyping; you may also want to first apply the Duncker Diagram.

- Case Study – Duncker Diagram

- Problem: People are being injured and dying in traffic accidents.

- Achieve Desired State: Decrease the number of traffic accidents

- Path 1: Driver education

- Solution 1a: Roll out a “Drive Safely” campaign

- Path 2: Traffic enforcement

- Solution 2a: Hire more policemen

- Path 3: Autonomous Vehicles

- Ok not to Achieve Desired State: Do NOT decrease the number of traffic accidents

- Path 1: Design a safer vehicle

- Solution 1: Air Bags

- Solution 2: Impact crumple zones

-

- Path 2: Design safer roadways

- Solution 1 – 7: Roadway Engineering Design Strategies To Make Roads Safer For Drivers

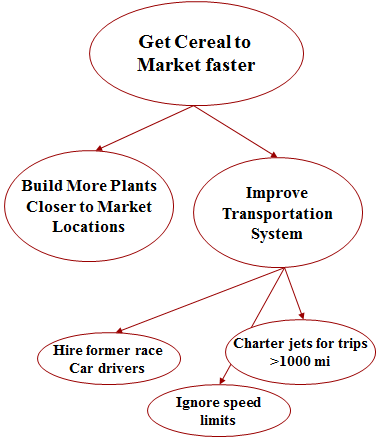

To Market, To Market

The Situation: Toasty O’s was one of the hottest selling cereals when it first came on the market. However, after several months, sales dropped. The consumer survey department was able to identify that customer dissatisfaction, as expressed in terms of taste, was related to the age of the cereal. Consequently, management determined that they must streamline the production process to get the cereal on the store shelves faster, thus ensuring a fresher product. Engineering had quite a time with this problem – there wasn’t much slack time that could be removed from the process to accomplish the goal.

Of the steps required to get the product on the shelves (manufacturing, packaging, storage, and shipping) manufacturing and packaging were the fastest so plans for building plants closer to the major markets were considered as was trying to add more trucks to get the cereal to market faster.

Sales of Toasty O’s are dropping. Consumer surveys have indicated dissatisfaction with a stale taste.

Perceived Mission Objective (The Problem):

“Streamline the production process to get the cereal on the store shelves faster, thus ensuring a fresher product.”

Second Perceived Objective:

Get the Cereal to Market Faster

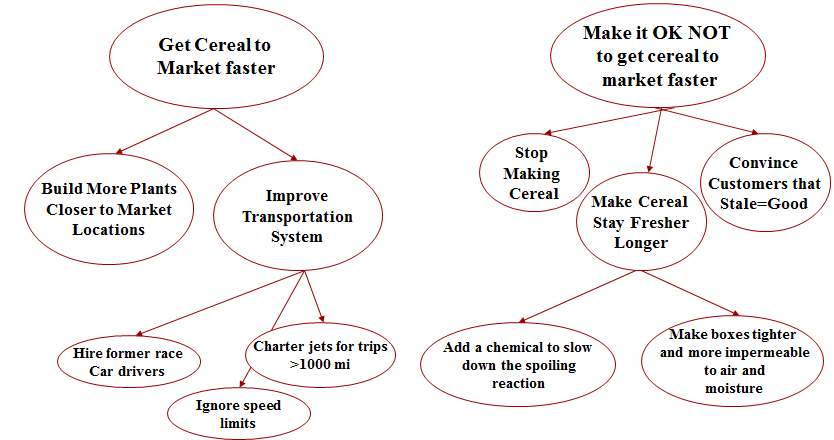

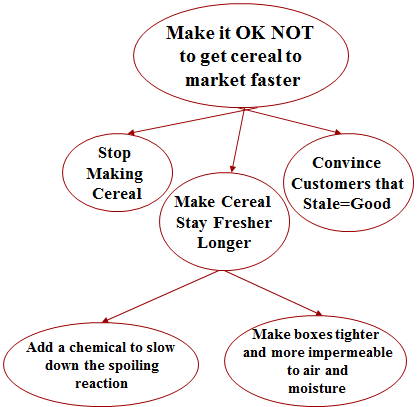

Duncker Diagram

Original Mission Statement

Get cereal to market faster.

The real problem was that the cereal was not staying fresh long enough, not that it wasn’t getting to market fast enough.

New Mission Statement

Make Toasty O’s boxes tighter and determine appropriate additive to slow down the spoiling reaction.