Level 2 Requirements – Final Iteration

By Kristine Abatay – Project Manager

& Elaine Doan – Robot Company Systems Engineer

The following three requirements are the initial level 2 requirements that were introduced during the Spiderbot PDR:

1. In order to match the speed of the rover project while on a flat surface, the servo motors will need to move a distance covered by 60 degrees in 0.13 seconds and utilize a tripod gait – the walking style that will allow Spiderbot to move quickest, which will be implemented in the coding of Spiderbot.

This value was obtained using the following calculations done by our controls systems member, Matthew Clegg.

To try to estimate a possible speed for Spiderbot, he first calculated a velocity based on the speed of the servo motors. A servo’s rated speed is how fast, in seconds, the arm can move 60 degrees. To apply this to Spiderbot, he took into account the motion of the bot in a tripod gait. The gait is the specific sequence of leg movements executed when Spiderbot is in motion. An analysis of the different possible walking styles that Spiderbot is capable of can be found in the following blog post link from last semester’s Hexapod project: https://www.arxterra.com/hexapod-gait-description/. The study will show that the most efficient possible walking style that Spiderbot can use is the tripod gait.

These calculations can be found at the following link to a previous post, which lays out the calculations used to determine these values:

https://www.arxterra.com/speed-calculations-component-modification/

Test: Since this time value is so quick, measurement of this speed will require implementation of a video recording device and slow motion playback in a video editor. Code will be run through a breakout board and Arduino to a servo that will be placed on top of a protractor, which will be marked off to accurately measure 60 degrees. A digital stopwatch will be placed near the servo and will increment its time while the servo motor operates. A video of the motor will be captured and opened within a video editing program which will modify the video to play in slow motion. This way, the milliseconds portion of the watch will be easier to read and the time for the servo motion can be recorded.

2. In order to meet the safety requirement outlined by the level 1 requirements, Spiderbot will need to be constructed from materials that will prevent it from being labeled as a hazard. Avoidance of materials such as LiPO batteries in the Spiderbot design will help achieve this.

Test: According to the Injury and Illness Prevention Program for CSULB (found here: http://daf.csulb.edu/offices/ppfm/ehs/programs/iipp/#policy1), “All…hazard class scenarios shall also be immediately reported to SRMIS and each will be addressed on a case by case basis with the individual college or department manager”. If the final construction of Spiderbot does not garner the attention of SRMIS by falling under the category of one of its four hazard classifications, then Spiderbot will have met the safety requirement.

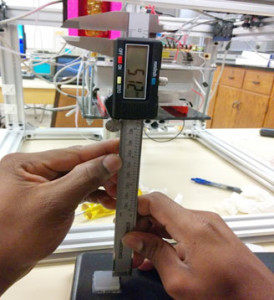

3. To meet the clearance specifications of 4 inches in height and 2.5 inches in width, Spiderbot’s 3D design will need to be at least 5 inches in height and 3 inches in width. The following design considerations were developed by Simon Abatay from manufacturing, to determine these value choices.

The femur length is chosen based off of reasonable servo specifications. Standard servo speeds from 0 to 60 degrees vary from 0.08 to 0.2 seconds. The femur length and servo speeds are critical for the spider to reach the speed requirement of 0.2003m/s. Based off of calculations, if the femur length is chosen to be 5 inches, the servo must rotate from 0 to 60 degrees along its z-axis within 0.12 seconds. If the femur length is chosen to be 3.5 inches, the servo must rotate at a speed of 0.09 seconds. This relationship shows that the longer the femur, the greater the distance traveled, thus the slower the servo has to move. Realistically, it would be ideal to choose a femur length that is longer than 3.5 inches. This is because finding a servo that moves at a speed of at least 1.2 seconds under load is more realistic than finding a servo that moves at 0.09 seconds under the same load.

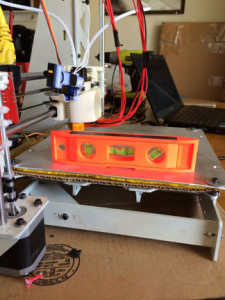

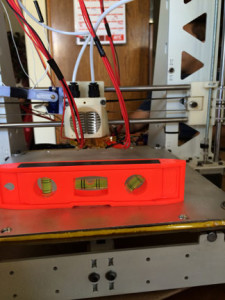

Test: These clearances will be checked within the SolidWorks. Once a complete leg and chassis design are made, the pieces can be connected in the program, and if the measurements done allow for the obstacle clearances, then this requirement will have been met.

This next list of additional level 2 requirements was written with minimal guidance from Robot Company’s Systems Engineer, Elaine Doan, who wrote the requirements for this semester’s Hexapod project, alongside Hexapod’s Computer Systems and Software member, Chau To:

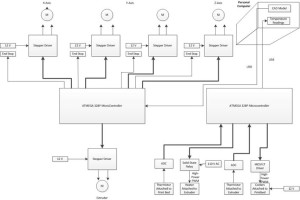

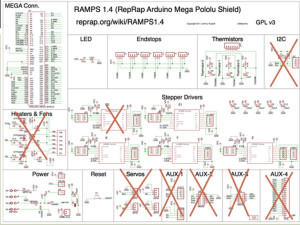

4. In order for Spiderbot to receive commands from the Arxterra Android App, via the Arxterra Control Panel, the microcontroller used must have a USB host interface.

For this reason, an Arduino Uno – R3 will be used, which will allow for communication, but will not accommodate all of the servos that will be used for Spiderbot.

Test: Send a command to the Android smart phone being used by Spiderbot, using the Arxterra control panel, and if the command executed matches the command that was sent, then this requirement will have been verified.

5. The microcontroller used must also provide connections to accommodate pins to control 20 servo motors.

Since the Arduino Uno – R3 does not directly accommodate all 20 servo motors, two Adafruit 16-ch 12-bit servo drivers will be used to provide power to them.

Test: Connect the servo driver used, along with a servo motor, to the microcontroller chosen and run a basic Arduino command. If the command sent to the servo motor matches the action executed by the servo motor, then this requirement will have been verified.

6. In order for motion of Spiderbot to occur, its battery will need to supply at least 10800 mAH.

This value is an estimate that accounts for the 18 servos that will be used to control the legs of Spiderbot, which is where a majority of the current will be allocated. The value was obtained from testing of the Power HD servo motors, whose results can be found here:

https://www.arxterra.com/current-test-of-the-power-hd-high-torque-servo-1501-mg/

The maximum current that was drawn from the servo motors, using a supply of 6V, was 0.6A. Multiplying this value by 18 yields the 10800 mAh stated above. Of course, this value overshoots the true amount of current that will be used by Spiderbot, considering the fact that all of the servo motors will not be drawing their maximum current simultaneously.

Test: Connect Spiderbot to power and let it run. If it lasts for at least 1 hour, then this requirement will have been verified.