By: Camilla Nelly Jensen (System Engineer)

Requirements:

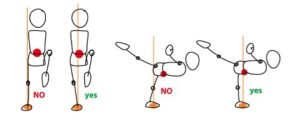

6. To maintain balance while performing static walking, a head and tail shall be implemented to the chassis of the Velociraptor to even out the shifted weight when standing on one leg and thus meet the Project Level 1, requirement 4.

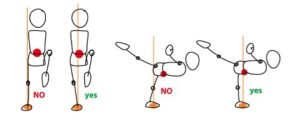

Figure 1: http://design.tutsplus.com/articles/human-anatomy-fundamentals-balance-and-movement–vector-20936

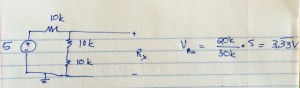

Verification [6]: Figure 1 shows, the center of mass is not supported when taking a step. Therefore, following the concepts of TITRUS III a head and tail shall be implemented to the body of the Velociraptor to shift the center of mass onto the foot so that it can maintain balance while walking.

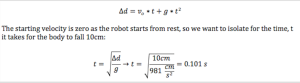

7. For the Velociraptor to perform dynamic walking servos moving at a speed of 0.101 sec/12.5° shall be implemented to the chassis and thus meet the Project Level 1, requirement 5.

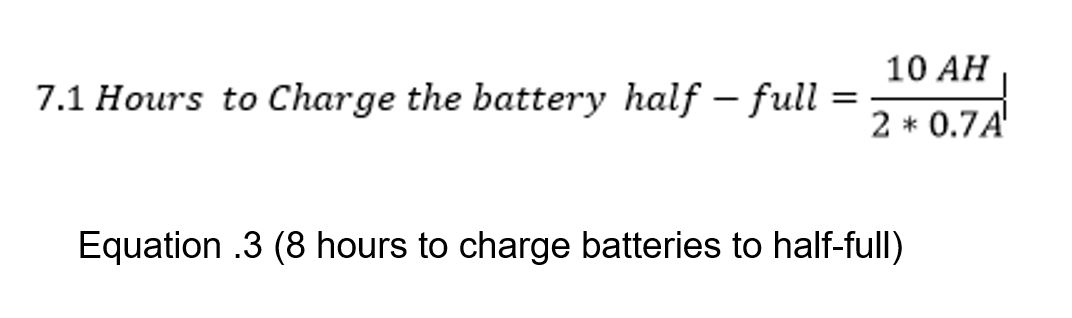

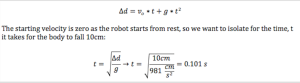

Verification[7]: Assuming that the legs of the Velociraptor will not exceed 10 cm in length, using physics equations we can estimate the time each leg of the Velociraptor has to perform a dynamic step:

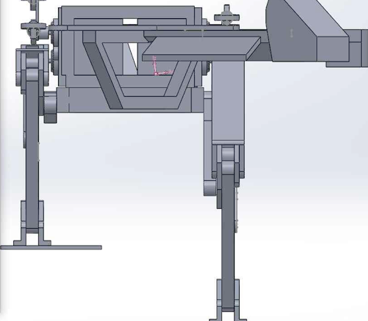

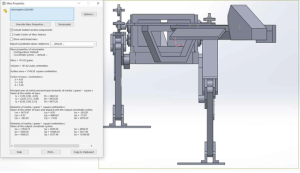

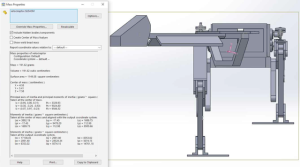

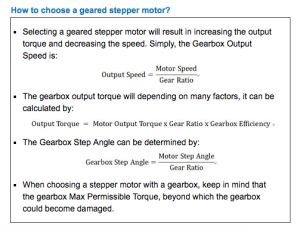

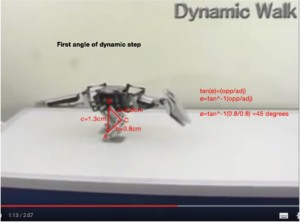

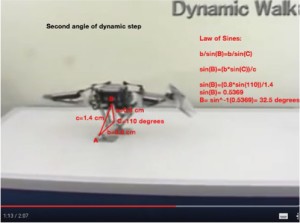

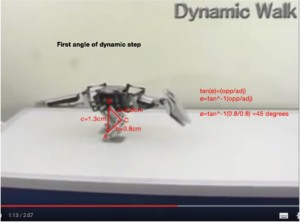

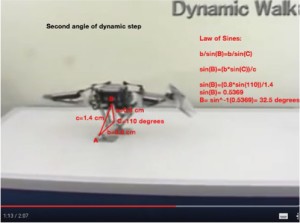

Researching TITRUS III performing dynamic walk as shown in figure 2. The angle of the right leg, performing first part of the dynamic step is calculated to 45°. The next part of the step the angle is calculated to 32.5°. Therefore subtracting these two angles we get the angle at which the TITRUS III pushes the right leg forward to perform one dynamic step to 12.5°

Therefore we estimate that the servos needed for the Velociraptor to perform dynamic walk will have to push the each leg forward at an angle of 12.5° per 0.101 seconds.

8. In order for the Velociraptor to travel on two different surfaces, the material that will be placed on the feet shall have a coefficient of friction of more than 1.0 in accordance to the Course Analysis as to refrain from slipping, and thus meet Project Level 1, requirement 3.

Verification[8]: The highest coefficient of friction of the surfaces that the Velociraptor will travel on is 1.0 from the friction between rubber and a solid.

10. In order for the robot to detect obstacles at a range of 20 cm in its path, ultrasonic sensors shall be implemented to the build of the Velociraptor and thus meeting the Project Level 1, requirement 7.

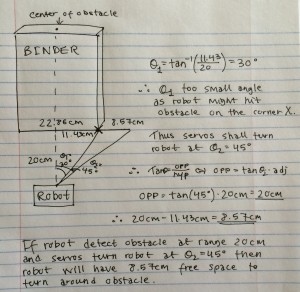

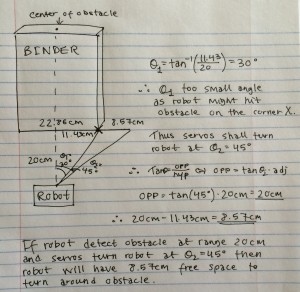

Figure 3: Ultrasonic Proximity sensor calculation

Verification[10]: The Velociraptor shall detect obstacles (Binder) at a range of 20 cm in its path in order to maneuverer around it without hitting the obstacle as calculated in figure 3 above. This requirement anticipates the servos to turn the robot at an angle of 45° rather than 30° in order to gain enough free space of 8.57 cm to maneuver around the obstacle without hitting the corner X of it.

11. To fully accommodate the movement of a turn, a total amount of 8 servos turning the robot at an angle of min. 45 ° degrees(referring back to requirement 10) to avoid obstacles shall be implemented to the Velociraptor and thus meeting the Project Level 1, requirement 8.

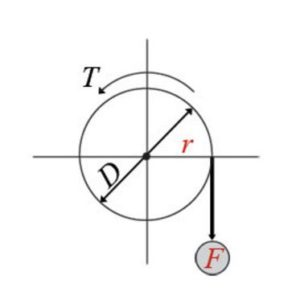

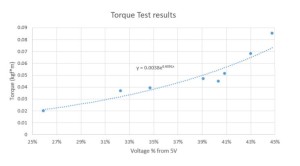

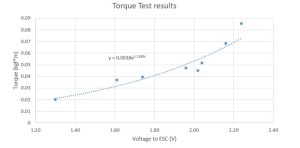

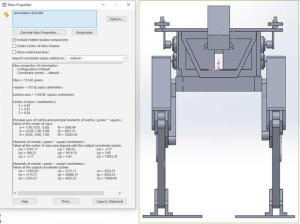

Verification[11]: An assumption of the weight of the Velociraptor’s head has been set to a total of 380g(130 g from batteries placed on the neck, 200g chassis and 50g for material for chassis of head of aluminum).

Researching from last semesters MicroBiped they used the MG92B servos which provided torque of 3.5kgcm at 6V. Dividing that with the length of the legs that will be equal to the length of neck(and tail) of 10cm equals: 3.5kgcm /10cm = 350g

This shows that one servo only provide torque enough to move a mass of 350g and not the estimated weight of 380 g for the Velociraptor’s head.

Hence this semesters Velociraptor will utilize a minimum of 2 servo per head, 2 servos per tail and 2 servos per each leg adding up to a total of 8 servos to insure that adequate torque is provided to fully accommodate the movement of a turn.