Spring 2016 3D SMD: Vacuum Pump Trade-off Study V2

By Henry Nguyen ( Electronics and Control)

Table of Contents

Introduction

In order to find a vacuum pump that best suits our pick and place SMD machine, we needed to compare several different options. Considering pressure and cost will be crucial for this trade off study. Our goal is to find a vacuum pump that is able to pick up surface mount components and IC chips when connected to a 12V solenoid valve. We found that we can modify a 60 -100 gallon Tetra Whisper Aquarium pump to act as a vacuum for the price of $19.00.

Equipment and Materials

- A 5mL syringe with a small needle with a diameter of less than 0.50mm

Figure 1. 5 mL Syringe

Figure 2. Needle heads

- Various surface mount components and IC Chips

Figure 3. Various surface mount components and IC Chips

- Vacuum pump (Modified aquarium pump)

- Product Dimensions: 3.4 x 5 x 8.4 inches ; 2.1 pounds

Figure 4. Tetra Aquarium Pump

- 3/16” tubing

Figure 5. Tubing

- 12V Solenoid Valve

Figure 6. 12V Solenoid Valve

Procedure

- We shall modify the following aquarium pump in order to turn it into a vacuum pump. The following link provides step-by-step details on how to modify our aquarium pump

- Tubing length shall be cut to be as short as possible to allow maximum suction pressure. The size shall be determined based on the design of our aluminum surface table. (Approximately 1.5 – 3 ft)

- A 5mL syringe shall be used as our vacuum head and will be modified by connecting our vacuum to the 12V solenoid valve and then to our syringe.

- After setting up our equipment, we shall be testing whether or not our vacuum is able to pick up a 402 component.

- Next we will be testing a heavy component in order to determine if our small needle is able to pick up the IC Chip.

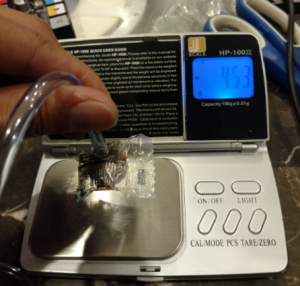

- Our last step is to test how much mass our vacuum pump is able to pick up. In order to do so, we will have a small scale with an accuracy of 0.1 grams and we will place an object on that scale. We will use our vacuum to see how much grams is deducted of the total mass when attempting to pick up the object. The following video shows a demonstration of this process.

Results

The following link is a rapid prototyping of our aquarium pump.

https://www.youtube.com/watch?v=a32c-TGHdyE&feature=youtu.be

Figure 7. Strength of Vacuum

For our strength tests of our vacuum, I decided to use an Vero Pica Gomas candy due to ease of access. The mass of this candy is 4.53 grams. I figured that if our vacuum has the strength to pick up this candy, other strength test will not be necessary since the mass any surface mount components we will be required to use will not exceed 4.53 grams. I found that our aquarium vacuum pump was able to successfully lift this candy into the air.

Figure 8. 37 0603 components on a scale

Next I decided to weigh 37 0603 components on a scale with a tolerance of 0.01 grams. I found that 37 0603 components did not reach a mass of 0.01 grams. We can safely assume our vacuum will be strong enough to pick up these components.

Figure 9. Vacuum nozzle picking up 0603 component

I found that our vacuum nozzle and vacuum was able to successfully pick up a 0603 component without falling off. The image above shows a 0603 component on the tip of our vacuum nozzle with our vacuum currently running.

To conclude our findings, I found that our aquarium pump was able to be successfully turned into a vacuum pump. A syringe was modified in order for it to be used as a vacuum nozzle; however, we did eventually purchased a vacuum nozzle meant to pick up 0402 components. We currently only had access to 0603 components therefore we ran our tests with 0603 instead of 0402 components. We found that we were able to successfully pick up our 0603 components. When our solenoid valve was on, our vacuum head became operable and we were able to pick up 0603 components. Once we shut off our solenoid valve, the 0603 components would either fall off our syringe, or stick on to our nozzle. This would not be an issue because the PCB on our machine will have solder paste on it allowing the components to easily be placed onto the PCB.

Conclusions

The final decision for our vacuum pump is to use the Tetra Whisper 60 – 100 gallon aquarium pump. The cost of this modified vacuum pump is $19 which is extremely cost efficient. We have also found that this pump is very quiet and will not cause much noise when running side-by-side with our X-Y plotter. Our vacuum pump and nozzle is able to pick up a 0603 component which is crucial to the design of our 3D SMD pick and place machine.

References

Vacuum Pump modification and image:

Sponges, S. (n.d.). Build an SMD Vacuum Pick and Place Tool. Retrieved February 25, 2016, from http://www.instructables.com/id/Circuit-Board-Lab-POV-Business-Card/step5/

Vacuum Pump mass test:

EXAIR: Manufacturing compressed air products since 1983. (n.d.). Retrieved February 25, 2016, from http://www.exair.com/pages/theater.aspx?gi=13001

ICs Image:

Curious Inventor. (n.d.) Hand full of SMDs Labeled. Retrieved February 25, 2016, from

http://store.curiousinventor.com/media/smt/hand_full_of_smds_labeled.jpg

Tetra Whisper Aquarium Pump Image:

Tetra Whisper Air Pump (Non-UL). (n.d.). Retrieved February 26, 2016, from http://www.amazon.com/Tetra-77851-Whisper-Pump-10-Gallon/dp/B0009YJ4N6/ref=sr_1_1?s=pet-supplies

3/16” Tubing Image:

Python. (n.d.). Retrieved February 26, 2016, from http://www.amazon.com/Python-Airline-Tubing-Aquarium-25-Feet/dp/B000255NYQ/ref=pd_bia_nav_t_1?ie=UTF8