Spring 2016 3D SMD: Verification Test — Reel Feeder

By Christine Vu (Missions, Systems, and Test) and Henry Nguyen (Electronics and Control)

Reel Feeder Design

To verify the reel feeder design has the correct function, a test will be conducted to determine its parameters and design.

Requirements

Section 4

The SMD pick and place machine shall have four 8mm reel feeders and one IC tray.

Section 4.1

All SMT resistors and capacitors shall remain in cut-tape of the reel feeders until the vacuum nozzle is ready to pick up the component.

Section 4.1.1

All reel feeders shall be installed on the working area, 12.2”x15.35”(310mmx390mm).

Section 4.1.2

Bracket to hold cut-tape of the reel feeders shall be higher than 0.04″.

Section 4.1.3

All motors used to peel off cut-tape of reel feeders must rotate 360°.

Section 4.2

IC tray shall store all IC chips required for one PCB assembly.

Section 4.2.1

IC tray shall be installed within working area, 12.2”x15.35” (310mmx390mm).

Applicable Tools

Hardware:

Reel Feeder

Micro Servo FS-90

| Equipment Type | Name (Brand) | Tolerance |

| Mitutoyo S/N 12519090 | Caliper | 0.001” |

Procedure

- Install reel feeder to the aluminum surface. Attach reel with SMT components.

- Install the IC tray to the working area.

- Install micro servo to reel feeder bracket. Servo wheel shaft shall be placed at an angle of approximately 45°. Record Servo wheel angle.

- Attach Z-axis and move the X-Y-axis motors to a component. Measure the clearance around the Z-axis. Record the clearance tolerance, which includes the distance around both the reel feeder and IC tray. Measure the height of the IC tray.

- Operate the micro servo by turning 360°. This requires timing of the speed of the micro servo and must be determined in the Arduino Code. Record this time.

- Determine initial measurement of the reel on the reel feeder. Record this measurement

- With the cut-tape attached to the micro servo wheel shaft, reel in the cut-tape.

- Observe the elevation of the reel feeder. Record the height of the reel feeder.

Results

| Parameter | Can the vacuum nozzle reach? [Y/N] | |

| Microservo rotation | >360° | Y |

| Distance between Nozzle and X-Axis Limiting switch (in.) | 3.011 | Y |

| Distance between Nozzle and cut-tape (in.) | 0.515 | Y |

| Distance between Reel Feeder component and X-Axis Limiting Switch (in.) | 4.161 | Y |

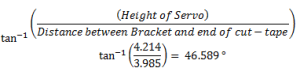

| Bracket for microservo height (in.) | 4.214 | Y |

| Distance between microservo and end of cut-tape (in.) | 2.975 | Y |

| Distance between vacuum nozzle and IC tray (in.) | 4.021″ | Y |

The angle of the cut-tape:

It was observed that increasing the angle at which the cut-tape was reeled required more force due to the way we changed the angle. If we changed the angle to approximately 60 degrees, it required us using the back bracket attached to the reel feeder and more force to pull the cut-tape.

Placement tolerance between the edge of reel feeder closest to the X-Axis and the nozzle:

4.161” – 3.011” = 1.15”.

Conclusion

Based on these parameters, we were able to conclude that our placement of the reel feeder system will be reached by the vacuum nozzle. Maximum rotation is more than 360°; however, the cut-tape would not stay in place of the servo if the wheel is holding too much of the cut-tape. Increasing the angle at which the cut-tape is allowed to turn resulted in ripping the cut-tape.