Spring 2016 Pathfinder Design and Manufacturing – Rocker Bogie Suspension System Design

By: Lindsay Levanas (Design and Manufacturing)

Table of Contents

Introduction

The goal of Spring 2016’s Pathfinder is to harbor a Google Tango tablet, phone, solar panels, pan and tilt system and self-contained electronics.1 To support this a rocker bogie suspension system2 will be used. As a purchasable rocker bogie suspension system could not be found to fit the size requirements of the tilt system design3 the suspension system will be built from scratch. This report shall document the design process.

Rocker Bogie Suspension System Design

To start with, a general design for the rocker bogie suspension system (hereafter referred to as suspension system) needed to be selected. To guarantee that basic proportions were kept, ServoCity’s Bogie Runt Rover4 was used as a model. To fit the requirements mentioned in the introduction, this model will be simplified and doubled in size.

Rocker Bogie Suspension System Measurement Process

ServoCity’s Bogie Runt Rover consists of six part types that require Solidworks modeling for Spring 2016’s Pathfinder design. To obtain accurate dimensions the individual parts were measured with digital calipers.

Placement and dimension of screw holes were also measured.

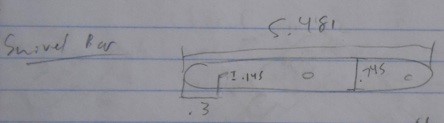

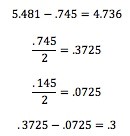

These measurements were then marked on rough sketches to allow for easy reference for the Solidworks model.

Where necessary, simple calculations were done to translate the digital caliper’s measurements into dimensions Solidworks requires.

For parts that were difficult for the digital calipers to measure, trace marks were made on paper and measurements were taken from there.

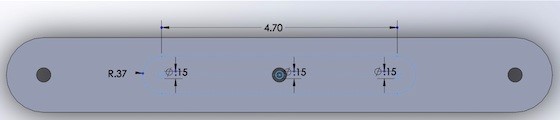

Rocker Bogie Suspension System Model Alterations – Size

After measuring and modeling all of the parts required for the suspension system design, a thickness needed to be selected. To start with, .25in was used, as this was the thickness in the original Runt Rover design. From there, the Solidworks model was doubled in size. The thickness however, was kept at .25in.

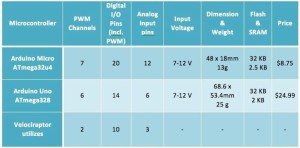

Material Selection

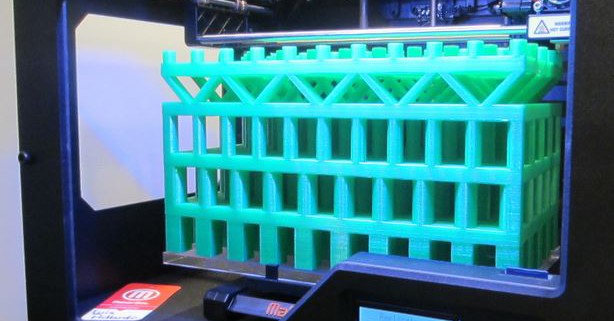

Now that the suspension system parts are completely modeled, a material needed to be selected for their fabrication. ABS plastic and aluminum were considered. While ABS plastic has a density of .0376 lb/in^3, compared to aluminum’s density of .0983 lb/in^3,5,6,7 the 3D printers available to Spring 2016’s Pathfinder at this time are not large enough to print the suspension system’s enlarged parts. Therefore, the suspension system will be made out of aluminum.

Rocker Bogie Suspension System Model Alterations – Simplification

To assist in the fabrication process, the suspension system parts will be simplified. As the aluminum fabricator currently available to Spring 2016’s Pathfinder is limited to drilling holes and cutting straight edges, the parts will be squared off where necessary. Their crucial measurements however, will be kept the same.

Rocker Bogie Suspension System Weight and Strength Check

Having modeled all of the parts, the next step was to check the weight and strength of the system as a whole. By setting the material of the parts in Solidworks, the weight of a part can be obtained. Alloy 6061 was used, as it is both a commonly used type of aluminum, and can be welded.

Above specified the weight of the swivel bar (the part illustrated in the previous section). Following this procedure for all of the parts, the total weight of the suspension system totaled 10.65lbs for .25in thick aluminum, and 5.34lbs for .125in thick aluminum.

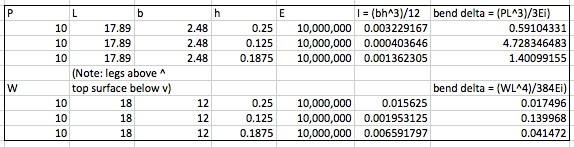

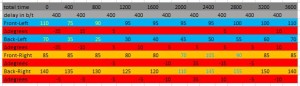

Keeping the weight in mind, the strength of the legs and top plate were then calculated. Stress and bending distances were solved for and listed in the below two charts respectively.8

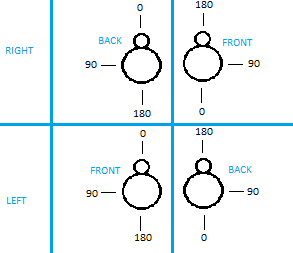

Note that the length used for the legs (17.89) was found by calculating the diagonal of the 10.84in by 14.23in rectangle illustrated below.

While all three thicknesses considered passed the stress test (it takes 6061 alloy aluminum 40,000psi to misshape beyond repair9) the amount each thickness would bend in the legs ranged from .6 to 4.7 inches. To compromise between the weight, stress, and bending tolerance, a thickness of .1875 was selected for the final design.

Conclusion and Future Plans

In conclusion, Spring 2016’s Pathfinder will consist of a rocker bogie suspension system where all parts are simplistically modeled after ServoCity’s Bogie Runt Rover and their measurements follow the procedure documented above. The material used will be alloy 6061 aluminum of thickness .1875in. The complete suspension system is illustrated and dimensioned below and in the future will hold a pan and tilt system, electronics enclosure box, and solar panels on it’s top surface.

Source Material

- Spring 2016 Pathfinder Preliminary Design Documentation, Level 1 Requirement, 2/19/16 http://arxterra.com/spring-2016-pathfinder-preliminary-design-documentation/

- Rocker Bogie, Design, 2/29/2016 https://en.wikipedia.org/wiki/Rocker-bogie

- Spring 2016 Pathfinder Design and Manufacturing – Tilt System Design, Tilt Base, 3/9/16 http://arxterra.com/pathfinder-design-and-manufacturing-tilt-system-design/

- Bogie Runt Rover https://www.servocity.com/html/bogie_runt_rovertm__637162_.html#.VvmvlJGprwI

- Metals and Alloys – Densities http://www.engineeringtoolbox.com/metal-alloys-densities-d_50.html

- ABS Material Datasheet http://teststandard.com/data_sheets/ABS_Data_sheet.pdf

- kg/m^3 to lb/in^3 https://www.google.com/search?client=safari&rls=en&q=kg/m%5E3+to+lb/in%5E3&ie=UTF-8&oe=UTF-8

- Bending Stresses for Simple Shapes http://atcpublications.com/Sample_pages_from_FDG.pdf

ASM Material Data Sheet http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA6061t6