Spring 2014 BioPrinter

By Ali Etezadkhah, Project Manager

Team members:

Ali Etezadkhah – Project Manager

Mevan Fernando – Sensors, Actuators & Powertrain

Anh Nguyen – Controls & Image Processing

Omair Tariq – Systems and Tests

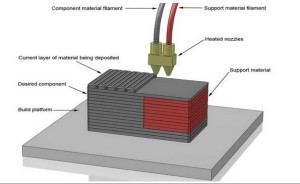

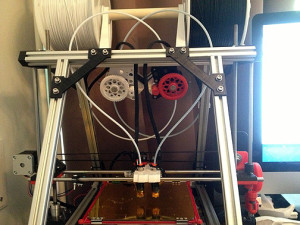

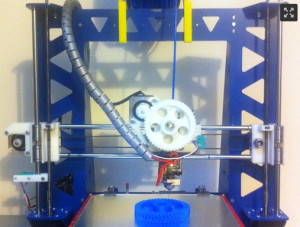

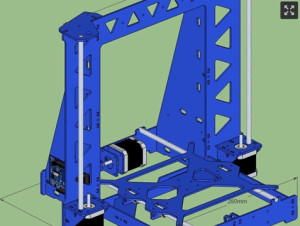

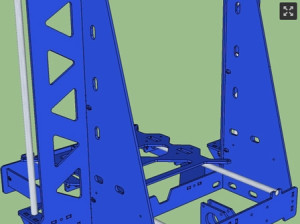

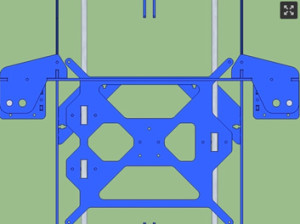

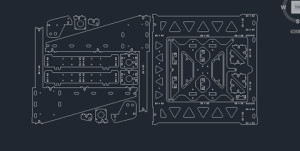

Our team has chosen to continue the work on the 3D bioprinter that was built last semester. We explored using different printer designs, but most of the models have a building platform that moves in the horizontal plane as well the vertical plane. Since we plan to use a heated gel to print, a stationary platform that only moves along the z-axis is preferred. In the next few blogposts, we will publish our research into different 3D printer models.

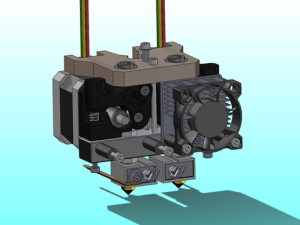

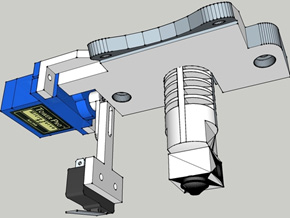

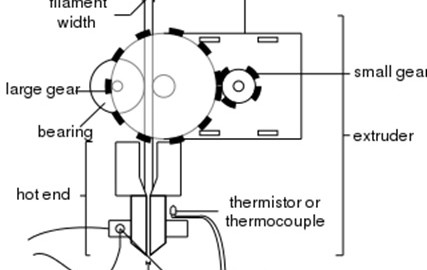

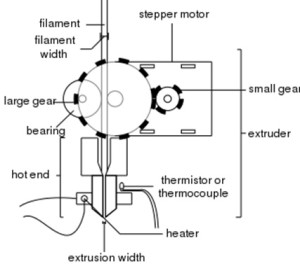

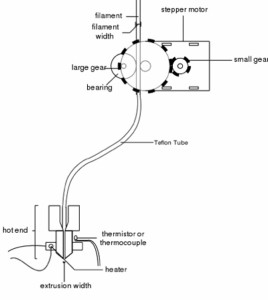

The team from last semester was able to print 3D structures using silicone, but silicone remains fluid until it dries in a few hours. Our challenge is to design an extruder optimized to print using a biological gel. When printing with plastics such as PLA or ABS, the extruder temperature is not critical and the structure begins to solidify immediately after extrusion. This is due to the large temperature differential between molten plastic, which is around 200°C, and the room temperature. When printing with biological media, the gel must be mixed and kept warm as it is loaded into the extruder. The temperature of the extruder must be maintained precisely to keep the gel right at the gelling temperature. As soon as an element is laid out by the print heat, it must be cooled quickly to maintain the structure.

The printer from last semester does not have a temperature controlled extruder. It also lacks the capability to cool the structure as it is being printed. Our challenge is to modify and redesign the printer to be able to print using biological media.