3D SMD

Pick and Place – Trade Off Study – Camera System

By: Kevin Ruelas (Electronics and Control) Due to the use of a servo driver to control the existing and additional servos, a separate Arduino can be used to house an independent camera system. This Arduino will have its own code as well as utilize visual software for edge detection. It was important to choose […]

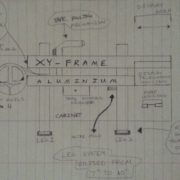

Pick and Place-Preliminary Project Plan

Belinda Vivas (Project Manager) Chastin Realubit (Mission, Systems, and Test) Kevin Ruelas (Electronics and Control) Tyler Jones (Manufacturing) Table of Contents Work Breakdown Structure By Belinda Vivas (Project Manager) and Chastin Realubit (Mission, Systems, and Test) The Work Breakdown Structure (WBS) is a summarized visual representation of the divided work between the three divisions (Systems, […]

Pick and Place – Preliminary Design Document

Belinda Vivas (Project Manager) Amber Scardina (Mission, Systems, and Test) Kevin Ruelas (Electronics and Control) Tyler Jones (Manufacturing) Chastin Realubit (Manufacturing) Table of Contents Program Objective/Mission Profile By: Belinda Vivas (Project Manager) Objective The second generation of the Pick and Place will create a 3-Dot 454 PC Board. It will ensure precision through […]

Spring 2016 3D SMD: Final Documentation

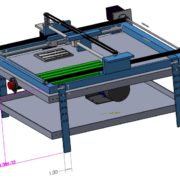

Table of Contents Executive Summary By Bao Loc Doan (Project Manager) Program Objective When humans manually pick up and place down surface mount components onto a printed circuit board (PCB), there are normally problems with efficiency. A surface mount component may be placed at the wrong spot or dropped. These mistakes cost the user money […]

Spring 2016 3D SMD: Verification Test — Working Area

By Christine Vu (Missions, Systems, and Test) and Henry Nguyen (Electronics and Control) Working Area Test Working area is defined by the area that includes PCB to assemble, reel feeders, and IC tray. To verify that our design meets the size criteria for working area, a test will be conducted to calculate its parameters. Requirements […]

Spring 2016 3D SMD: Verification Test — Reel Feeder

By Christine Vu (Missions, Systems, and Test) and Henry Nguyen (Electronics and Control) Reel Feeder Design To verify the reel feeder design has the correct function, a test will be conducted to determine its parameters and design. Requirements Section 4 The SMD pick and place machine shall have four 8mm reel feeders and one IC […]

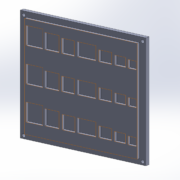

Spring 2016 3D SMD: IC Tray

By Nasser Alsharafi (Manufacturing) The Custom 3D Printed IC Tray The custom 3D printed IC tray is designed to house 21 evenly spaced different sized common IC components. One of the largest and most desired ICs we will be using is the ATMega32U4 IC. This IC is the standard for which we will calculate our […]

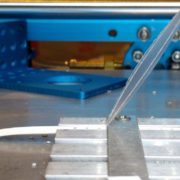

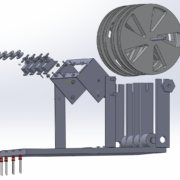

Spring 2016 3D SMD: Reel Feeder Bracket

By Nasser Alsharafi (Manufacturing) Table of Contents The Reel Feeder The Reel Feeder shown above is a major component of the pick and place machine. This component is fully automated, and has custom fabricated aluminum parts. It is made up an aluminum base, four SMD part reels, four servos, four legs, and one axle, 4 […]

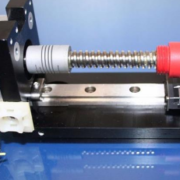

Spring 2016 3D SMD: Z-Axis Linear Slide Actuator

By Henry Nguyen (Electronics and Control) Introduction For our Z-Axis actuator, we found that our thread drive will constantly cause our nozzle to shift towards the left when going down and towards the right when going up. This was caused by the two 4mm rods and the thread screw we were using. A slight solution […]

Spring 2016 3D SMD: Verification Test — Cable Fatigue

By: Christine Vu (Missions, Systems, and Test) Table of Contents Cable Test A test will be conducted to determine that the bending radius will have a minimum bend radius of 10x its cable diameter. Requirements Section 1 EE400D Assembly The SMD pick and place machine shall pick up and place down all SMT components provided […]