Spring 2017 Prosthetic Hand: Resource Allocation Reports

The Robot Company | CEO Professor Gary Hill

Blog Post Created By Project Manager | Bianca Esquivel

Project Reports Created by Mission, Systems, and Test Engineer | Chris Bautista

Cost Report

The Project Allocation for cost was $350. This more then enough covers for the margin and total expected cost added up. The expected prices are estimates based on the type of components the prosthetic group has decided on. Since buying multiple servos, force sense resistors, and flex sensors are costly, a decision was made to choose options on the lower cost end. Margins for items bought were based on whether the item was on sale at the time the reports were created. Since the customer would like the item to be low cost for a prosthetic system, the hand coordinated with the arm in order to share the filament.

Measured current draw will be calculated after the resources have been allocated.

Mass Report

The mass report is an initial estimation of the total mass of the prosthetic hand. The hand needs to be lightweight as to not inconvenience the customer. The mass of the fingers are the summation of the Index, Middle, Ring, and Pinky fingers. Since the fingers, thumb, and palm’s weight could not be calculated, they needed to be calculated in a more creative way.

The previous year’s 3D printed hand had a measured weight of 210 g altogether. An educated guess is that the palm should weigh 1.5 times the weight of all the fingers. An educated guess is the thumb weighs three-quarters the weight of a finger, so it weighs three-sixteenths the weight of all the fingers combined. Therefore, we have an equation of x+1.5x+0.1875x=210where x equals the weight of a finger. Solving for x gives us a sum weight of 78 g for all the fingers, 25 g for the thumb, and 118 g for the palm.

Again, measured current draw will be calculated after the resources have been allocated.

Power Report

The power report template was adjusted to have a minimum and maximum current draw, which helped calculate the updated average expected current draw, formerly titled expected current. Operation voltage was added as well to add more detailed on the resource.

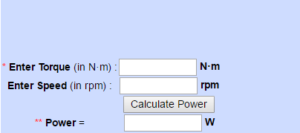

The average current was calculated by taking the average between maximum and minimum current values Average = Minimum + Maximum2. All the values for operational voltage were given. However, not all the minimum and maximum current values were given, specifically the Futaba S3003 Standard Servo. In order to calculate the minimum and maximum current draws, we first had to know the basic concept of Current=VoltagePower. Since we are given the operational voltage, the only unknown was the power. Power was calculated by knowing the torque and speed, which needed to be changed into Nm and RPM.1,2 Finally, the Power was solved via the same resource used to calculate the powers website.1Current was then solved for with the lower and upper bound value for operational voltage to get minimum and maximum current values, with the above formula. This explains the high uncertainty value at 15%.

Again, measured current draw will be calculated after the resources have been allocated.